Research on hot spinning and pressure forming technology of TC4 titanium alloy gas cylinders

-

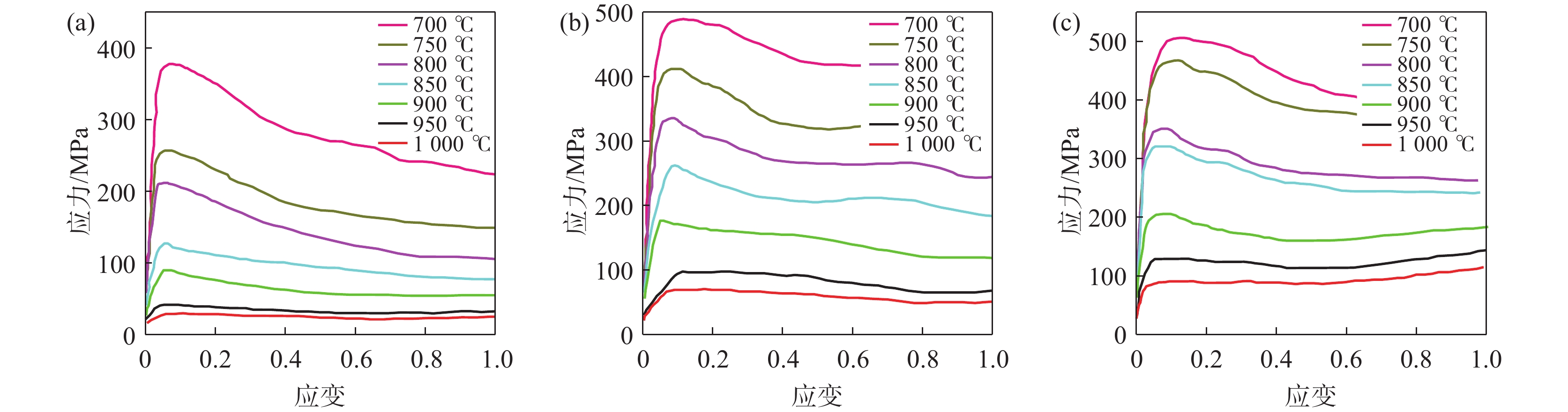

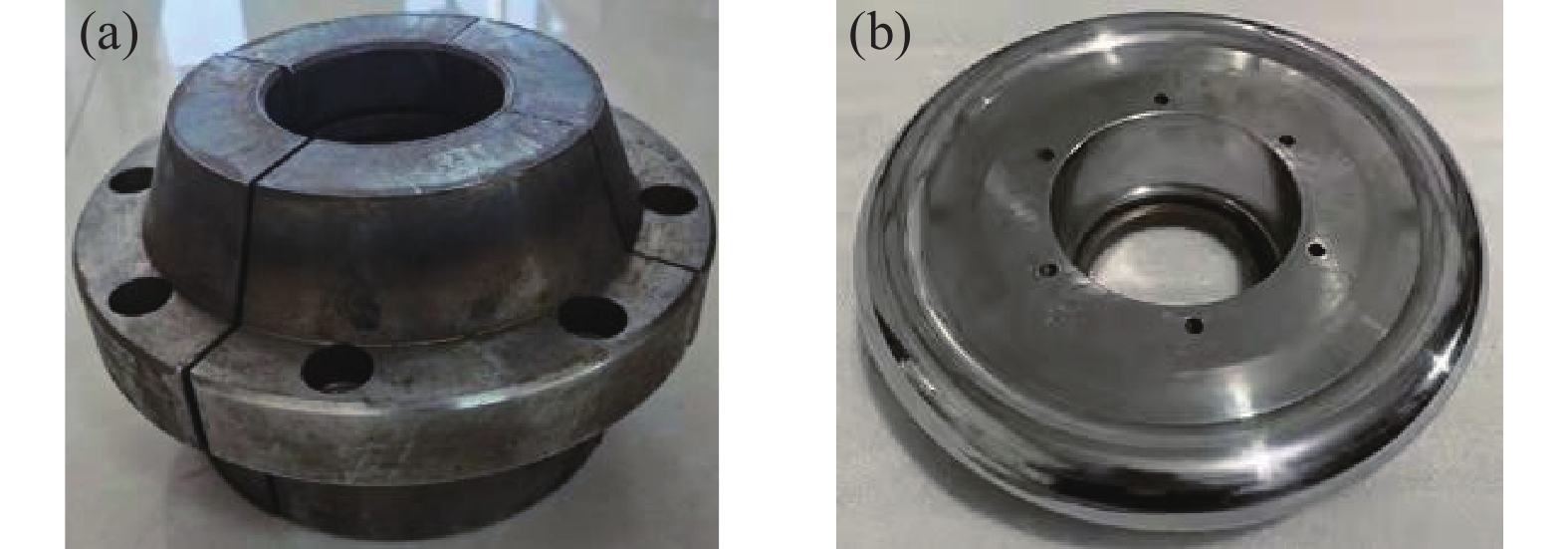

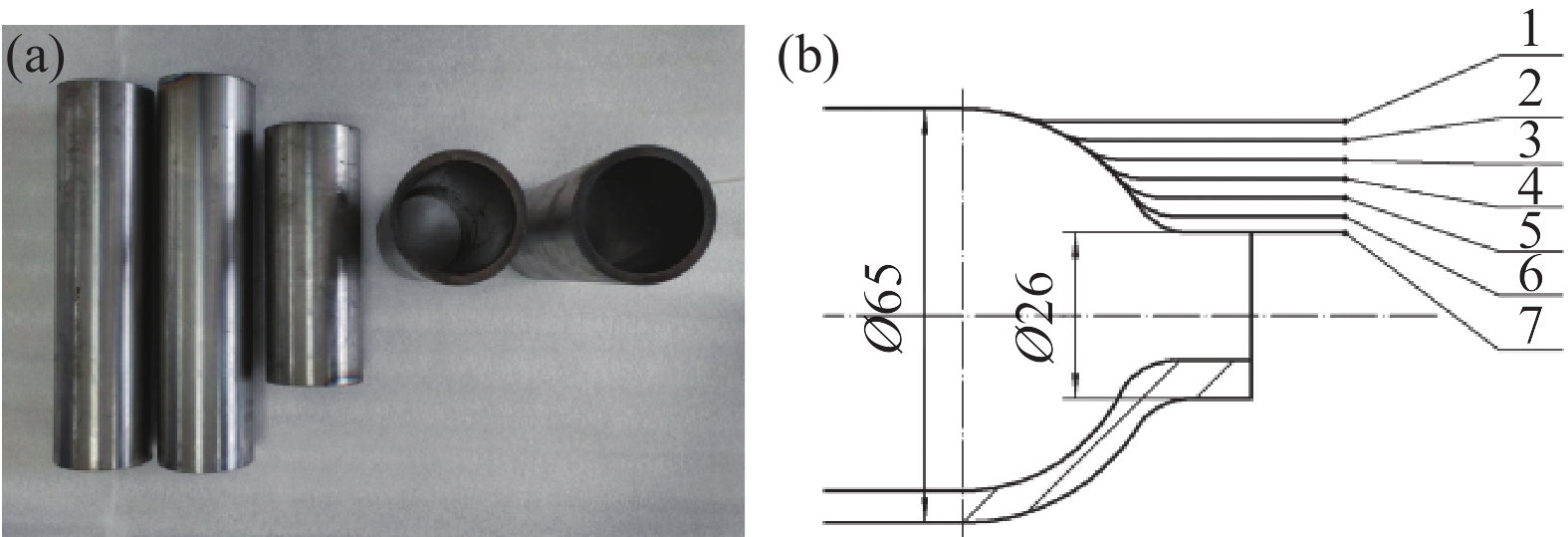

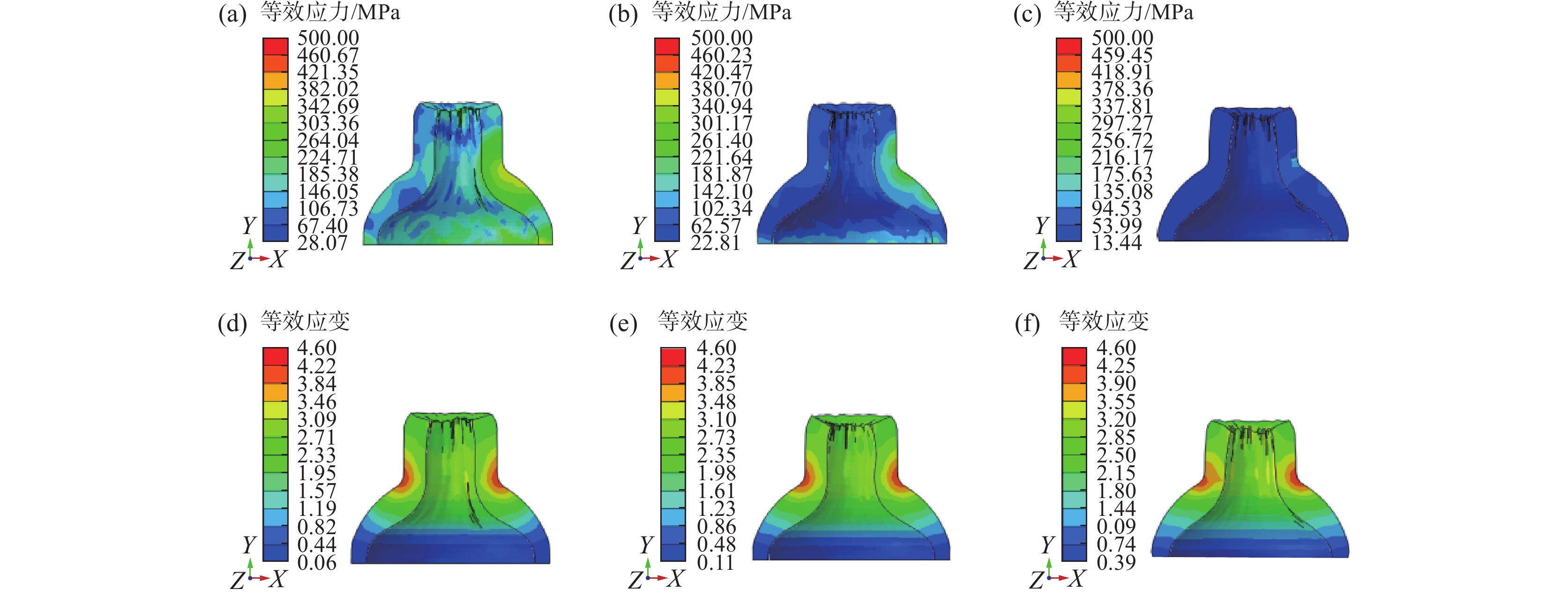

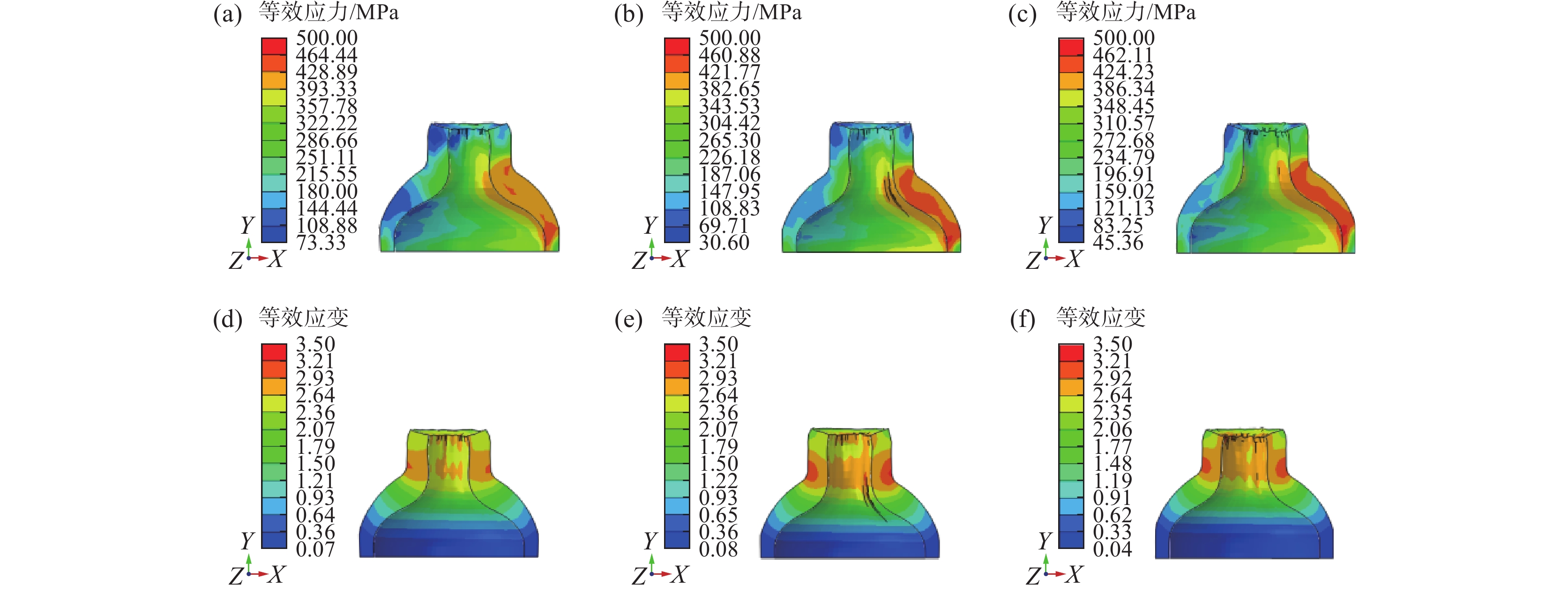

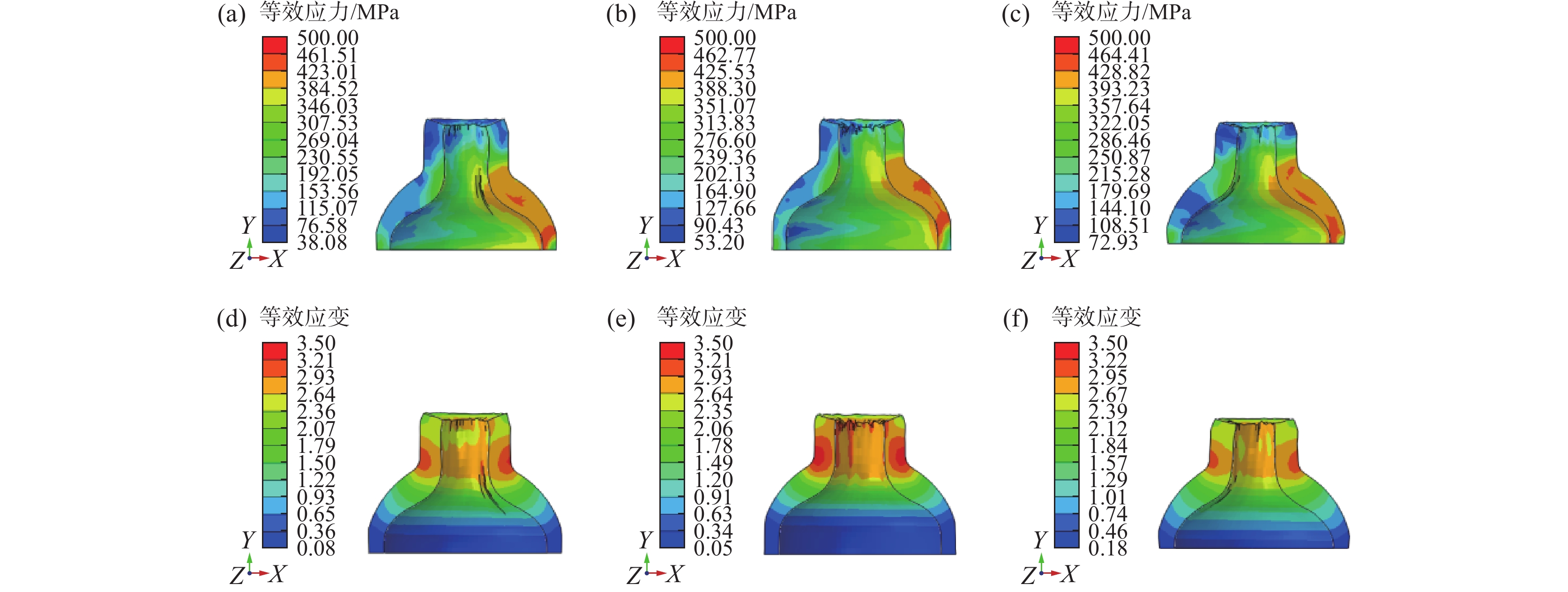

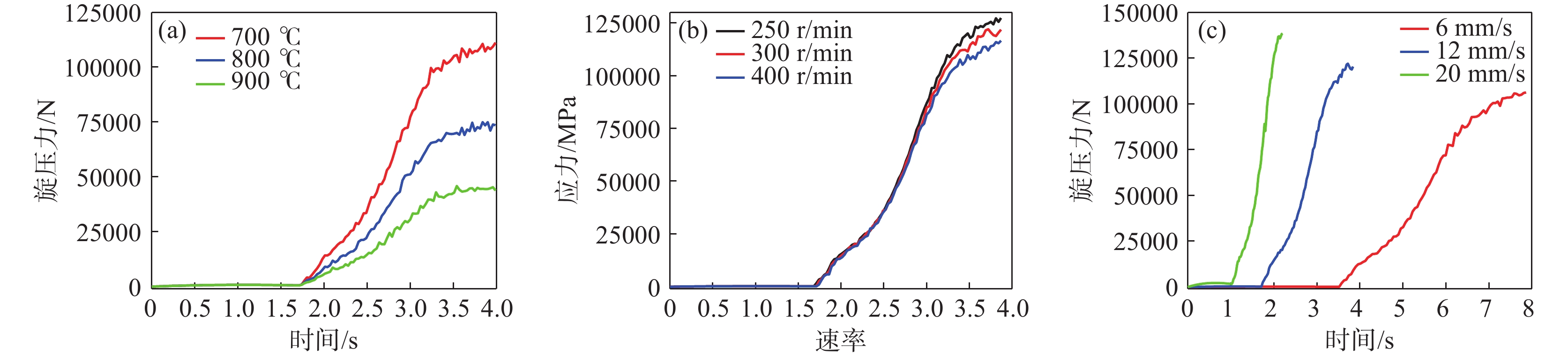

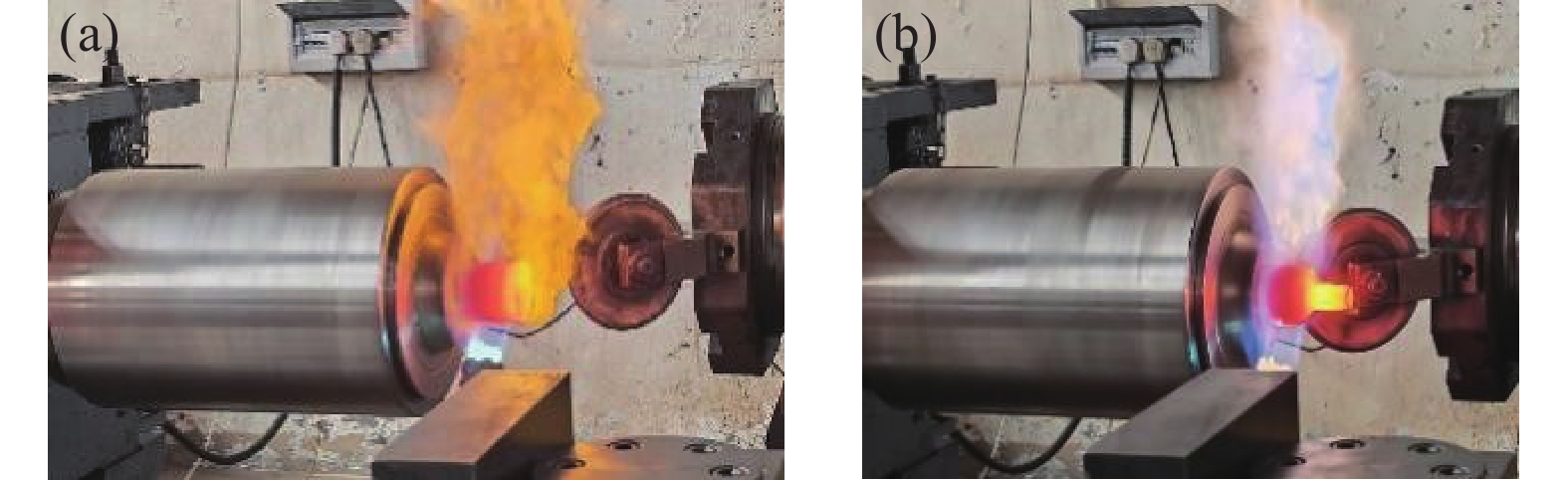

摘要: 通过数值仿真方法构建了TC4钛合金气瓶热旋压成形的数值仿真模型,并通过试验验证了该模型的可靠性。在热模拟试验中,以0.1、1、10 s−1三种应变速率为条件,详细探究了TC4材料在700~

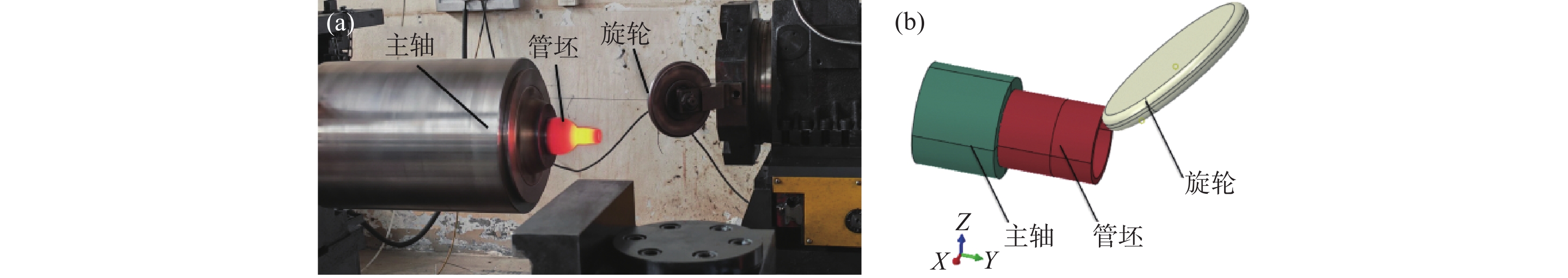

1000 ℃下的流变应力分布。综合数值仿真分析,深入研究了成形温度、主轴转速、进给速度等关键工艺参数对TC4钛合金成形的影响,并最终制定了气瓶热旋压成形工艺。通过多道次TC4钛合金热旋压成形试验,进一步验证了所提出工艺的可行性,为TC4钛合金气瓶的制造提供了科学而可行的技术路线。Abstract: This study employs numerical simulation methods to construct a simulation model of the hot spinning and pressure forming of TC4 titanium alloy gas cylinders, and the reliability of the model is verified through experimental validation. In thermal simulation experiments conducted at three strain rates of 0.1, 1 s−1 and 10 s−1, the rheological stress distribution of TC4 material at temperatures ranging from 700 ℃ to1000 ℃ is extensively investigated. Through comprehensive numerical simulation analysis, the study delves into the influence of key process parameters such as forming temperature, spindle speed, and feed rate on the shaping of TC4 titanium alloy. Ultimately, a thermal spinning and pressure forming process for gas cylinders is formulated. The feasibility of the proposed process is further validated through multiple iterations of TC4 titanium alloy hot spinning and pressure forming experiments. This research provides a scientifically sound and viable technological pathway for the manufacturing of TC4 titanium alloy gas cylinders.-

Key words:

- spinning and pressure forming /

- TC4 /

- numerical simulation /

- titanium alloy

-

表 1 TC4材料力学性能

Table 1. Mechanical properties of TC4

屈服强度/MPa 抗拉强度/MPa 伸长率/% 泊松比 弹性模量/MPa 密度/(t·mm−3) 928 1103 15.5 0.34 110000 4.5×10−9 表 2 TC4钛合金气瓶热旋压成形工艺参数

Table 2. Process Parameters for Hot Spinning and Pressure Forming of TC4 Titanium Alloy Gas Cylinders

主轴转速/(r·min−1) 进给道次/次 加热方式 进给速度/(mm·s−1) 道次进给量/mm 加热温度/℃ 250~400 7 火焰 5~8 2 700~900 -

[1] FENG Y Q, JIA S X, WANG W Q, et al. Development of TC4 ELI titanium alloy hemisphere shell for manned submersible[J]. Titanium Industry Progress, 2016,33(1):19-22. (冯雅奇, 贾栓孝, 王韦琪, 等. 深潜器载人舱用TC4 ELI钛合金半球壳的研制[J]. 钛工业进展, 2016,33(1):19-22.FENG Y Q, JIA S X, WANG W Q, et al. Development of TC4 ELI titanium alloy hemisphere shell for manned submersible[J]. Titanium Industry Progress, 2016, 33(1): 19-22. [2] LI J. Design and simulation of 40MPa high pressure gas bottle made of TC4[D]. Huazhong University of Science & Technology, 2005. (李杰. 40MPa钛合金高压气瓶的设计及仿真[D]. 华中科技大学, 2005.LI J. Design and simulation of 40MPa high pressure gas bottle made of TC4[D]. Huazhong University of Science & Technology, 2005. [3] MENG X J, SHI J. Application of titanium alloys for naval vessels[J]. Titanium Industry Progress, 2003,20(4):23-26. (孟祥军, 时锦. 漫谈钛合金在舰船上的应用[J]. 钛工业进展, 2003,20(4):23-26. doi: 10.3969/j.issn.1009-9964.2003.04.006MENG X J, SHI J. Application of titanium alloys for naval vessels[J]. Titanium Industry Progress, 2003, 20(4): 23-26. doi: 10.3969/j.issn.1009-9964.2003.04.006 [4] QIN P, LI Z Q, WANG F F. Automatic argon arc welding process for titanium alloy cylinders used in a certain type of missile[J]. Welding Technology, 2012,41(11):27-29. (秦平, 李中强, 王方方. 某型导弹用钛合金气瓶自动氩弧焊工艺[J]. 焊接技术, 2012,41(11):27-29. doi: 10.3969/j.issn.1002-025X.2012.11.008QIN P, LI Z Q, WANG F F. Automatic argon arc welding process for titanium alloy cylinders used in a certain type of missile[J]. Welding Technology, 2012, 41(11): 27-29. doi: 10.3969/j.issn.1002-025X.2012.11.008 [5] LÜ X Y, HOU H L, ZHANG S H, et al. 3D elastic plastic FEM simulation of TC4 alloy flow forming[J]. Forging & Stamping Technology, 2005,30(6):38-41. (吕昕宇, 侯红亮, 张士宏, 等. TC4合金流动旋压三维弹塑性有限元模拟[J]. 锻压技术, 2005,30(6):38-41. doi: 10.3969/j.issn.1000-3940.2005.06.013LÜ X Y, HOU H L, ZHANG S H, et al. 3D elastic plastic FEM simulation of TC4 alloy flow forming[J]. Forging & Stamping Technology, 2005, 30(6): 38-41. doi: 10.3969/j.issn.1000-3940.2005.06.013 [6] WANG F C, YU Z D, LI X K, et al. Experimental research on hot-spinning of TC4 titanium alloy tube[J]. Die Mould Manufacture, 2017,17(12):1040-1042. (汪发春, 于志德, 李兴凯, 等. TC4钛合金筒形件的热旋成形工艺研究[J]. 模具制造, 2017,17(12):1040-1042. doi: 10.3969/j.issn.1671-3508.2017.12.016WANG F C, YU Z D, LI X K, et al. Experimental research on hot-spinning of TC4 titanium alloy tube[J]. Die Mould Manufacture, 2017, 17(12): 1040-1042. doi: 10.3969/j.issn.1671-3508.2017.12.016 [7] LI Q J, LÜ H J, WANG Q, et al. FEM numerical simulation of spinning processing for thin TC4 alloy workpiece with curvilinear shape[J]. Journal of Tiangong University, 2008,27(2):61-65. (李启军, 吕宏军, 王琪, 等. 薄壁曲母线TC4钛合金构件热旋模拟与试验研究[J]. 天津工业大学学报, 2008,27(2):61-65. doi: 10.3969/j.issn.1671-024X.2008.02.017LI Q J, LÜ H J, WANG Q, et al. FEM numerical simulation of spinning processing for thin TC4 alloy workpiece with curvilinear shape[J]. Journal of Tiangong University, 2008, 27(2): 61-65. doi: 10.3969/j.issn.1671-024X.2008.02.017 [8] LI Q J, FAN K C, WANG Q, et al. Factors influencing spinforming of large-diameter, thin-walled TC4 alloy tube[J]. Aerospace Materials & Technology, 2012,42(1):86-88. (李启军, 范开春, 王琪, 等. 大尺寸薄壁钛合金筒体旋压成形质量影响因素[J]. 宇航材料工艺, 2012,42(1):86-88. doi: 10.3969/j.issn.1007-2330.2012.01.019LI Q J, FAN K C, WANG Q, et al. Factors influencing spinforming of large-diameter, thin-walled TC4 alloy tube[J]. Aerospace Materials & Technology, 2012, 42(1): 86-88. doi: 10.3969/j.issn.1007-2330.2012.01.019 [9] ZHAO G W. Research on spinning forming technology of spherical gas cylinder[D]. Shenyang: Northeastern University, 2019. (赵国伟. 某型号内胆旋压成型技术研究[D]. 沈阳:东北大学, 2019.ZHAO G W. Research on spinning forming technology of spherical gas cylinder[D]. Shenyang: Northeastern University, 2019. [10] ZHANG M C. The FEM simulation on forming process of high pressure vessel of titanium alloy[D]. Xi’an: Northwestern Polytechnical University, 2003. (张敏聪. 钛合金高压容器成形过程的有限元模拟[D]. 西安:西北工业大学, 2003.ZHANG M C. The FEM simulation on forming process of high pressure vessel of titanium alloy[D]. Xi’an: Northwestern Polytechnical University, 2003. [11] ABAQUS Inc. ABAQUS analysis user’s manual[M]. Version 6.12, Providence: ABAQUS Inc. , 2010. [12] GUO H F, SUN T, LI J L. Tribological properties of TC4 alloy under different friction conditions[J]. Hot Working Technology, 2014,43(10):40-43. (郭华锋, 孙涛, 李菊丽. 不同摩擦条件下TC4钛合金摩擦学性能研究[J]. 热加工工艺, 2014,43(10):40-43.GUO H F, SUN T, LI J L. Tribological properties of TC4 alloy under different friction conditions[J]. Hot Working Technology, 2014, 43(10): 40-43. -

下载:

下载: