Discussion on the preparation of hydrogen-rich reducing gas by coupling metallurgical solid waste oxygen carrier and chemical looping gasification technology

-

摘要: 氢气以及富氢还原气体的来源是制约氢能在钢铁行业应用的关键,而化学链气化技术可以制备高品质的富氢还原气体,其工艺成熟、成本低廉。载氧体是化学链气化技术中重要的媒介,基于载氧体的性能和类型,综述了化学链气化技术中铁基载氧体的应用现状,冶金固体废弃物载氧体的制备和应用,讨论了冶金固废载氧体耦合化学链气化技术制备富氢还原气体的可行性,并对冶金固废载氧体在化学链气化技术制备富氢还原气体领域的研究趋势和发展方向进行了展望。Abstract: The sources of hydrogen and hydrogen-rich reducing gases are the key factors restricting the application of hydrogen energy in the iron and steel industry. However, chemical looping gasification technology can produce high quality hydrogen-rich reducing gases, and this process is mature with low cost. Oxygen carriers play a crucial role in the chemical looping gasification technology. Based on the capabilities and categories of the oxygen carrier, this paper reviews the application of iron-based oxygen carriers in the chemical looping gasification technology. The preparation and utilization of oxygen carriers from metallurgical solid waste are described in detail. The feasibility of generating hydrogen-rich reducing gases by coupling metallurgical solid waste oxygen carriers with chemical looping gasification technology is discussed further. Finally, the research trends and future development directions of solid waste oxygen carriers by using chemical looping gasification technology to produce hydrogen-rich reducing gas are prospected.

-

样本 文山

赤泥西安

赤泥广西

赤泥越南

赤泥中州

赤泥河南

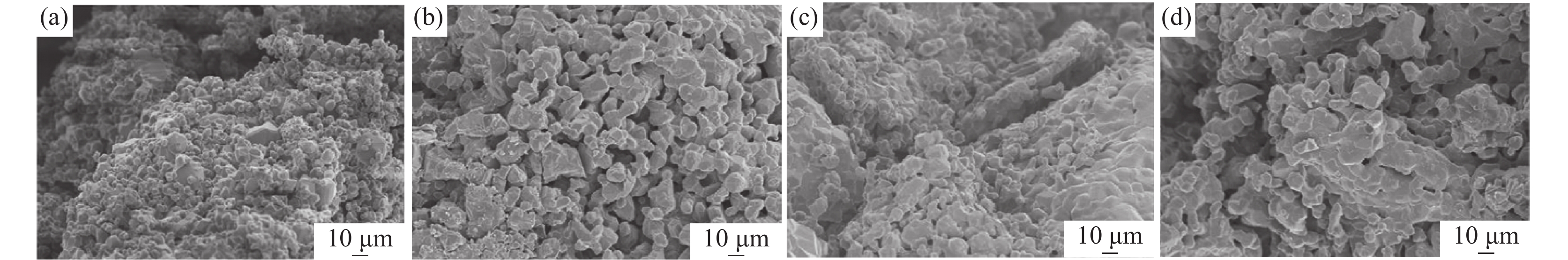

赤泥山东

赤泥Fe2O3 29.34 42.31 74.28 70.32 14.97 26.80 13.94 Al2O3 25.46 19.53 12.68 10.86 23.78 28.65 27.15 SiO2 19.39 17.64 3.13 11.53 20.71 25.91 22.34 TiO2 5.41 5.64 6.10 0.68 4.97 1.79 4.97 Na2O 6.20 5.99 0.07 0.61 5.36 12.66 2.50 CaO 13.69 0.61 2.65 0.65 15.64 2.31 22.78 其他 0.51 8.28 1.09 5.35 14.57 1.88 6.32 表 2 不同铜冶炼工艺的铜渣组成[43]

Table 2. Compositions of copper slag in the different copper smelting processes[43]

% 冶炼方法 SiO2 FeO Fe2O3 CaO MgO Al2O3 Cu 密闭鼓风法 31~39 33~42 3~10 6~19 0.8~7.0 4~12 0.35~2.4 转炉法 16~28 48~65 12~29 1~2 0~2 5~10 1.1~2.9 艾萨法 31~34 40~58 7.5 2.3 2.0 0.2 0.6 闪速熔炉法 28~38 38~54 12~15 5~15 1~3 2~12 0.17~0.33 -

[1] ZHANG S H, WU X Z, LIU R, et al. Discussion on smelting characteristics and problems of blast furnace with hydrogen-rich gas injection[J]. Iron & Steel, 2024,59(1):1-11. (张淑会, 武校章, 刘然, 等. 喷吹富氢气体高炉冶炼特点及存在问题的探讨[J]. 钢铁, 2024,59(1):1-11.ZHANG S H, WU X Z, LIU R, et al. Discussion on smelting characteristics and problems of blast furnace with hydrogen-rich gas injection[J]. Iron & Steel, 2024, 59(1): 1-11. [2] YUAN X, PENG F, SUN Z H. Analysis of reducing pollution and carbon for hydrogen-based shaft furnace direct reduction technology[J]. Energy for Metallurgical Industry, 2024,43(3):3-7,43. (员晓, 彭锋, 孙泽辉. 氢基竖炉直接还原技术减污降碳分析[J]. 冶金能源, 2024,43(3):3-7,43. doi: 10.3969/j.issn.1001-1617.2024.03.001YUAN X, PENG F, SUN Z H. Analysis of reducing pollution and carbon for hydrogen-based shaft furnace direct reduction technology[J]. Energy for Metallurgical Industry, 2024, 43(3): 3-7,43. doi: 10.3969/j.issn.1001-1617.2024.03.001 [3] TANG G Y, GU J, YANG Q, et al. Research progress in chemical looping gasification technology of organic solid waste[J]. Acta Petrolei Sinica (Petroleum Processing Section), 2021,37(3):700-718. (唐亘炀, 顾菁, 杨秋, 等. 有机固体废弃物化学链气化技术研究进展[J]. 石油学报(石油加工), 2021,37(3):700-718.TANG G Y, GU J, YANG Q, et al. Research progress in chemical looping gasification technology of organic solid waste[J]. Acta Petrolei Sinica (Petroleum Processing Section), 2021, 37(3): 700-718. [4] BHAVSAR S, NAJERA M, VESER G. Chemical looping dry reforming as novel, intensified process for CO2 activation[J]. Chemical Engineering & Technology, 2012,35(7):1281-1290. [5] TIAN X, NIU P J, MA Y X, et al. Chemical-looping gasification of biomass: Part II. Tar yields and distributions[J]. Biomass and Bioenergy, 2018,108:178-189. doi: 10.1016/j.biombioe.2017.11.007 [6] HUANG Z, HE F, FENG Y P, et al. Synthesis gas production through biomass direct chemical looping conversion with natural hematite as an oxygen carrier[J]. Bioresource Technology, 2013,140:138-145. doi: 10.1016/j.biortech.2013.04.055 [7] GUO W J, GE H J, SHEN L H, et al. Experimental study on chemical looping gasification of biomass with hematite base on 25 kWth fluidized beds[J]. Journal of Thermal Science and Technology, 2017,16(1):78-86. (郭万军, 葛晖骏, 沈来宏, 等. 基于铁矿石载氧体25kWth串行流化床生物质化学链气化实验研究[J]. 热科学与技术, 2017,16(1):78-86.GUO W J, GE H J, SHEN L H, et al. Experimental study on chemical looping gasification of biomass with hematite base on 25 kWth fluidized beds[J]. Journal of Thermal Science and Technology, 2017, 16(1): 78-86. [8] SUN G Z, AN Z W, CHEN Y M, et al. Research progress on sludge/biomass chemical looping gasification and ash-moisture influence on gasification characteristics[J]. Clean Coal Technology, 2023,29(9):1-13. (孙国震, 安泽文, 陈岩明, 等. 基于铁基载氧体的污泥/生物质化学链气化及其灰分-水分影响特性研究进展[J]. 洁净煤技术, 2023,29(9):1-13.SUN G Z, AN Z W, CHEN Y M, et al. Research progress on sludge/biomass chemical looping gasification and ash-moisture influence on gasification characteristics[J]. Clean Coal Technology, 2023, 29(9): 1-13. [9] DENG G X. Study on methane chemical looping combustion performance of red mud oxygen carrier[D]. Kunming: Kunming University of Science and Technology, 2018. (邓贵先. 赤泥氧载体的甲烷化学链燃烧性能研究[D]. 昆明: 昆明理工大学, 2018.DENG G X. Study on methane chemical looping combustion performance of red mud oxygen carrier[D]. Kunming: Kunming University of Science and Technology, 2018. [10] DONG X J, ZUO Z L, YANG H Q, et al. Calcination modification and redox characteristics of copper slag-based oxygen carrier[J]. Mining and Metallurgical Engineering, 2023,43(6):107-111. (董鑫江, 左宗良, 杨涵奇, 等. 铜渣氧载体煅烧改性及氧化还原特性研究[J]. 矿冶工程, 2023,43(6):107-111. doi: 10.3969/j.issn.0253-6099.2023.06.023DONG X J, ZUO Z L, YANG H Q, et al. Calcination modification and redox characteristics of copper slag-based oxygen carrier[J]. Mining and Metallurgical Engineering, 2023, 43(6): 107-111. doi: 10.3969/j.issn.0253-6099.2023.06.023 [11] GAO Z F, LONG H M, GAO X P, et al. Preparation and characteristics of Mn-Ce-doped Fe-based catalysts using metallurgical dust and mud containing iron[J]. Chinese Journal of Engineering, 2024,46(3):407-419. (高志芳, 龙红明, 高翔鹏, 等. 冶金含铁尘泥制备的Mn–Ce掺杂Fe基催化剂及特性[J]. 工程科学学报, 2024,46(3):407-419.GAO Z F, LONG H M, GAO X P, et al. Preparation and characteristics of Mn-Ce-doped Fe-based catalysts using metallurgical dust and mud containing iron[J]. Chinese Journal of Engineering, 2024, 46(3): 407-419. [12] TIAN X, WANG K, ZHAO H B, et al. Chemical looping with oxygen uncoupling of high-sulfur coal using copper ore as oxygen carrier[J]. Proceedings of the Combustion Institute, 2017,36(3):3381-3388. doi: 10.1016/j.proci.2016.08.056 [13] BAO J H, CHEN L Y, LIU F, et al. Evaluating the effect of inert supports and alkali sodium on the performance of red mud oxygen carrier in chemical looping combustion[J]. Industrial & Engineering Chemistry Research, 2016,55(29):8046-8057. [14] LIU L M, ZHAO H B, ZHENG C G. Advances on oxygen carriers of chemical-looping combustion[J]. Coal Conversion, 2006,29(3):83-93. (刘黎明, 赵海波, 郑楚光. 化学链燃烧方式中氧载体的研究进展[J]. 煤炭转化, 2006,29(3):83-93. doi: 10.3969/j.issn.1004-4248.2006.03.021LIU L M, ZHAO H B, ZHENG C G. Advances on oxygen carriers of chemical-looping combustion[J]. Coal Conversion, 2006, 29(3): 83-93. doi: 10.3969/j.issn.1004-4248.2006.03.021 [15] MONAZAM E R, BREAULT R W, SIRIWARDANE R. Kinetics of magnetite (Fe3O4) oxidation to hematite (Fe2O3) in air for chemical looping combustion[J]. Industrial & Engineering Chemistry Research, 2014,53(34):13320-13328. [16] MIAO Z W, HU Z F, JIANG E C, et al. Hydrogen-rich syngas production by chemical looping reforming on crude wood vinegar using Ni-modified HY zeolite oxygen carrier[J]. Fuel, 2020,279(1):118547. [17] RYDEN M, LYNGFELT A, MATTISSON T. Synthesis gas generation by chemical-looping reforming in a continuously operating laboratory reactor[J]. Fuel, 2006,85(12-13):1631-1641. doi: 10.1016/j.fuel.2006.02.004 [18] FRICK V, RYDEN M, LEION H. Investigation of Cu-Fe and Mn-Ni oxides as oxygen carriers for chemical-looping combustion[J]. Fuel Processing Technology, 2016,150:30-40. doi: 10.1016/j.fuproc.2016.04.032 [19] ZENG L P, HUANG F, ZHU X, et al. Chemical looping conversion of methane over CeO2-based and Co3O4-based Co3O4-CeO2 oxygen carriers: controlling of product selectivity[J]. Chemical Journal of Chinese Universities, 2017,38(1):115-125. (曾良鹏, 黄樊, 祝星, 等. 铈基与钴基Co3O4-CeO2氧载体上甲烷化学链转化特性: 产物选择性控制[J]. 高等学校化学学报, 2017,38(1):115-125. doi: 10.7503/cjcu20160411ZENG L P, HUANG F, ZHU X, et al. Chemical looping conversion of methane over CeO2-based and Co3O4-based Co3O4-CeO2 oxygen carriers: controlling of product selectivity[J]. Chemical Journal of Chinese Universities, 2017, 38(1): 115-125. doi: 10.7503/cjcu20160411 [20] JOHANSSON M, And M T, Lyngfelt A. Creating a synergy effect by using mixed oxides of iron and nickel oxides in the combustion of methane in a chemical-looping combustion reactor[J]. Energy Fuels, 2006, 20(6): 2399-2407. [21] GUO Q J, HU X D, LIU Y Z, et al. Coal chemical-looping gasification of Ca-based oxygen carriers decorated by CaO[J]. Powder Technology, 2015,275:60-68. doi: 10.1016/j.powtec.2015.01.061 [22] JERNDAL E, MATTISSON T, LYNGFELT A. Thermal analysis of chemical-looping combustion[J]. Chemical Engineering Research and Design, 2006,84(9):795-806. doi: 10.1205/cherd05020 [23] FENG F, GONGYE L P, WEI L, et al. Application of chemical looping combustion in carbon dioxide mitigation and research development[J]. Chemical Industry Times, 2009,23(4):67-71. (冯飞, 公冶令沛, 魏龙, 等. 化学链燃烧在二氧化碳减排中的应用及其研究进展[J]. 化工时刊, 2009,23(4):67-71. doi: 10.3969/j.issn.1002-154X.2009.04.019FENG F, GONGYE L P, WEI L, et al. Application of chemical looping combustion in carbon dioxide mitigation and research development[J]. Chemical Industry Times, 2009, 23(4): 67-71. doi: 10.3969/j.issn.1002-154X.2009.04.019 [24] WU Y T, LIAO Y F, LIU G C, et al. Syngas production by chemical looping gasification of biomass with steam and CaO additive[J]. International Journal of Hydrogen Energy, 2018,43(42):19375-19383. doi: 10.1016/j.ijhydene.2018.08.197 [25] FENG Y. Experiments on coal and biomass chemical looping gasification based on CaO sorbent[D]. Hangzhou: Zhejiang University, 2017. (冯毅. 基于氧化钙载体的生物质与褐煤化学链气化过程的实验研究[D]. 杭州: 浙江大学, 2017.FENG Y. Experiments on coal and biomass chemical looping gasification based on CaO sorbent[D]. Hangzhou: Zhejiang University, 2017. [26] MOLINO A, CHIANESE S, MUSMARRA D. Biomass gasification technology: The state of the art overview[J]. Journal of Energy Chemistry, 2016,25(1):10-25. doi: 10.1016/j.jechem.2015.11.005 [27] WU Q. Study on coproduction of hydrogen and syngas by biomass chemical chain gasification with Ca-Fe based oxygen carrier[D]. Wuhan: Huazhong University of Science and Technology, 2022. (吴琼. Ca-Fe基氧载体生物质化学链气化共制备氢与合成气研究[D]. 武汉: 华中科技大学, 2022.WU Q. Study on coproduction of hydrogen and syngas by biomass chemical chain gasification with Ca-Fe based oxygen carrier[D]. Wuhan: Huazhong University of Science and Technology, 2022. [28] WANG S D. Characteristics and mechanism of biomass chemical looping gasification with Fe2O3/CaO[D]. Qingdao: China University of Petroleum (East China), 2021. (王士铎. Fe2O3/CaO作用下生物质化学链气化特性与机理研究[D]. 青岛: 中国石油大学(华东), 2021.WANG S D. Characteristics and mechanism of biomass chemical looping gasification with Fe2O3/CaO[D]. Qingdao: China University of Petroleum (East China), 2021. [29] CHEN Z H. Characteristic and mechanism investigation on biomass chemical looping gasification based on Mn-Fe composite oxygen carriers[D]. Guangzhou: South China University of Technology, 2020. (陈智豪. 基于锰铁复合载氧体的生物质化学链气化特性及机理研究[D]. 广州: 华南理工大学, 2020.CHEN Z H. Characteristic and mechanism investigation on biomass chemical looping gasification based on Mn-Fe composite oxygen carriers[D]. Guangzhou: South China University of Technology, 2020. [30] XIAO Y. Experiment and reaction mechanism on chemical looping gasification of biomass with barium ferrite oxygen carrier[D]. Nanjing: Southeast University, 2021. (肖艳. 基于铁酸钡载氧体的生物质化学链气化实验和反应机理研究[D]. 南京: 东南大学, 2021.XIAO Y. Experiment and reaction mechanism on chemical looping gasification of biomass with barium ferrite oxygen carrier[D]. Nanjing: Southeast University, 2021. [31] OREIZ M, DE DIEGO L F, ABAD A, et al. Hydrogen production by auto-thermal chemical-looping reforming in a pressurized fluidized bed reactor using Ni-based oxygen carriers[J]. International Journal of Hydrogen Energy, 2010,35(1):151-160. doi: 10.1016/j.ijhydene.2009.10.068 [32] ISHIDA M, JIN H G. A novel chemical-looping combustor without NOx formation[J]. Industrial & engineering chemistry research, 1996,35(7):2469-2472. [33] WANG X D, JIN B S, DONG Y H, et al. Thermodynamic performance investigation on coal chemical looping combustion coupling with hydrogen generation in moving bed[J]. Electric Power Technology and Protection, 2022,38(4):300-306. (王旭东, 金保昇, 董月红, 等. 移动床煤化学链燃烧耦合制氢系统的热力学特性研究[J]. 电力科技与环保, 2022,38(4):300-306.WANG X D, JIN B S, DONG Y H, et al. Thermodynamic performance investigation on coal chemical looping combustion coupling with hydrogen generation in moving bed[J]. Electric Power Technology and Protection, 2022, 38(4): 300-306. [34] JIANG J Z. Design and test of a hydrogen production system based on chemical looping combustion theory[D]. Beijing: North China Electric Power University, 2011. (蒋景周. 基于化学链燃烧原理的制氢系统设计与实验[D]. 北京: 华北电力大学, 2011.JIANG J Z. Design and test of a hydrogen production system based on chemical looping combustion theory[D]. Beijing: North China Electric Power University, 2011. [35] LEION H, MATTISSON T, LYNGFELT A. Solid fuels in chemical looping combustion[J]. Int. J. Greenhouse Gas Control, 2008,2(2):180-600. doi: 10.1016/S1750-5836(07)00117-X [36] LÜ Y L. Study on the characteristics of chemical chain co-gasification of coal and biomass[J]. Energy Consery Ation, 2024,43(6):87-90. (吕玉林. 煤和生物质化学链共气化特性研究[J]. 节能, 2024,43(6):87-90. doi: 10.3969/j.issn.1004-7948.2024.06.025LÜ Y L. Study on the characteristics of chemical chain co-gasification of coal and biomass[J]. Energy Consery Ation, 2024, 43(6): 87-90. doi: 10.3969/j.issn.1004-7948.2024.06.025 [37] WU J K, GONG Z Q, LU C M, et al. Preparation and performance of modified red mud-based catalysts for selective catalytic reduction of NOx with NH3[J]. Catalysts, 2018,8(1):35. doi: 10.3390/catal8010035 [38] HE J. Study on the Chemical looping combustion performance of red mud-based oxygen carriers[D]. Maanshan: Anhui University of Technology, 2021. (何静. 赤泥基载氧体化学链燃烧性能研究[D]. 马鞍山: 安徽工业大学, 2021.HE J. Study on the Chemical looping combustion performance of red mud-based oxygen carriers[D]. Maanshan: Anhui University of Technology, 2021. [39] DUAN Z. Red mud removal of sodium iron extraction and oxygen storage regulation[D]. Kunming: Kunming University of Science and Technology, 2023. (段珍. 赤泥脱钠提铁及储氧性能调控[D]. 昆明: 昆明理工大学, 2023.DUAN Z. Red mud removal of sodium iron extraction and oxygen storage regulation[D]. Kunming: Kunming University of Science and Technology, 2023. [40] ZHANG H F, CHEN L, LIU X Y, et al. Characteristics of cyanobacteria pyrolysis and gasification during chemical looping process with red mud oxygen carrier[J]. Journal of Fuel Chemistry and Technology, 2021,49(12):1802-1811. (张海峰, 陈璐, 刘先宇, 等. 基于赤泥载氧体的蓝藻化学链热解和气化特性研究[J]. 燃料化学学报, 2021,49(12):1802-1811. doi: 10.1016/S1872-5813(21)60087-7ZHANG H F, CHEN L, LIU X Y, et al. Characteristics of cyanobacteria pyrolysis and gasification during chemical looping process with red mud oxygen carrier[J]. Journal of Fuel Chemistry and Technology, 2021, 49(12): 1802-1811. doi: 10.1016/S1872-5813(21)60087-7 [41] LIN S. Study on modification of red mud for chemical looping combustion of coal[D]. Kunming: Kunming University of Science and Technology, 2020. (林伸. 赤泥用于煤化学链燃烧的改性研究[D]. 昆明: 昆明理工大学, 2020.LIN S. Study on modification of red mud for chemical looping combustion of coal[D]. Kunming: Kunming University of Science and Technology, 2020. [42] LIU Y. Research on gasification utilization technology of traditional Chinese medicine waste slag based on chemical looping technology[D]. Xuzhou: China University of Mining and Technology, 2019. (刘阳. 基于化学链的中药废渣气化利用技术研究[D]. 徐州: 中国矿业大学, 2019.LIU Y. Research on gasification utilization technology of traditional Chinese medicine waste slag based on chemical looping technology[D]. Xuzhou: China University of Mining and Technology, 2019. [43] ZHANG S H, WANG B Y, LAN C C, et al. Research status and prospect of recycling technologies of valuable metallic elements from copper slag[J]. China Nonferrous Metallurgy, 2022,51(3):84-93. (张淑会, 王宝勇, 兰臣臣, 等. 铜渣中有价金属元素回收技术的研究现状及展望[J]. 中国有色冶金, 2022,51(3):84-93.ZHANG S H, WANG B Y, LAN C C, et al. Research status and prospect of recycling technologies of valuable metallic elements from copper slag[J]. China Nonferrous Metallurgy, 2022, 51(3): 84-93. [44] DENG Z B, HUANG Z, HE F, et al. Evaluation of calcined copper slag as an oxygen carrier for chemical looping gasification of sewage sludge[J]. International Journal of Hydrogen Energy, 2019,44(33):17823-17834. doi: 10.1016/j.ijhydene.2019.05.039 [45] DONG N H, HUO R Q, LIU M, et al. Chemical looping gasification of sewage sludge using copper slag modified by NiO as an oxygen carrier[J]. Chinese Journal of Chemical Engineering, 2021,29:335-343. doi: 10.1016/j.cjche.2020.09.007 [46] WANG Y H, LIU M, DONG N H, et al. Chemical looping gasification of high nitrogen wood waste using a copper slag oxygen carrier modified by alkali and alkaline earth metals[J]. Chemical Engineering Journal, 2021,410(15):128344. [47] WANG J S, LI Y, FENG H X, et al. Progress in treating difficult-to-handle dust and sludge and full-scale resource utilization in an iron and steel industry cluster[J]. Chinese Journal of Engineering, 2021,43(12):1737-1749. (王静松, 李岩, 冯怀萱, 等. 钢铁产业集聚区难处理尘泥处理与全量资源化利用进展[J]. 工程科学学报, 2021,43(12):1737-1749. doi: 10.3321/j.issn.1001-053X.2021.12.bjkjdxxb202112014WANG J S, LI Y, FENG H X, et al. Progress in treating difficult-to-handle dust and sludge and full-scale resource utilization in an iron and steel industry cluster[J]. Chinese Journal of Engineering, 2021, 43(12): 1737-1749. doi: 10.3321/j.issn.1001-053X.2021.12.bjkjdxxb202112014 [48] LIU H T. Study on preparation of doped iron-based oxygen carrier by metallurgical dust[D]. Maanshan: Anhui University of Technology, 2019. (刘海涛. 冶金尘泥制备掺杂型铁基载氧体的研究[D]. 马鞍山: 安徽工业大学, 2019.LIU H T. Study on preparation of doped iron-based oxygen carrier by metallurgical dust[D]. Maanshan: Anhui University of Technology, 2019. [49] NIU F S, HE S T, ZHANG J X, et al. Study on ultrasonically-enhanced deep eutectic solvents leaching of zinc from zinc-containing metallurgical dust sludge[J]. Metals, 2022,12(11):1856. doi: 10.3390/met12111856 [50] GAO Z F, WU Z J, LIU W M. Preparation and chemical looping combustion properties of Fe2O3/Al2O3 derived from metallurgy iron-bearing dust[J]. Journal of Environmental Chemical Engineering, 2016,4(2):1653-1663. doi: 10.1016/j.jece.2016.02.031 [51] GAO Z F, SU C, LI N, et al. Preparation of Ca-Fe oxygen carrier using metallurgical dust[J]. Journal of Iron and Steel Research, 2018,30(10):782-788. (高志芳, 苏畅, 李娜, 等. 冶金尘泥制备钙铁双氧载体材料[J]. 钢铁研究学报, 2018,30(10):782-788.GAO Z F, SU C, LI N, et al. Preparation of Ca-Fe oxygen carrier using metallurgical dust[J]. Journal of Iron and Steel Research, 2018, 30(10): 782-788. [52] HILDOR F, LEION H, LINDERHOLM C J, et al. Steel converter slag as an oxygen carrier for chemical-looping gasification[J]. Fuel Processing Technology, 2020,210(15):106576 [53] ZHANG Z Y, WANG X T, ZHANG L L, et al. Characteristics of steel slag as an oxygen carrier for chemical looping gasification of sewage sludge[J]. Energy, 2022,247(15):123534. [54] HAN J. Investigation on chemical looping gasification of sewage sludge using sewage sludge ash as oxygen carrier[D]. Hefei: University of Science and Technology of China, 2021. (韩静. 以污泥灰为载氧体的污泥化学链气化特性研究[D]. 合肥: 中国科学技术大学, 2021.HAN J. Investigation on chemical looping gasification of sewage sludge using sewage sludge ash as oxygen carrier[D]. Hefei: University of Science and Technology of China, 2021. [55] CHEN J, SU M, ZHANG X B, et al. Research progress in preparation of reducing gases for hydrogen metallurgy[J]. China Metallurgy, 2023,33(1):24-33. (陈健, 苏敏, 张新波, 等. 氢冶金还原性气体的制备研究进展[J]. 中国冶金, 2023,33(1):24-33.CHEN J, SU M, ZHANG X B, et al. Research progress in preparation of reducing gases for hydrogen metallurgy[J]. China Metallurgy, 2023, 33(1): 24-33. -

下载:

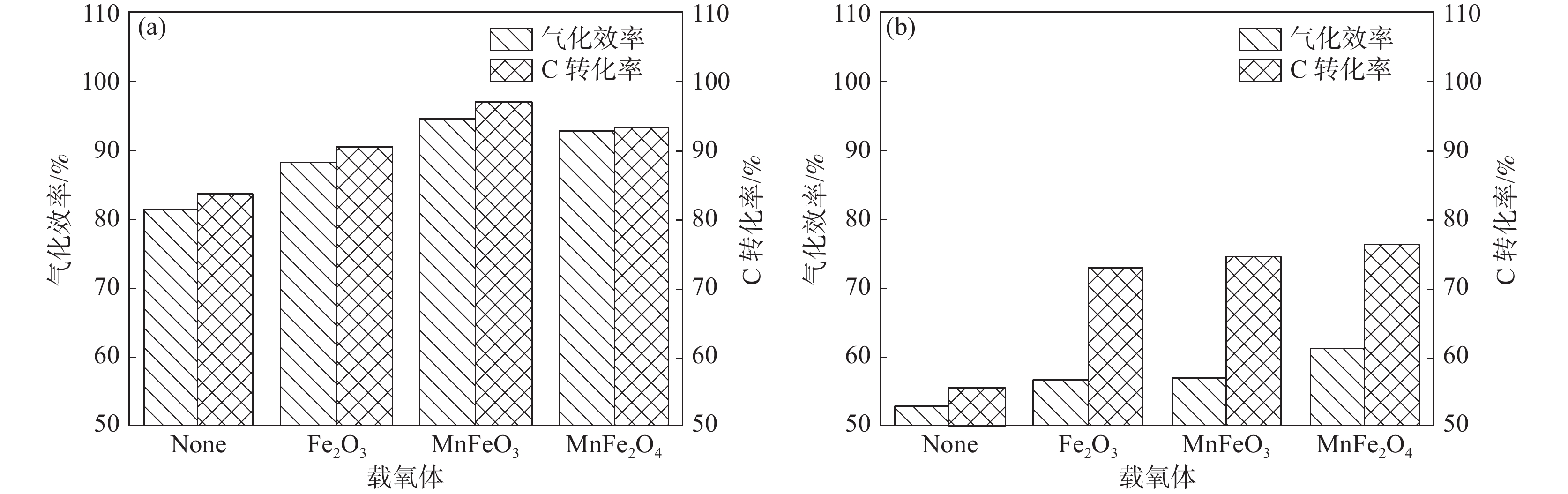

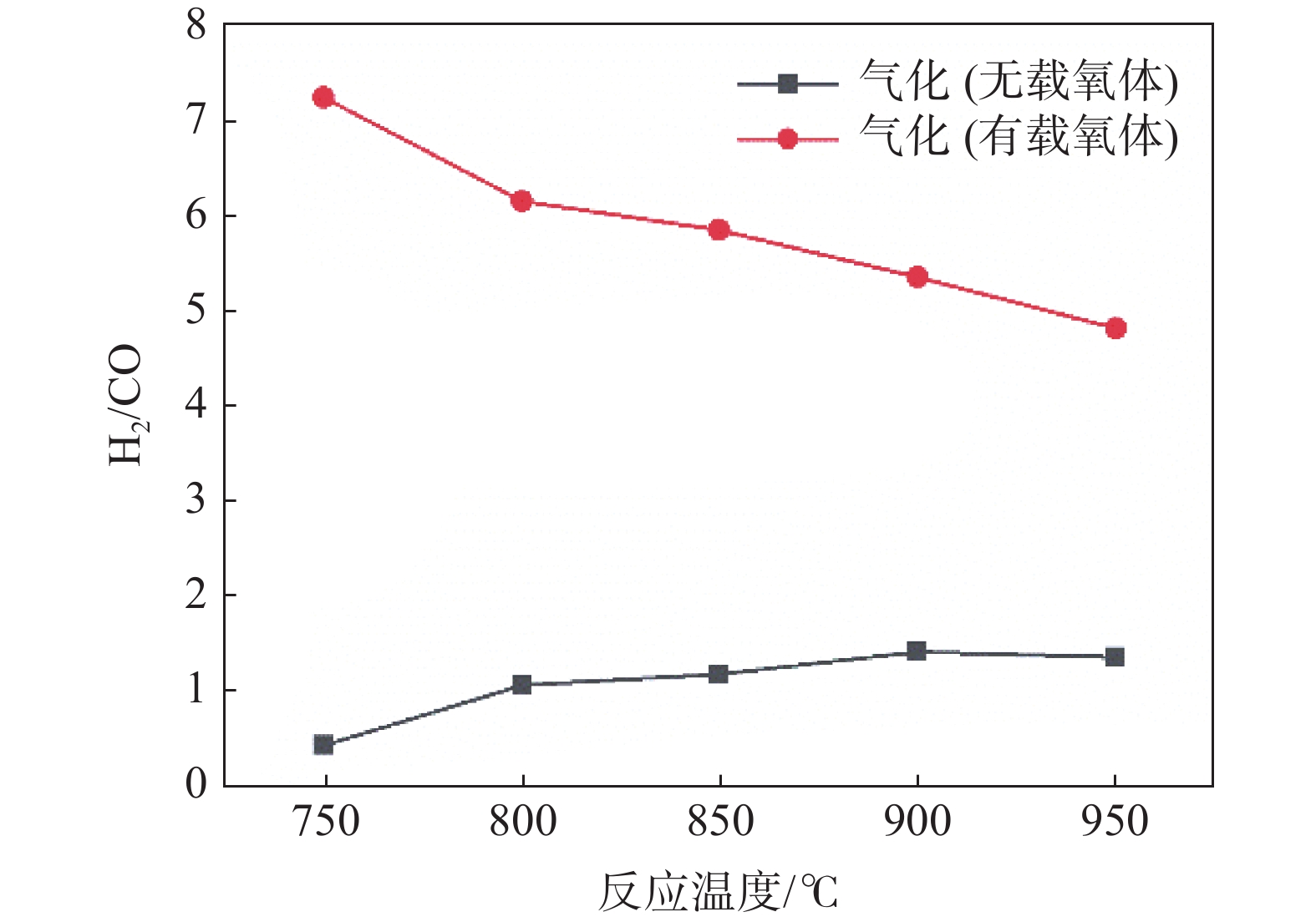

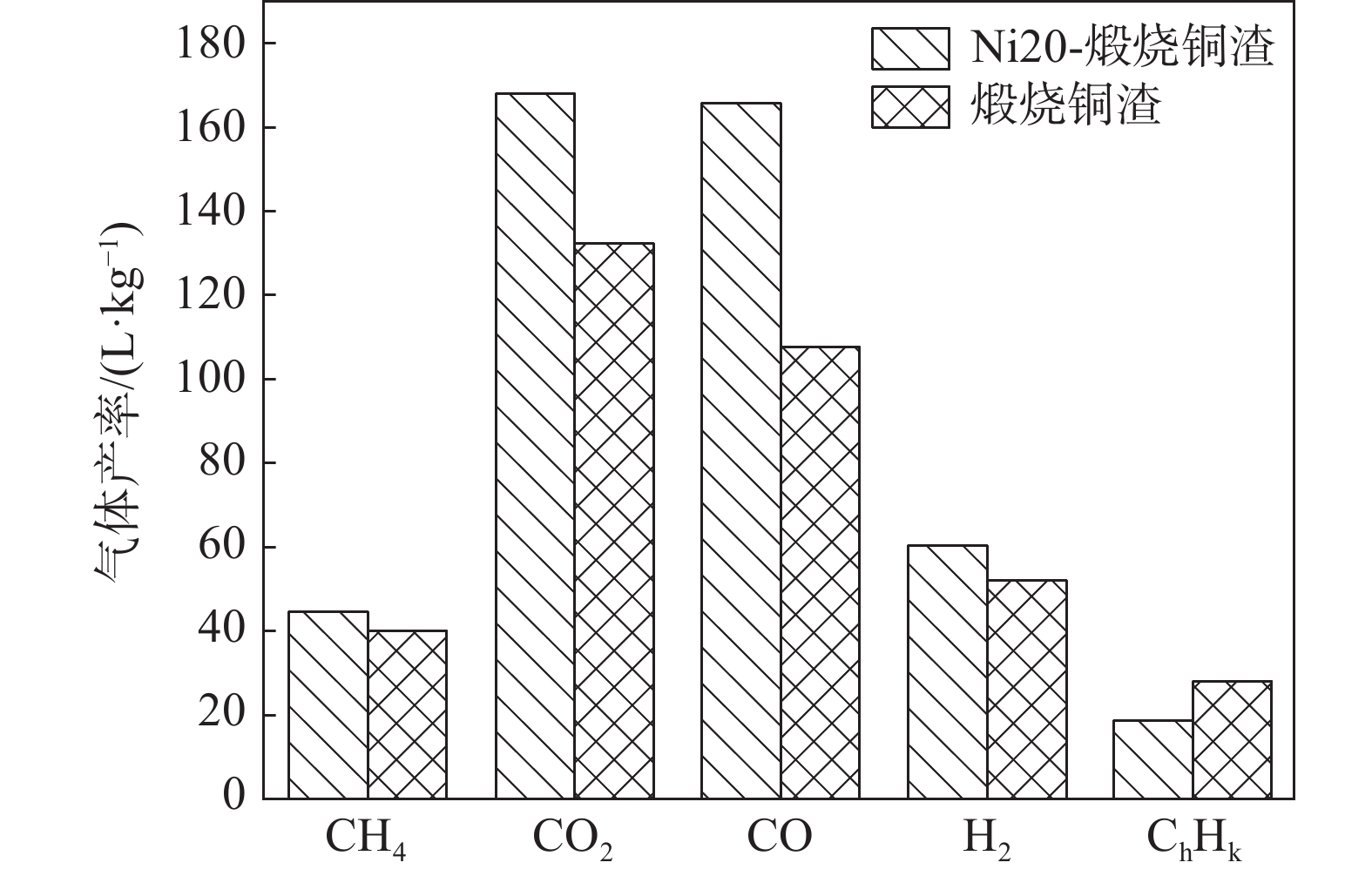

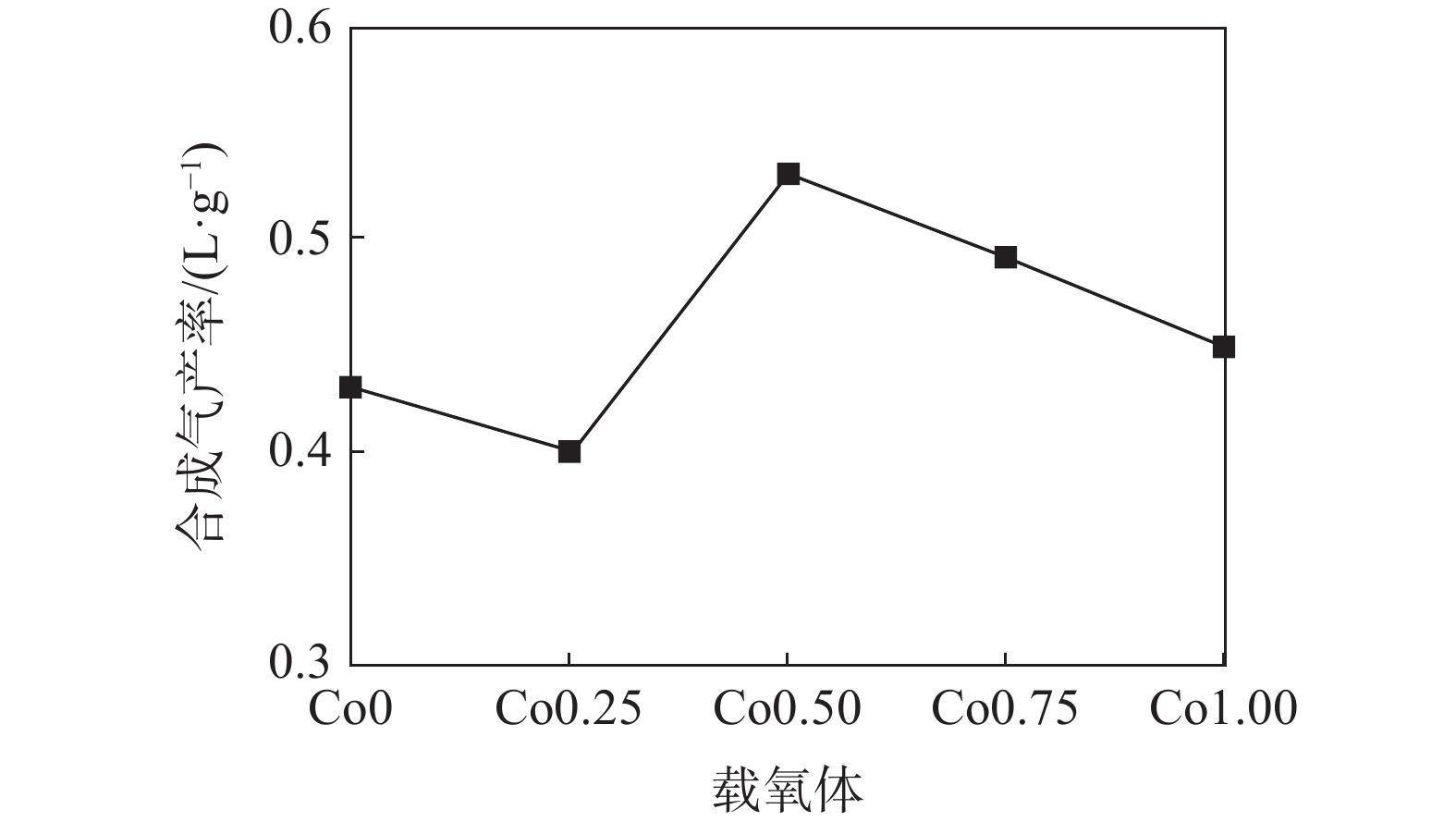

下载: