Competitive reduction mechanism of vanadium and titanium of vanadium-titanium magnetite metallized pellets smelted by electric arc furnace

-

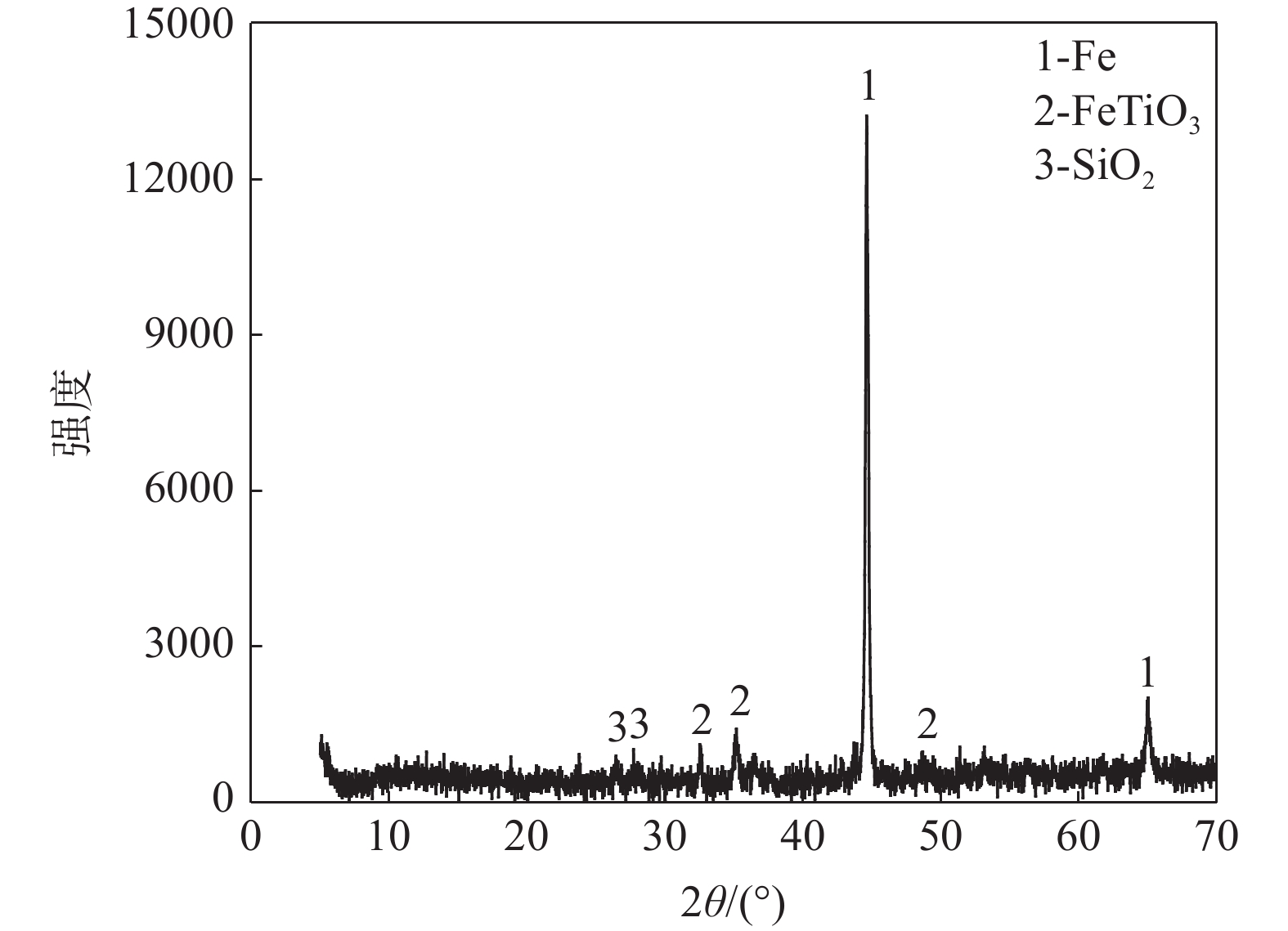

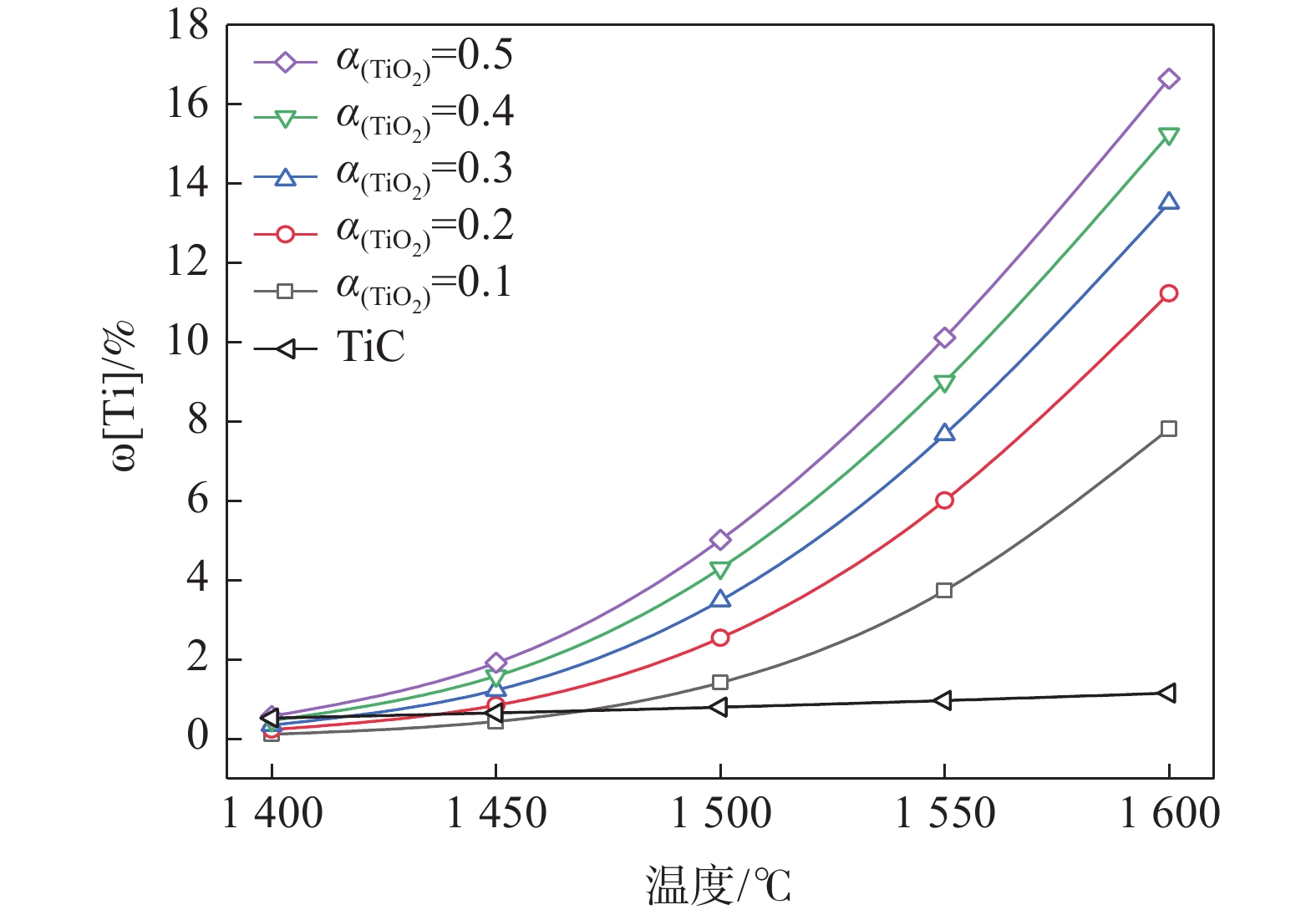

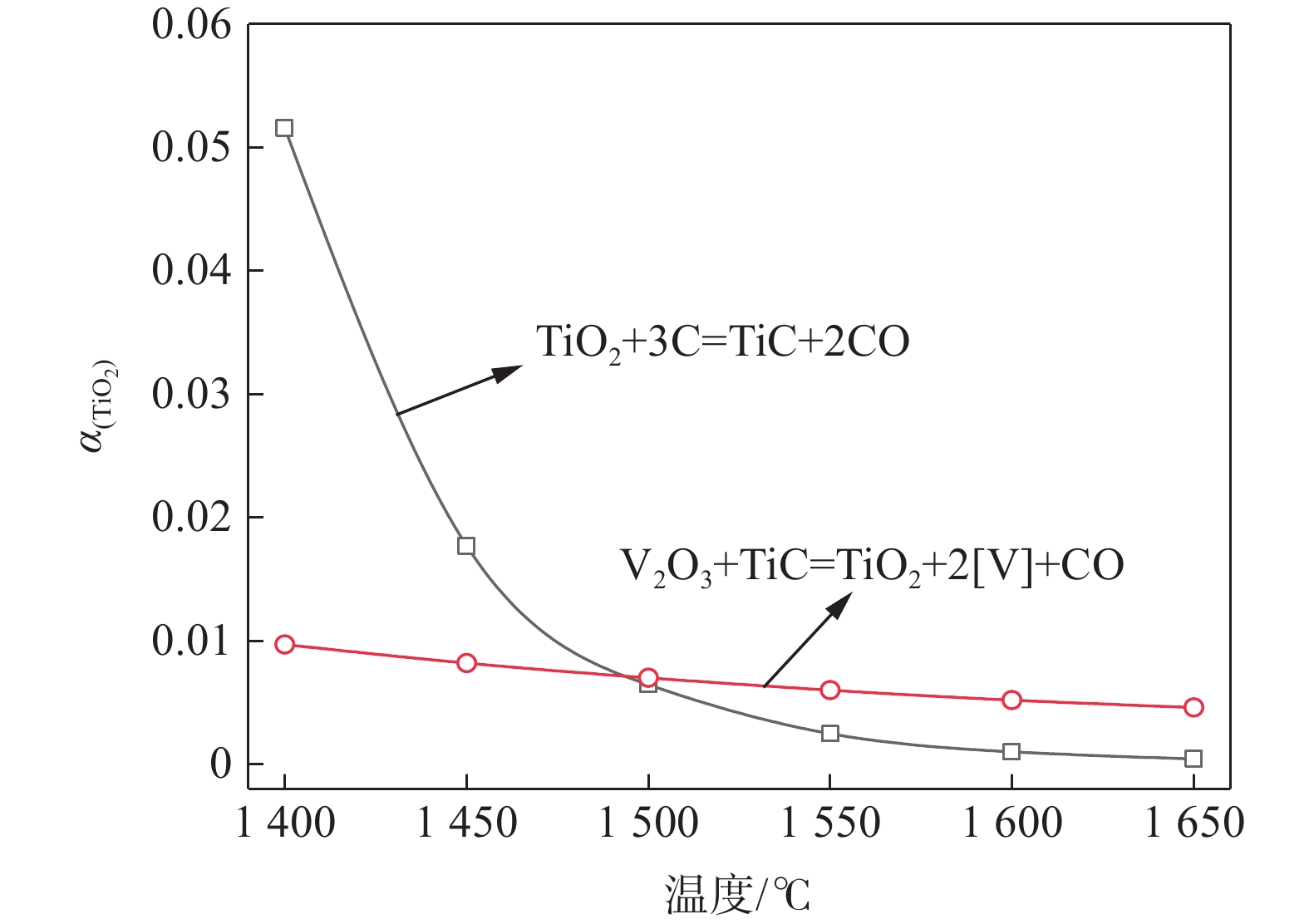

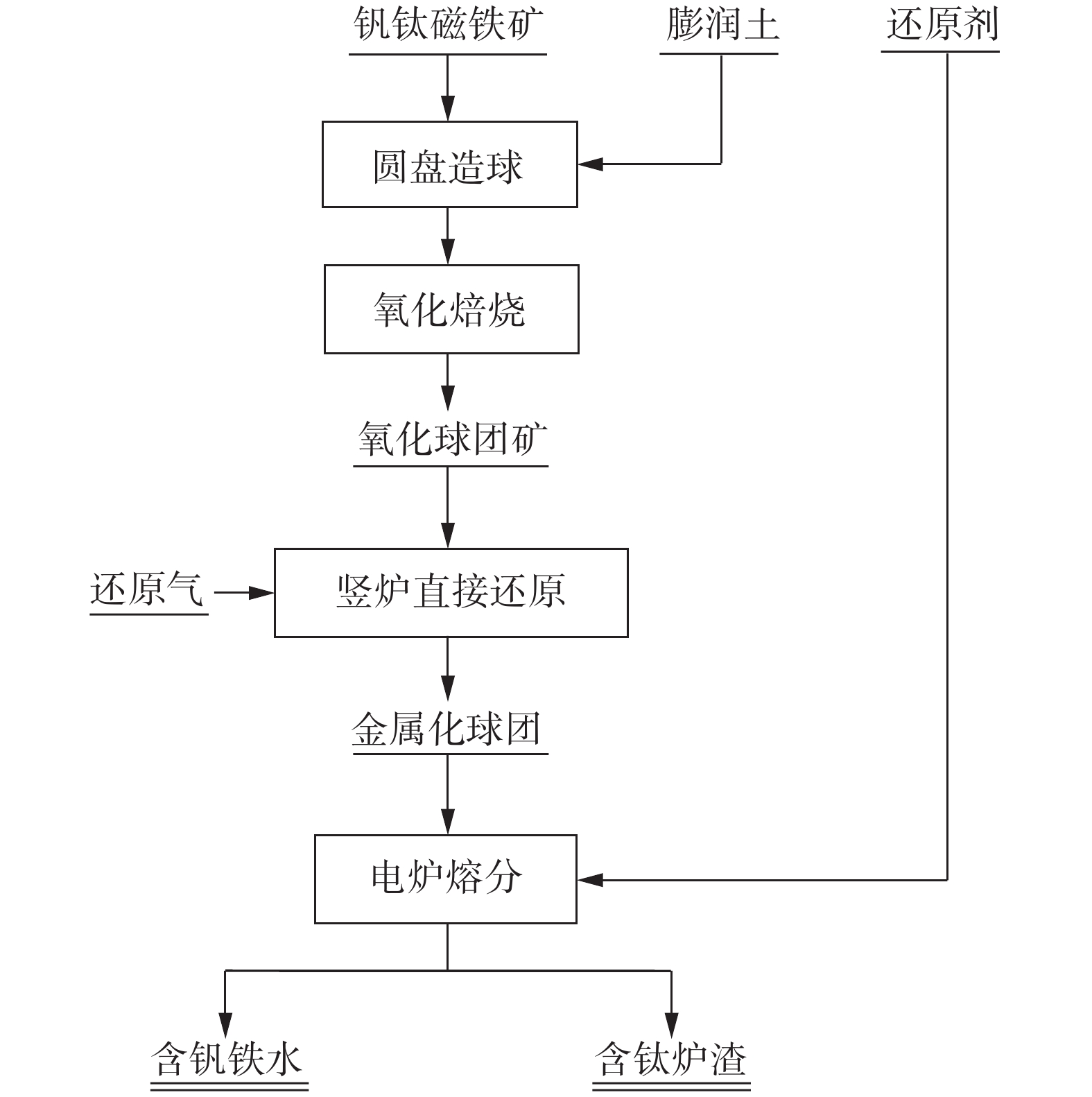

摘要: 钒钛磁铁矿是一种富含铁、钒、钛等多种金属元素的特殊铁矿资源。高炉冶炼钒钛磁铁矿技术已经非常成熟,但需要配加普通铁精矿,造成炉渣中TiO2含量低,难以进行TiO2的资源化回收。为了实现钒钛磁铁矿中铁、钒、钛的综合利用,钒钛磁铁矿气基竖炉直接还原-电炉熔分技术逐渐被认为是回收铁、钒、钛的最有效技术。该技术可以实现全钒钛磁铁矿冶炼,不需要配加熔剂,可以获得高TiO2含量的炉渣,进行炉渣中TiO2的资源化利用。钒钛磁铁矿金属化球团电炉熔分过程中,为了将钒还原进入铁水,需要配加还原剂进行深度还原,熔渣中的钒和钛会竞争还原。笔者进行了熔渣中V2O5和TiO2与碳还原反应的热力学计算,得到了TiO2与C反应生成TiC以及V2O5对TiC反应的抑制关系。计算结果表明,在熔分温度

1500 ℃以上,还原剂碳配加量足够的条件下,钒钛磁铁矿金属化球团电炉熔分过程中不可避免会还原生成TiC,V2O5虽然可以抑制TiC的生成,但由于熔渣中TiO2含量高、活度大,V2O5活度小,V2O5难以抑制TiC的生成。钒钛磁铁矿金属化球团电炉熔分仍然存在炉渣变稠,电炉排渣困难的问题。Abstract: Vanadium titano-magnetite is a special iron ore resource rich in multiple elements such as iron, vanadium, titanium. The blast furnace process for vanadium titano-magnetite is very mature, but it requires the addition of ordinary iron concentrate, resulting low TiO2 content in the slag, making it difficult to recover TiO2 from slag. To achieve comprehensive utilization of vanadium titano-magnetite, the process of direct reduction in gas-based shaft furnace and smelting in electric arc furnace is currently considered as the most effective technology to recover iron, vanadium and titanium. This technology can smelt vanadium titano-magnetite entirely without the need for flux, producing slag with high TiO2 content. During the electric arc furnace melting of vanadium titano-magnetite metalized pellets, reducing agents need be added to deeply reduce vanadium into the molten iron, and vanadium and titanium in the slag will compete for reduction. In this paper, the thermodynamics of reduction reaction of V2O5 and TiO2 with carbon in slag was calculated. The reaction process of TiO2 with C to form TiC, and the inhibition relationship of V2O5 on the TiC formation were analyzed. The results show that TiC is inevitable when the melting temperature is above1500 ℃ and the reducing agent of carbon is sufficient. It is difficult for V2O5 to inhibit the formation of TiC because of the high TiO2 activity and low V2O5 activity in slag. The problem of slag thickening and difficult slag discharge in electric arc furnace is still existed in smelting of vanadium-titanium magnetite metallized pellets. -

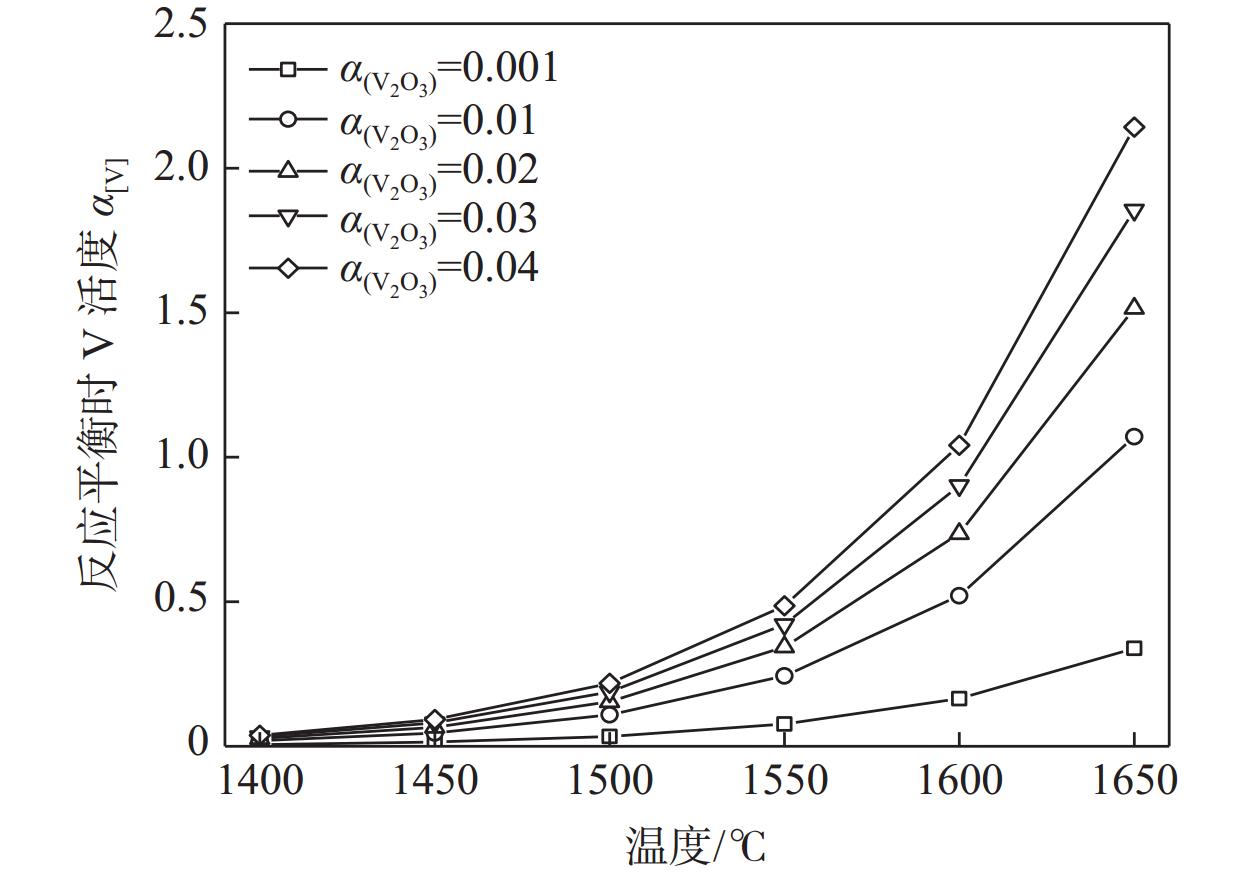

图 3 不同温度条件下V的平衡活度$ {\bf{\alpha }}_{[{\rm{V}}]} $与熔渣中V2O3活度${\bf{\alpha}}_{\mathrm{\left(V_2O_3\right)}} $的关系

Figure 3. The relationship between the equilibrium activity $ {{\bf{\alpha}}}_{[{\rm{V}}]} $ and the activity ${\boldsymbol{\alpha}}_{\mathrm{\left(V_2O_3\right)}} $ in slag at different temperatures

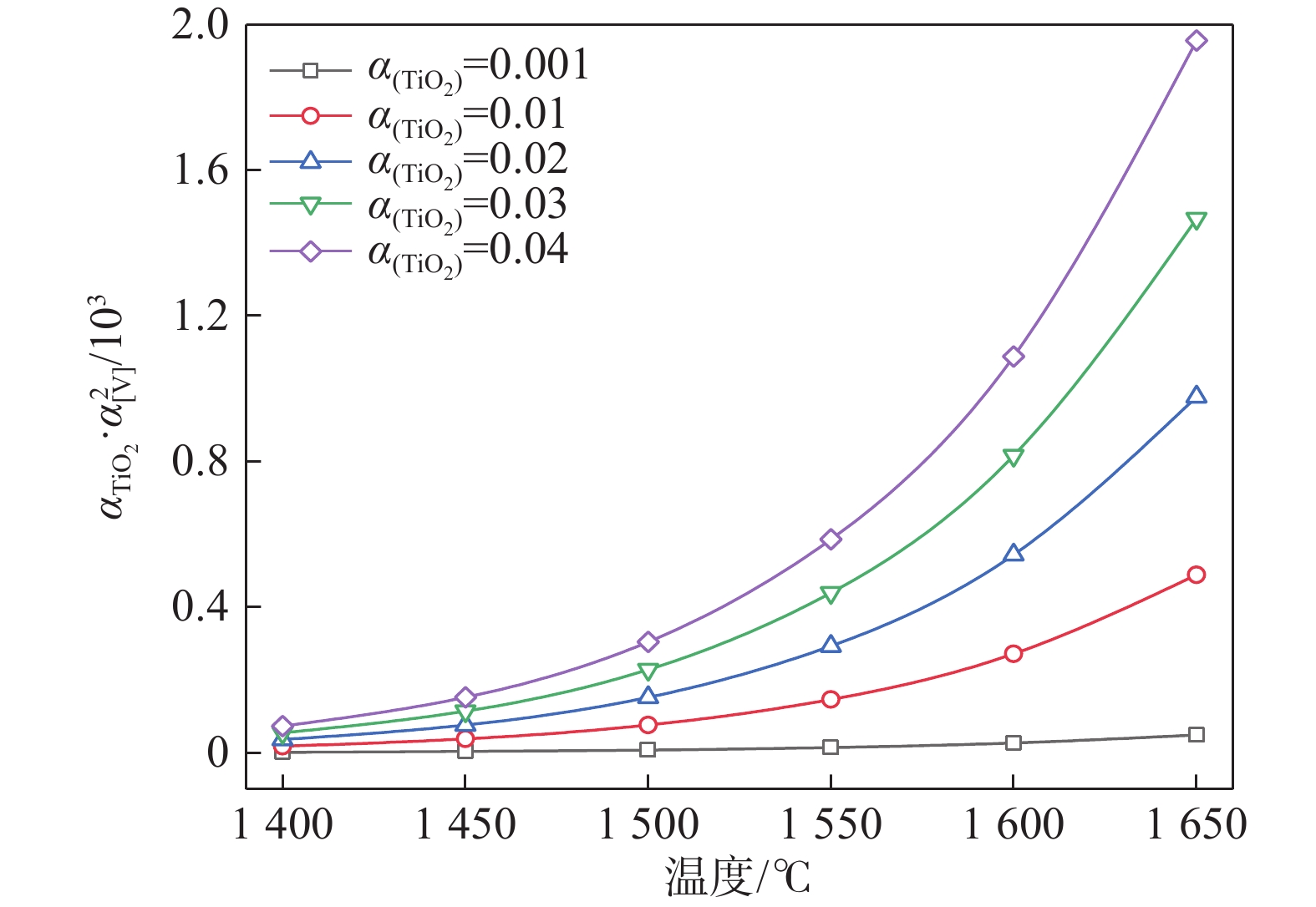

图 5 不同温度条件下$ {\alpha }_{\left(\mathrm{T}\mathrm{i}{\mathrm{O}}_{2}\right)} \cdot {{\alpha }_{\left[\mathrm{V}\right]}}^{2} $与熔渣中V2O3活度$ {\alpha }_{\left({\mathrm{V}}_{2}{\mathrm{O}}_{3}\right)} $的关系

Figure 5. The relationship between $ {{\alpha}_{\left(\mathrm{TiO_2}\right)}\cdot\mathrm{\alpha}_{\left[\mathrm{V}\right]}}^{2} $ and $ \mathrm{\alpha}_{\left(\mathrm{V_2O_3}\right)} $ in slag at different temperatures

表 1 钒钛磁铁矿金属化球团成分

Table 1. Chemical composition of vanadium titano-magnetite metallized pellets

% TFe MFe FeO CaO MgO Al2O3 SiO2 TiO2 V2O5 Cr2O3 MnO C S 67.66 57.54 12.76 0.22 1.51 4.25 4.16 15.94 2.35 0.71 0.48 0.082 0.016 -

[1] CHEN R F, LONG T, CHEN Q S, et al. New energy-storage metal vanadium resources: demand prediction and supply analysis[J]. Strategic Study of CAE, 2024,26(3):74-85. (陈仁凤, 龙涛, 陈其慎, 等. 新型储能金属钒资源需求预测与供应分析[J]. 中国工程科学, 2024,26(3):74-85. doi: 10.15302/J-SSCAE-2024.03.010CHEN R F, LONG T, CHEN Q S, et al. New energy-storage metal vanadium resources: demand prediction and supply analysis[J]. Strategic Study of CAE, 2024, 26(3): 74-85. doi: 10.15302/J-SSCAE-2024.03.010 [2] AN Z S, CHEN Y, ZHAO W, et al. 2023 China titanium industry development report[J]. Iron Steel Vanadium Titanium, 2024,45(3):1-8. (安仲生, 陈岩, 赵巍, 等. 2023年中国钛工业发展报告[J]. 钢铁钒钛, 2024,45(3):1-8.AN Z S, CHEN Y, ZHAO W, et al. 2023 China titanium industry development report[J]. Iron Steel Vanadium Titanium, 2024, 45(3): 1-8. [3] HUANG Y, CHU M S, YAN R J. Application of optimization technology for vanadium titanate smelting index in 1750 m3 blast furnace of Pangang group[J]. China Metallurgy, 2024,34(2):96-107. (黄云, 储满生, 闫瑞军. 攀钢1750 m3高炉冶炼钒钛矿指标优化技术应用[J]. 中国冶金, 2024,34(2):96-107.HUANG Y, CHU M S, YAN R J. Application of optimization technology for vanadium titanate smelting index in 1750 m3 blast furnace of Pangang group[J]. China Metallurgy, 2024, 34(2): 96-107. [4] LA X S, ZHANG Z F, CHEN S J, et al. Forming reason of hearth sediments in vanadium titanium magnetite BF smelting process[J]. Journal of Iron and Steel Research, 2015,27(7):20-25. (喇校帅, 张振峰, 陈树军, 等. 高炉冶炼钒钛矿过程中炉缸沉积物的形成原因[J]. 钢铁研究学报, 2015,27(7):20-25.LA X S, ZHANG Z F, CHEN S J, et al. Forming reason of hearth sediments in vanadium titanium magnetite BF smelting process[J]. Journal of Iron and Steel Research, 2015, 27(7): 20-25. [5] PANG Z D, LÜ X W, YAN Z M, et al. Viscosity and free running temperature of ultra-high TiO2 bearing blast furnace slag[J]. Iron and Steel, 2020,55(8):181-186. (庞正德, 吕学伟, 严志明, 等. 超高TiO2高炉渣黏度及熔化性温度[J]. 钢铁, 2020,55(8):181-186.PANG Z D, LÜ X W, YAN Z M, et al. Viscosity and free running temperature of ultra-high TiO2 bearing blast furnace slag[J]. Iron and Steel, 2020, 55(8): 181-186. [6] XIE H E, YU W Z, YOU Z X, et al. The effect of titanium carbonitride on the viscosity of high–titanium–type blast furnace slag[J]. Metals, 2019, 9: 395. [7] LÜ Q, TANG Q, SUN Y Q, et al. Relationship between blast furnace slag properties of vanadium titano-magnetite and reduction of vanadium oxide[J]. Iron Steel Vanadium Titanium, 2016,37(6):1-4. (吕庆, 唐琦, 孙艳芹, 等. 钒钛磁铁矿高炉冶炼的炉渣性质与钒氧化物还原关系[J]. 钢铁钒钛, 2016,37(6):1-4.LÜ Q, TANG Q, SUN Y Q, et al. Relationship between blast furnace slag properties of vanadium titano-magnetite and reduction of vanadium oxide[J]. Iron Steel Vanadium Titanium, 2016, 37(6): 1-4. [8] BAI C G, LÜ X W, QIU G B, et al. Research process on high efficiency metallurgy and clean extraction of vanadium-titanium magnetite ore in Panxi area[J]. The Chinese Journal of Process Engineering, 2022,22(10):1390-1399. (白晨光, 吕学伟, 邱贵宝, 等. 攀西钒钛磁铁矿资源高效冶金及清洁提取研究进展[J]. 过程工程学报, 2022,22(10):1390-1399. doi: 10.12034/j.issn.1009-606X.222302BAI C G, LÜ X W, QIU G B, et al. Research process on high efficiency metallurgy and clean extraction of vanadium-titanium magnetite ore in Panxi area[J]. The Chinese Journal of Process Engineering, 2022, 22(10): 1390-1399. doi: 10.12034/j.issn.1009-606X.222302 [9] ZHANG S S, HU P, RAO J T, et al. Comprehensive utilization status of vanadium-titanium magnetite and feasibility analysis of HIsmelt smelting[J]. Journal of Central South University (Science and Technology), 2021,52(9):3085-3092. (张树石, 胡鹏, 饶家庭, 等. 钒钛磁铁矿综合利用技术现状及HIsmelt冶炼可行性分析[J]. 中南大学学报(自然科学版), 2021,52(9):3085-3092.ZHANG S S, HU P, RAO J T, et al. Comprehensive utilization status of vanadium-titanium magnetite and feasibility analysis of HIsmelt smelting[J]. Journal of Central South University (Science and Technology), 2021, 52(9): 3085-3092. [10] GAO J J, HONG L K, XU H J, et al. Smelting-separation for metallized pellets of vanadium-titanium magnetite and slag phase analysis[J]. Nonferrous Metals (Extractive Metallurgy), 2018(3):14-18. (高建军, 洪陆阔, 徐洪军, 等. 钒钛磁铁矿金属化球团还原熔分试验及渣相分析[J]. 有色金属(冶炼部分), 2018(3):14-18.GAO J J, HONG L K, XU H J, et al. Smelting-separation for metallized pellets of vanadium-titanium magnetite and slag phase analysis[J]. Nonferrous Metals (Extractive Metallurgy), 2018(3): 14-18. [11] ZHANG Y H, LONG H M, CHUN T J, et al. Recovery of iron from vanadium-bearing titanomagnetite by deep direct reduction and melting process[J]. Journal of Iron and Steel Research, 2016,28(9):17-23. (张艳华, 龙红明, 春铁军, 等. 钒钛磁铁矿深度直接还原熔分提铁[J]. 钢铁研究学报, 2016,28(9):17-23.ZHANG Y H, LONG H M, CHUN T J, et al. Recovery of iron from vanadium-bearing titanomagnetite by deep direct reduction and melting process[J]. Journal of Iron and Steel Research, 2016, 28(9): 17-23. [12] GAO J J, HONG L K, ZHANG J, et al. Experiment study of vanadium titano-magnetite by full oxygen bath smelting process[J]. Iron Steel Vanadium Titanium, 2018,39(2):8-13. (高建军, 洪陆阔, 张俊, 等. 钒钛磁铁矿全氧熔池熔炼试验研究[J]. 钢铁钒钛, 2018,39(2):8-13. doi: 10.7513/j.issn.1004-7638.2018.02.001GAO J J, HONG L K, ZHANG J, et al. Experiment study of vanadium titano-magnetite by full oxygen bath smelting process[J]. Iron Steel Vanadium Titanium, 2018, 39(2): 8-13. doi: 10.7513/j.issn.1004-7638.2018.02.001 [13] HAN Z W. Experimental study on new process of gas-based direct reduction-electric furnace smelting separation for vanadium-titanium magnetite[D]. Shenyang: Northeastern University, 2011. (韩子文. 钒钛磁铁矿气基竖炉直接还原-电炉熔分新工艺的实验研究[D]. 沈阳: 东北大学, 2011.HAN Z W. Experimental study on new process of gas-based direct reduction-electric furnace smelting separation for vanadium-titanium magnetite[D]. Shenyang: Northeastern University, 2011. [14] QIN T X, HU X, ZHANG K Z, et al. Technical and economic analysis of the new process of smelting vanadium-titanium magnetite[C]. Panzhihua: 2010 Symposium on non blast furnace ironmaking and comprehensive utilization of vanadium-titanium magnetite. (秦廷许, 胡晓, 张珂泽, 等. 钒钛磁铁矿冶炼新流程技术经济分析[C]. 攀枝花: 2010年非高炉炼铁学术年会暨钒钛磁铁矿综合利用技术研讨会.QIN T X, HU X, ZHANG K Z, et al. Technical and economic analysis of the new process of smelting vanadium-titanium magnetite[C]. Panzhihua: 2010 Symposium on non blast furnace ironmaking and comprehensive utilization of vanadium-titanium magnetite. [15] LIU S L. Study on technology and theory of direct reduction by RHF and smelting separation by arc furnace from vanadium and titanium iron concentrate[D]. Chongqing: Chongqing University. (刘松利. 钒钛铁精矿转底炉直接还原-电炉熔分工艺与理论研究[D]. 重庆: 重庆大学, 2010.LIU S L. Study on technology and theory of direct reduction by RHF and smelting separation by arc furnace from vanadium and titanium iron concentrate[D]. Chongqing: Chongqing University. [16] LIAO J L, LI J, WANG X D, et al. Influence of TiO2 and basicity on viscosity of Ti bearing slag[J]. Ironmaking Steelmaking, 2012,39(2):133-139. doi: 10.1179/1743281211Y.0000000064 [17] WANG S, GUO Y F, JIANG T, et al. Reduction behaviors of iron, vanadium and titanium oxides in smelting of vanadium titanomagnetite metallized pellets[J]. JOM, 2017,69(9):1646-1653. doi: 10.1007/s11837-017-2367-x [18] DU H G. Principle of blast furnaces melting vanadium- titanium magnetite[M]. Beijing: Science Press, 1996: 62. (杜鹤桂. 高炉冶炼钒钛磁铁矿原理[M]. 北京: 科学出版社, 1996: 62.DU H G. Principle of blast furnaces melting vanadium- titanium magnetite[M]. Beijing: Science Press, 1996: 62. -

下载:

下载: