Effect of laminar flow cooling process on microstructure and mechanical properties of hot rolled DP600 steel

-

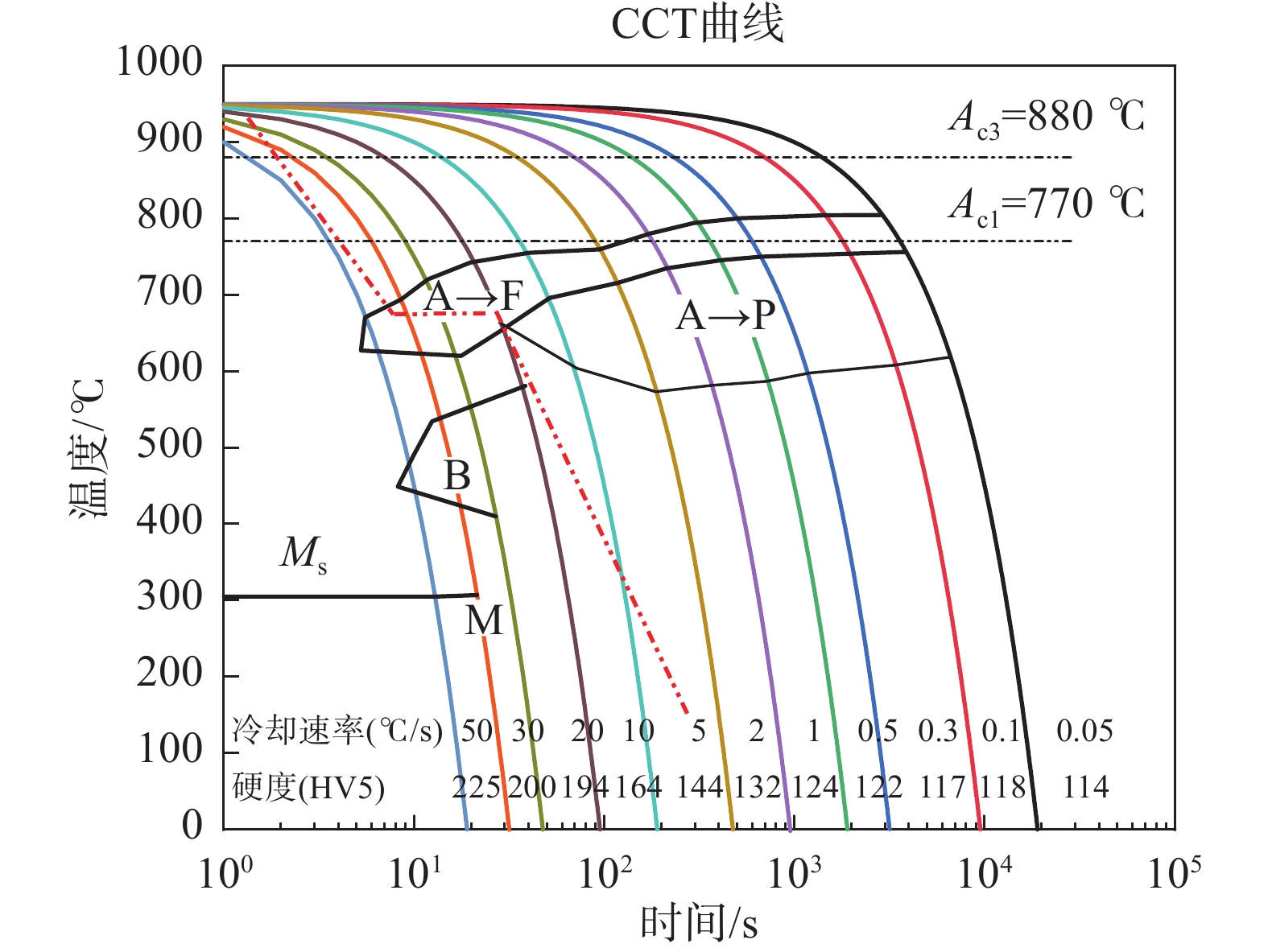

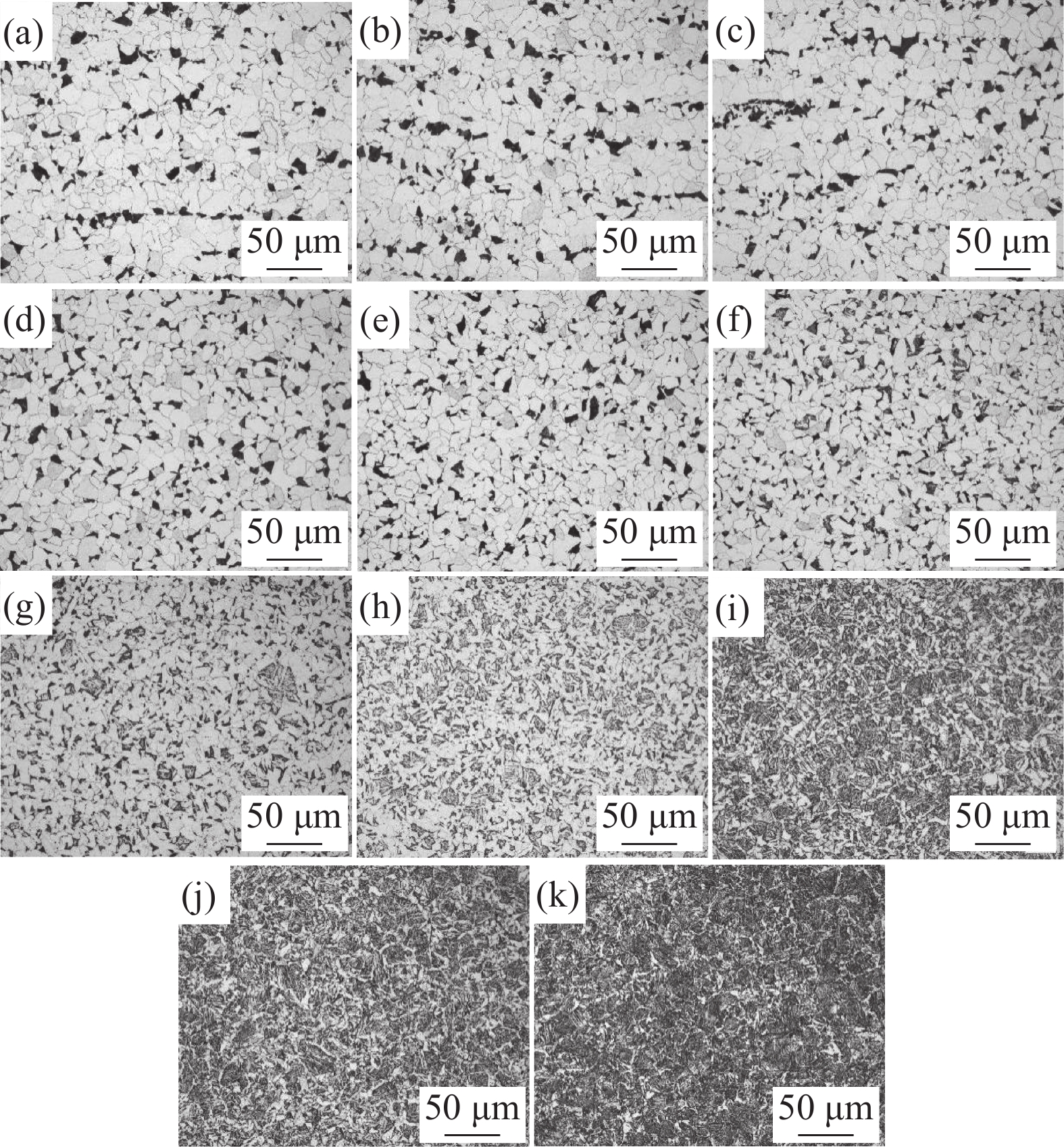

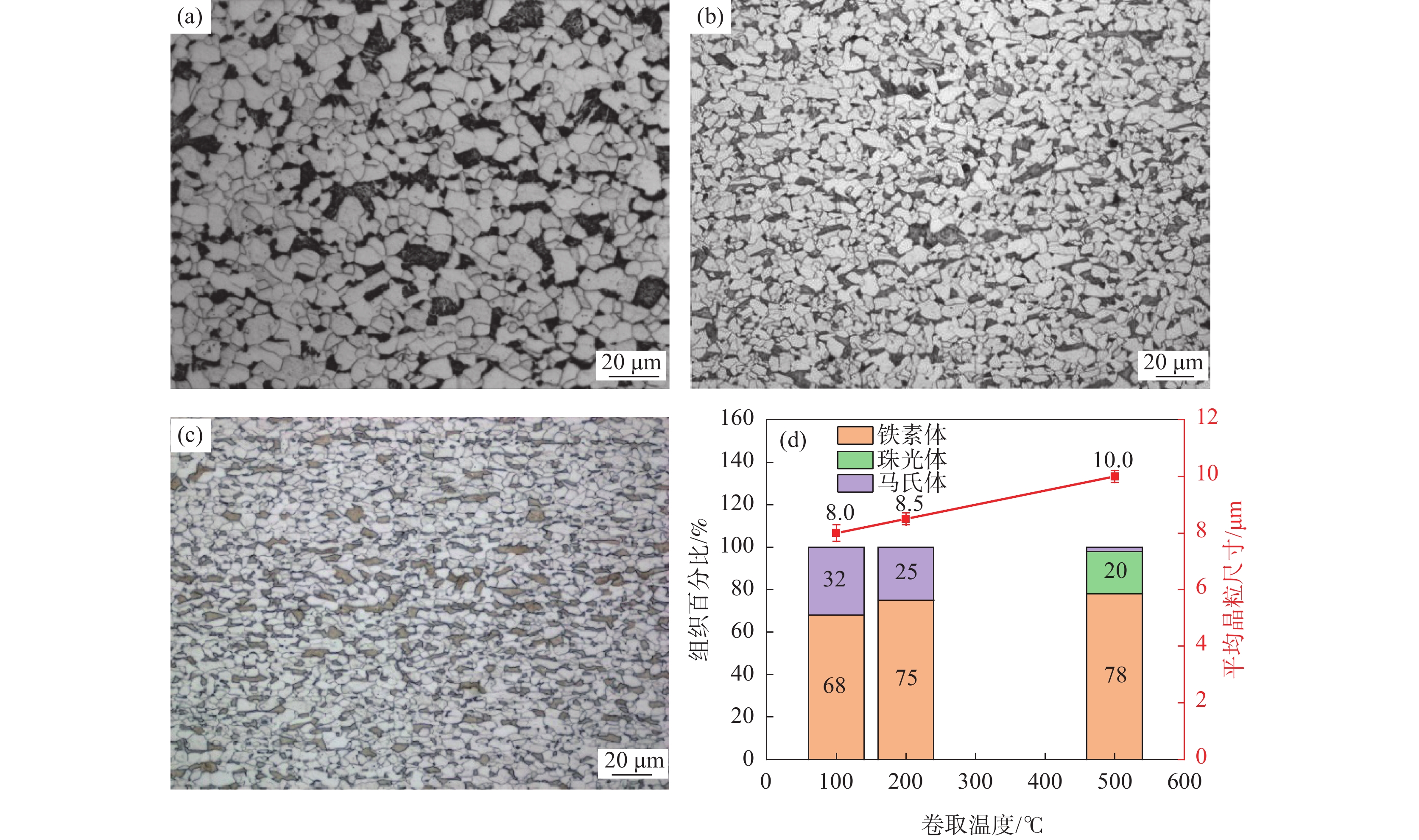

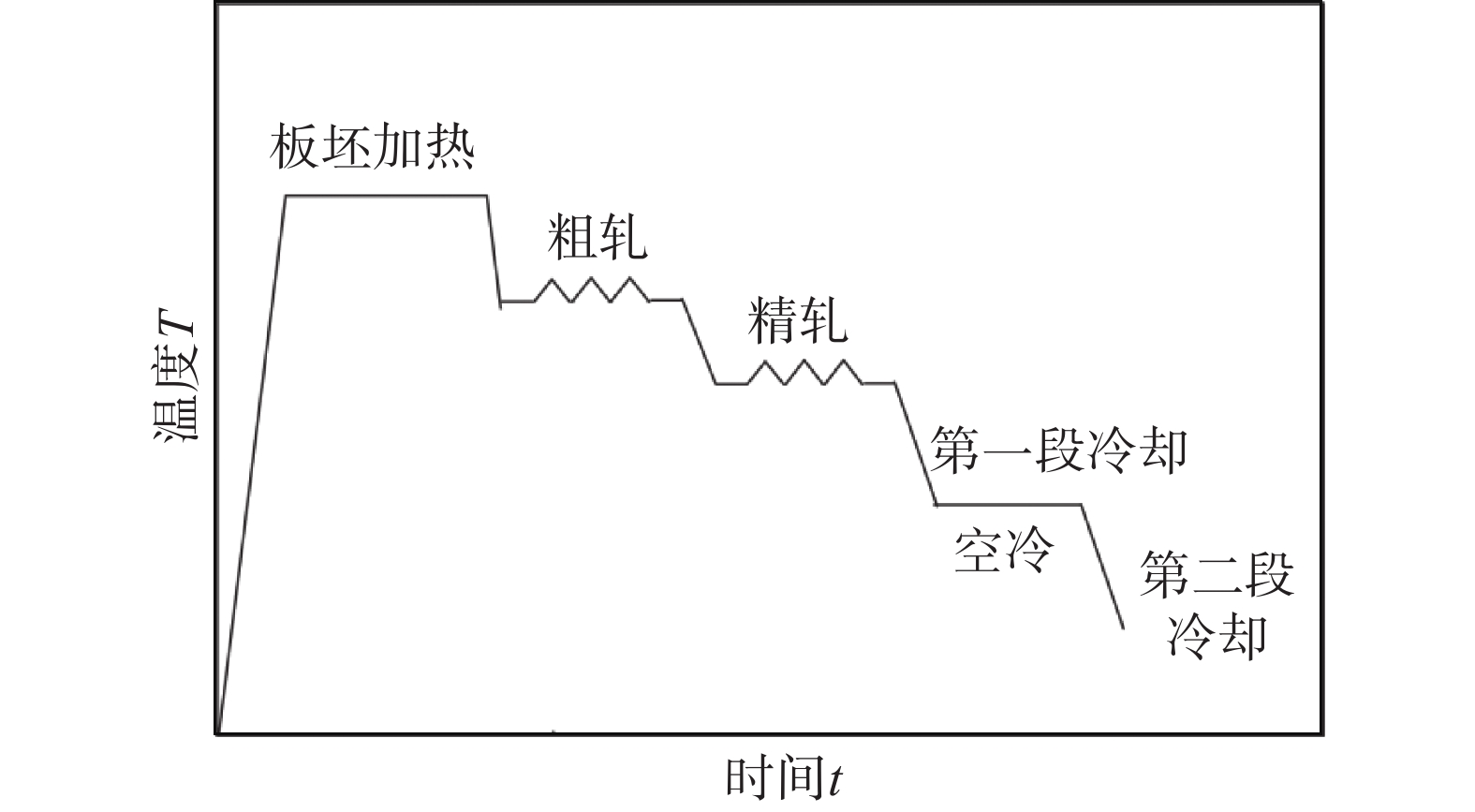

摘要: 测定了DP600 钢的 CCT 曲线,在不同层流冷却工艺下对该钢进行工业试生产,研究了冷却速率、空冷温度和卷取温度对其组织性能的影响。结果表明:当冷却速率 < 10 ℃/s 时,DP600 钢发生珠光体相变;当冷却速率为 ≥10 ℃/s 时,DP600 钢发生贝氏体相变;当冷却速率 > 20 ℃/s 时,DP600 钢发生马氏体相变。随着空冷温度由 700 ℃ 降低到 620、500 ℃,试验钢的显微组织分别为铁素体加马氏体、珠光体、贝氏体,抗拉强度先降低后升高。随着卷取温度由 500 ℃ 降低到 200 ℃ 以下,试验钢的组织由铁素体加珠光体变为铁素体加马氏体,且卷取温度低于100 ℃以下时,马氏体呈条带状偏聚分布,进而导致延伸率和冷弯性能不合格。空冷温度 700 ℃、卷取温度 200 ℃ 时,DP600 钢的力学性能满足要求,此时组织为75% 的铁素体加 25% 的马氏体,平均晶粒尺寸 (8.5 ± 0.3)μm,屈服强度 (397 ± 9)MPa,抗拉强度( 659 ± 13)MPa,延伸率 27% ± 1.1%。Abstract: The CCT curve of DP600 steel was measured and the steel was industrially produced under different laminar flow cooling processes. The effects of cooling rate, air cooling temperature, and coiling temperature on the microstructures and mechanical properties of the steel were studied. The results show that when the cooling rate is less than 10 °C/s, pearlite transformation occurs in DP600 steel. Bainite transformation occurs in DP600 steel when the cooling rate is ≥ 10 °C/s. And martensite transition occurs in DP600 steel when the cooling rate is higher than 20 ℃/s. As the air cooling temperature decreased from 700 ℃ to 620℃ and 500 ℃, the microstructures of the tested steel were ferrite/martensite, pearlite and bainite respectively, and the tensile strength decreased first and then increased. When the coiling temperature reduced from 500 ℃ to below 200 ℃, the microstructures changed from ferrite/pearlite to ferrite/martensite. When the coiling temperature was below 100 ℃, the morphology of martensite changed from diffusing distribution to banded segregation distribution, which in turn leads to the unqualified elongation and cold bending properties. When the air cooling temperature was 700 ℃ and coiling temperature was 200 ℃, the mechanical properties of DP600 steel met the requirements, with the microstructure of 75% ferrite and 25% martensite in volume fraction, the average grain size of (8.5±0.3) μm, the yield strength of (397±9) MPa, the tensile strength of (659±13) MPa, and the elongation rate of 27%±1.1%.

-

表 1 DP600 钢的化学成分及力学性能要求

Table 1. Chemical composition and mechanical properties requirements of the DP600 steel

化学成分/% 力学性能 C Si Mn P S Cr Als 屈服强度/MPa 抗拉强度/MPa 延伸率/% 180°冷弯 ≤0.12 ≤0.20 ≤1.70 ≤0.10 ≤0.01 ≤1.20 ≥0.015 330~470 580~700 ≥24.0 d=0.5a 表 2 DP600 钢的层流冷却工艺参数

Table 2. Laminar flow cooling process parameters of the DP600 steel

工艺 温度/℃ 冷却速率/(℃·s−1) 终轧 空冷 卷取 第一段 第二段 1 820 700 200 15.9 49.7 2 820 500 200 42.4 29.8 3 820 700 500 15.9 19.9 4 820 700 100 15.9 59.6 5 820 620 200 26.5 41.7 表 3 不同空冷温度、卷取温度条件下DP600试验钢的力学性能

Table 3. Mechanical properties of the DP600 tested steel produced at different air cooling temperatures and coiling temperatures

空冷温度

/℃卷取温度

/℃屈服强度

/MPa抗拉强度

/MPa伸长率

/%180°冷弯 700 200 397±9 659±13 27.0±1.1 合格 620 200 411±9 597±11 26.5±1.1 合格 500 200 541±12 623±12 25.0±1.0 合格 700 500 384±8 588±11 24.5±1.0 合格 700 200 397±9 659±13 27.0±1.1 合格 700 100 426±9 709±13 21.5±0.9 不合格 要求值 330~470 580~700 ≥24.0 d=0.5a合格 -

[1] KANG Y L. Lightweight vehicle, advanced high strength steel and energy saving and emission reduction[J]. Iron and steel, 2008,43(6):1-7. (康永林. 汽车轻量化先进高强钢与节能减排[J]. 钢铁, 2008,43(6):1-7. doi: 10.3321/j.issn:0449-749X.2008.06.001KANG Y L. Lightweight vehicle, advanced high strength steel and energy saving and emission reduction[J]. Iron and steel, 2008, 43(6): 1-7. doi: 10.3321/j.issn:0449-749X.2008.06.001 [2] JIA G F, ZHANG Z Q, ZHOU X G, et al. Development of high quality hot rolled dual phase steel[J]. Steel rolling, 2020,37(3):22-25. (贾改风, 张志强, 周晓光, 等. 高品质热轧双相钢的开发[J]. 轧钢, 2020,37(3):22-25.JIA G F, ZHANG Z Q, ZHOU X G, et al. Development of high quality hot rolled dual phase steel[J]. Steel rolling, 2020, 37(3): 22-25. [3] CHEN W J, YIN S, PEI X H. Mechanical property and formability of 580DP and 700DP hot rolled dual phase steel[J]. Materials for mechanical engineering, 2020,44(7):92-97. (陈维晋, 殷胜, 裴新华. 580DP 与 700DP 热轧双相钢的力学性能与成形性能[J]. 机械工程材料, 2020,44(7):92-97. doi: 10.11973/jxgccl202007020CHEN W J, YIN S, PEI X H. Mechanical property and formability of 580DP and 700DP hot rolled dual phase steel[J]. Materials for mechanical engineering, 2020, 44(7): 92-97. doi: 10.11973/jxgccl202007020 [4] XU F. Research on TMCP process of 600MPa grade hot rolled dual phase wheel steel[D]. Shenyang: Northeastern university, 2011: 5-7. (徐锋. 600MPa级热轧双相车轮钢控轧控冷工艺研究[D]. 沈阳: 东北大学, 2011: 5-7.XU F. Research on TMCP process of 600MPa grade hot rolled dual phase wheel steel[D]. Shenyang: Northeastern university, 2011: 5-7. [5] LIU Z C, REN H P. Bainite and bainite transformation[M]. Beijing: Metallurgical industry press, 2009: 99-100. (刘宗昌, 任慧平. 贝氏体与贝氏体相变[M]. 北京: 冶金工业出版社, 2009: 99-100.LIU Z C, REN H P. Bainite and bainite transformation[M]. Beijing: Metallurgical industry press, 2009: 99-100. [6] YUAN G, LI C N, SUN D D, et al. Development status of hot rolled dual-phase steel and development of high strength hot rolled dual-phase steel[J]. Engineering sciences, 2014,16(2):39-45. (袁国, 利成宁, 孙丹丹, 等. 热轧双相钢的发展现状及高强热轧双相钢的开发[J]. 中国工程科学, 2014,16(2):39-45. doi: 10.3969/j.issn.1009-1742.2014.02.004YUAN G, LI C N, SUN D D, et al. Development status of hot rolled dual-phase steel and development of high strength hot rolled dual-phase steel[J]. Engineering sciences, 2014, 16(2): 39-45. doi: 10.3969/j.issn.1009-1742.2014.02.004 [7] ZHANG J C. Study on the control of microstructure and properties of hot rolled dual phase steel and the micro deformation mechanism[D]. Shenyang: Northeastern university, 2017: 2-4. (张洁岑. 热轧双相钢组织性能调控及其微观变形机制研究[D]. 沈阳: 东北大学, 2017: 2-4.ZHANG J C. Study on the control of microstructure and properties of hot rolled dual phase steel and the micro deformation mechanism[D]. Shenyang: Northeastern university, 2017: 2-4. [8] SUN M J, ZHAO N, XIA X M. Study on stage cooling precision control and microstructure and properties of 600 MPa grade hot rolled dual phase steel[J]. Hot working technology, 2017,46(13):169-172. (孙明军, 赵楠, 夏小明. 600 MPa 级热轧双相钢分段冷却精确控制及组织性能研究[J]. 热加工工艺, 2017,46(13):169-172.SUN M J, ZHAO N, XIA X M. Study on stage cooling precision control and microstructure and properties of 600 MPa grade hot rolled dual phase steel[J]. Hot working technology, 2017, 46(13): 169-172. [9] ZHOU L Y, ZHANG D, JIANG B, et al. Transformation behavior and properties of high strength hot rolled dual phase steel[J]. Transactions of materials and heat treatment, 2014,35(4):116-120. (周乐育, 张丹, 蒋波, 等. 高强度热轧双相钢分段相变行为及性能[J]. 材料热处理学报, 2014,35(4):116-120.ZHOU L Y, ZHANG D, JIANG B, et al. Transformation behavior and properties of high strength hot rolled dual phase steel[J]. Transactions of materials and heat treatment, 2014, 35(4): 116-120. [10] CAI Z, WANG S Z, XU J Q, et al. Present situation and development trend of dual phase steel produced in TSCR line[J]. Steel rolling, 2018,35(2):59-64. (蔡珍, 汪水泽, 徐进桥, 等. 短流程热轧双相钢的生产现状及发展趋势[J]. 轧钢, 2018,35(2):59-64.CAI Z, WANG S Z, XU J Q, et al. Present situation and development trend of dual phase steel produced in TSCR line[J]. Steel rolling, 2018, 35(2): 59-64. [11] COLDREN P, TITHER G, DOANE D V. Dual phase hot rolled steel trip: US, 4072543[P]. 1978-02-07. [12] SUN W P. Hot rolled dual phase steel sheet: US8337643 B2 [P]. 2012-12-25. [13] SUN C, QI J J, ZHANG Z X, et al. TMCP process and properties of 600 MPa grade hot rolled dual phase wheel steel in medium temperature coiling[J]. Hot working technology, 2022,51(13):24-27. (孙超, 齐建军, 张志新, 等. 600 MPa 级中温卷取型热轧双相车轮钢 TMCP 工艺及性能[J]. 热加工工艺, 2022,51(13):24-27.SUN C, QI J J, ZHANG Z X, et al. TMCP process and properties of 600 MPa grade hot rolled dual phase wheel steel in medium temperature coiling[J]. Hot working technology, 2022, 51(13): 24-27. [14] ZHANG D, LIANG G L, YE X Y. Study on ferrite control process in bainite dual phase steel[J]. Hot working technology, 2019,48(11):62-65. (张丹, 梁国俪, 叶校瑛. 贝氏体双相钢中铁素体控制工艺研究[J]. 热加工工艺, 2019,48(11):62-65.ZHANG D, LIANG G L, YE X Y. Study on ferrite control process in bainite dual phase steel[J]. Hot working technology, 2019, 48(11): 62-65. [15] XIONG W L, LIANG W, WU T, et al. Effect of controlled cooling process on microstructure and mechanical properties of hot rolled dual phase steel[J]. Heat treatment of metals, 2022,47(9):130-133. (熊维亮, 梁文, 吴腾, 等. 控冷工艺对热轧双相钢组织与性能的影响[J]. 金属热处理, 2022,47(9):130-133.XIONG W L, LIANG W, WU T, et al. Effect of controlled cooling process on microstructure and mechanical properties of hot rolled dual phase steel[J]. Heat treatment of metals, 2022, 47(9): 130-133. [16] WANG Z G, LIU B, WU R, et al. Effect of martensite volume fraction on mechanical properties and n value of hot rolled dual phase steel[J]. Hot working technology, 2018,47(14):64-67. (王志刚, 刘斌, 吴润, 等. 马氏体体积分数对热轧双相钢力学性能和 n 值的影响[J]. 热加工工艺, 2018,47(14):64-67.WANG Z G, LIU B, WU R, et al. Effect of martensite volume fraction on mechanical properties and n value of hot rolled dual phase steel[J]. Hot working technology, 2018, 47(14): 64-67. [17] SETO K, FUNAKAWA Y, KANEKO S. Hot rolled high strength steels for suspension and chassis parts “ NANOHITEN ” and “ BHT Steel ”[J]. JFE technical report, 2007,10:19-25. [18] MAJUMDAR S, ROY S, RAY K K. Fatigue performance of dual phase steels for automobile wheel application[J]. Fatigue & fracture of engineering materials & structures, 2017,40:315-322. [19] PICKERING F B. Materials science and technology (Vol. 7): Constitution and properties of steels[M]. Liu J H, Translate. Beijing: Science press, 1999: 15-70. (F Brian Pickering. 材料科学与技术丛书(第7卷): 钢的组织与性能[M]. 刘嘉禾, 译. 北京: 科学出版社, 1999: 15-70.PICKERING F B. Materials science and technology (Vol. 7): Constitution and properties of steels[M]. Liu J H, Translate. Beijing: Science press, 1999: 15-70. [20] ZHANG X H, LI Y Q, PANG H L, et al. Effect of Nb and Cr on microstructure and properties of low C and low Si cold rolled high strength dual phase steels[J]. Transactions of materials and heat treatment, 2009,30(1):96-99. (张学辉, 李永强, 庞海轮, 等. Nb和Cr对冷轧低碳低硅双相钢组织性能的影响[J]. 材料热处理学报, 2009,30(1):96-99.ZHANG X H, LI Y Q, PANG H L, et al. Effect of Nb and Cr on microstructure and properties of low C and low Si cold rolled high strength dual phase steels[J]. Transactions of materials and heat treatment, 2009, 30(1): 96-99. [21] DONG Y, XU Y B, WU D, et al. Effect of deformation temperature on the microstructure of Nb microalloyed dual phase steel[J]. Acta metallurgica sinica, 2009,45(11):1314-1319. (董毅, 许云波, 吴迪, 等. 变形温度对含Nb双相钢显微组织的影响[J]. 金属学报, 2009,45(11):1314-1319. doi: 10.3321/j.issn:0412-1961.2009.11.007DONG Y, XU Y B, WU D, et al. Effect of deformation temperature on the microstructure of Nb microalloyed dual phase steel[J]. Acta metallurgica sinica, 2009, 45(11): 1314-1319. doi: 10.3321/j.issn:0412-1961.2009.11.007 -

下载:

下载: