Material corrosion and prevention of high-pressure piping systems in seawater reverse osmosis desalination plants

-

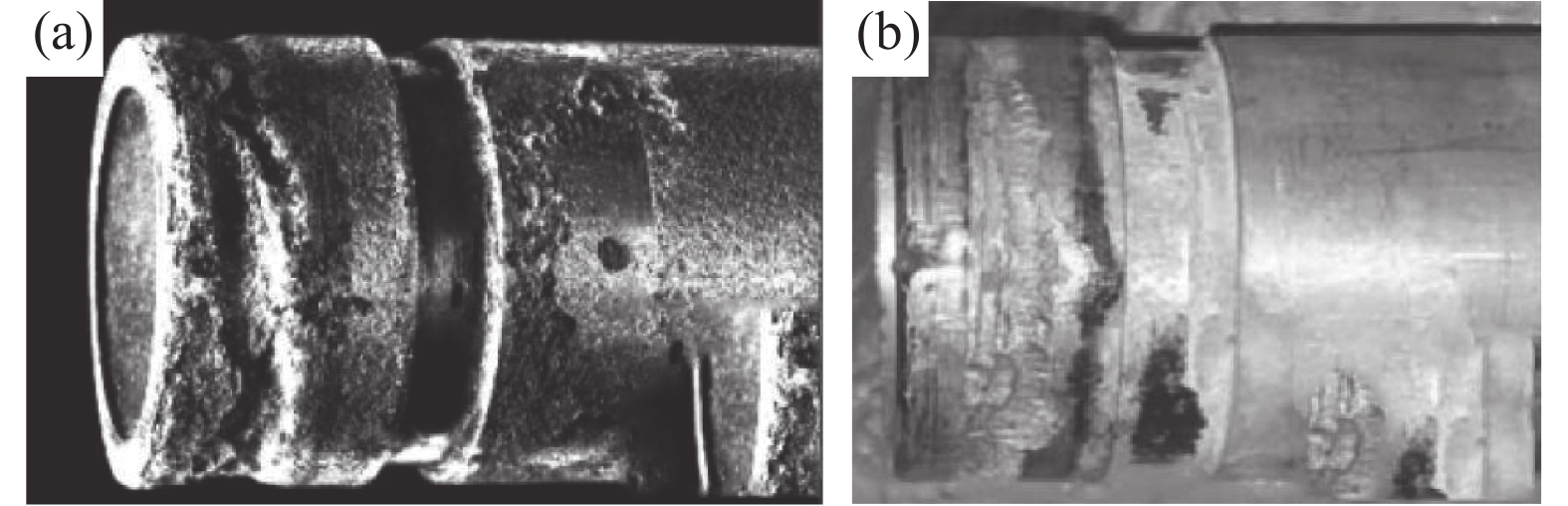

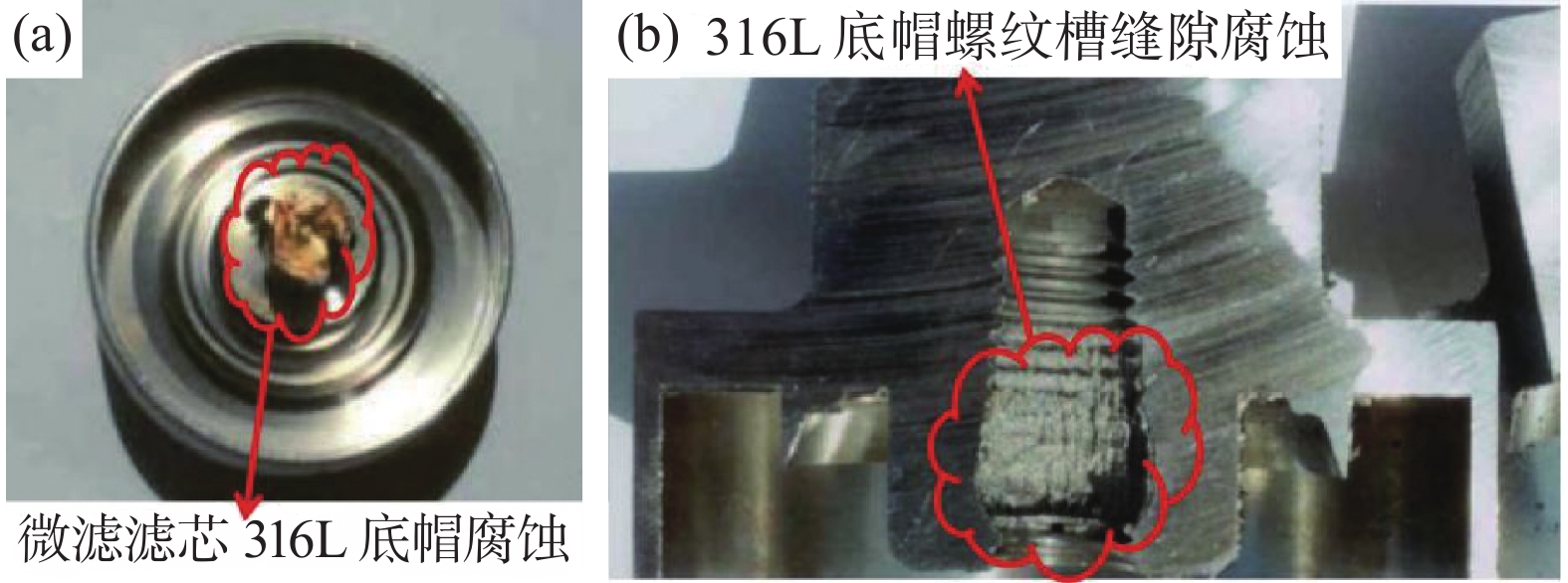

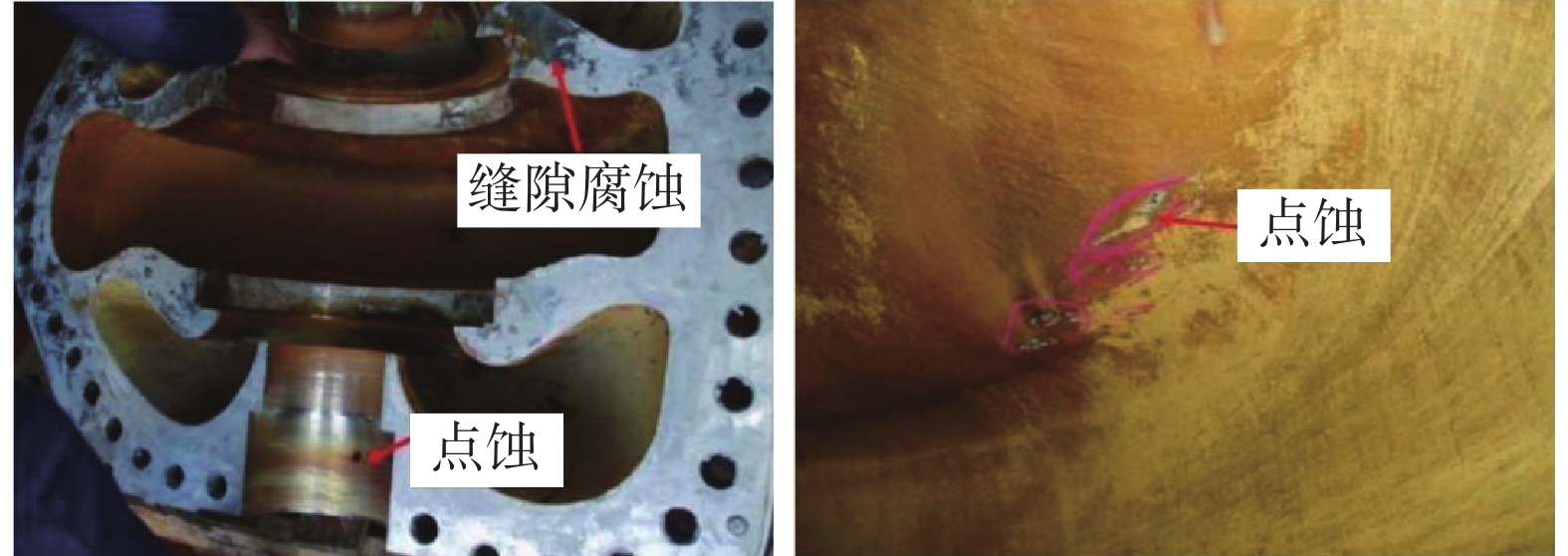

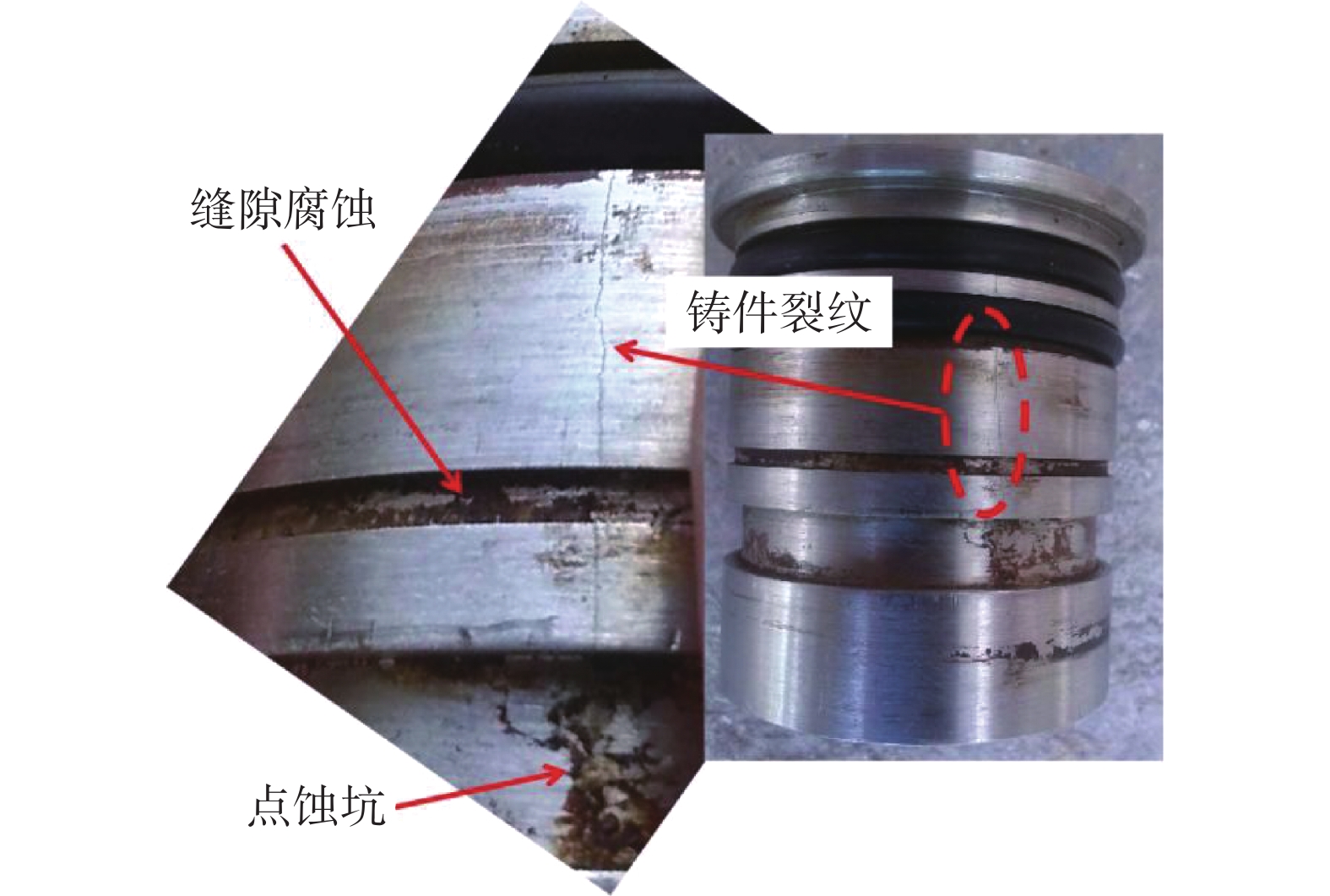

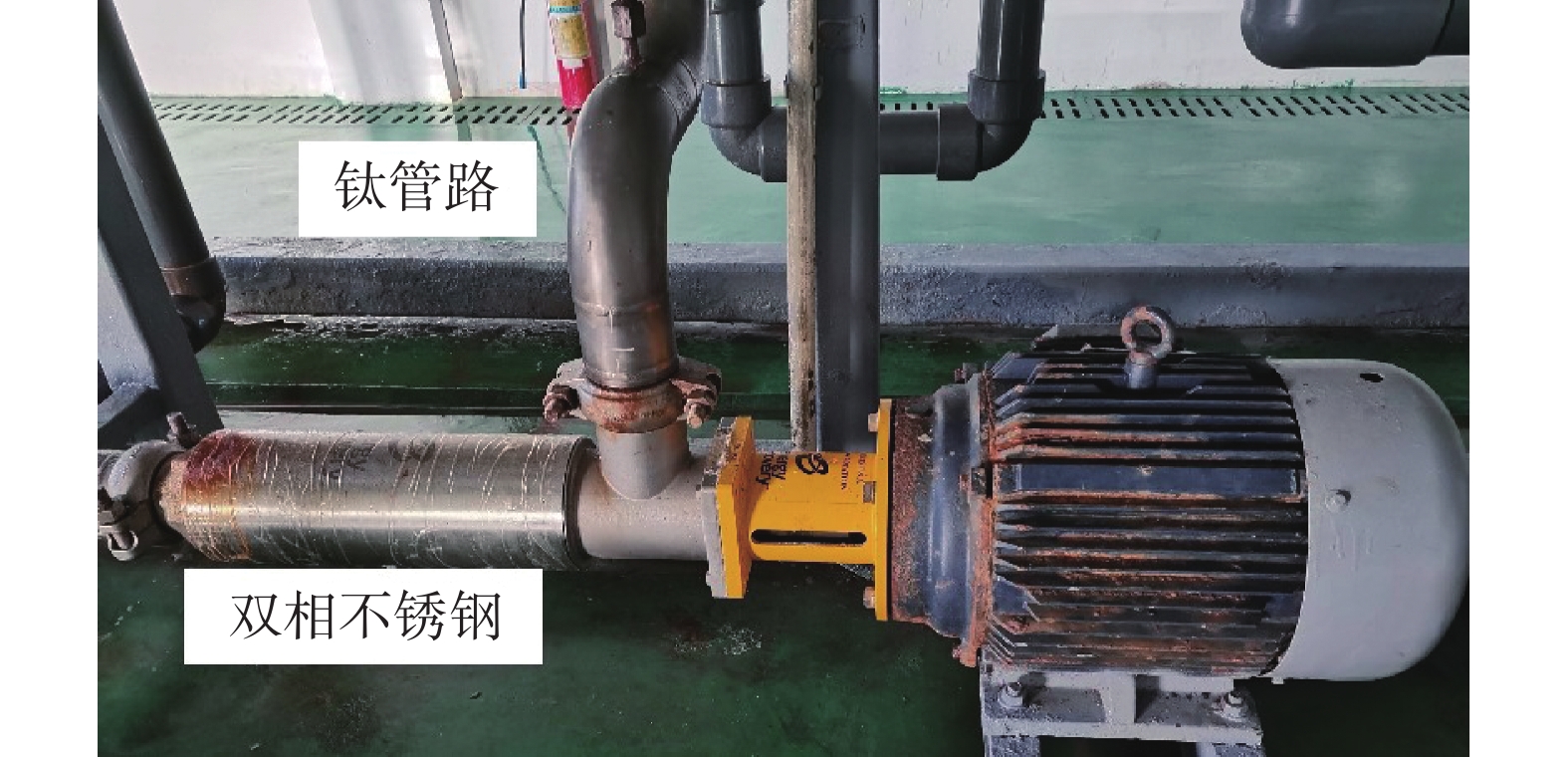

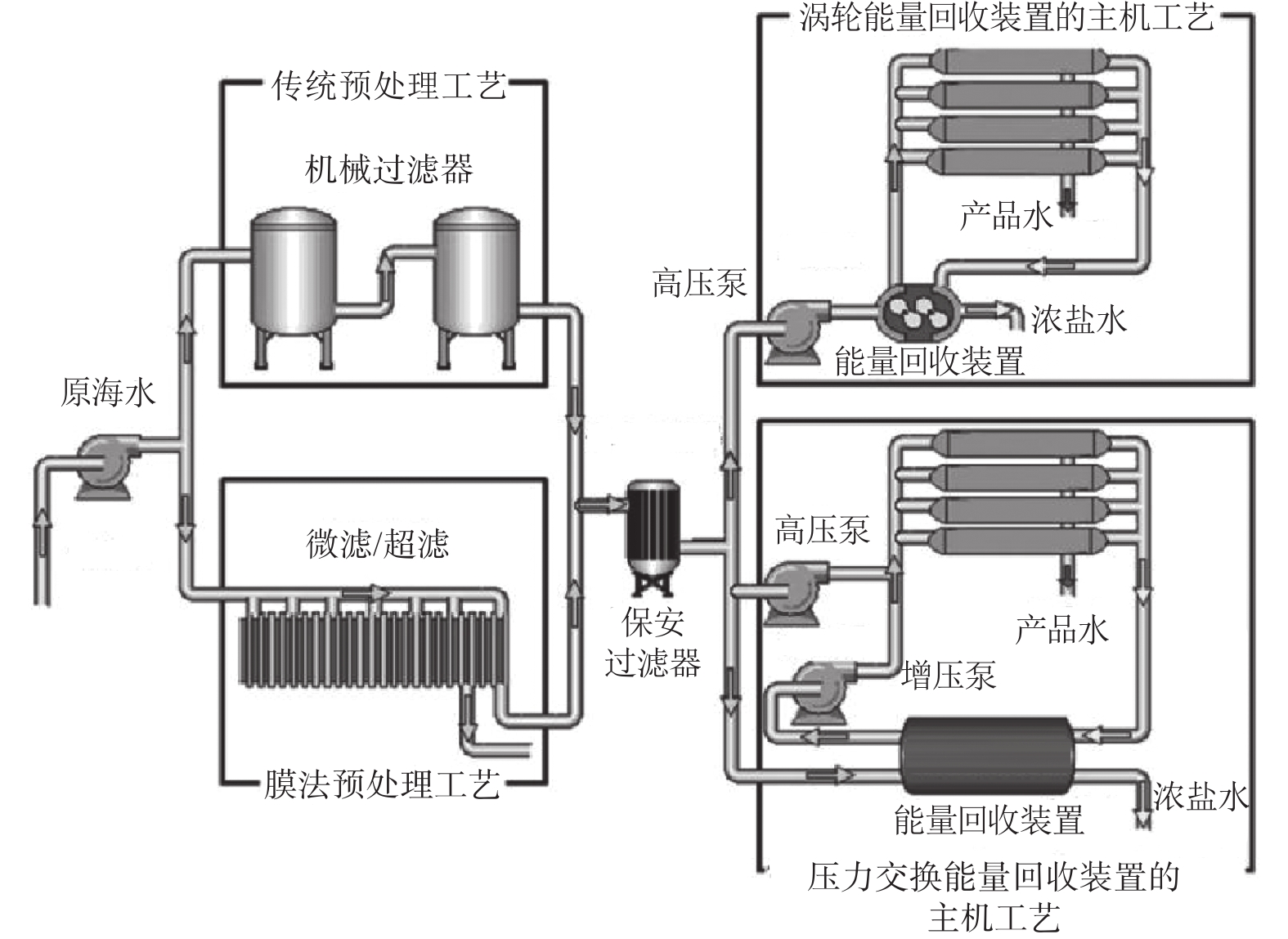

摘要: 海水淡化是解决沿海地区淡水不足、内陆地区水质退化、工业生产升级转型,促进水资源、水生态、水环境融合发展的有效技术手段。反渗透海水淡化技术凭借配置灵活、投资和产水能耗低等特点,成为国内外海水淡化市场的主流技术。然而,在苛刻环境下处理强腐蚀性海水,反渗透海水淡化装备材料面临较高的腐蚀风险。而且,海水盐度、环境温度升高和余氯残留加剧了奥氏体不锈钢的点蚀和缝隙腐蚀现象。在调研国内外工程经验基础上,总结了反渗透海水淡化在不同操作条件下的工程装备常规选材模式,分析了在部分极端环境下高压管路系统的材料腐蚀机理与防护策略。通过长期应用考察,证明了钛制高压管路系统可有效避免在强海水腐蚀环境下的材料点蚀和缝隙腐蚀问题,适合在我国南部海域以及中东、北非、南亚等地区推广应用。Abstract: Seawater desalination is considered one of the most viable and technically feasible strategies for the mitigation of water scarcity in the coastal areas, water quality degradation in the inland regions, and the promotion of green transitions in industrial structure. It is beneficial to the integrated water resources, water ecology and water environment development. Modern seawater reverse osmosis (SWRO) desalination technology has attracted more attention because of flexible design, less investment and energy-consuming in water production. However, SWRO desalination plants pose a high level of corrosion risk as they handle and process aggressive seawater under severe operating conditions. And the rising salinity and temperature of seawater, or even trace amount of free chlorine, are important challenges that further exacerbate the pitting and crevice corrosion phenomena of austenitic stainless steels. According to the investigation of domestic and international research findings and engineering experience, the most practical material for use in SWRO desalination plants under different operating environments is summarized. The corrosion mechanism and protective measures of high-pressure piping system in some extreme environments have been discussed. Furthermore, after long-term application, it has been proved that the high-pressure piping system with titanium alloy is effective to resist pitting and crevice corrosion under the extremely aggressive environment. Titanium alloy is suitably used in SWRO desalination plants located in the South China Sea, as well as in the Middle East, North Africa, and South Asia.

-

表 1 海水淡化行业用不锈钢等级与耐腐蚀参数[11]

Table 1. Corrosion resistance factors for stainless steel grades available in the desalination industry[11]

钢种 牌号 PREN注 CPT/℃ CCT/℃ 奥氏体 304L 18 <10 <0 316L 24 15 −2.5 超级奥氏体 254 SMO 43 87 35 4565 46 92 40 双相钢 LDX 2101 26 13 <0 2304 26 25 <0 2205 35 33 14 超级双相钢 2507 43 77 38 注:PREN为耐点蚀当量(Pitting Resistance Equivalent Number)的英文缩写,是一种反映不锈钢一般综合耐蚀性的标示方法,PREN值越高,表示不锈钢的相对耐蚀性能更强。 表 2 SWRO淡化工程主要装备材料

Table 2. The most practical materials for use in SWRO desalination projects

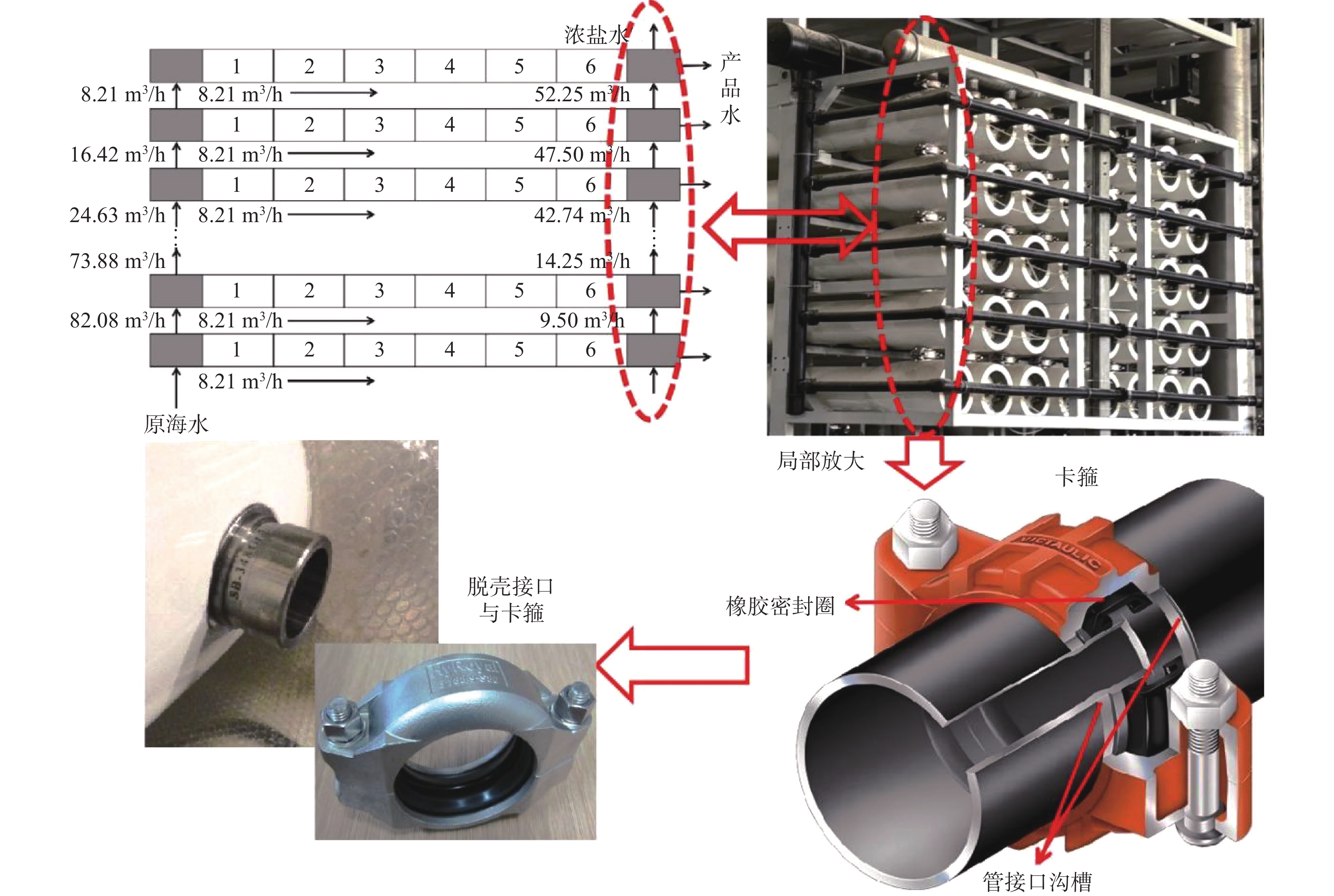

单元 组件 材料 取排水单元 取水管路 混凝土或玻璃钢 浓水排放管路 混凝土或玻璃钢 海水预处理单元 双介质-重力

式过滤器混凝土内衬橡胶层 双介质-压力

式过滤器碳钢喷涂环氧乙烯或

内衬氯丁二烯橡胶保安过滤器 玻璃钢或316L、

904L不锈钢超滤膜壳 玻璃钢或PVC 海水管路(低压) 主干管道为玻璃钢

分支管道为PVC低压蝶阀 壳体为2205双相钢或

橡胶内衬球墨铸铁

阀板为耐蚀镍合金钢或316L

密封圈为橡胶或聚四氟乙烯反渗透膜堆 膜组件 芳香聚酰胺膜材料 端板(内)支撑 2507双相不锈钢或

6Mo奥氏体不锈钢端板和密封环(外) 316L不锈钢 膜壳 玻璃钢 卡接短管及卡箍 2507双相不锈钢或

6Mo奥氏体不锈钢高压管路 主干管道为2205双相钢

分支管道为2507双相不锈

钢或6Mo奥氏体不锈钢高压阀以及控制

和紧急切断阀阀体为2205双相钢

阀座为PTFE高压泵及能量

回收装置外罩 2205或2507等相当耐蚀

等级双相不锈钢叶轮、轴及轴套 2205或2507等相当耐蚀

等级双相不锈钢轴承托架 铸铁HT200 螺栓 316L、904L不锈钢 辅助管道和设备 产水管路(低压) PVC、玻璃钢或316L不锈钢 化学清洗 PVC、玻璃钢或316L不锈钢 -

[1] RUAN G L, GAO C J. Seawater utilization equipment and materials[M]. Beijing: Chemical Industry Press, 2017. (阮国岭, 高从堦. 海水资源综合利用装备与材料[M]. 北京: 化学工业出版社, 2017.RUAN G L, GAO C J. Seawater utilization equipment and materials[M]. Beijing: Chemical Industry Press, 2017. [2] SHACHAF N, HAABURGER T. Comparison of multiple port and end port connections for pressure vessels[J]. Desalination, 2008, 221: 202-206. [3] OLSSON J. Stainless steels for desalination plants[J]. Desalination, 2005, 183(1-3): 217-225. [4] MALIK A U, ISMAEEL A, MOBIN M, et al. An overview of the localized corrosion problems in seawater desalination plants-some recent case studies[J]. Desalin. Water Treat, 2010, 20: 22-34. [5] BETTS A J, BOULTON L H. Crevice corrosion: review of mechanisms, modelling, and mitigation[J]. Br. Corros. J., 1993,28(4):279-295. doi: 10.1179/000705993799156299 [6] LARCHÉ N, BOILLOT P, DÉZERVILLE P, et al. Crevice corrosion performance of high alloy stainless steels and Ni-based alloy in desalination industry[J]. Desalination and Water Treatment, 2015,55(9):2491-2501. [7] AL-ODWANI A, CAREW J, AL-TABTABAEI M, et al. Materials performance in SWRO desalination plant at KISR research and development program[J]. Desalination, 2001,135:99-110. doi: 10.1016/S0011-9164(01)00143-6 [8] LANG F J, RUAN W H, LI M C, et al. Influence of temperature on corrosion of 316L stainless steel in seawater[J]. Corros. Sci. Prot. Technol., 2012,24(1):61-64. (郎丰军, 阮伟慧, 李谋成, 等. 温度对316L不锈钢耐海水腐蚀性能的影响[J]. 腐蚀科学与防护技术, 2012,24(1):61-64.LANG F J, RUAN W H, LI M C, et al. Influence of temperature on corrosion of 316L stainless steel in seawater[J]. Corros. Sci. Prot. Technol., 2012, 24(1): 61-64. [9] LIANG M H, ZHAO G X, FENG Y R, et al. Critical pitting temperature of 22Cr duplex stainless steel[J]. Corros. Sci. Prot. Technol., 2005,17(6):392-394. (梁明华, 赵国仙, 冯耀荣, 等. 22Cr双相不锈钢的临界点蚀温度研究[J]. 腐蚀科学与防护技术, 2005,17(6):392-394. doi: 10.3969/j.issn.1002-6495.2005.06.005LIANG M H, ZHAO G X, FENG Y R, et al. Critical pitting temperature of 22Cr duplex stainless steel[J]. Corros. Sci. Prot. Technol., 2005, 17(6): 392-394. doi: 10.3969/j.issn.1002-6495.2005.06.005 [10] HE J, YAN M S, YANG L J, et al. Electrochemical corrosion and critical pitting temperature of S32750 super duplex stainless steel in NaCl solution[J]. J. Chin. Soc. Corr. Pro., 2015,35(2):106-112. (何进, 晏敏胜, 杨丽景, 等. S32750超级双相不锈钢在NaCl溶液中的临界点蚀温度及电化学腐蚀机理[J]. 中国腐蚀与防护学报, 2015,35(2):106-112.HE J, YAN M S, YANG L J, et al. Electrochemical corrosion and critical pitting temperature of S32750 super duplex stainless steel in NaCl solution[J]. J. Chin. Soc. Corr. Pro., 2015, 35(2): 106-112. [11] ARGYRIS P, MARIA L, KATHERINE-JOANNE H. Stainless steel in thermal desalination and brine treatment: current status and prospects[J]. Met. Mater. Int., 2020, 26: 1463-1482. [12] SCHORR M, VALDEZ B, ELIEZER A, et al. Managing corrosion in desalination plants[J]. Corros. Rev., 2019,37(2):103-113. doi: 10.1515/corrrev-2018-0038 [13] MEROUFEL A, LARCHÉ N, AL-FOZAN S, et al. Crevice corrosion behavior of stainless steels and nickel-based alloy in the natural seawater-Effect of crevice geometry, temperature and seawater world location[J]. Water Treat., 2017,69:202-209. doi: 10.5004/dwt.2017.0448 [14] BYRNE G, FRANCIS R, WARBURTON G, et al. Electrochemical potential and the corrosion resistance of stainless steels in SWRO applications[C]. The International Desalination Association World Congress on Desalination and Water Reuse, 2009, Dubai, UAE, REF: IDAWC/DB09-145. [15] YAKUWA H, MIYASAKA M, SUGIYAMA K. Evaluation of crevice corrosion resistance of duplex and super duplex stainless steels for seawater pumps[C]. NACE Corrosion, 2009:09194. [16] AYLOR D M, HAYS R A, KAIN R M, et al. Crevice corrosion performance of candidate naval ship seawater valve materials in quiescent and flowing natural seawater[C]. NACE Corrosion, 1999:329. [17] LARCHÉ N, DÉZERVILLE P, LE FLOUR D. Corrosion and corrosion management investigations in seawater reverse osmosis desalination plants[J]. Desalin. Water Treat., 2013,51:1744-1761. doi: 10.1080/19443994.2012.714666 [18] ZHANG H, JIANG Z T, LIU E X. Seasonal variation characteristics of temperature in the Yellow and East China Seas[J]. China Water Transport, 2016,16(11):167-170. (张虹, 蒋志婷, 刘恩旭. 黄、东海水温季节变化特征[J]. 中国水运, 2016,16(11):167-170.ZHANG H, JIANG Z T, LIU E X. Seasonal variation characteristics of temperature in the Yellow and East China Seas[J]. China Water Transport, 2016, 16(11): 167-170. [19] TORRES C, JOHNSEN R, IANNUZZI M. Crevice corrosion of solution annealed 25Cr duplex stainless steels: effect of W on critical temperatures[J]. Corros. Sci., 2021,178:109053. doi: 10.1016/j.corsci.2020.109053 [20] LIU Z X, XIE Y, CHU X Y, et al. Evolution of the sigma phase and its effect on the corrosion resistance of ASTM A890 3A duplex stainless steel[J]. Mater. Today Commun., 2023,36:106926. doi: 10.1016/j.mtcomm.2023.106926 [21] MAHAJANAM S P V, CASE R P, RINCON H E, et al. Effect of sigma phase on the corrosion and stress corrosion of 2205 and 2507 duplex stainless steels[C]. NACE Corrosion, 2011: 11173. [22] TAN H, JIANG Y, DENG B, et al. Effect of annealing temperature on the pitting corrosion resistance of super duplex stainless steel UNS S32750[J]. Mater. Charact., 2009,60(9):1049-1054. doi: 10.1016/j.matchar.2009.04.009 [23] ZHANG Y, HU J, DONG Y, et al. Effect of heat treatment on the microstructure and mechanical properties of hot-rolled plate from duplex stainless steel 2205[J]. Met. Sci. Heat Treat., 2023,65:3-6. doi: 10.1007/s11041-023-00882-6 [24] LARCHÉ N, DÉZERVILLE P, LE FLOUR D, et al. Corrosion of stainless steel components in seawater reverse osmosis desalination plants-investigations on adapted internal cathodic protection[J]. Desalin. Water Treat., 2015,55(9):2478-2490. doi: 10.1080/19443994.2014.939499 [25] SHORKRI A, FARD M S. Corrosion in seawater desalination industry: A critical analysis of impacts and mitigation strategies[J]. Chemosphere, 2022,307:135640. doi: 10.1016/j.chemosphere.2022.135640 [26] THABET H K, EL-SHAMY O A A, ASHMAWY A M, et al. The impact of corrosion inhibitors in desalination systems[J]. ACS Omega, 2023,8:45224-45231. doi: 10.1021/acsomega.3c07129 -

下载:

下载: