Fatigue life prediction of Aermet100 steel in the atmosphere

-

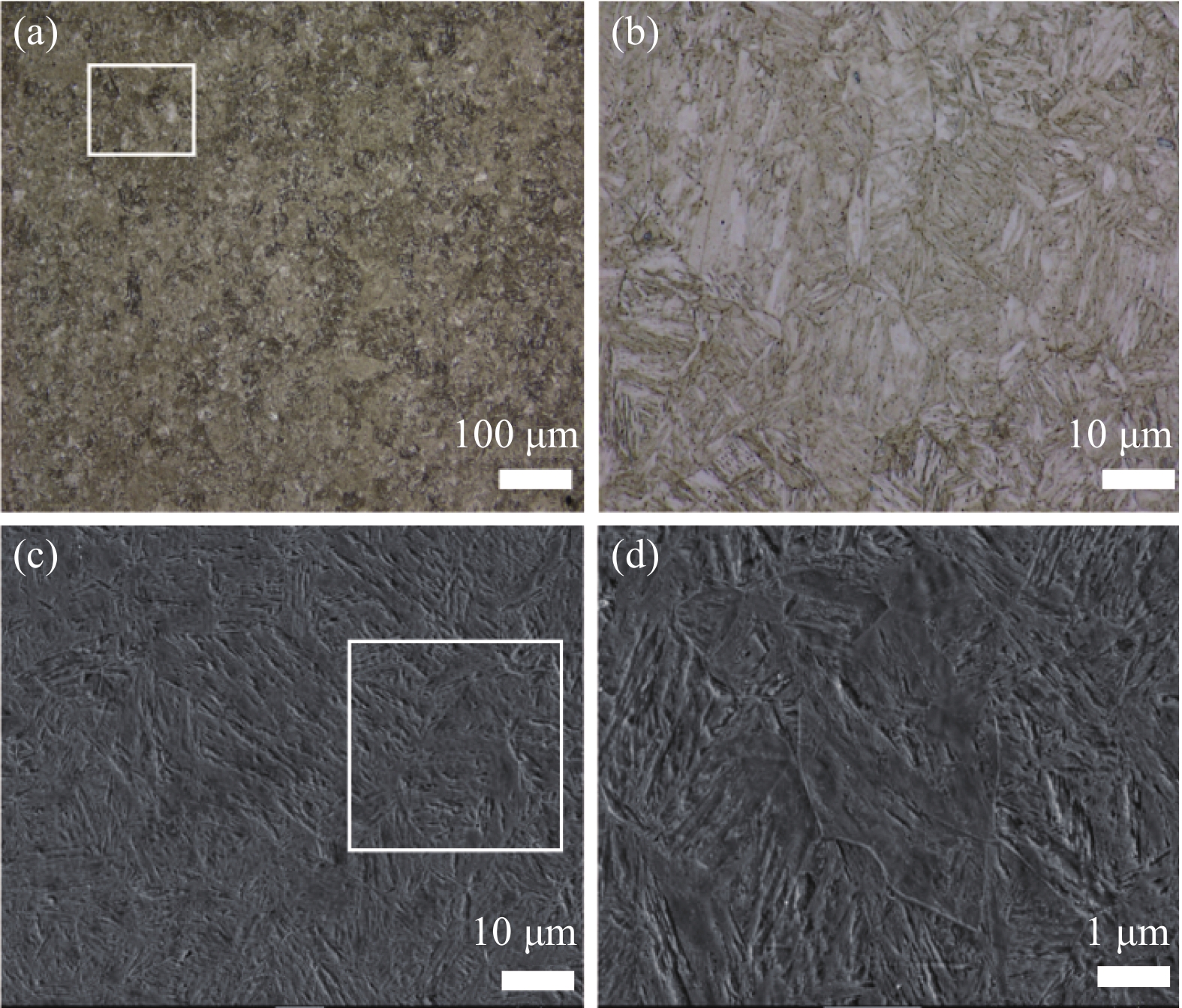

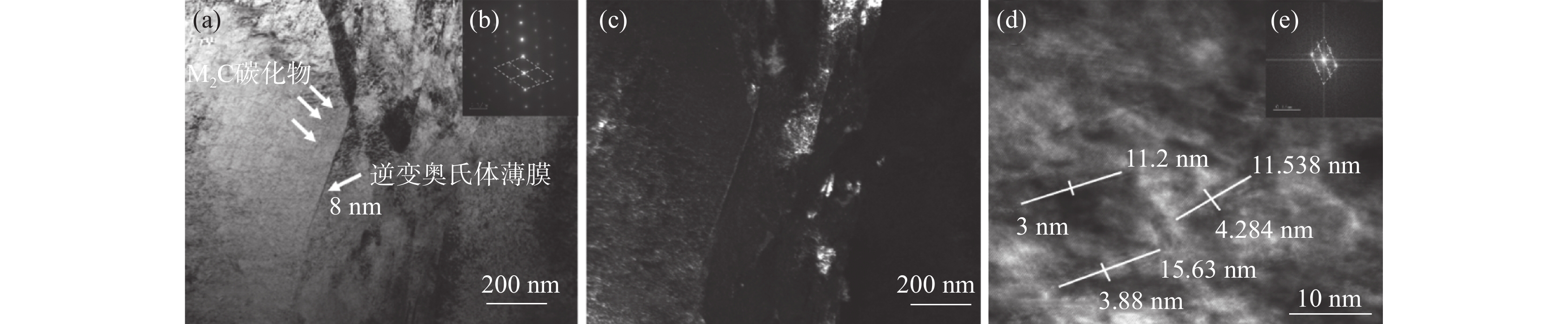

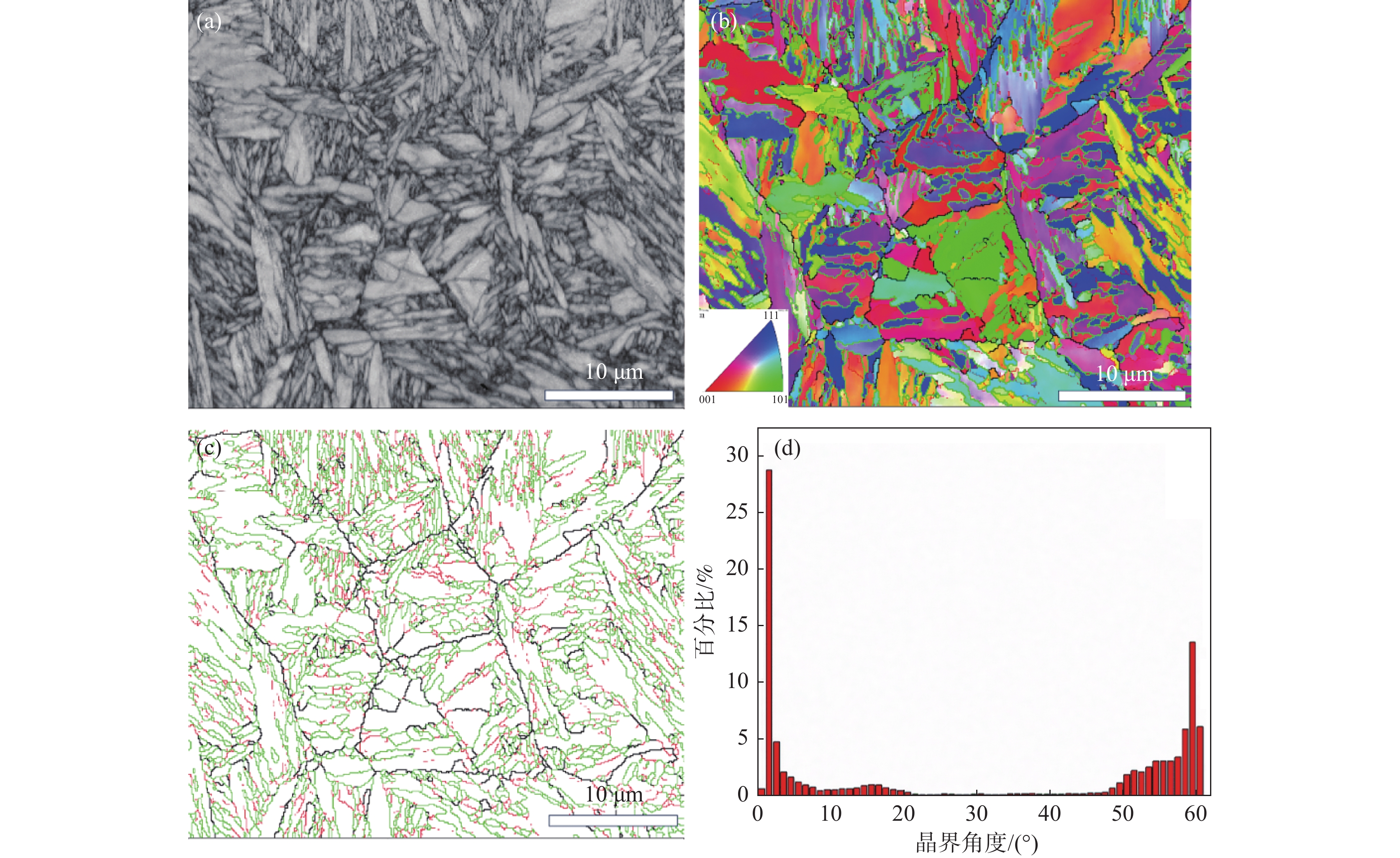

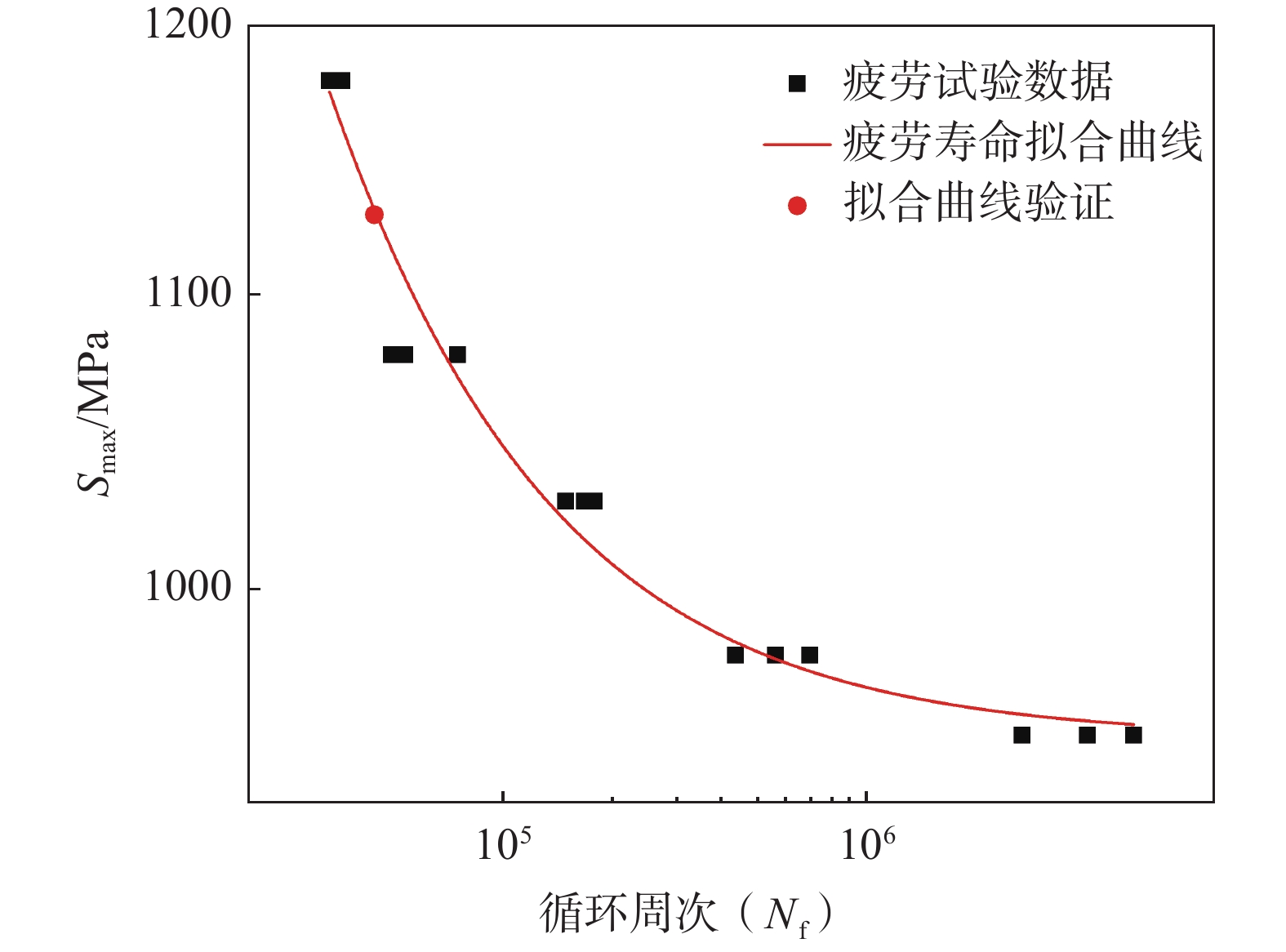

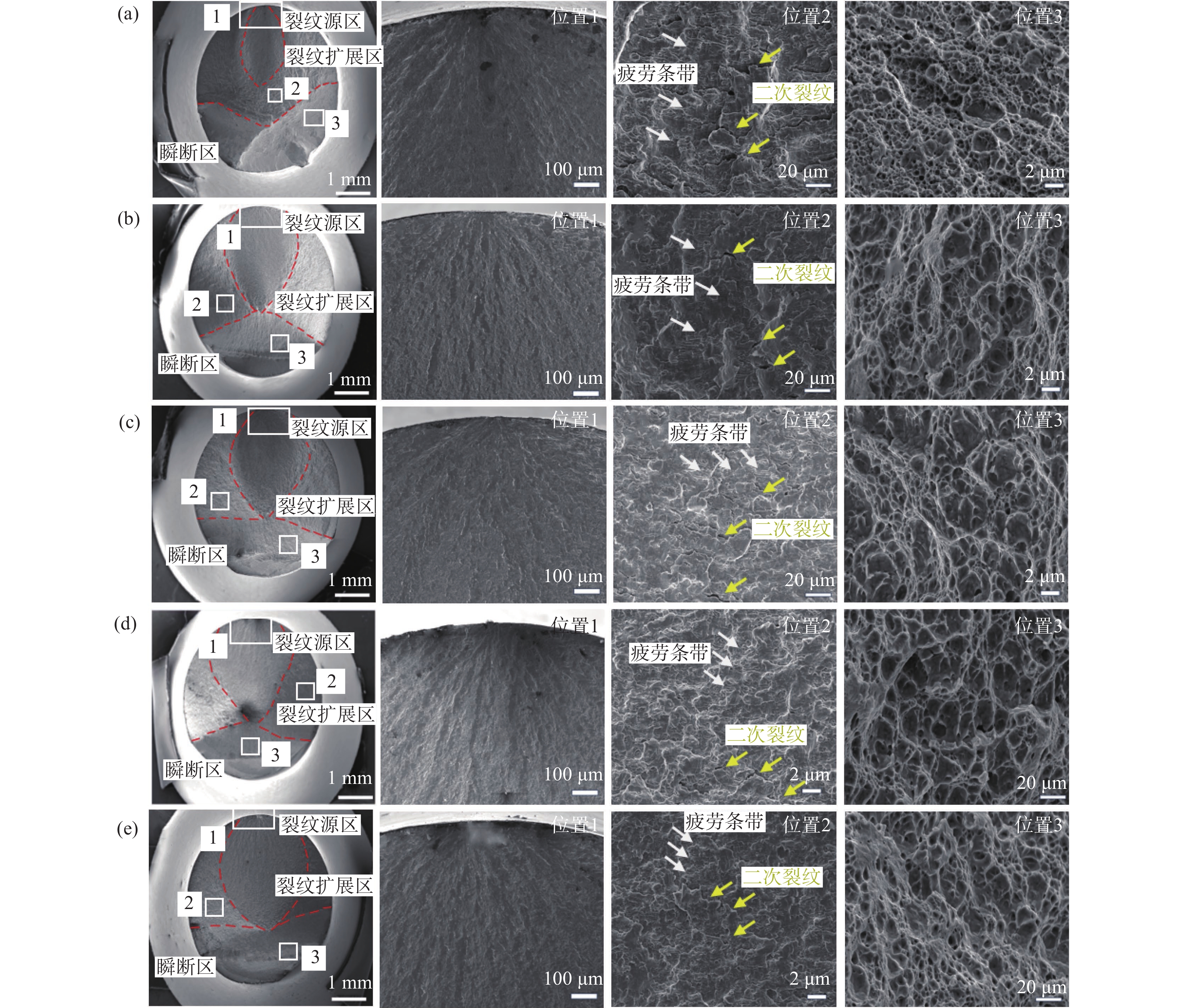

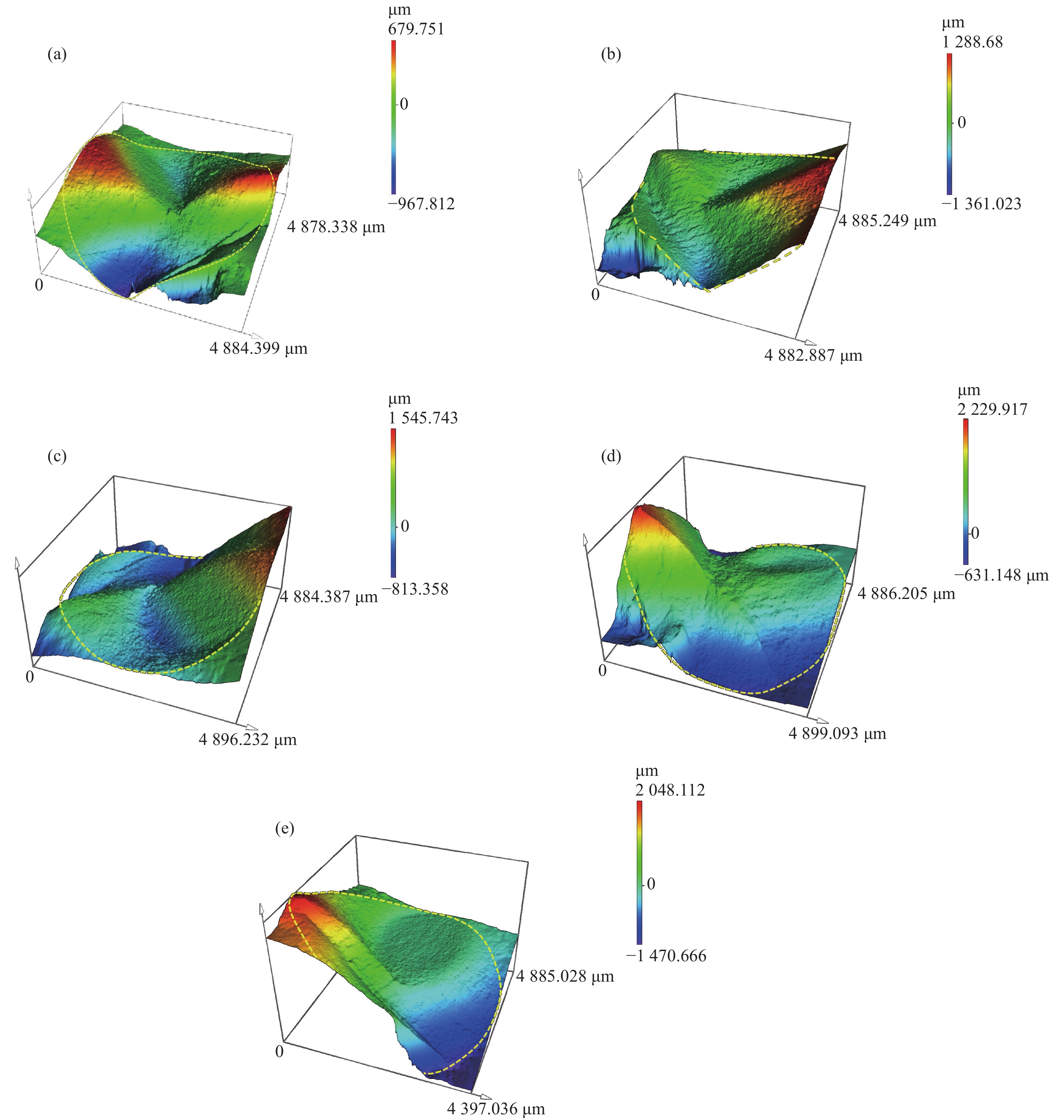

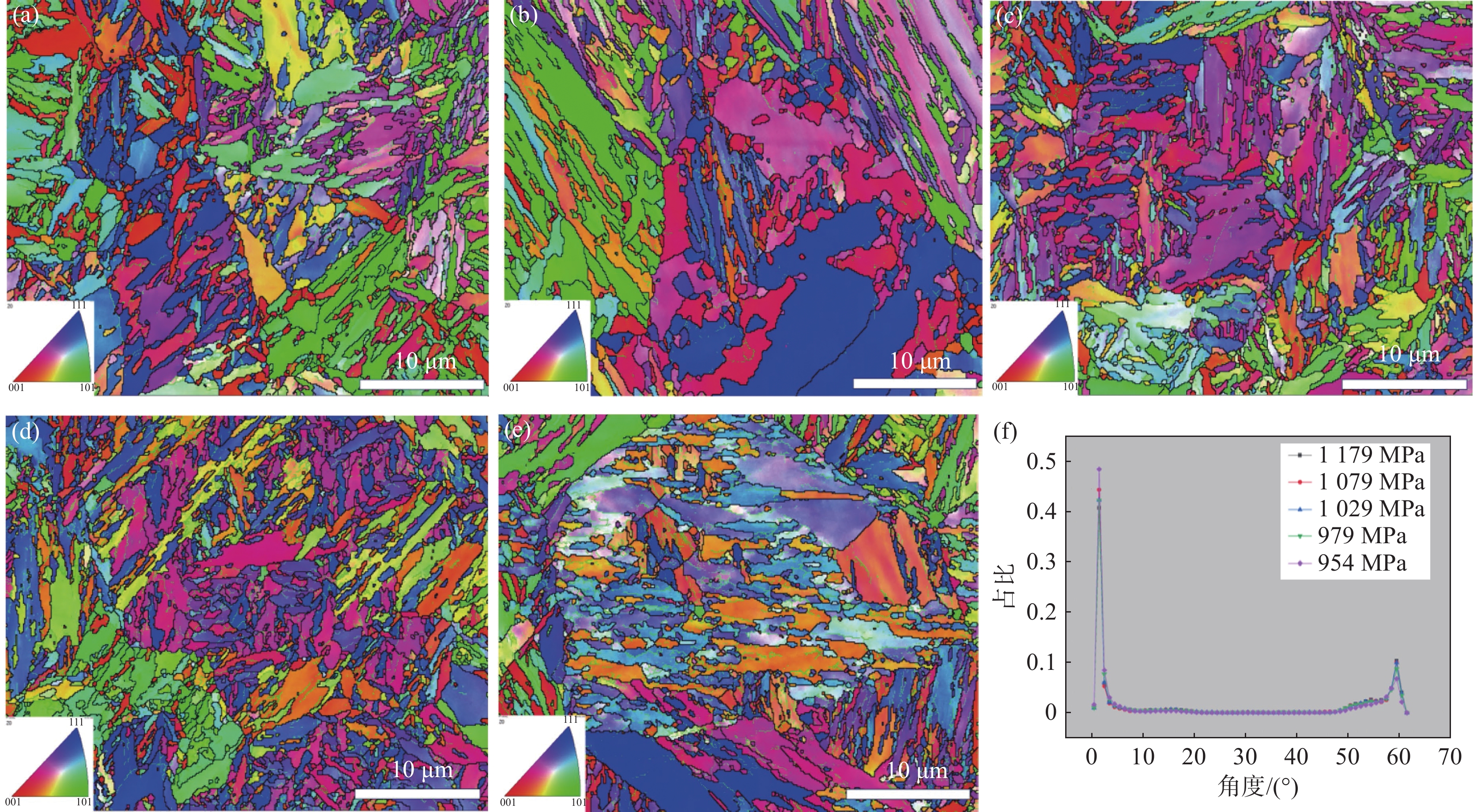

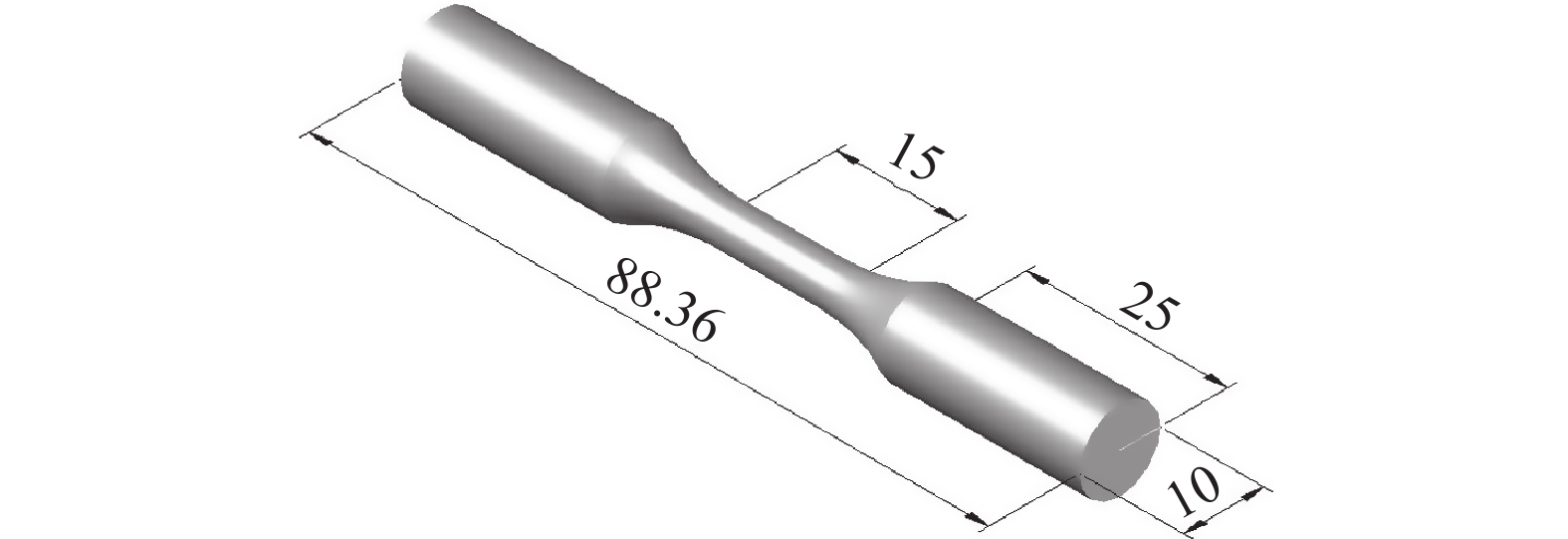

摘要: 疲劳是高强钢在服役过程中常见的失效形式之一,一旦发生将造成灾难性的事故。针对常用A100高强钢的微观组织以及在大气中的高周疲劳寿命进行相关研究,结果表明:A100高强钢微观组织主要由马氏体束,厚度约8 nm的逆变奥氏体薄膜和直径2~4 nm、长约9~14 nm的棒状M2C碳化物构成。在疲劳试验中,随着应力降低,微观组织中亚晶界数量增多,板条块界的数量显著减少,马氏体组织拉长。同时,拟合获得了疲劳寿命与应力水平的关系:lgN=7.54−1.29lg(Smax-953.06)。Abstract: Fatigue is one of the common failure modes of high strength steels in service. Once it occurs, it will cause catastrophic accidents. In this study, the microstructures and high cycle fatigue life of A100 high strength steel in the atmosphere were studied. The results show that the microstructures of A100 high strength steel are mainly composed of martensite bundles, the reversed austenite films with a thickness of 8 nm and rod-like M2C carbides with 2~4 nm in diameter and 9~14 nm in length. In the fatigue tests, the number of subgrain boundaries in the microstructures increases with a significant decrease of the number of lath boundaries as the stress decreases, and the martensite structure is elongated. In the meanwhile, the relationship between the fatigue life and stress level was obtained by fitting the S-N fatigue life curves: lgN = 7.54−1.29lg (Smax-953.06 ).

-

Key words:

- high-strength steel /

- fatigue properties /

- high cycle fatigue /

- life expectancy

-

表 1 Aermet100化学成分

Table 1. Chemical composition of the aermet100 steel

% C Co Cr Mn Mo Ni P S Si Ti O N H 0.255 14.27 3.14 <0.005 1.32 12.22 0.0041 < 0.0005 0.155 <0.005 0.0019 0.0009 0.00006 -

[1] WANG X P. Ultra high strength steel 23Co14Ni12Cr3MoE (A100) large forgings for aircraft landing gear[R]. Engineering Technology, 2020-11-27. (王小萍.飞机起落架用超高强度钢23Co14Ni12Cr3MoE(A100)大型锻材[R]. 工程科技, 2020-11-27.WANG X P. Ultra high strength steel 23Co14Ni12Cr3MoE (A100) large forgings for aircraft landing gear[R]. Engineering Technology, 2020-11-27. [2] WANG X H, LUO H W. Research and application progress of ultra high strength stainless steel for aircraft landing gear[J]. Material Engineering, 2019,47(9):1-12. (王晓辉, 罗海文. 飞机起落架用超高强度不锈钢的研究及应用进展[J]. 材料工程, 2019,47(9):1-12. doi: 10.11868/j.issn.1001-4381.2019.000122WANG X H, LUO H W. Research and application progress of ultra high strength stainless steel for aircraft landing gear[J]. Material Engineering, 2019, 47(9): 1-12. doi: 10.11868/j.issn.1001-4381.2019.000122 [3] SUN Y K, ZHANG W. Development and research status of civil aircraft landing gear materials[J]. Hot Working Process, 2018, 47(20): 22-24, 29. (孙艳坤, 张威. 民机起落架用材料的发展与研究现状[J]. 热加工工艺, 2018, 47(20): 22-24, 29.SUN Y K, ZHANG W. Development and research status of civil aircraft landing gear materials[J]. Hot Working Process, 2018, 47(20): 22-24, 29. [4] HE Y Y, ZHAO Y. Study on quality control of heat treatment mechanical properties of A-100 steel for landing gear[J]. New Technology and Process, 2016(6):7982. (贺亚勇, 赵勇. 起落架用A-100钢热处理力学性能质量控制研究[J]. 新技术新工艺, 2016(6):7982.HE Y Y, ZHAO Y. Study on quality control of heat treatment mechanical properties of A-100 steel for landing gear[J]. New Technology and Process, 2016(6): 7982. [5] China academy of aeronautical science and technology. Reliability analysis and design guide for aircraft structures[M]. Xi’an : Northwestern Polytechnical University Press, 1995. (中国航空科学技术研究院. 飞机结构可靠性分析与设计指南[M]. 西安: 西北工业大学出版社, 1995.China academy of aeronautical science and technology. Reliability analysis and design guide for aircraft structures[M]. Xi’an : Northwestern Polytechnical University Press, 1995. [6] PENG W W, ZENG W D, YAN W Q, et al. Effect of tempering process on microstructure and toughness of aermet100 ultra-high strength steel[J]. Journal of Material Heat Treatment, 2013,34(6):58-61. (彭雯雯, 曾卫东, 闫文巧, 等. 回火工艺对Aermet100超高强度钢组织与韧性的影响[J]. 材料热处理学报, 2013,34(6):58-61.PENG W W, ZENG W D, YAN W Q, et al. Effect of tempering process on microstructure and toughness of aermet100 ultra-high strength steel[J]. Journal of Material Heat Treatment, 2013, 34(6): 58-61. [7] LI Z, GU L X, LI H Q, et al. Research progress of 23Co14Ni12Cr3MoE (A-100) Steel[J]. Journal of Aeronautical Materials, 2017,37(6):16-24. (李志, 古立新, 李惠曲, 等. 23Co14Ni12Cr3MoE(A-100)钢的研究进展[J]. 航空材料学报, 2017,37(6):16-24. doi: 10.11868/j.issn.1005-5053.2017.001006LI Z, GU L X, LI H Q, et al. Research progress of 23Co14Ni12Cr3MoE (A-100) Steel[J]. Journal of Aeronautical Materials, 2017, 37(6): 16-24. doi: 10.11868/j.issn.1005-5053.2017.001006 [8] LI J, GU L X, LI ZHI, et al. Study on tempering temperature sensitivity of mechanical properties of aerMet100 steel[J]. Heat Treatment of Metals, 2010,35(3):33-36. (李杰, 古立新, 李志, 等. AerMet100钢力学性能的回火温度敏感性研究[J]. 金属热处理, 2010,35(3):33-36.LI J, GU L X, LI ZHI, et al. Study on tempering temperature sensitivity of mechanical properties of aerMet100 steel[J]. Heat Treatment of Metals, 2010, 35(3): 33-36. [9] WANG X. Study on hot deformation behavior and thermomechanical treatment process of aermet100 steel[D]. Nanchang: Nanchang Hangkong University, 2016. (王鑫. AerMet100钢热变形行为及形变热处理工艺研究[D]. 南昌: 南昌航空大学, 2016.WANG X. Study on hot deformation behavior and thermomechanical treatment process of aermet100 steel[D]. Nanchang: Nanchang Hangkong University, 2016. [10] WANG X R. AerMet100 – ultra high strength steel with excellent comprehensive properties[J]. Journal of Beijing University of Aeronautics and Astronautics, 1996(6):5-10. (王晓茹. AerMet100-极好综合性能的超高强度钢[J]. 北京航空航天大学学报, 1996(6):5-10.WANG X R. AerMet100 – ultra high strength steel with excellent comprehensive properties[J]. Journal of Beijing University of Aeronautics and Astronautics, 1996(6): 5-10. [11] LI J, LI Z, YAN M G. Development of high alloy ultra-high strength steel[J]. Material Engineering, 2007(4):61-65. (李杰, 李志, 颜鸣皋. 高合金超高强度钢的发展[J]. 材料工程, 2007(4):61-65. doi: 10.3969/j.issn.1001-4381.2007.04.016LI J, LI Z, YAN M G. Development of high alloy ultra-high strength steel[J]. Material Engineering, 2007(4): 61-65. doi: 10.3969/j.issn.1001-4381.2007.04.016 [12] LIU Z B, LIANG J X, SU J, et al. Research and development status of high strength stainless steel[J]. Journal of Metals, 2020,56(4):549-557. (刘振宝, 梁剑雄, 苏杰, 等. 高强度不锈钢的研究及发展现状[J]. 金属学报, 2020,56(4):549-557.LIU Z B, LIANG J X, SU J, et al. Research and development status of high strength stainless steel[J]. Journal of Metals, 2020, 56(4): 549-557. [13] WANG H L, ZHANG J, ZHU J C, et al. Structures of m2c carbides and its influence on strengthening in aermet100 steel at the typical tempering temperature 482 °C[J]. Vacuum, 2023, 21. [14] WANG H L, ZHANG J, ZHU J C, et al. The evolution of a microstructure during tempering and its influence on the mechanical properties of aermet100 steel[J]. Materials, 2023, 16, 6907. [15] HU S S, SHI L L, H Kun, et al. Effect of tempering holding time on mechanical properties and microstructure of a100 steel[J]. Metal Thermal, 2021,46(2):140-143. (胡生双, 史利利, 何坤, 等. 回火保温时间对A-100钢力学性能和组织的影响[J]. 金属热处理, 2021,46(2):140-143.HU S S, SHI L L, H Kun, et al. Effect of tempering holding time on mechanical properties and microstructure of a100 steel[J]. Metal Thermal, 2021, 46(2): 140-143. [16] YE W B. Development of A100 secondary hardening ultra-high strength alloy[J]. Special Steel Technology, 2014, 20 (1): 1416, 26. (叶文冰. A100二次硬化型超高强度合金研制[J]. 特钢技术, 2014, 20(1): 1416, 26.YE W B. Development of A100 secondary hardening ultra-high strength alloy[J]. Special Steel Technology, 2014, 20 (1): 1416, 26. [17] YANG X H, ZHANG S H, WANG Z T, et al. Hot deformation behavior of aermet100 ultra-high strength steel[J]. Journal of Plastic Engineering, 2007(6):121-126. (杨小红, 张士宏, 王忠堂, 等. AerMet100超高强度钢热变形行为[J]. 塑性工程学报, 2007(6):121-126. doi: 10.3969/j.issn.1007-2012.2007.06.027YANG X H, ZHANG S H, WANG Z T, et al. Hot deformation behavior of aermet100 ultra-high strength steel[J]. Journal of Plastic Engineering, 2007(6): 121-126. doi: 10.3969/j.issn.1007-2012.2007.06.027 [18] STRIZAK J P, TIAN H, LIAW P K, et al. Fatigue properties of type 316LN stainless steel in air and mercury[J]. Journal of Nuclear Materials, 2005,343(1-3):134144. [19] MICHLER T, NAUMANN J, WIEBESIEK J, et al. Influence of frequency and waveform on S-N fatigue of commercial austenitic stainless steels with different nickel contents in inert gas and in high pressure gaseous hydrogen[J]. International Journal of Fatigue, 2016,96:67-77. [20] SU H Y, LIU R D, LU Y P, et al. The shape and size of the tensile-compression high cycle fatigue specimen of automobile sheet are selected [J]. Physicochemical Test : physical volume, 2021, 57 (10) : 27-31. (苏洪英, 刘仁东, 芦延鹏, 等. 汽车薄板拉-压高周疲劳试样的形状和尺寸选取[J]. 理化检验: 物理分册, 2021, 57(10): 27-31.SU H Y, LIU R D, LU Y P, et al. The shape and size of the tensile-compression high cycle fatigue specimen of automobile sheet are selected [J]. Physicochemical Test : physical volume, 2021, 57 (10) : 27-31. -

下载:

下载: