Study on the granulation of sub-millimeter fine-grade artificial rutile with high-speed stirring

-

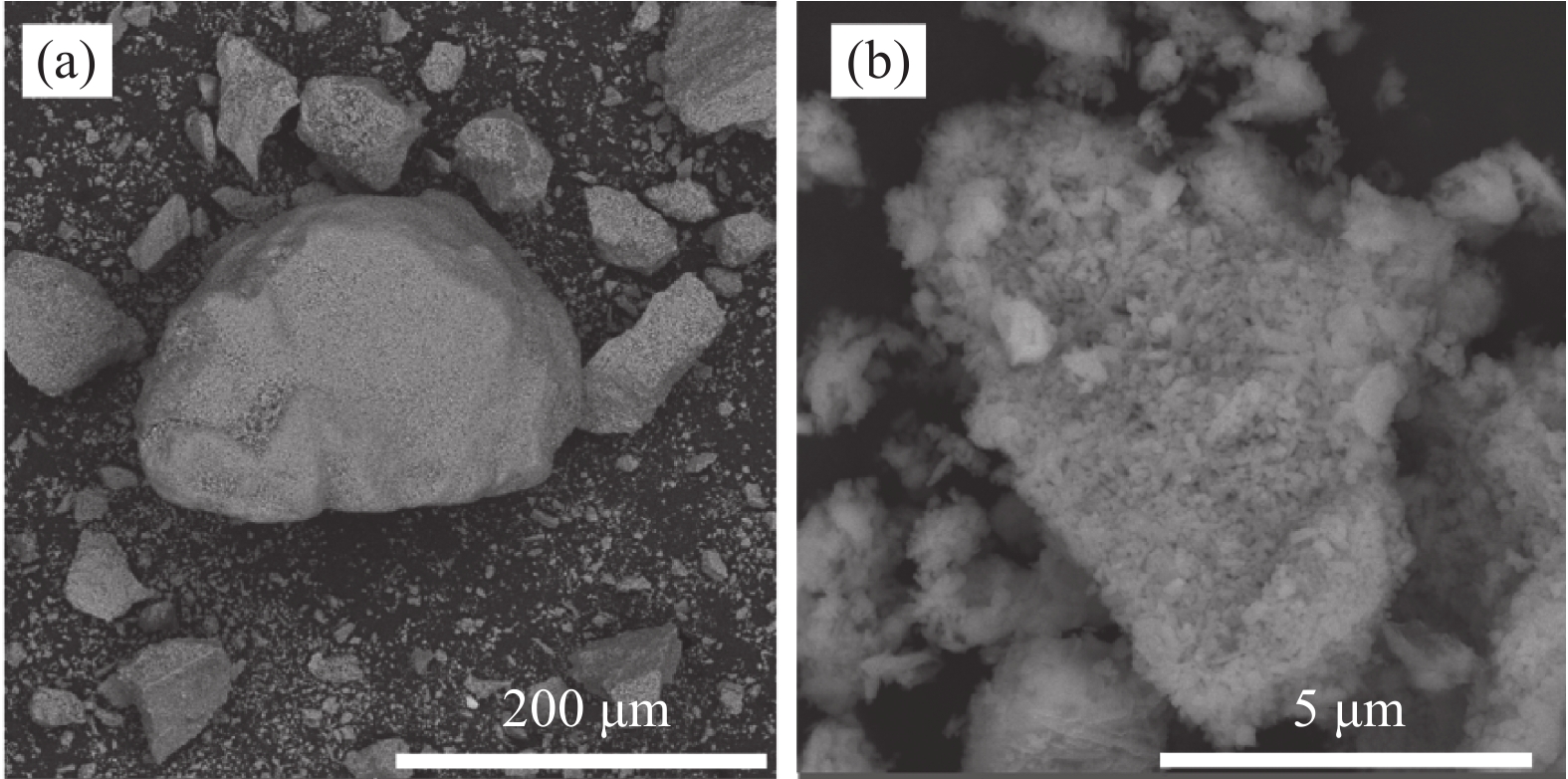

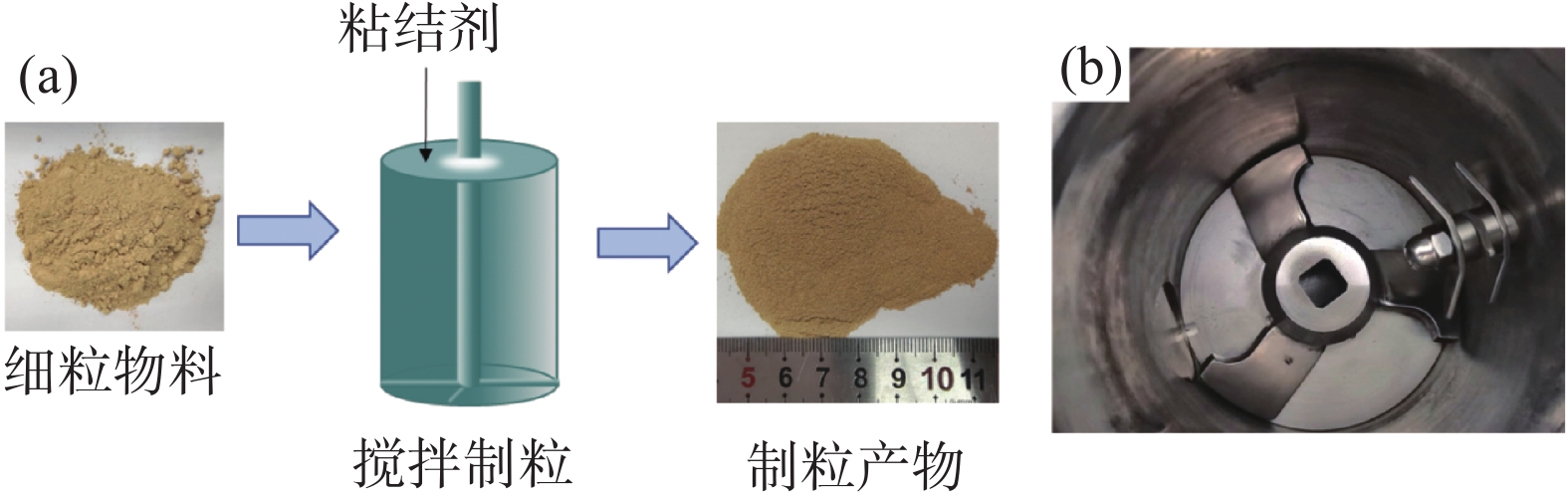

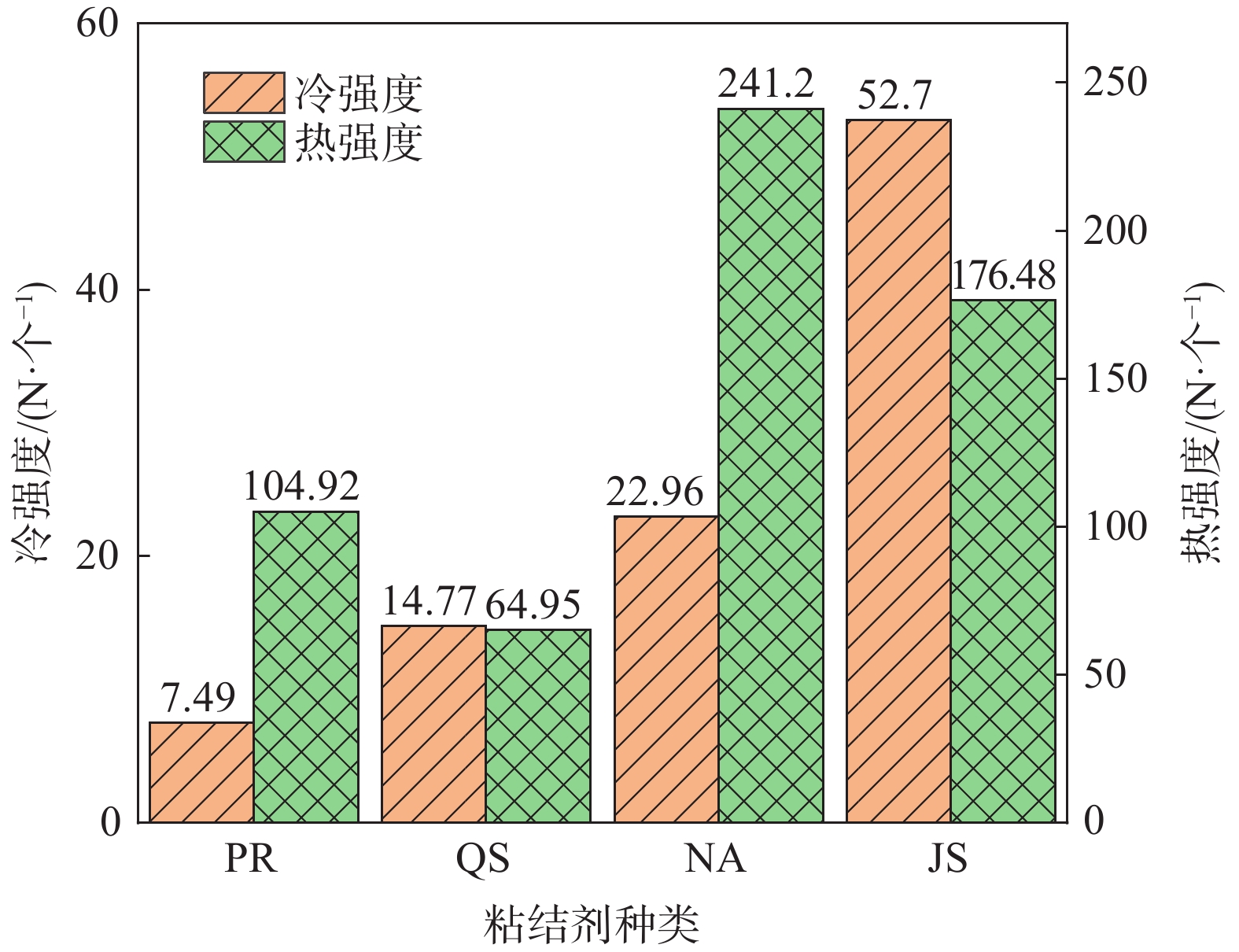

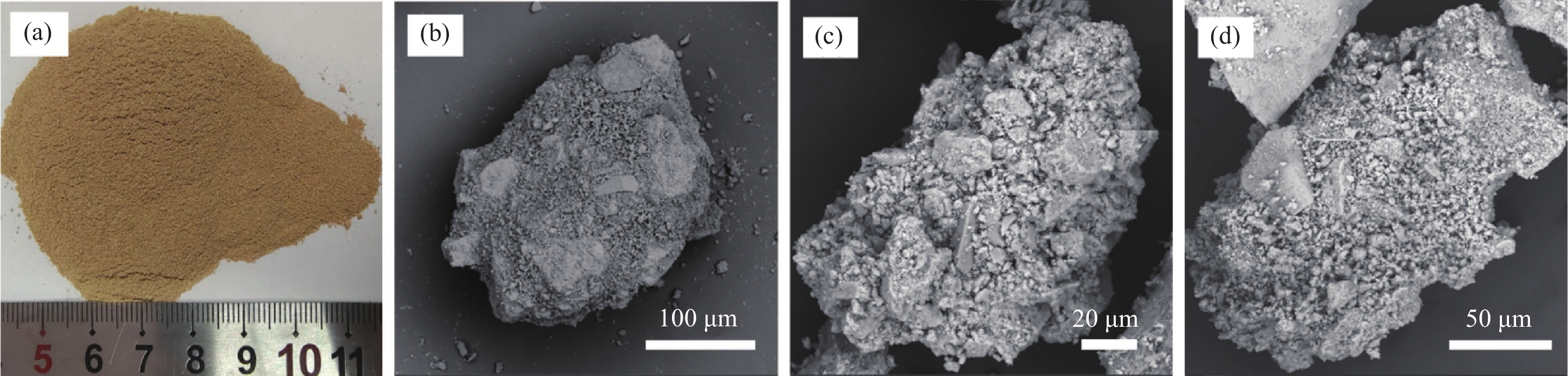

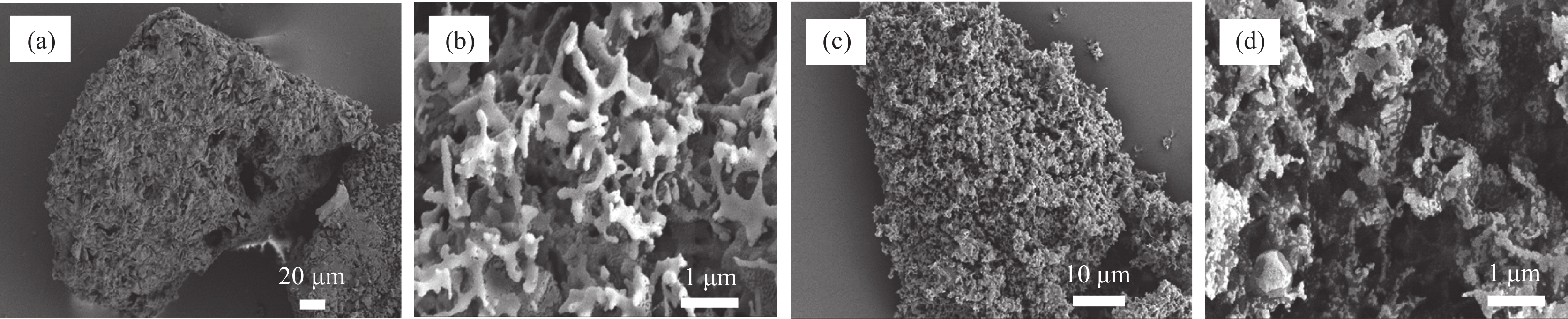

摘要: 对亚毫米级细粒人造金红石搅拌制粒工艺进行研究。通过试验对比,选定最佳制粒制度为:NA为添加剂,NA添加量1.5%,制粒水分20%,混合转速为300、600 r/min的时间分别为3 、5 min,切割刀转速600 r/min。获得粒径为0.097~0.45 mm的制粒产品,制粒后粒径小于0.097 mm的颗粒占比低于15%。对制粒产品进行强度检测,干燥及

1000 ℃热处理后磨损指数分别为8.54%、4.40%,表明经过热处理后颗粒的强度得到有效提升。制粒后产物在流态化氯化环境中仍能保持完整形态,氯化反应30 min后,残余物中TiO2占比仅12.64%,氯化效果较好。-

关键词:

- 亚毫米级细粒人造金红石 /

- 高速搅拌 /

- 沸腾氯化 /

- 钛资源利用

Abstract: The high-speed stirring process of sub-millimeter fine-grained artificial rutile was studied in this paper. Through testing and comparison, the optimal granulation conditions were determined as follows: NA as an additive, 1.5% NA addition, 20% moisture content, a mixing speed of 300 r/min and 600 r/min for 3 and 5 minutes, respectively, and a cutting knife speed of 600 r/min. The resulting granulated products had particle sizes ranging from 0.097 mm to 0.45 mm, with particles smaller than 0.097 mm comprising less than 15% of the total. The strength of the granulated products was assessed, revealing wear indices of 8.54% after drying and 4.40% after heat treatment at1000 °C, indicating a significant improvement in granule strength after heat treatment. The pelletized product maintained its structural integrity in a fluidized chlorination environment. After 30 min of chlorination, the residual TiO2 content was only 12.64%, demonstrating effective chlorination performance. -

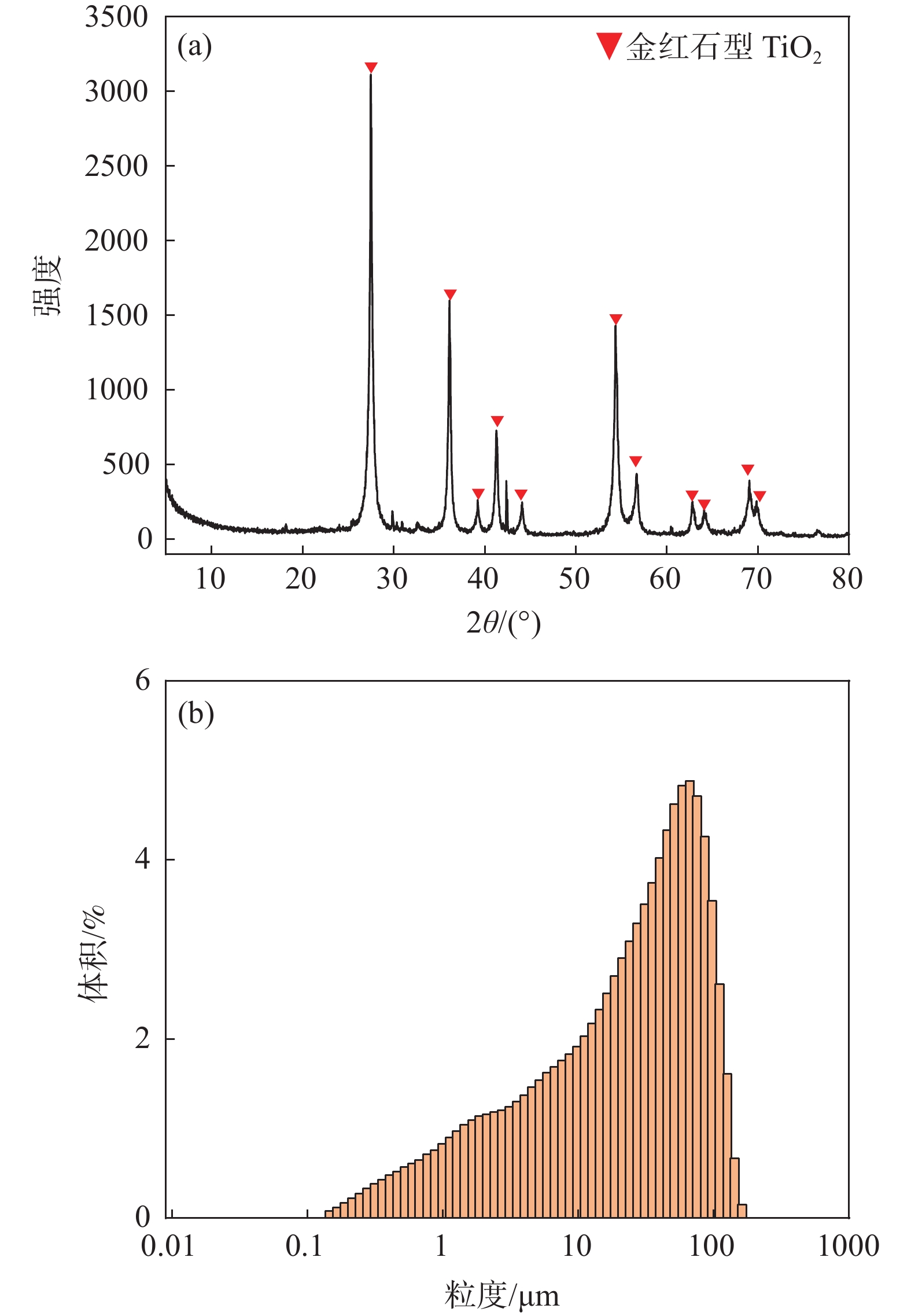

表 1 亚毫米级细粒人造金红石主要化学成分

Table 1. Main chemical composition of sub-millimeter fine grade artificial rutile

% TiO2 TFe SiO2 Al2O3 MgO CaO 88.62 2.40 5.19 0.394 0.615 0.753 表 2 粘结剂添加量对产物粒度分布的影响

Table 2. Influence of binder addition on product particle size distribution

编号 NA添加量/% 制粒时间/min 切割刀转速/(r·min−1) 制粒产物粒度分布/% 400 r/min 600 r/min +0.45 mm 0.097~0.45 mm −0.097 mm 1 1.5 3 5 600 29.20 58.10 12.70 2 1.0 9.63 59.38 30.99 3 0.7 4.54 48.18 47.28 表 3 制粒转速对产物粒度分布的影响

Table 3. Influence of granulation speed on product size distribution

编号 NA添加量/% 制粒转速/(r·min−1) 切割刀转速

/(r·min−1)制粒产物粒度分布/% 3 min 5 min +0.45 mm 0.097~0.45 mm −0.097 mm 1 1.5 300 600 600 25.29 60.48 14.28 2 300 700 26.50 53.35 20.16 3 400 600 29.20 58.10 12.70 表 4 切割刀转速对产物粒度分布的影响

Table 4. Influence of cutting knife speed on product particle size distribution

编号 NA添加量/% 制粒时间/min 切割刀转速/(r·min−1) 制粒产物粒度分布/% 300 r/min 600 r/min +0.45 mm 0.097~0.45 mm −0.097 mm 1 1.5 3 5 300 45.28 43.95 10.77 2 400 31.76 57.32 10.92 3 500 39.40 49.19 11.41 4 600 25.29 60.48 14.23 表 5 制粒时间对产物粒度分布的影响

Table 5. Influence of granulation time on product size distribution

编号 NA添加量/% 制粒时间/min 切割刀转速/

(r·min−1)制粒产物粒度分布/% 300 r/min 600 r/min +0.45 mm 0.097~0.45 mm −0.097 mm 1 1.5 4 4 600 42.93 43.65 13.42 2 3 5 25.29 60.48 14.23 3 3 6 35.27 49.18 15.55 4 2 5 30.04 48.96 21.00 表 6 不同条件下亚毫米级细粒人造金红石制粒产物化学成分

Table 6. Chemical compositions of sub-millimeter fine-grade artificial rutile granulation products under different conditions

组号 重量/g 化学成分/% CaO MgO TFe SiO2 TiO2 Al2O3 1 130 0.753 0.615 2.4 5.19 88.62 0.394 2 49.47 1.31 0.94 0.672 7.71 49.69 0.47 3 21.00 2.58 1.92 1.05 11.55 12.64 0.74 注:氯化后样品化学成分中包含配入石油焦,其含量未标注在内。 -

[1] AN Z S, CHEN Y, ZHAO W, et al. Report on China titanium industry progress in 2023[J]. Titanium Industry Progress, 2024,41(2):41-48. (安仲生, 陈岩, 赵巍, 等. 2023年中国钛工业发展报告[J]. 钛工业进展, 2024,41(2):41-48.AN Z S, CHEN Y, ZHAO W, et al. Report on China titanium industry progress in 2023[J]. Titanium Industry Progress, 2024, 41(2): 41-48. [2] NGUYEN T H, LEE M S. A review on the recovery of titanium dioxide from ilmenite ores by direct leaching technologies[J]. Mineral Processing and Extractive Metallurgy Review, 2019,40(4):231-247. doi: 10.1080/08827508.2018.1502668 [3] GÁZQUEZ M J, BOLÍVAR J P, GARCÍA-TENORIO R, et al. A review of the production cycle of titanium dioxide pigment[J]. Materials Science and Applications, 2014,5:441-458. doi: 10.4236/msa.2014.57048 [4] MO W, DENG G Z, LUO F C. Titanium metallurgy [M]. Beijing: Metallurgical Industry Press, 1998. (莫畏, 邓国珠, 罗方承. 钛冶金[M]. 北京: 冶金工业出版社, 1998MO W, DENG G Z, LUO F C. Titanium metallurgy [M]. Beijing: Metallurgical Industry Press, 1998. [5] LI Z. Research on upgrading Panzhihua-Xichang ilmenite to prepare synthetic rutile[D]. Beijing: University of Chinese Academy of Sciences (Institute of Process Engineering), 2021. (李哲. 攀西钛精矿提质制备人造金红石研究[D]. 北京:中国科学院大学(中国科学院过程工程研究所), 2021.LI Z. Research on upgrading Panzhihua-Xichang ilmenite to prepare synthetic rutile[D]. Beijing: University of Chinese Academy of Sciences (Institute of Process Engineering), 2021. [6] LIU J. Development of study on preparation of Ti-rich raw materials for boiling chlorinated from Panzhihua titanium resources[J]. China Nonferrous Metallurgy, 2018,47(6):49-53. (刘娟. 攀枝花钛资源制备沸腾氯化用富钛原料研究进展[J]. 中国有色冶金, 2018,47(6):49-53. doi: 10.3969/j.issn.1672-6103.2018.06.014LIU J. Development of study on preparation of Ti-rich raw materials for boiling chlorinated from Panzhihua titanium resources[J]. China Nonferrous Metallurgy, 2018, 47(6): 49-53. doi: 10.3969/j.issn.1672-6103.2018.06.014 [7] ZHU F X, MA S R, MA Z S, et al. Preparation of TiCl4 from panzhihua ilmenite concentrate by boiling chlorination[J]. Journal of Materials Research and Technology, 2023,23:2703-2718. doi: 10.1016/j.jmrt.2023.01.190 [8] BONSACK J P, SCHNEIDER F E. Entrained-flow chlorination of titaniferous slag to produce titanium tetrachloride[J]. Metallurgical Materials Transactions B 2001, 32: 389-293. [9] ZHANG W S, ZHU Z W, CHENG C Y. A literature review of titanium metallurgical processes[J]. Hydrometallurgy, 2011,108(3):177-188. [10] KAHN J A. Non-rutile feedstocks for the production of titanium[J]. JOM, 1984,36(7):33-38. doi: 10.1007/BF03338498 [11] CHEN Q, KASOMO R M, LI H Q, et al. Froth flotation of rutile-An overview[J]. Minerals Engineering, 2021,163:106797. doi: 10.1016/j.mineng.2021.106797 [12] LI Z, CHEN C X. Development status of global titanium resources industry[J]. Acta Geoscientica Sinica, 2021,42(2):245-250. (李政, 陈从喜. 全球钛资源行业发展现状[J]. 地球学报, 2021,42(2):245-250. doi: 10.3975/cagsb.2020.102001LI Z, CHEN C X. Development status of global titanium resources industry[J]. Acta Geoscientica Sinica, 2021, 42(2): 245-250. doi: 10.3975/cagsb.2020.102001 [13] HOU X L, CHEN F, ZHENG F Q, et al. Research status of granulation technology process of fine-grade rich titanium material[J]. Multipurpose Utilization of Mineral Resources, 2022(4):100-105. (侯晓磊, 陈凤, 郑富强, 等. 细粒富钛料制粒工艺技术研究现状[J]. 矿产综合利用, 2022(4):100-105. doi: 10.3969/j.issn.1000-6532.2022.04.018HOU X L, CHEN F, ZHENG F Q, et al. Research status of granulation technology process of fine-grade rich titanium material[J]. Multipurpose Utilization of Mineral Resources, 2022(4): 100-105. doi: 10.3969/j.issn.1000-6532.2022.04.018 [14] WANG H P. Design and optimization of fluidized reactor adapting to fine-grade rich titanium material[D]. Chongqing: Chongqing University, 2018. (王海鹏. 细粒级钛原料循环流态化工艺的模型实验及温度效应研究[D]. 重庆:重庆大学, 2018.WANG H P. Design and optimization of fluidized reactor adapting to fine-grade rich titanium material[D]. Chongqing: Chongqing University, 2018. [15] CHEN X L, ZHOU X W, GAN M, et al. Study on the fluidized bed granulation of fine-grained rutile concentrate[J]. Powder Technology, 2017,315:53-59. doi: 10.1016/j.powtec.2017.03.036 [16] YE E D, MIAO H J, CHENG X Z, et al. Fine-grained synthetic rutile pelletizing binding agent and its method of use, CN105271390B [P/OL]. (叶恩东, 缪辉俊, 程晓哲, 等. 细粒级人造金红石造粒结合剂及其使用方法, 中国: 105271390B [P/OL].YE E D, MIAO H J, CHENG X Z, et al. Fine-grained synthetic rutile pelletizing binding agent and its method of use, CN105271390B [P/OL]. [17] CHEN Z C, LU P, WANG J X, et al. A fine-grained titanium raw material agglomeration method, CN102776365A [P/OL]. (陈祝春, 陆平, 王建鑫, 等. 一种细粒级钛原料的团粒方法, CN102776365A [P/OL].CHEN Z C, LU P, WANG J X, et al. A fine-grained titanium raw material agglomeration method, CN102776365A [P/OL]. [18] JIANG X X, JIANG W, WANG S D, et al. A method of fine-grained titanium-rich material granulation, CN106319246B [P/OL]. (蒋训雄, 蒋伟, 汪胜东, 等. 细粒级富钛料造粒方法, CN106319246B [P/OL].JIANG X X, JIANG W, WANG S D, et al. A method of fine-grained titanium-rich material granulation, CN106319246B [P/OL]. [19] LIU X H, MING C L, LI L, et al. Experimental study on granulation of fine titanium-rich materials[J]. Ferro-Alloys, 2019,50(6):30-34. (刘祥海, 明崇伦, 李露, 等. 细粒级富钛料造粒试验研究[J]. 铁合金, 2019,50(6):30-34.LIU X H, MING C L, LI L, et al. Experimental study on granulation of fine titanium-rich materials[J]. Ferro-Alloys, 2019, 50(6): 30-34. [20] CHEN F, YE E D, GUO Y F, et al. A composite binder and a granulation method used for granulation of fine-grained titanium raw material, CN202411201665.9 [P/OL] (陈凤, 叶恩东, 郭宇峰, 等. 一种用于细粒富钛料制粒的复合粘结剂、制粒方法, CN202411201665.9 [P/OL].CHEN F, YE E D, GUO Y F, et al. A composite binder and a granulation method used for granulation of fine-grained titanium raw material, CN202411201665.9 [P/OL] [21] LI L, ZHU F X, DENG P, et al. Behavior of magnesium impurity during carbochlorination of magnesium-bearing titanium slag in chloride media[J]. Journal of Materials Research Technology, 2021,13:204-215. doi: 10.1016/j.jmrt.2021.04.072 -

下载:

下载: