Effect of borax on microstructure and viscosity of fluorine-free mold fluxes containing titanium-bearing blast furnace slag

-

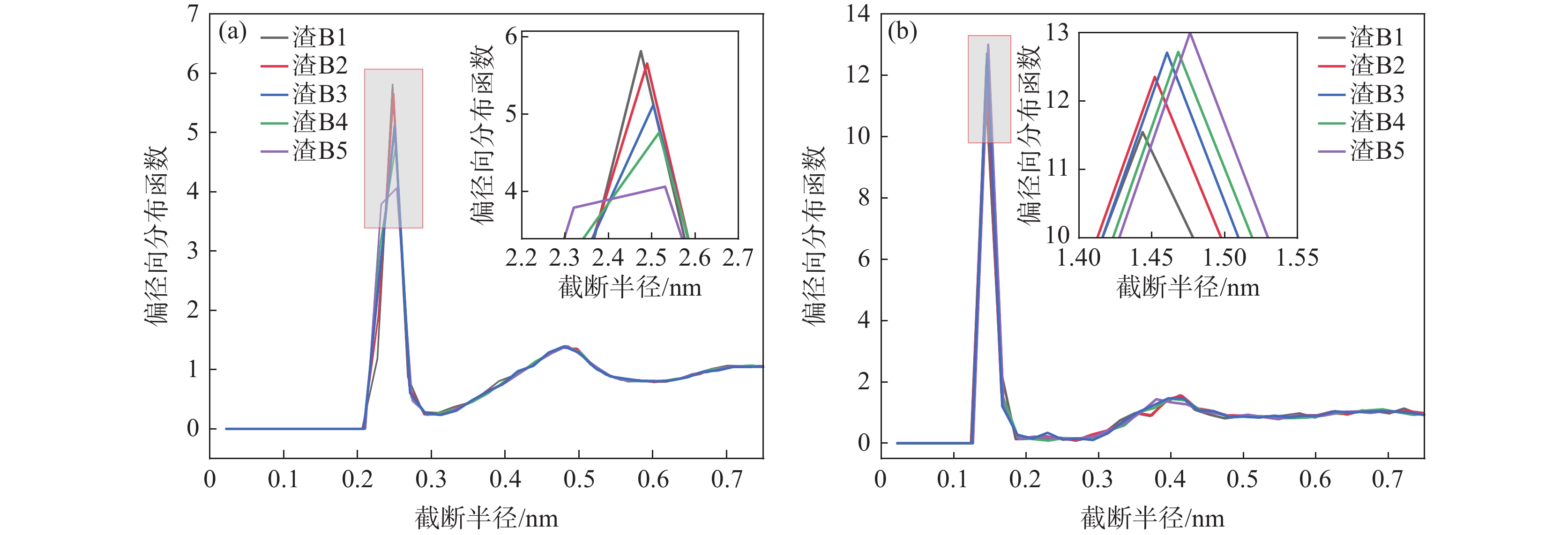

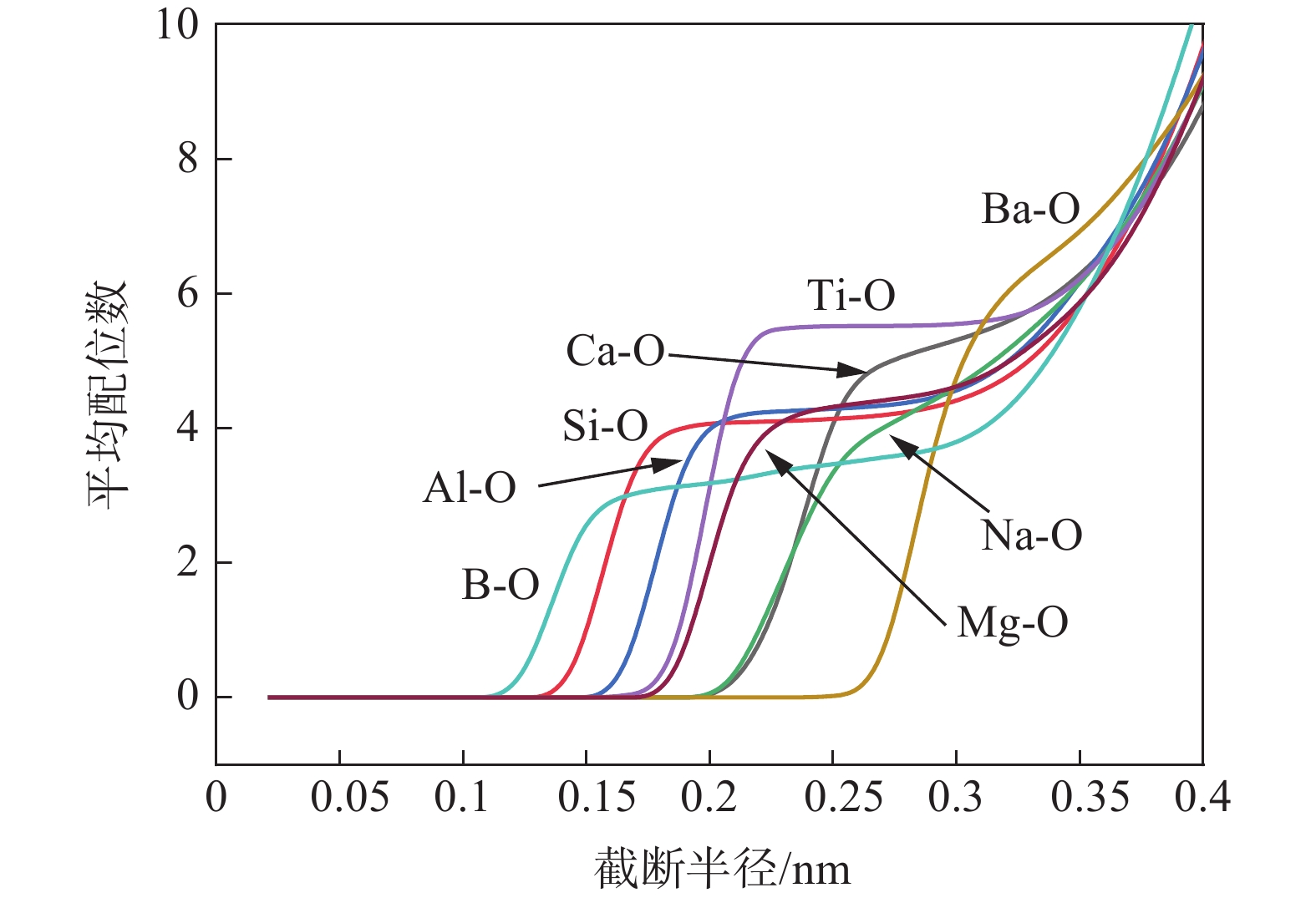

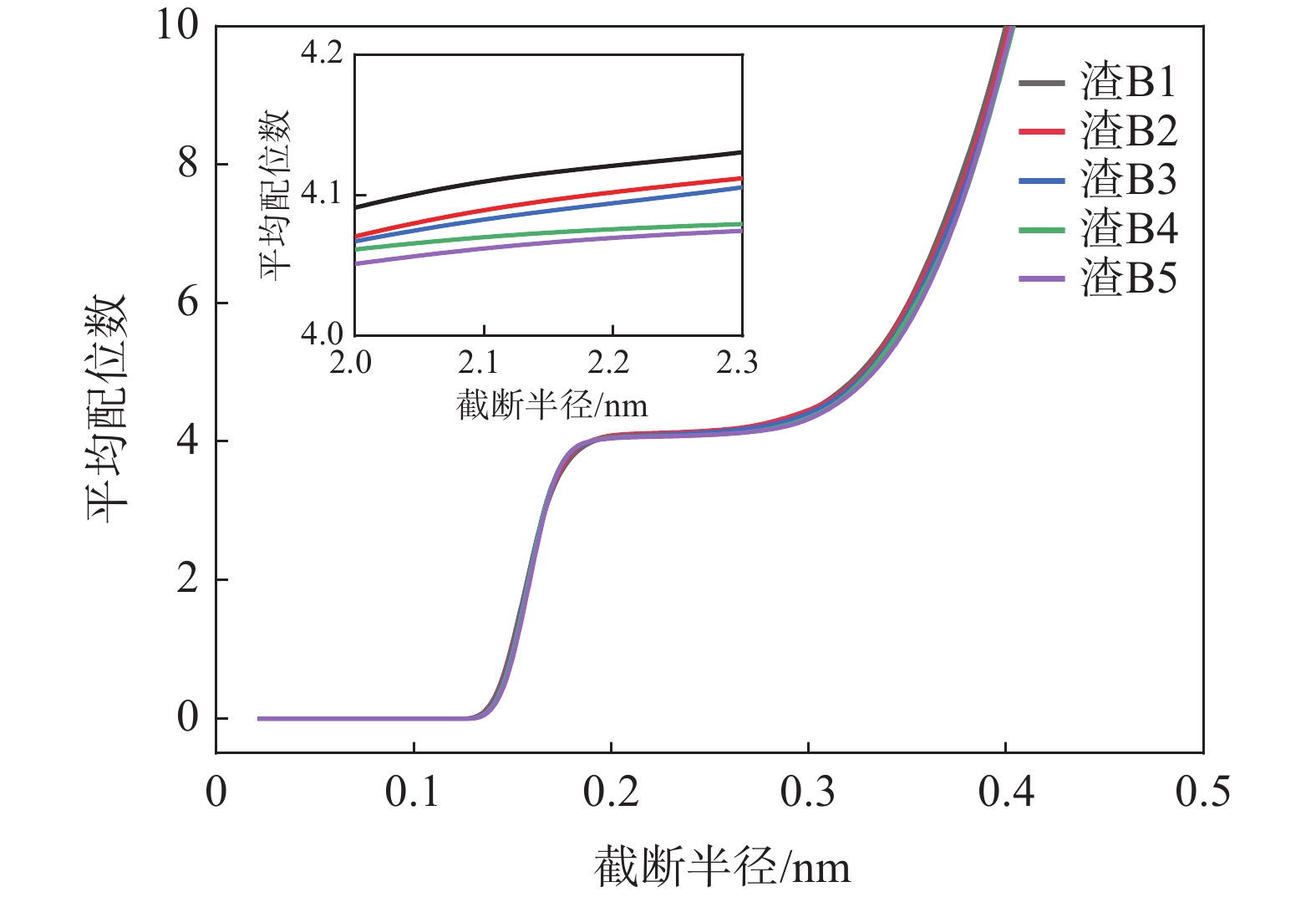

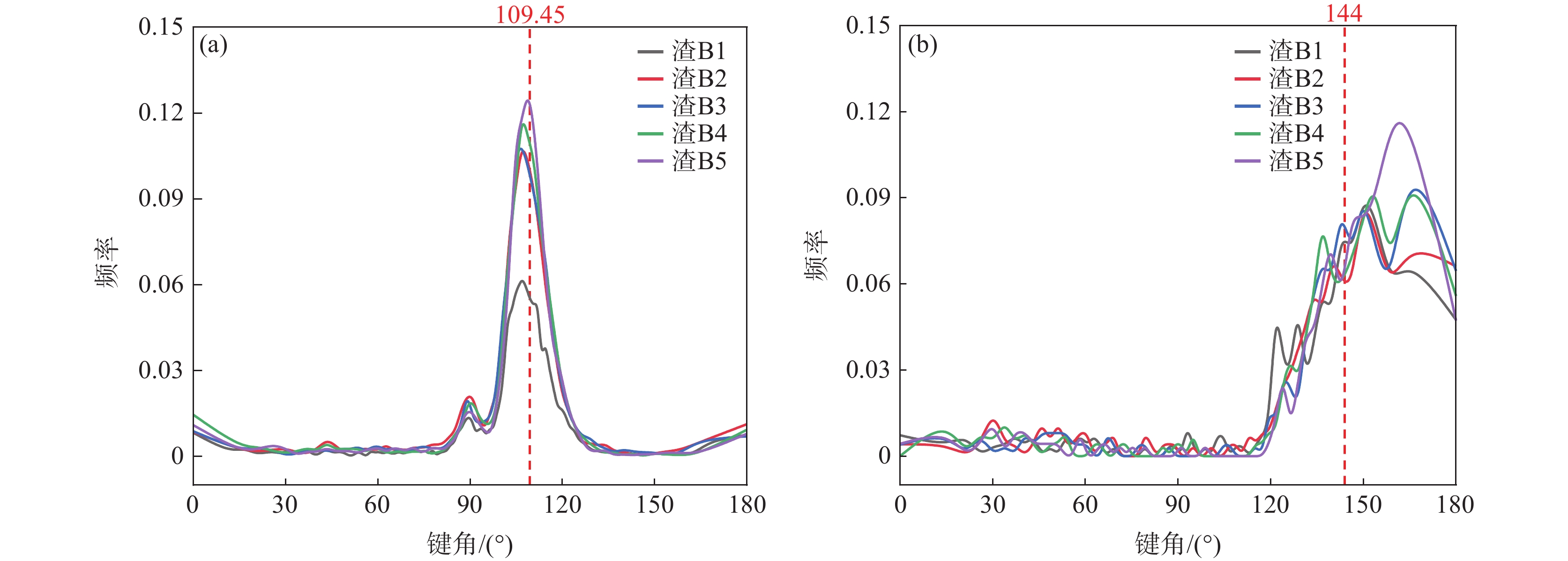

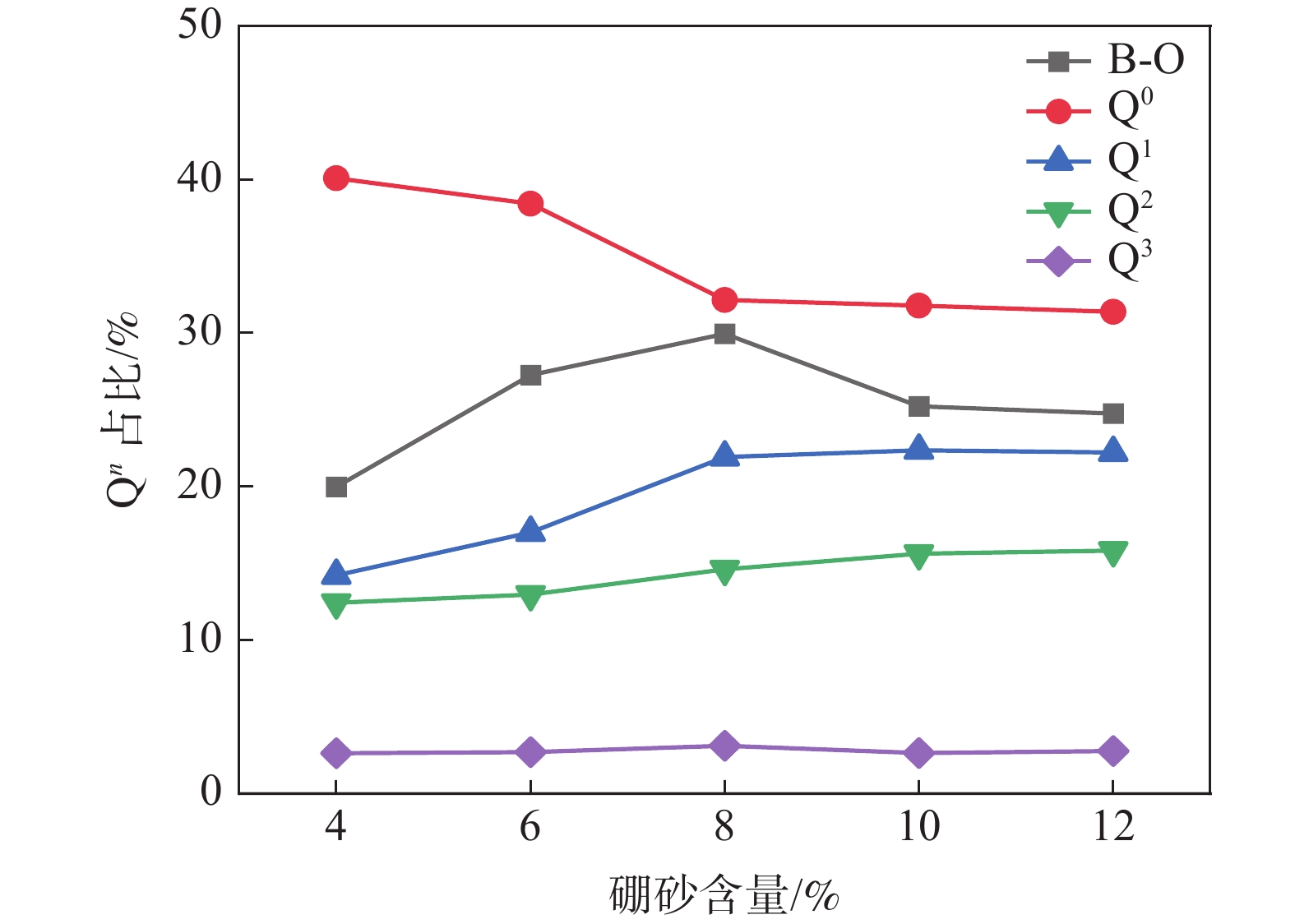

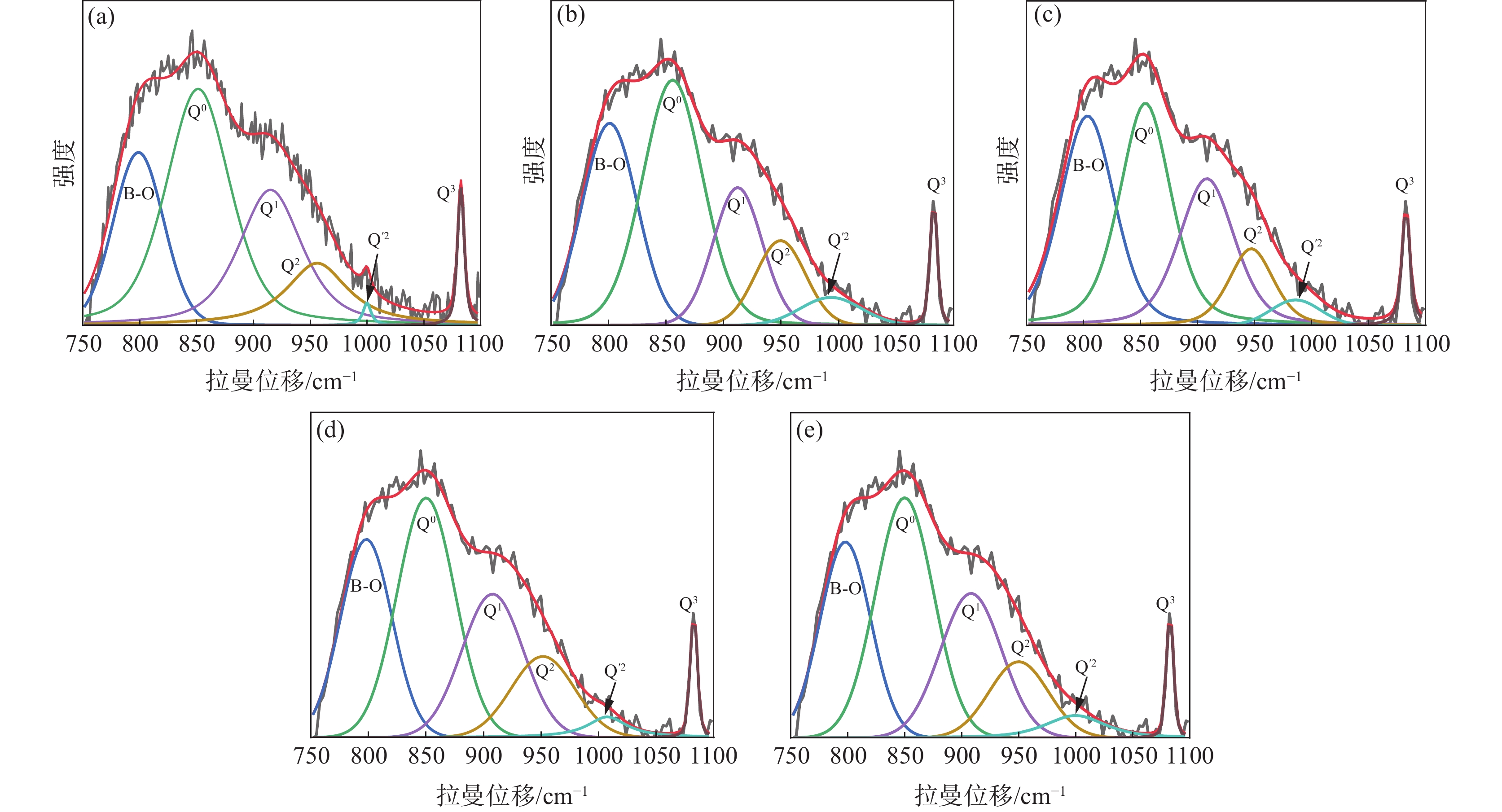

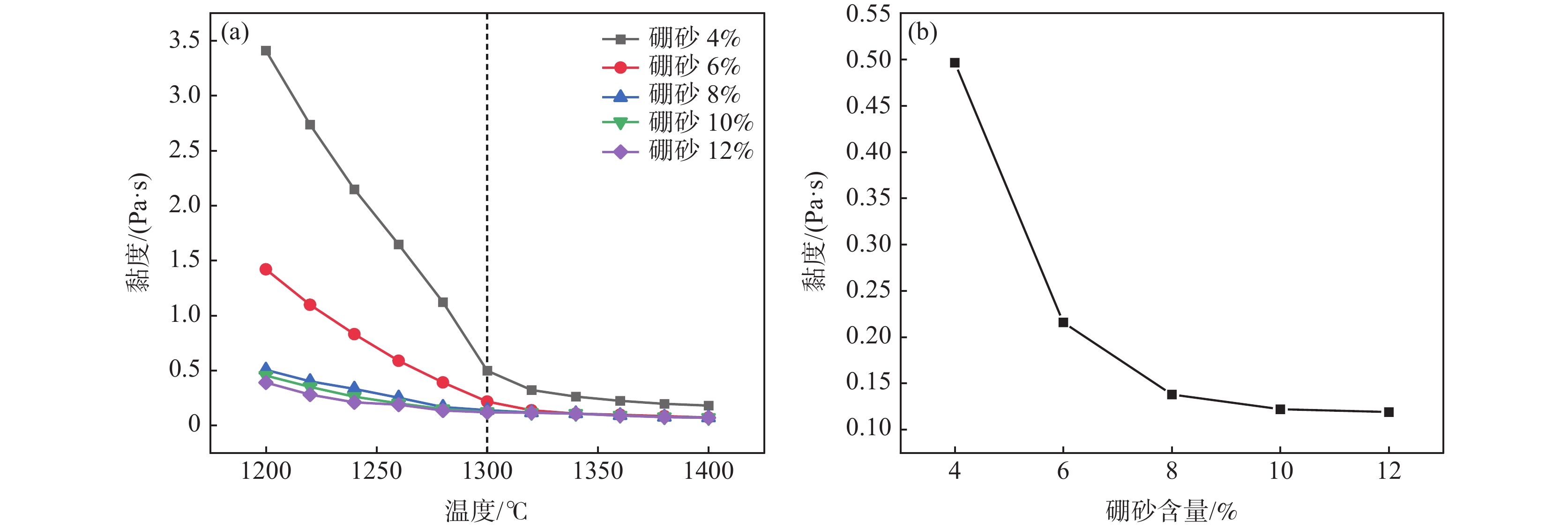

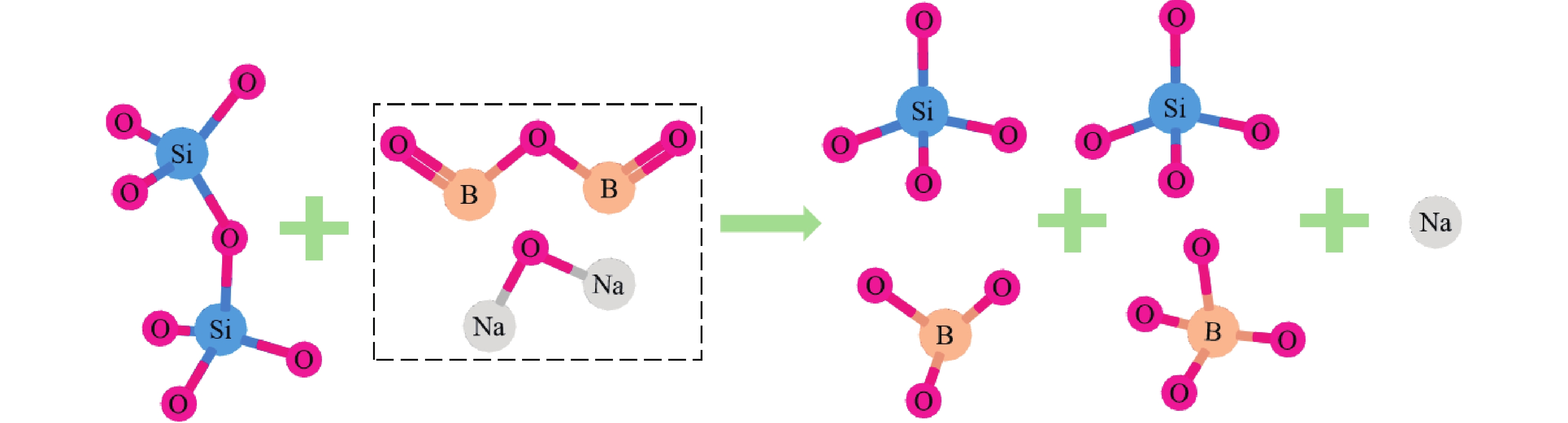

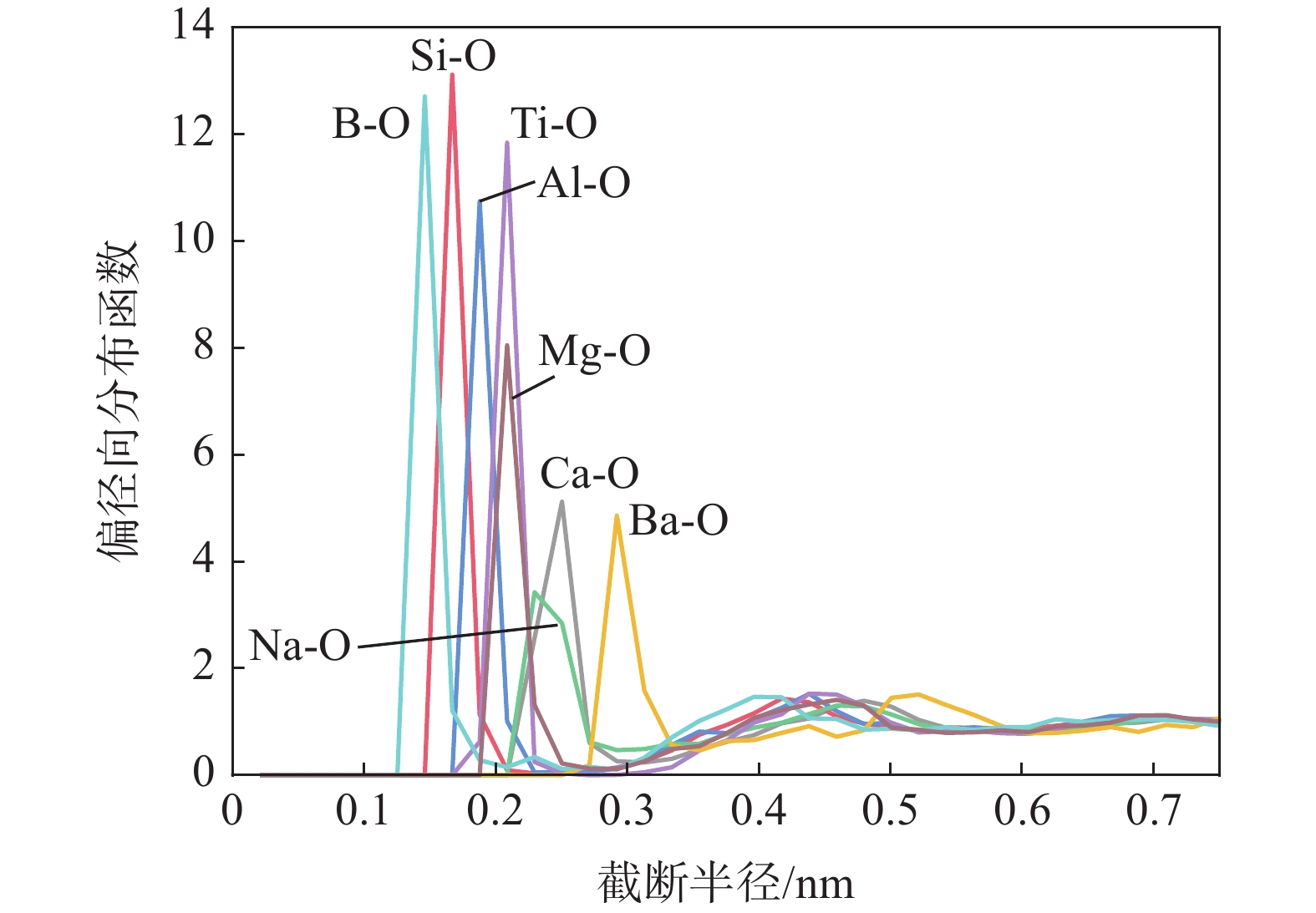

摘要: 为明晰硼砂作为氟替代物在含钛无氟保护渣中的作用机制,选用含钛高炉渣、石灰石、石英砂、纯碱、毒重石和硼砂等工业矿物原料配制含钛矿渣基无氟保护渣,采用分子动力学模拟和拉曼光谱技术研究了熔渣的偏径向分布函数、平均配位数、键角分布和结构单元Qn分布等结构特征,并从熔渣微观结构层面解析了宏观性能黏度随硼砂含量变化的内因。结果表明,随硼砂含量的增加(4%~12%),含钛矿渣基无氟保护渣的熔渣中Ca-O结构稳定性变差,低聚合度B-O结构大量形成,∠Si-O-Si键角有序度降低,结构单元Q0逐渐解聚转化为Q1和Q2,网络结构变得更加复杂且整体聚合度减小,即在宏观上表现为黏度性能下降;当硼砂含量增加至8%以上时,含钛矿渣基无氟保护渣降至低黏度水平并趋于稳定。Abstract: To clarify the role of borax as a fluoride substitute in fluoride-free and titanium-bearing mold fluxes, the test samples were prepared using industrial raw materials such as titanium-bearing blast furnace slag, limestone, quartz, soda ash, witherite, and borax. Molecular dynamics simulation and Raman spectroscopy were used to study structural characteristics of the samples, including radial distribution function, average coordination number, bond angle distribution, and structural unit Qn distribution. The intrinsic factors of the viscosity changing with borax content were analyzed from the perspective of slag structure. The results show that with the increase of borax content (from 4% to 12%), the stability of the Ca-O structure deteriorates, a large amount of low polymerization degree B-O structure forms, the order degree of Si-O-Si bond angle decreases, and the structural units Q0 gradually depolymerize into Q1 and Q2, making the slag structure more complex and the overall polymerization degree smaller. That is, the viscosity performance decreases macroscopically. Moreover, when the borax content increases to more than 8%, the fluoride-free and titanium-bearing mold fluxes reaches a low and steady viscosity level.

-

表 1 配渣原料的化学成分

Table 1. Chemical compositions of raw materials

% 原料 SiO2 CaO TiO2 Al2O3 MgO Na2O B2O3 CaCO3 Na2CO3 BaCO3 含钛高

炉渣24.74 26.71 22.31 11.87 8.96 石英 98.32 石灰石 97.15 纯碱 >99 毒重石 >99 硼砂 30.49 68.51 表 2 试验渣的化学成分

Table 2. Chemical compositions of slags

% 渣号 CaO SiO2 Al2O3 MgO TiO2 BaO Na2O B2O3 B1 35.78 27.63 6.05 4.56 11.36 2.94 8.19 3.49 B2 34.88 26.22 6.01 4.54 11.30 2.93 8.91 5.20 B3 33.13 25.93 5.94 4.49 11.17 2.90 9.58 6.86 B4 32.27 24.56 5.91 4.46 11.11 2.88 10.28 8.53 B5 30.57 24.29 5.85 4.41 10.99 2.85 10.92 10.12 表 3 分子动力学模型相关参数

Table 3. Molecular dynamics simulation related parameters

渣

号原子个数/个 总数/

个密度/

(g·cm−3)边长/

nmCa Si Al Mg Ti Ba Na B O B1 988 475 73 177 147 30 272 62 2776 5000 2.88 41.247 B2 967 452 73 176 146 30 298 92 2766 5000 2.81 41.488 B3 921 449 73 175 145 29 321 122 2765 5000 2.73 41.727 B4 900 426 72 174 145 29 345 152 2755 5000 2.67 41.946 B5 856 423 72 173 144 29 368 181 2755 5000 2.60 42.179 -

[1] WANG W L, XU H, ZHAI B Y, et al. A review of the melt structure and crystallization behavior of non-reactive mold flux for the casting of advanced high-strength steels[J]. Steel Research International, 2022,93(3):2100073. doi: 10.1002/srin.202100073 [2] MILLS K C, FOX A B. The role of mould fluxes in continuous casting-so simple yet so complex[J]. ISIJ International, 2003,43(10):1479-1486. doi: 10.2355/isijinternational.43.1479 [3] HE Y M, HE S P. Analysis of the lubrication and heat transfer control function of mold powder[J]. Continuous Casting, 2021(2):2-6. (何宇明, 何生平. 结晶器保护渣的润滑与传热控制功能剖析[J]. 连铸, 2021(2):2-6.HE Y M, HE S P. Analysis of the lubrication and heat transfer control function of mold powder[J]. Continuous Casting, 2021(2): 2-6. [4] ZHAO J X, ZHAO Z Y, SHANG N, et al. Effect and influence analysis of fluoride in mold powder for continuous casting[J]. Iron and Steel, 2018,53(10):8-15. (赵俊学, 赵忠宇, 尚南, 等. 连铸保护渣中氟化物作用及影响分析[J]. 钢铁, 2018,53(10):8-15.ZHAO J X, ZHAO Z Y, SHANG N, et al. Effect and influence analysis of fluoride in mold powder for continuous casting[J]. Iron and Steel, 2018, 53(10): 8-15. [5] HAN X L, ZHAO K, LIU L, et al. Research progress of metallurgical properties of fluorine-free continuous casting mold fluxes[J]. Materials Reports, 2022,36(11):187-193. (韩秀丽, 赵凯, 刘磊, 等. 无氟连铸保护渣冶金性能的研究进展[J]. 材料导报, 2022,36(11):187-193. doi: 10.11896/cldb.20100199HAN X L, ZHAO K, LIU L, et al. Research progress of metallurgical properties of fluorine-free continuous casting mold fluxes[J]. Materials Reports, 2022, 36(11): 187-193. doi: 10.11896/cldb.20100199 [6] WANG X J, WU B B, ZHU L G, et al. Research status and prospect of fluoride-free mold fluxes[J]. Foundry Technology, 2016,37(9):1914-1918. (王杏娟, 武宾宾, 朱立光, 等. 无氟连铸保护渣的研究现状及展望[J]. 铸造技术, 2016,37(9):1914-1918.WANG X J, WU B B, ZHU L G, et al. Research status and prospect of fluoride-free mold fluxes[J]. Foundry Technology, 2016, 37(9): 1914-1918. [7] WANG X J, QU S, LIU R, et al. Research status and prospect of continuous casting mold flux for high titanium steel[J]. Materials Review, 2021,35(S1):467-472. (王杏娟, 曲硕, 刘然, 等. 高钛钢专用连铸保护渣研究现状及展望[J]. 材料导报, 2021,35(S1):467-472.WANG X J, QU S, LIU R, et al. Research status and prospect of continuous casting mold flux for high titanium steel[J]. Materials Review, 2021, 35(S1): 467-472. [8] LIU G P. Research status and application of titanium-containing fluorine-free mold flux for continuous casting[J]. World Nonferrous Metals, 2022(11):163-165. (刘国鹏. 含钛无氟连铸用保护渣研究现状及应用[J]. 世界有色金属, 2022(11):163-165. doi: 10.3969/j.issn.1002-5065.2022.11.055LIU G P. Research status and application of titanium-containing fluorine-free mold flux for continuous casting[J]. World Nonferrous Metals, 2022(11): 163-165. doi: 10.3969/j.issn.1002-5065.2022.11.055 [9] HAN X L, LIU Y Y, LIU L, et al. Review on research progress of properties and application of titanium-containing continuous casting[J]. Iron and Steel, 2022,57(10):10-18. (韩秀丽, 刘盈盈, 刘磊, 等. 含钛型连铸保护渣性能及应用研究进展[J]. 钢铁, 2022,57(10):10-18.HAN X L, LIU Y Y, LIU L, et al. Review on research progress of properties and application of titanium-containing continuous casting[J]. Iron and Steel, 2022, 57(10): 10-18. [10] SUN L F, LIU C J, JIANG M F. Viscosity characteristics of continuous casting mold flux containing titanium dioxide[J]. Journal of the Chinese Ceramic Society, 2008(3):395-399. (孙丽枫, 刘承军, 姜茂发. 含二氧化钛连铸保护渣的黏性特征[J]. 硅酸盐学报, 2008(3):395-399. doi: 10.3321/j.issn:0454-5648.2008.03.026SUN L F, LIU C J, JIANG M F. Viscosity characteristics of continuous casting mold flux containing titanium dioxide[J]. Journal of the Chinese Ceramic Society, 2008(3): 395-399. doi: 10.3321/j.issn:0454-5648.2008.03.026 [11] WANG W L, CAI D, ZHANG L, et al. Effect of TiO2 and TiN on the viscosity, fluidity, and crystallization of fluorine-free mold fluxes for casting Ti-bearing steels[J]. Steel Research International, 2021,92(2):2000314. doi: 10.1002/srin.202000314 [12] WANG Z, SHU Q, CHOU K. Viscosity of fluoride-free mold fluxes containing B2O3 and TiO2[J]. Steel Research International, 2013,84(8):766-776. doi: 10.1002/srin.201200256 [13] XIN Q, WEN G, PING T. Viscosity and viscosity estimate model of fluoride-free and titanium-bearing mold fluxes[J]. Journal of Iron and Steel Research International, 2010,17(6):6-10. doi: 10.1016/S1006-706X(10)60105-7 [14] SHU Q, WANG Z, KLUG J L, et al. Effects of B2O3 and TiO2 on crystallization behavior of slags in Al2O3-CaO-MgO-Na2O-SiO2 system[J]. Steel Research International, 2013,84(11):1138-1145. doi: 10.1002/srin.201200341 [15] WANG Z, SHU Q, CHOU K. Study on structure characteristics of B2O3 and TiO2-bearing F-free mold flux by Roman spectroscopy[J]. High Temperature Materials and Processes, 2013,32(3):265-273. doi: 10.1515/htmp-2012-0137 [16] WANG X J, TIAN K, FAN Y P, et al. Effect of TiO2 on the properties of continuous casting ternary fluorine-free CaO-SiO2-TiO2 slag system[J]. Materials Review, 2018,32(12):2100-2104. (王杏娟, 田阔, 樊亚鹏, 等. TiO2对连铸三元无氟CaO-SiO2-TiO2渣系特性的影响[J]. 材料导报, 2018,32(12):2100-2104. doi: 10.11896/j.issn.1005-023X.2018.12.030WANG X J, TIAN K, FAN Y P, et al. Effect of TiO2 on the properties of continuous casting ternary fluorine-free CaO-SiO2-TiO2 slag system[J]. Materials Review, 2018, 32(12): 2100-2104. doi: 10.11896/j.issn.1005-023X.2018.12.030 [17] BOTHMA J A, PISTORIUS P C. Heat transfer through mould flux with titanium oxide additions[J]. Ironmaking and Steelmaking, 2007,34(6):513-520. doi: 10.1179/174328107X203912 [18] WEN G H, TANG P, LI S C, et al. Study of fluoride-free mold powder for slab continuous casting[J]. Iron and Steel, 2005,40(7):29-32. (文光华, 唐萍, 李书成, 等. 无氟板坯连铸结晶器保护渣的研究[J]. 钢铁, 2005,40(7):29-32. doi: 10.3321/j.issn:0449-749X.2005.07.007WEN G H, TANG P, LI S C, et al. Study of fluoride-free mold powder for slab continuous casting[J]. Iron and Steel, 2005, 40(7): 29-32. doi: 10.3321/j.issn:0449-749X.2005.07.007 [19] MIAO S T, WEN G H, TANG P, et al. Study on crystallographic ore phase of mold slag for fluorine-free continuous casting[J]. Journal of Iron and Steel Research, 2006,18(10):20-22. (苗胜田, 文光华, 唐萍, 等. 无氟连铸结晶器保护渣的结晶性能[J]. 钢铁研究学报, 2006,18(10):20-22. doi: 10.3321/j.issn:1001-0963.2006.10.005MIAO S T, WEN G H, TANG P, et al. Study on crystallographic ore phase of mold slag for fluorine-free continuous casting[J]. Journal of Iron and Steel Research, 2006, 18(10): 20-22. doi: 10.3321/j.issn:1001-0963.2006.10.005 [20] ZHANG Z T, WEN G H, ZHANG Y Y. Crystallization behavior of F-free mold fluxes[J]. International Journal of Minerals, Metallurgy, and Materials, 2011,18(2):150-158. doi: 10.1007/s12613-011-0415-z [21] HAN W D, QIU S T, ZHANG X Z, et al. Heat transfer and mineral structure of fluorine-free mold slag film on molds[J]. Journal of Iron and Steel Research, 2007(3):14-16. (韩文殿, 仇圣桃, 张兴中, 等. 结晶器无氟保护渣渣膜的传热性和矿物结构[J]. 钢铁研究学报, 2007(3):14-16. doi: 10.3321/j.issn:1001-0963.2007.03.004HAN W D, QIU S T, ZHANG X Z, et al. Heat transfer and mineral structure of fluorine-free mold slag film on molds[J]. Journal of Iron and Steel Research, 2007(3): 14-16. doi: 10.3321/j.issn:1001-0963.2007.03.004 [22] HAN W D, QIU S T, GAN Y, et al. Heat transfer research and production practice of TiO2-containing fluorine-free mold powder[J]. Journal of Iron and Steel Research, 2006(1):9-10. (韩文殿, 仇圣桃, 干勇, 等. 含TiO2无氟保护渣的传热研究及生产实践[J]. 钢铁研究学报, 2006(1):9-10. doi: 10.3321/j.issn:1001-0963.2006.01.003HAN W D, QIU S T, GAN Y, et al. Heat transfer research and production practice of TiO2-containing fluorine-free mold powder[J]. Journal of Iron and Steel Research, 2006(1): 9-10. doi: 10.3321/j.issn:1001-0963.2006.01.003 [23] FAN X Y, ZHANG J L, JIAO K X, et al. Influence of B2O3 on viscosity and structure of low MgO slag containing titanium[J]. Metallurgical Research & Technology, 2018,115(3):313-319. [24] ZHOU H M, CHENG M H, LI J. Effect of Na2O on the glass-ceramics structure and properties of MgO-Al2O3-B2O3-SiO2 system[J]. China Ceramics, 2019,55(2):44-49. (周宏明, 程名辉, 李荐. Na2O对MgO-Al2O3-B2O3-SiO2体系微晶玻璃结构和性能的影响[J]. 中国陶瓷, 2019,55(2):44-49.ZHOU H M, CHENG M H, LI J. Effect of Na2O on the glass-ceramics structure and properties of MgO-Al2O3-B2O3-SiO2 system[J]. China Ceramics, 2019, 55(2): 44-49. [25] SU D Y, YOU J L, WANG J, et al. Raman spectra of B2O3-Na2O-CaO-SiO2 glasses structure[J]. Spectroscopy and Spectral Analysis, 2023,43(S1):249-250. (苏东艳, 尤静林, 王建, 等. B2O3-Na2O-CaO-SiO2玻璃结构的拉曼光谱研究[J]. 光谱学与光谱分析, 2023,43(S1):249-250.SU D Y, YOU J L, WANG J, et al. Raman spectra of B2O3-Na2O-CaO-SiO2 glasses structure[J]. Spectroscopy and Spectral Analysis, 2023, 43(S1): 249-250. -

下载:

下载: