Research on additive repair special powder and process of 921 steel for marine equipment

-

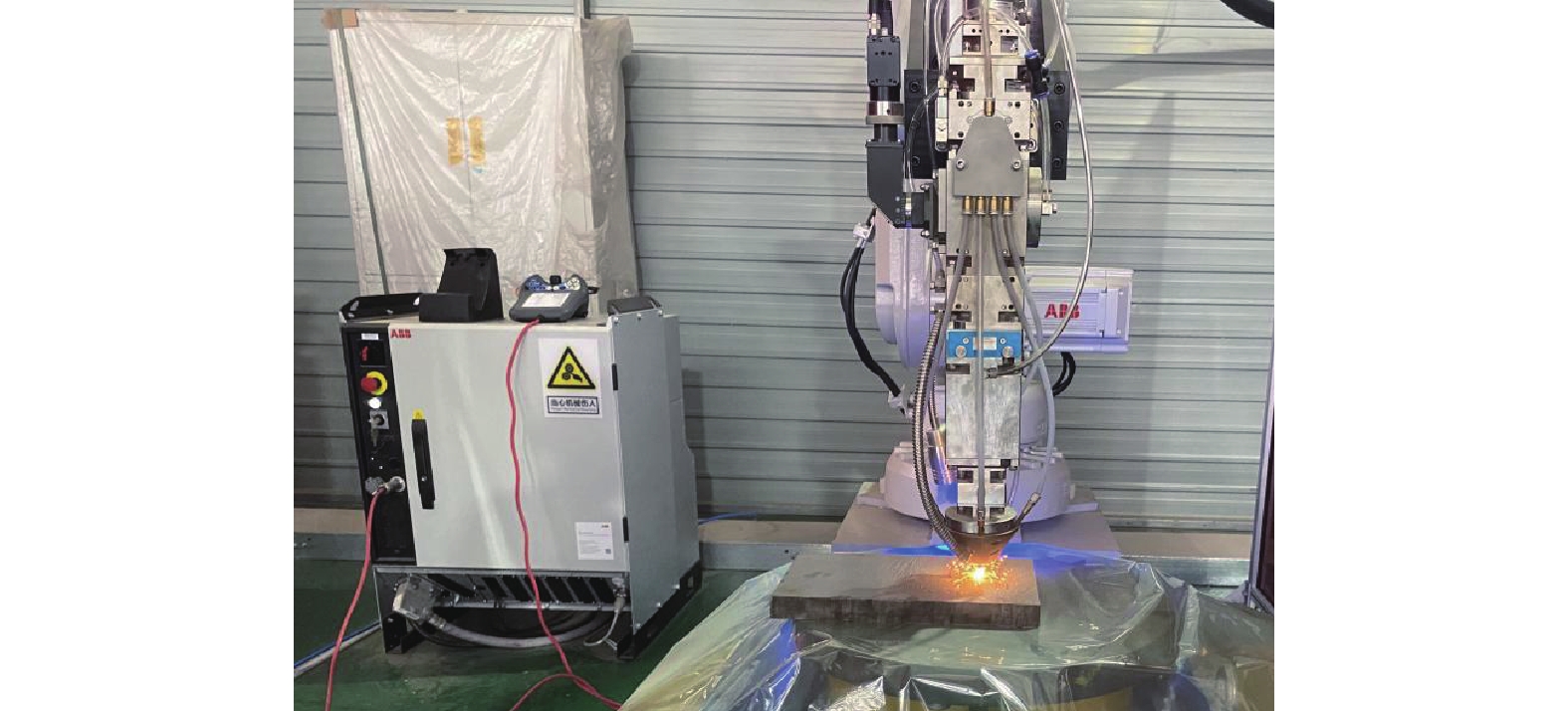

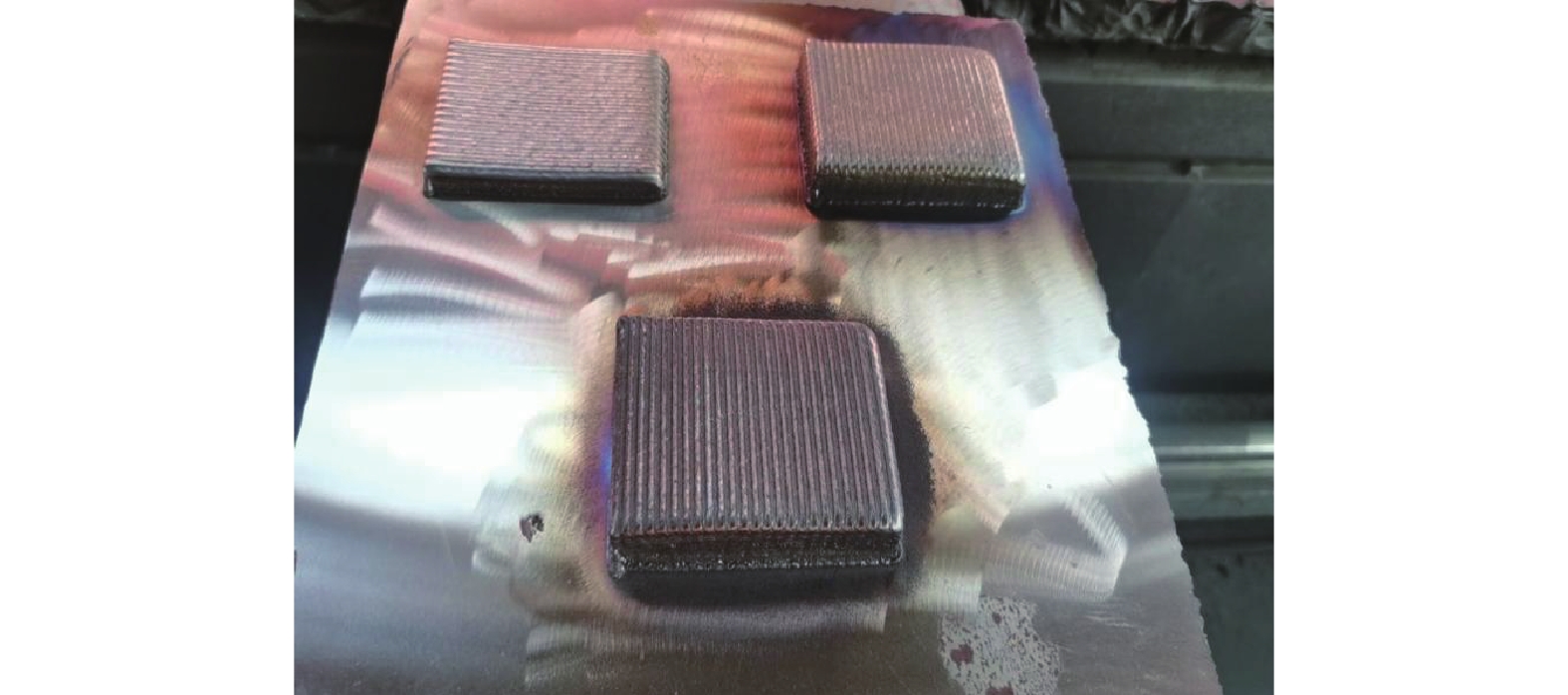

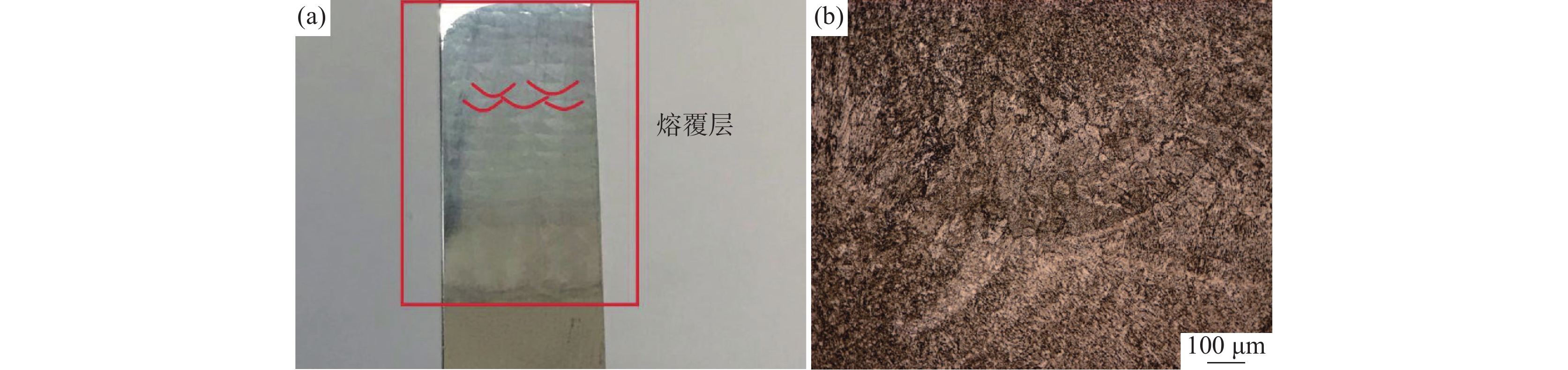

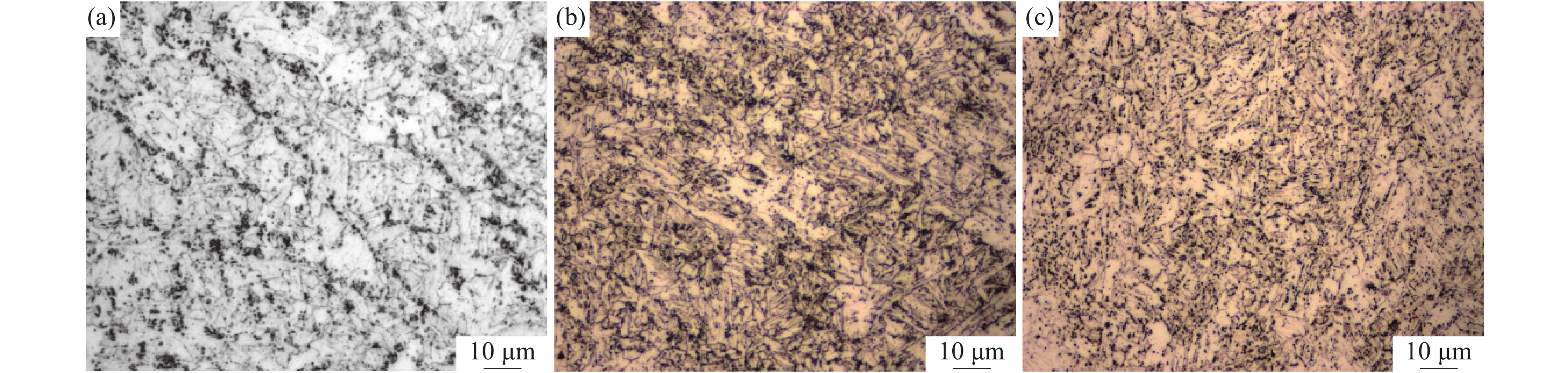

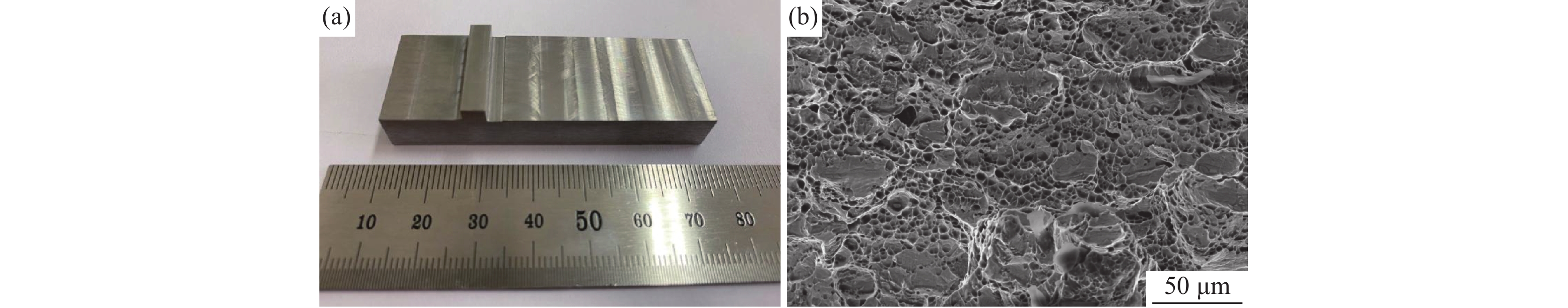

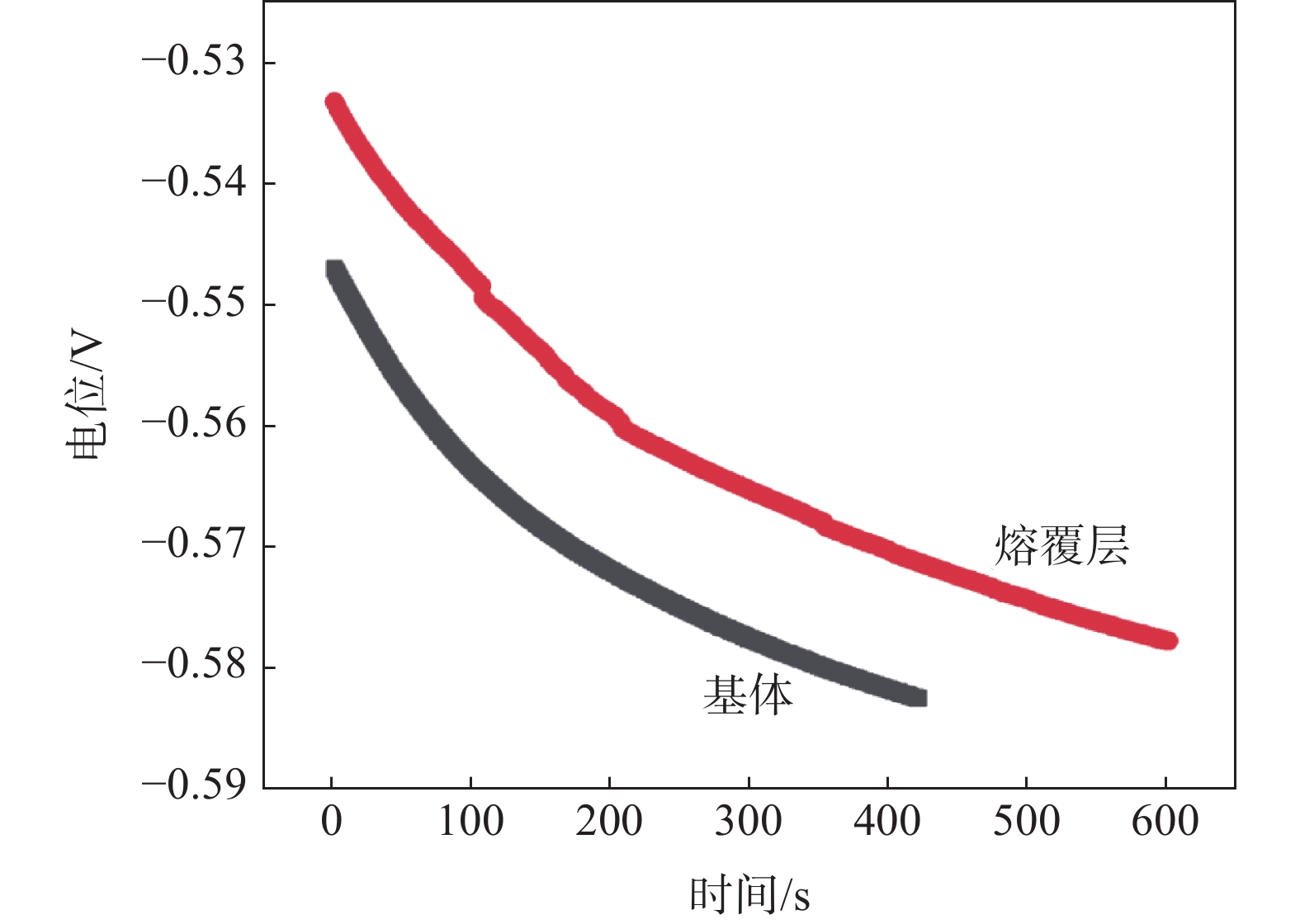

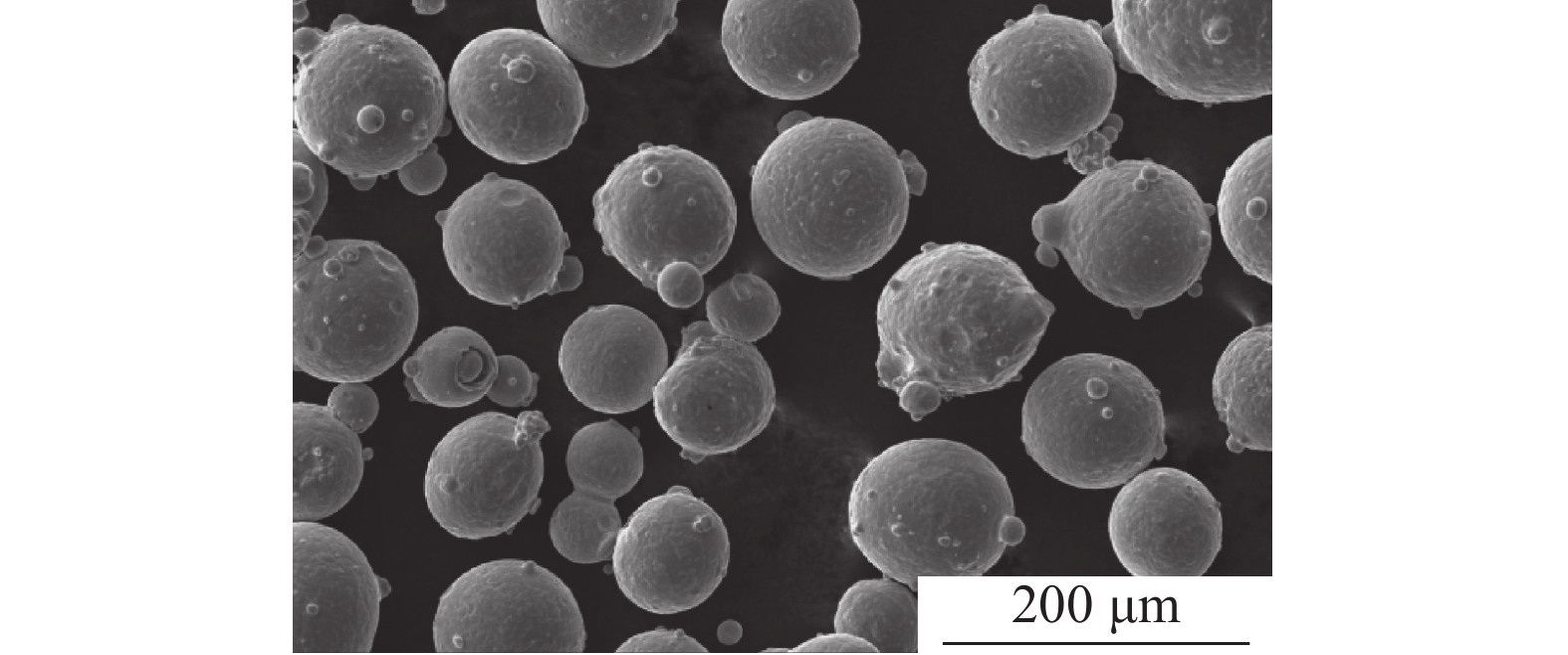

摘要: 研究了用于921钢材表面开展激光增材制造与修复的专用粉体及配套工艺。通过合理调控合金组分,利用气雾化工艺,获得尺寸均匀的球形雾化粉末;利用激光同轴送粉设备在921钢基材上进行增材制造,优化工艺参数,可获得力学性能匹配良好,无宏观缺陷的熔覆层,实现对921钢基材的增材与修复目的。经测试,修复层力学性能满足相关修复指标要求,化学成分与设定保持一致,无开裂分层等缺陷,具备良好机加工性能,有助于实现大型海洋结构的自主修复,提高服役可靠性。Abstract: In this paper the specialized powder and supporting technology for laser additive manufacturing and repair on the surface of 921 steel had been investigated. By adjusting the alloy composition reasonably a spherical atomized powder with uniform size can be obtained through atomization process. A laser coaxial powder feeding equipment had been used for additive manufacturing on 921 steel substrate. As a result a well matched mechanical performance and macroscopic defect free cladding layer can be obtained, achieving the purpose of additive and repair on 921 steel substrate. Testing result indicates the mechanical properties of the repaired layer meet the relevant repair index requirements, the chemical composition remains consistent with the setting, and there are no defects such as cracking and layering. It has good machining performance, which helps to achieve autonomous repair of large marine structures and improve service reliability.

-

Key words:

- 921 steel /

- additive manufacturing /

- laser /

- ocean /

- mechanical property

-

表 1 粉末的化学成分设计

Table 1. Alloying design of powder

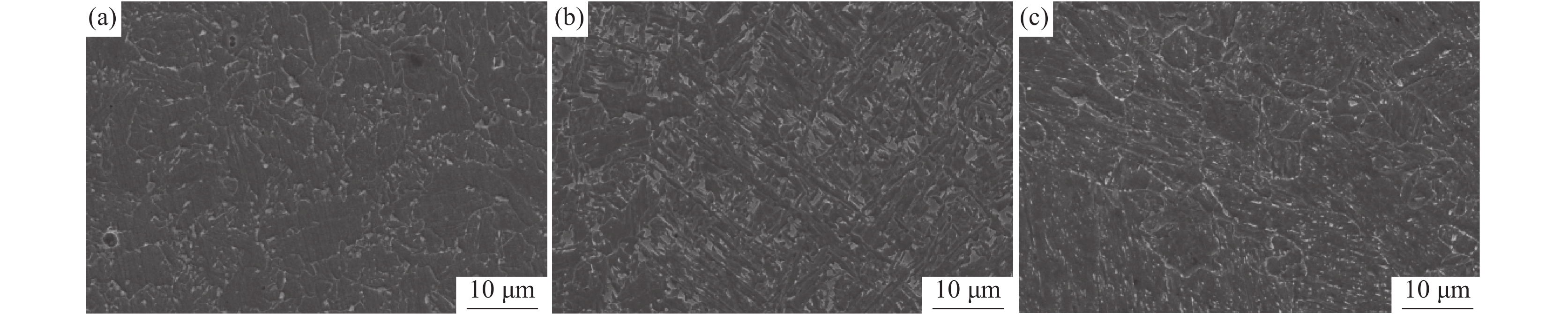

% C Si Mn S P Mo Ni O N H Fe 0.03~0.05 0.3~0.4 1.3~1.5 ≤0.004 ≤0.01 0.2~0.5 3.3~3.5 ≤0.005 ≤0.006 ≤0.005 余量 表 2 粉末实际化学成分

Table 2. Measured chemical compositions of powder

% 样品名 C Si Mn Mo Ni O S P N H Fe 0.2Mo 0.031 0.37 1.30 0.21 3.27 0.009 0.004 0.004 0.002 余量 0.3Mo 0.023 0.34 1.29 0.33 3.48 0.012 0.004 0.004 0.002 0.002 余量 0.5Mo 0.029 0.34 1.31 0.51 3.27 0.011 0.004 0.004 0.002 余量 表 3 激光熔覆工艺参数

Table 3. Laser cladding process parameters

搭接率/% 激光功率/kW 载粉气流量/(L·min−1) 保护气流量/(L·min−1) 激光头行走速率/(m·min−1) 工作距离/mm 50~60 1~3 10~15 9~13 1~5 13~15 表 4 增材区域力学性能

Table 4. Mechanical properties of additive region

样品名 抗拉强度/MPa 界面结合强度/MPa 延伸率/% 显微硬度(HV) 冲击功

(−50 ℃)/J0.2Mo 623.3 567 25.8 212.2 103 0.3Mo 678.5 590 20.0 233.1 99 0.5Mo 750.3 631 18.1 261.2 81 表 5 AWS D3.6M:2017 A标准力学性能规定

Table 5. AWS D3.6M:2017 A standard mechanical properties specification

基体最小抗拉强度/MPa 平均冲击功/J 最小冲击功/J 熔覆层缺陷 ≥550 34 23 目视及无损测试无缺陷 -

[1] KOU R K. Study on high pressure dry underwater laser cladding repair technology and properties of 921A ship steel[D]. Beijing: Beijing Institute of Petrochemical Technology, 2022. (寇荣魁. 921A舰船钢高压干法水下激光熔覆修复工艺及性能研究[D]. 北京:北京石油化工学院, 2022.KOU R K. Study on high pressure dry underwater laser cladding repair technology and properties of 921A ship steel[D]. Beijing: Beijing Institute of Petrochemical Technology, 2022. [2] FANG Z G, LIU B, LI G M, et al. Requirement and development analysis of warship equipment materials system[J]. Materilas China, 2014,33(7):385-393. (方志刚, 刘斌, 李国明, 等. 舰船装备材料体系发展与需求分析[J]. 中国材料进展, 2014,33(7):385-393.FANG Z G, LIU B, LI G M, et al. Requirement and development analysis of warship equipment materials system[J]. Materilas China, 2014, 33(7): 385-393. [3] HART P, RICHARDSON I M, NIXON J H. The effects of pressure on electrical performance and weld bead geometry in high pressure GMA welding[J]. Welding in the World, 2001, 45: 25-33. [4] ZHU D F, ZHU J L, JIAO X D, et al. Microstructure and mechanical properties of 921A steel welding joint by laser-MAG hybrid welding[J]. Welding & Joining, 2022(9): 25-29, 42. (朱东芳, 朱加雷, 焦向东, 等. 921A钢激光-MAG复合焊接头组织及性能[J]. 焊接, 2022(9): 25-29, 42.ZHU D F, ZHU J L, JIAO X D, et al. Microstructure and mechanical properties of 921A steel welding joint by laser-MAG hybrid welding[J]. Welding & Joining, 2022(9): 25-29, 42. [5] GARASIC I, KRALJ S, KOZUH Z, et al. Analysis of underwater repair technology on the jack-up platform spud can[J]. Brodogradnja, 2010, 61(2): 153-160. [6] WOODWARD N, KNAGENHELM H O, BERGE J O, et al. Hyperbaric GMA welding for contingency repair using a fillet welded sleeve at 1 000 m water depth[C]. Proceedings of the International Offshore and Polar Engineering Conference, 2007:3403. [7] KARATZAS V A, KOTSIDIS E A, TSOUVALIS N G, et al. Experimental fatigue study of composite patch repaired steel plates with cracks[J]. Applied composite materials, 2015, 22(5): 507-523. [8] HAN L G, WU X M, CHEN G D, et al. Local dry underwater welding of 304 stainless steel based on a microdrain cover[J]. Journal of Materials Processing Technology, 2019,268:47-53. doi: 10.1016/j.jmatprotec.2018.12.029 [9] SHAO C L, XIAO J L, ZHU J L, et al. Research on surface repair technology of laser wire-filled cladding and verification on pressure environment[J]. Journal of Beijing Institute of Petrochemical Technology, 2021,29(4):14-18. (邵长磊, 肖镌璐, 朱加雷, 等. 激光填丝熔覆表面修复工艺研究及压力环境验证[J]. 北京石油化工学院学报, 2021,29(4):14-18.SHAO C L, XIAO J L, ZHU J L, et al. Research on surface repair technology of laser wire-filled cladding and verification on pressure environment[J]. Journal of Beijing Institute of Petrochemical Technology, 2021, 29(4): 14-18. [10] SUN G, WANG Z, LU Y, et al. Underwater laser welding/cladding for high-performance repair of marine metal materials: A review[J]. Chinese Journal of Mechanical Engineering, 2022(1): 35. [11] MAKIHARA Y, MIWA Y, HIROSE N, et al. The application of the welding technique at fillet groove by the YAG-laser repair-welding robot for underwater environment[C]. 12th International Conference on Nuclear Engineering, 2004, 2, 149-155. [12] SRIDAR S, ZHAO Y, LI K, et al. Post-heat treatment design for high-strength low-alloy steels processed by laser powder bed fusion[J]. Materials Science & Engineering, A. 2020,788: 139531. [13] RODRIGUES T A, DUARTE V R, TOMÁS D, et al. In-situ strengthening of a high strength low alloy steel during wire and arc additive manufacturing (WAAM)[J]. Additive Manufacturing, 2020, 34: 101200. -

下载:

下载: