The influence of Al2O3 content on the microstructure and properties of low basicity refining slag

-

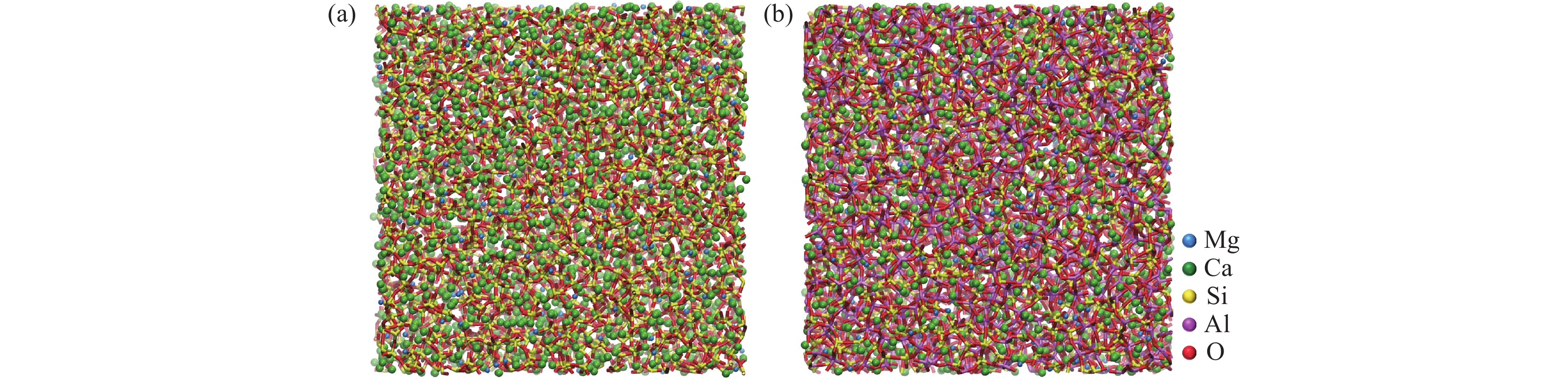

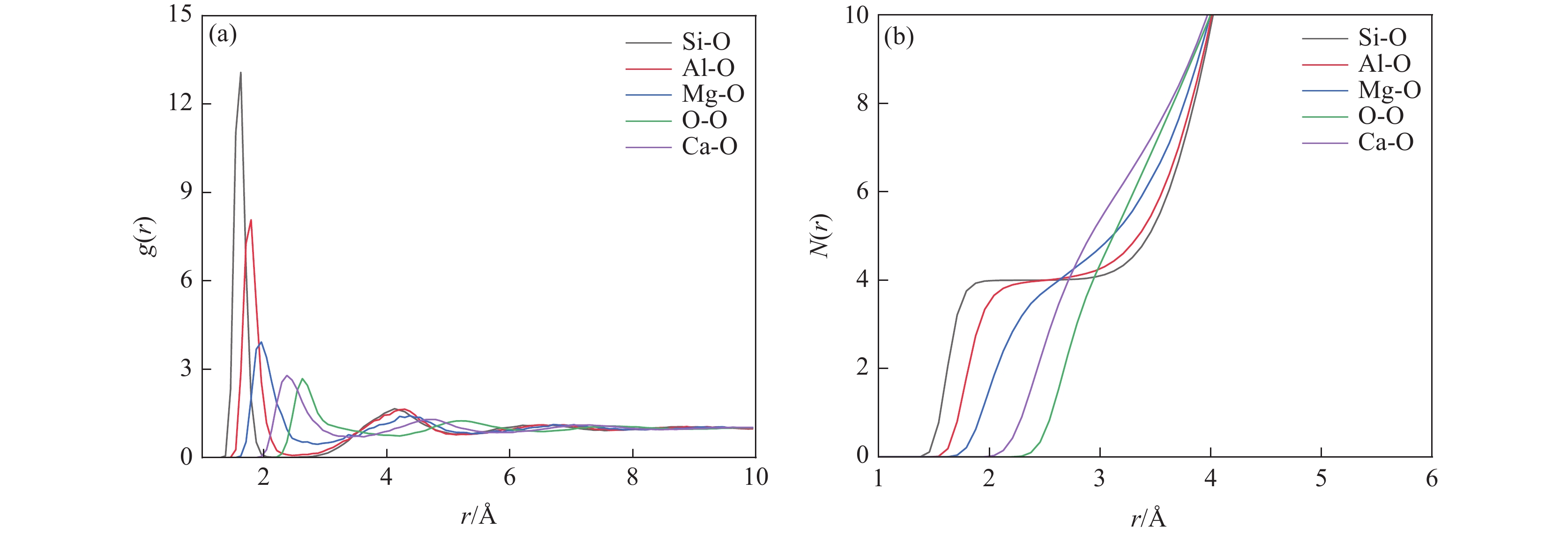

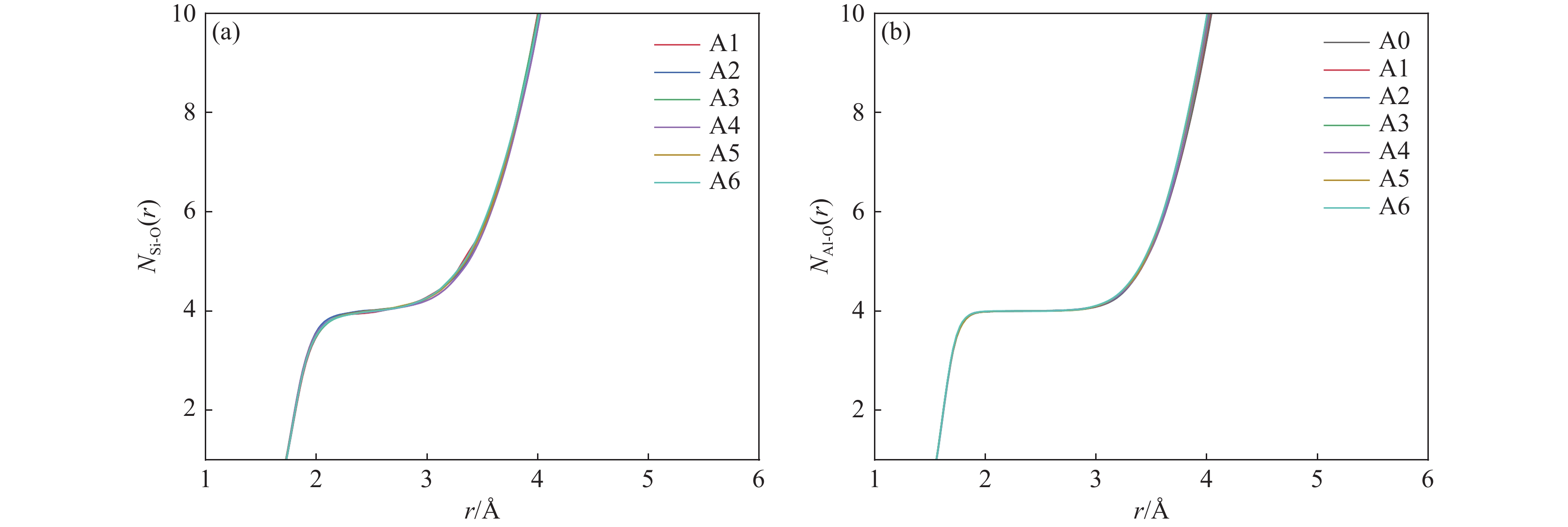

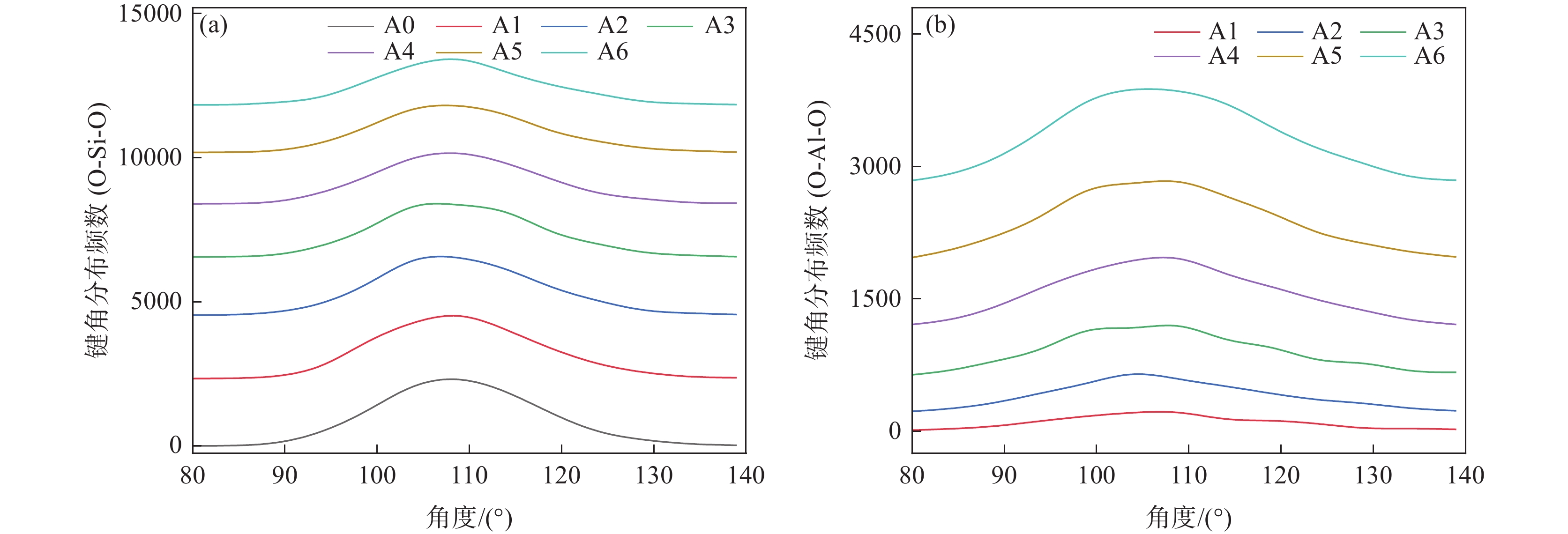

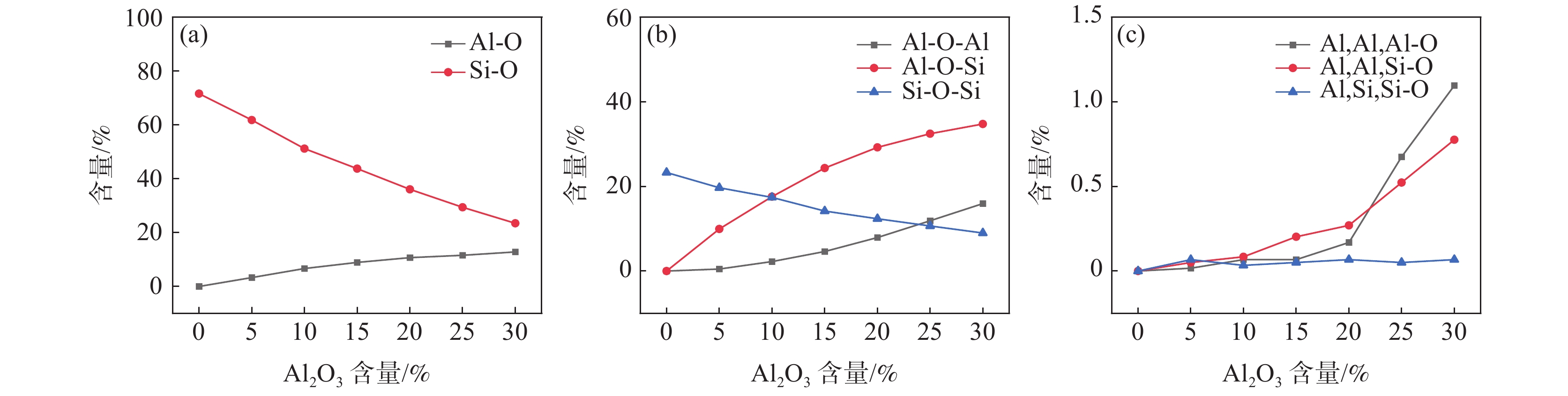

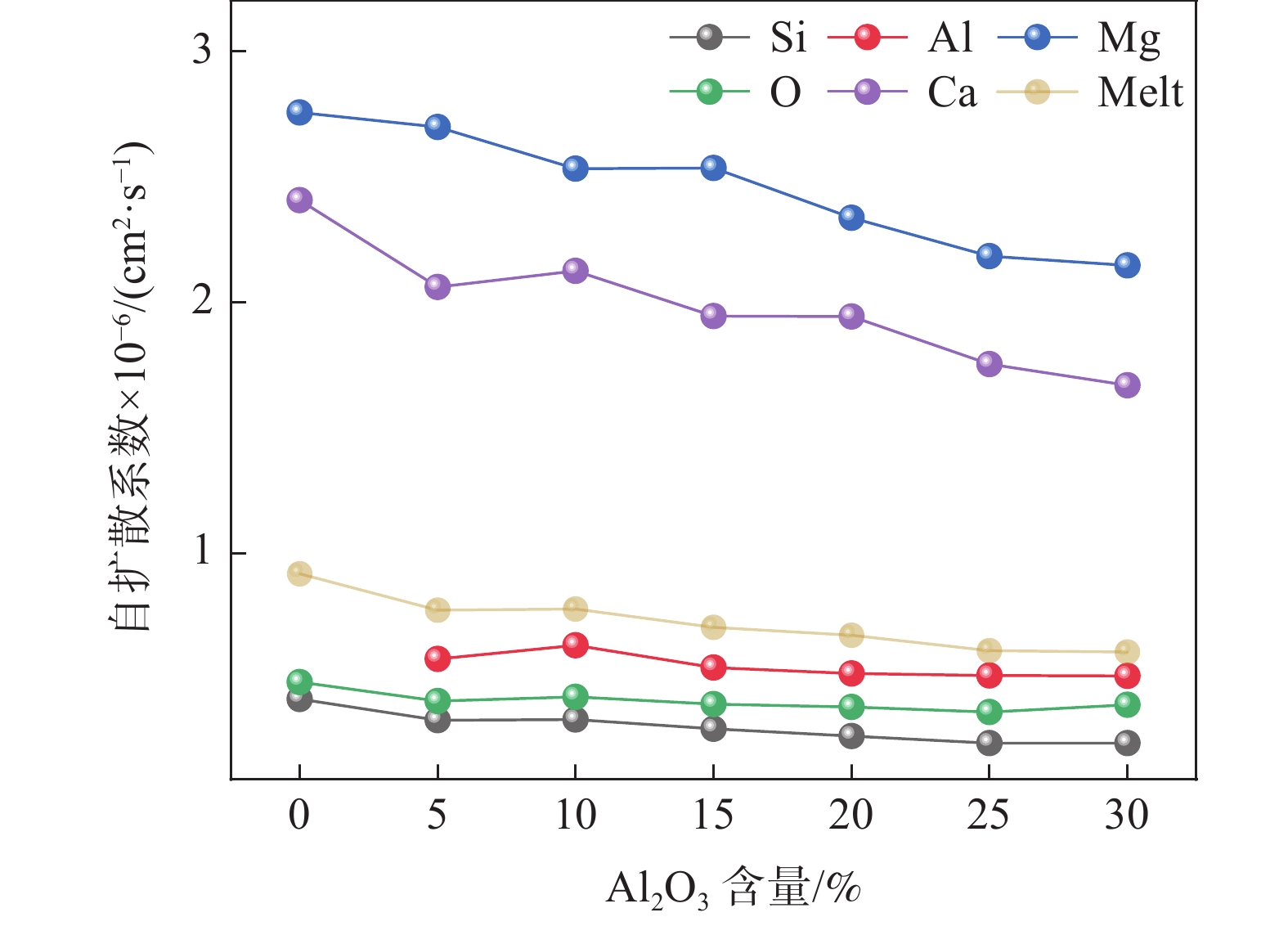

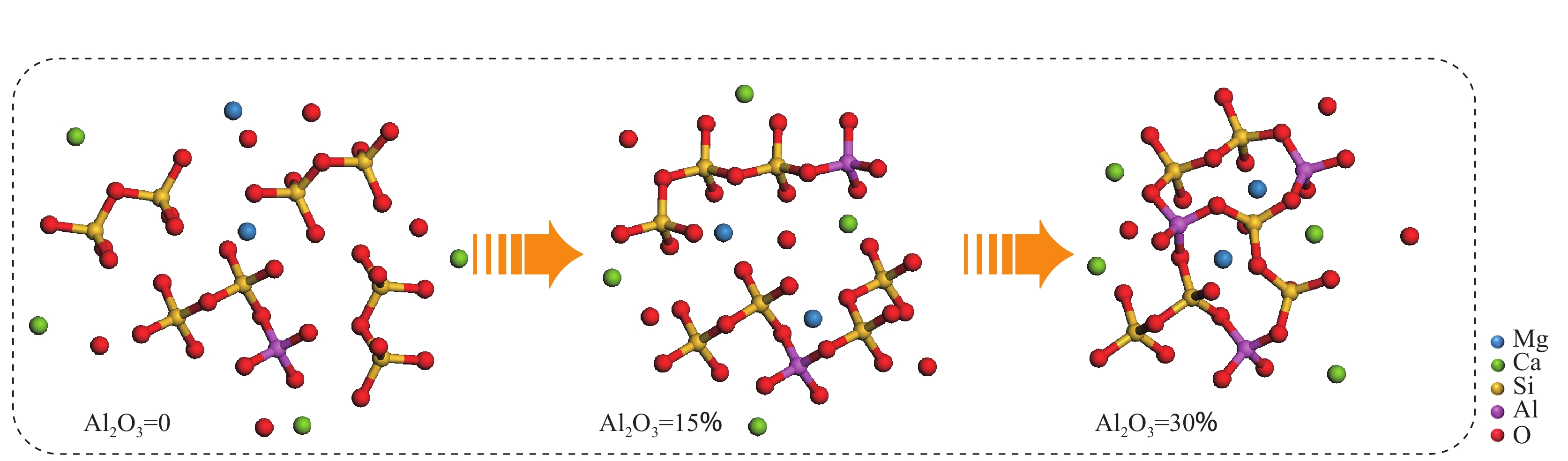

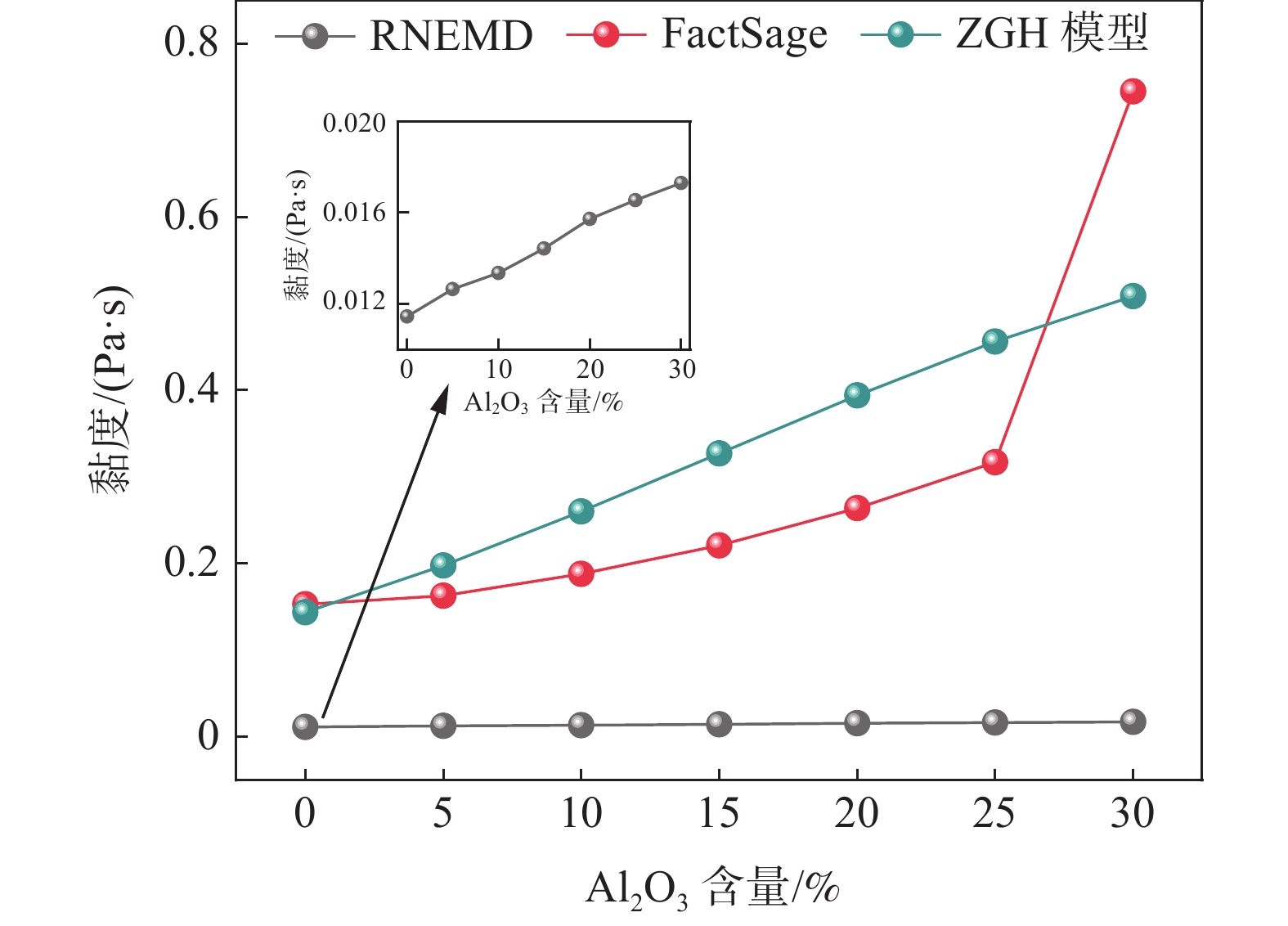

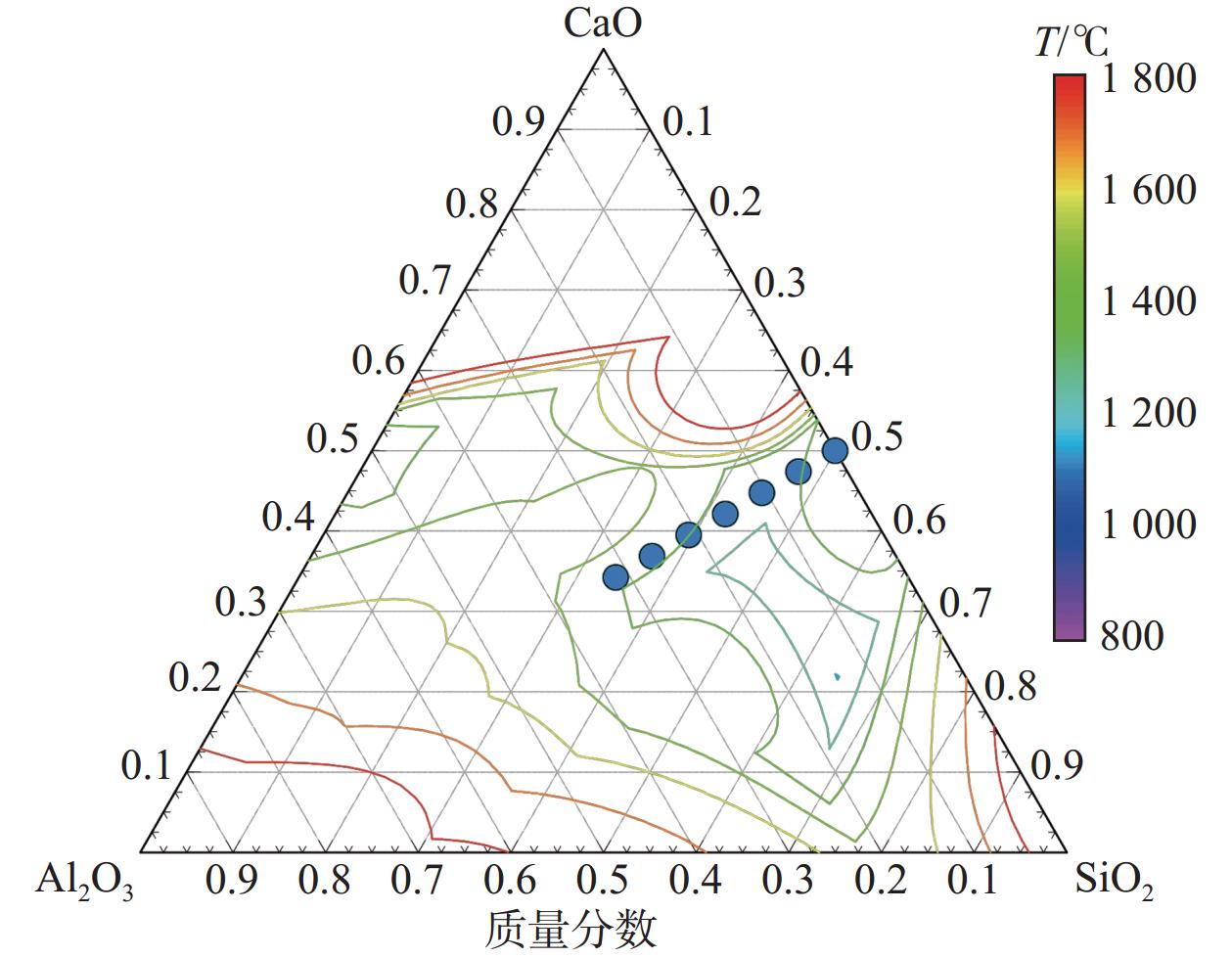

摘要: 探讨了低碱度精炼渣系CaO-MgO-Al2O3-SiO2中Al2O3含量对其微观结构和性能的影响。采用分子动力学模拟方法,系统地分析了不同Al2O3含量对低碱度精炼渣系的微观结构与性质的影响。结果表明,Al2O3含量的增加对体系的径向分布函数、配位数和键角等无明显影响,但显著降低了体系的FO和NBO含量,强化了体系的网络结构。此外,Al2O3含量的增加使渣系中元素的扩散能力降低,扩散能力的顺序为Mg2+>Ca2+>Al3+>O2−>Si4+。随着Al2O3质量分数的增加,渣系黏度逐渐增大,这与扩散系数的变化趋势相反。该结果建立了低碱度渣系结构与性能之间的联系,为非铝脱氧工艺采用适合的低碱度渣提供了理论支撑。Abstract: The effect of Al2O3 content on the microstructure and properties of low basicity refining slag system CaO-MgO-Al2O3-SiO2 was investigated. The effect of different Al2O3 contents on the microstructure and properties of the low basicity refining slag system was systematically analyzed using molecular dynamics simulation. The results showed that the increase of Al2O3 content had no significant effect on the radial distribution function, coordination number and bond angle of the system, but significantly reduced the FO and NBO contents of the system and strengthened the network structure of the system. In addition, the increase of Al2O3 content decreased the diffusion ability of elements in the slag system, and the order of diffusion ability was Mg2+>Ca2+>Al3+>O2−>Si4+. The viscosity of the slag system gradually increased with the increase of Al2O3 mass fraction, which was opposite to the trend of the diffusion coefficient. The results establish a link between the structure and performance of low basicity slag systems, and provide theoretical support for the use of suitable low basicity slags for non-aluminum deoxidation processes.

-

Key words:

- refining slag /

- low basicity /

- Al2O3 content /

- molecular dynamics simulation /

- viscosity /

- diffusion coefficient

-

表 2 原子有效电荷和Buckingham势函数参数[14]

Table 2. Atomic effective charge and Buckingham potential function parameters

元素 原子有效电荷/e Buckingham势函数参数 Aij /eV ρij /Å Cij /eV·Å6 Si +2.4 13702.91 0.193817 54.681 Al +1.8 12201.42 0.195628 31.997 Ca +1.2 7747.183 0.252623 93.109 Mg +1.2 7063.4907 0.210901 19.210 O −1.2 2029.22 0.343645 192.58 注:1 Å=0.1 nm 表 1 渣系成分

Table 1. Slag compositions

% 模型 CaO Al2O3 SiO2 MgO A0 47.5 0 47.5 5 A1 45 5 45 5 A2 42.5 10 42.5 5 A3 40 15 40 5 A4 37.5 20 37.5 5 A5 35 25 35 5 A6 32.5 30 32.5 5 -

[1] WANG Z L, BAO Y P, GU C, et al. Control of Ds inclusions in GCr15 bearing steel based on non-aluminum deoxidation process[J]. Special Steel, 2022,43(6):8-12. (王仲亮, 包燕平, 顾超, 等. 基于非铝脱氧工艺的GCr15轴承钢中Ds类夹杂物控制[J]. 特殊钢, 2022,43(6):8-12.WANG Z L, BAO Y P, GU C, et al. Control of Ds inclusions in GCr15 bearing steel based on non-aluminum deoxidation process[J]. Special Steel, 2022, 43(6): 8-12. [2] XIAO W, BAO Y P, WANG M, et al. Inclusions evolution and control of non-aluminum deoxidized GCr15 bearing steel[J]. Iron and Steel, 2021,56(1):37-42. (肖微, 包燕平, 王敏, 等. 非铝脱氧GCr15轴承钢的夹杂物演变和控制[J]. 钢铁, 2021,56(1):37-42.XIAO W, BAO Y P, WANG M, et al. Inclusions evolution and control of non-aluminum deoxidized GCr15 bearing steel[J]. Iron and Steel, 2021, 56(1): 37-42. [3] GU C, WANG Z L, XIAO W, et al. Research status and progress on cleanliness of high-fatigue-life bearing steels[J]. Chinese Journal of Engineering, 2021,43(3):299-310. (顾超, 王仲亮, 肖微, 等. 高疲劳寿命轴承钢洁净度现状及研究进展[J]. 工程科学学报, 2021,43(3):299-310.GU C, WANG Z L, XIAO W, et al. Research status and progress on cleanliness of high-fatigue-life bearing steels[J]. Chinese Journal of Engineering, 2021, 43(3): 299-310. [4] WANG Z L, BAO Y P, GU C, et al. Key metallurgical technology for high-quality bearing steel production based on the nonaluminum deoxidation process [J]. Chinese Journal of Engineering, 2022; 44(9): 1607-1619. (王仲亮, 包燕平, 顾超, 等. 基于非铝脱氧工艺的高品质轴承钢关键冶金技术研究[J]. 工程科学学报. 2022; 44(9): 1607-1619.WANG Z L, BAO Y P, GU C, et al. Key metallurgical technology for high-quality bearing steel production based on the nonaluminum deoxidation process [J]. Chinese Journal of Engineering, 2022; 44(9): 1607-1619. [5] LIU C W, ZHANG H, CAO L, et al. Effect of VD low basicity slag on inclusions of GCr15 bearing steel[J]. Special Steel, 2023,44(6):78-82. (刘春伟, 张昊, 曹磊, 等. VD低碱度渣对GCr15轴承钢夹杂物的影响[J]. 特殊钢, 2023,44(6):78-82.LIU C W, ZHANG H, CAO L, et al. Effect of VD low basicity slag on inclusions of GCr15 bearing steel[J]. Special Steel, 2023, 44(6): 78-82. [6] MA T W, NIU Z G, BAI Z Y, et al. Deoxidation effects of EAF-CAB basic slag treatment on ball-bearing steel[J]. Iron and Steel, 1990(6):24-29. (马廷温, 牛正刚, 白增玉, 等. EAF-CAB-低碱度渣处理轴承钢脱氧效果的研究[J]. 钢铁, 1990(6):24-29.MA T W, NIU Z G, BAI Z Y, et al. Deoxidation effects of EAF-CAB basic slag treatment on ball-bearing steel[J]. Iron and Steel, 1990(6): 24-29. [7] XU T. Research on inclusion control of bearing steel low-basicity slag refining process [D]. Anshan: University of Science and Technology Liaoning, 2021. (许涛. 轴承钢低碱度渣精炼过程夹杂物控制研究 [D]. 鞍山: 辽宁科技大学 2021.XU T. Research on inclusion control of bearing steel low-basicity slag refining process [D]. Anshan: University of Science and Technology Liaoning, 2021. [8] CAO Y R, XU B, WANG Z Z, et al. Molecular dynamics simulation of effect of Al2O3 on structure and viscosity of molten blast furnace slag[J]. Sintering and Pelletizing, 2022,47(6):57-65. (曹亚然, 徐博, 王铮铮, 等. Al2O3对熔融态高炉渣结构与黏度影响的分子动力学模拟[J]. 烧结球团, 2022,47(6):57-65.CAO Y R, XU B, WANG Z Z, et al. Molecular dynamics simulation of effect of Al2O3 on structure and viscosity of molten blast furnace slag[J]. Sintering and Pelletizing, 2022, 47(6): 57-65. [9] HU J, YAO M C, ZHONG T, et al. Effect of B2O3 on Microstructure and transport properties of melt titanium-containing blast furnace slag[J]. Nonferrous Metals, 2024(1):41-53. (胡金, 姚明灿, 钟通, 等. B2O3对含钛高炉渣熔体微观结构与输运性质的影响[J]. 有色金属(冶炼部分), 2024(1):41-53.HU J, YAO M C, ZHONG T, et al. Effect of B2O3 on Microstructure and transport properties of melt titanium-containing blast furnace slag[J]. Nonferrous Metals, 2024(1): 41-53. [10] SUN T. Microstructure and viscosity characteristics analysis of red mud based microcrystalline glass[D]. Jinan: Shandong Jianzhu University, 2023. (孙涛. 赤泥基微晶玻璃的微观结构及其粘度特性分析[D]. 济南: 山东建筑大学, 2023.SUN T. Microstructure and viscosity characteristics analysis of red mud based microcrystalline glass[D]. Jinan: Shandong Jianzhu University, 2023. [11] WU T, WANG QIAN, YU C F, et al. Structural and viscosity properties of CaO-SiO2-Al2O3-FeO slags based on molecular dynamic simulation[J]. J Non-Cryst Solids, 2016,450:23-31. doi: 10.1016/j.jnoncrysol.2016.07.024 [12] GU C, LÜ Z Y, BAO Y P. Size-dependent dissolution behavior of CaO in the CaO-SiO2-FeO slag system: A molecular dynamics study[J]. J Mol Liq, 2022,367:120488. doi: 10.1016/j.molliq.2022.120488 [13] JIANG C H, LI K J, ZHANG J L, et al. Molecular dynamics simulation on the effect of MgO/Al2O3 ratio on structure and properties of blast furnace slag under different basicity conditions[J]. Metall Mater Trans B, 2019,50:367-375. doi: 10.1007/s11663-018-1450-1 [14] GU G X, LIU X, ZHANG L L, et al. Mixed alkaline earth effect on the structure and elastic modulus of CaO-MgO-Al2O3-SiO2 glasses: A molecular dynamics simulation[J]. J Non-Cryst Solids, 2023,600:122027. doi: 10.1016/j.jnoncrysol.2022.122027 [15] THOMPSON A P, AKTULGA H M, BERGER R, et al. LAMMPS-a flexible simulation tool for particle-based materials modeling at the atomic, meso, and continuum scales[J]. Comput Phys Commun, 2022,271:108171. doi: 10.1016/j.cpc.2021.108171 [16] MÜLLER-PLATHE F. Reversing the perturbation in nonequilibrium molecular dynamics: An easy way to calculate the shear viscosity of fluids[J]. Phys Rev E, 1999,59(5):4894. doi: 10.1103/PhysRevE.59.4894 [17] ZHANG G H, CHOU K, MILLS K. A structurally based viscosity model for oxide melts[J]. Metall Mater Trans B, 2014,45:698-706. -

下载:

下载: