Effect of different scrap titanium on microstructure and mechanical properties of TC4 alloy ingots

-

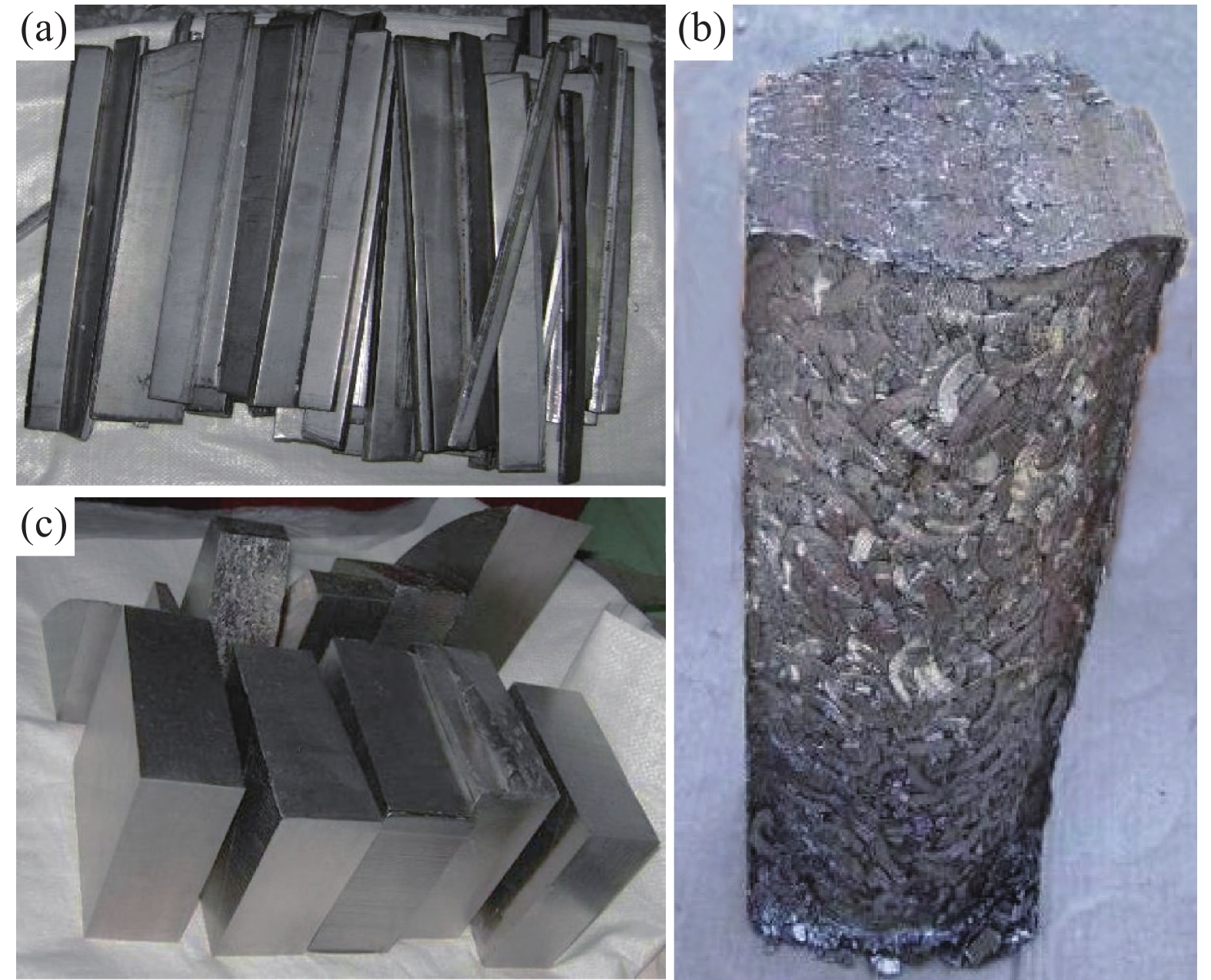

摘要: 采用钛板切边、钛屑、钛坯切头及高纯原料制备了TC4合金铸锭,从成分、微观组织、硬度等方面系统分析了不同类型碎钛料对离心铸造技术的适用性。结果表明,四类铸锭中N、O、H等杂质元素的含量均符合GB/T6614−2014要求;但是,由于碎钛料在不同的热加工过程中会发生物理和化学变化,从而对合金凝固过程产生重要影响,使铸锭微观组织和性能存在一定差异。四类铸锭的硬度均满足GB/T6614−2014要求,这进一步证实了离心铸造技术可以较好地适用于碎钛料回收。热处理后,4#合金的微观组织均匀化程度显著改善,异常组织区域完全消失。真空气淬工艺Ⅰ处理后试样的硬度值(HRC)最大,为32.5。Abstract: In this study, TC4 alloy ingots were prepared using surplus titanium plate, titanium chip, surplus titanium billet and high-purity raw material. The suitability of centrifugal casting technology to different scrap titanium was systematically analyzed in terms of composition, microstructure and hardness. The results show that the contents of N, O and H elements in the four ingots satisfy the requirements of GB/T6614-2014. However, due to the physical and chemical reactions that occur in scrap titanium materials during different hot forming processes, they can have an important influence on the solidification process of TC4 alloys, resulting in some differences in microstructural and mechanical properties of ingots. In addition, the hardness of the four ingots meets the requirements of GB/T6614-2014, which further confirms that the centrifugal casting technology can be applied to the recovery of scrap titanium. After heat treatment, the microstructure homogenization of 4# alloy was significantly improved, and the abnormal areas disappeared. The maximum hardness value of 32.5 HRC was obtained for the samples treated by vacuum argon quenching process I.

-

Key words:

- scrap titanium /

- TC4 alloy /

- microstructure /

- hardness /

- vacuum heat treatment

-

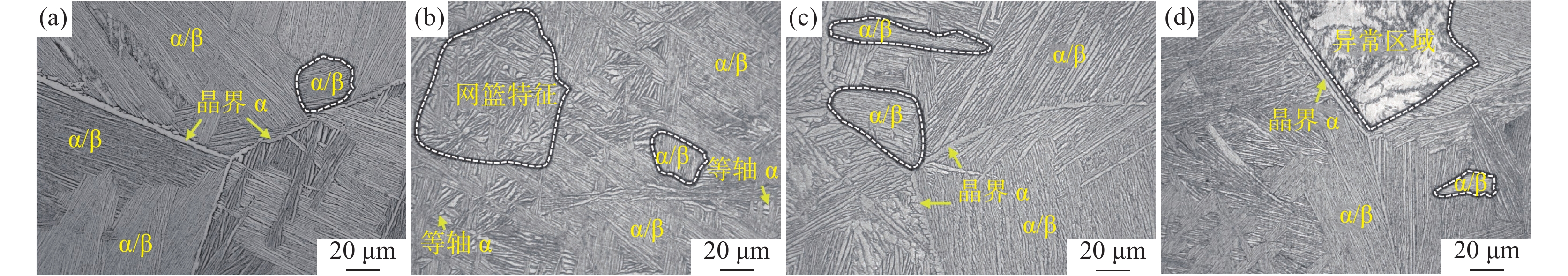

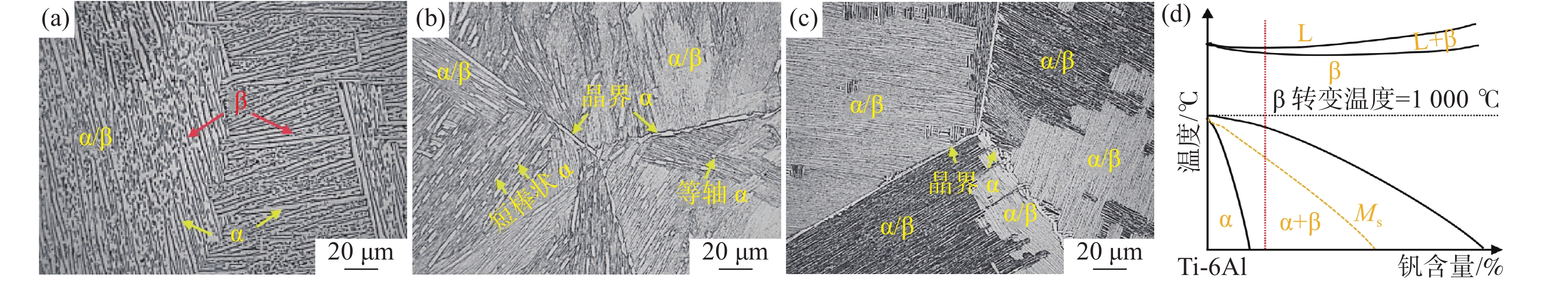

图 3 热处理态4#合金的微观组织及TC4合金的相图

(a) 真空等温退火; (b) 真空气淬工艺Ⅰ处理; (c) 真空气淬工艺Ⅱ处理;(d) TC4合金相图[13]

Figure 3. Microstructure of 4# alloy and the phase diagram of TC4 alloy

表 1 冶炼原料添加量

Table 1. Additions of raw materials

kg 合金 海绵钛 纯Al Al−47.5%V TA2板材切边 TA2车削屑 TA2钛坯切头 1# 13.50 0.34 1.26 2# 0.34 1.26 13.51 3# 0.34 1.26 13.51 4# 0.34 1.26 13.51 表 2 不同碎钛料的成分

Table 2. Compositions of different scrap titanium

% 原料 Ti N O H 高纯原料 99.9070 0.0280 0.0620 0.0030 TA2板材切边 99.9190 0.0190 0.0590 0.0030 TA2车削屑 99.9100 0.0230 0.0650 0.0020 TA2钛坯切头 99.9070 0.0280 0.0620 0.0030 表 3 不同碎钛料制备的TC4合金铸锭成分

Table 3. Compositions of TC4 alloy ingots prepared from different scrap titanium

% 合金 原料 Al V N O H 1# 高纯原料 6.05 4.34 0.011 0.063 0.011 2# TA2板材切边 5.59 4.39 0.043 0.071 0.002 3# TA2车削屑 5.61 4.56 0.007 0.075 0.003 4# TA2钛坯切头 5.66 4.94 0.013 0.076 0.003 GB/T6614−2014 5.5~6.5 3.5~4.5 ≤0.05 ≤0.20 ≤0.015 表 4 不同碎钛料制备的TC4合金硬度取样检测结果

Table 4. Hardness of TC4 alloy prepared from different scrap titanium

合金 HRC1 HRC2 HRC3 HRC4 HRC5 平均值 1# 37.5 35.0 36.5 36.0 37.6 36.5 2# 29.7 29.6 31.8 29.2 31.8 30.4 3# 29.4 34.0 34.9 33.2 34.6 33.2 4# 29.3 33.1 32.8 31.6 31.4 31.6 GB/T6614−2014 ≤39.3 表 5 热处理态4#合金的硬度

Table 5. Hardness of heat-treated 4# alloy

合金 HRC1 HRC2 HRC3 HRC4 HRC5 平均值 真空退火 28.4 28.4 24.6 22.9 27.3 26.3 真空气淬工艺Ⅰ 31.2 30.0 33.6 35.1 32.5 32.5 真空气淬工艺Ⅱ 32.8 32.8 27.0 32.0 31.2 31.2 -

[1] HE T Z, CHEN Y Y. Influence of mold design on shrinkage porosity of Ti‐6Al‐4V alloy ingots[J]. Metals, 2022,12:2122. doi: 10.3390/met12122122 [2] CUI C X, HU B M, ZHAO L, et al. Ti-based alloy production technology, market prospects and industry development[J]. Materials & Design, 2011,32(3):1684-1691. [3] HOU Z Q, LI B H, FENG G W, et al. Development and application of Ti-based alloy casting technologies in the field of aerospace[J]. Aerospace Shanghai (Chinese & English), 2022,39(1):1-14. [4] FENG Q Y, TONG X W, WANG J, et al. Status quo and development tendency on the research of low cost titanium alloy[J]. Materials Reports, 2017,31:128-134. (冯秋元, 佟学文, 王俭, 等. 低成本钛合金研究现状与发展趋势[J]. 材料导报, 2017,31:128-134. doi: 10.11896/j.issn.1005-023X.2017.011.018FENG Q Y, TONG X W, WANG J, et al. Status quo and development tendency on the research of low cost titanium alloy[J]. Materials Reports, 2017, 31: 128-134. doi: 10.11896/j.issn.1005-023X.2017.011.018 [5] LI B B, PEI T, ZHANG Q, et al. Research on TC4 residual titanium recycling technology with the electron beam cold hearth melting with the power of 3600 kW[J]. Development and Application of Materials, 2020,35:48-52, 59. (李渤渤, 裴腾, 张强, 等. 3600 kW大功率ALD电子束冷床炉TC4碎钛回收工艺研究[J]. 材料开发与应用, 2020,35:48-52, 59.LI B B, PEI T, ZHANG Q, et al. Research on TC4 residual titanium recycling technology with the electron beam cold hearth melting with the power of 3600 kW[J]. Development and Application of Materials, 2020, 35: 48-52, 59. [6] HUANG D Y. Study on thermal deformation behavior and microstructure of TA1 prepared by EB furnace smelting residual titanium[D]. Kunming: Kunming University of Science and Technology, 2021. (黄东亚. EB炉熔炼碎钛制备的TA1热变形行为及组织研究[D]. 昆明: 昆明理工大学, 2021.HUANG D Y. Study on thermal deformation behavior and microstructure of TA1 prepared by EB furnace smelting residual titanium[D]. Kunming: Kunming University of Science and Technology, 2021. [7] YANG Y C. Ways of reducing the cost for titanium materials[J]. Aerospace Materials & Technology, 2004,34:5-7. (杨遇春. 钛材降低成本的途径[J]. 宇航材料工艺, 2004,34:5-7. doi: 10.3969/j.issn.1007-2330.2004.03.002YANG Y C. Ways of reducing the cost for titanium materials[J]. Aerospace Materials & Technology, 2004, 34: 5-7. doi: 10.3969/j.issn.1007-2330.2004.03.002 [8] LI J, WU Y J, FROES F H. New cost Effective titanium powders footnote[J]. Materials Technology, 2002,17(3):143-147. doi: 10.1080/10667857.2002.11752971 [9] GUO W. South Korea develops residual titanium recovery technology[J]. Titanium Industry Progress, 2014,1:5. (郭薇. 韩国开发出碎钛回收技术[J]. 钛工业进展, 2014,1:5.GUO W. South Korea develops residual titanium recovery technology[J]. Titanium Industry Progress, 2014, 1: 5. [10] ZHANG T. The establishment of a titanium alloy recycling plant in Europe reduces dependence on imported titanium alloys[J]. Iron Steel Vanadium Titanium, 2016,37(5):79. (张涛. 欧洲建立钛合金回收厂减少对进口钛合金的依赖[J]. 钢铁钒钛, 2016,37(5):79.ZHANG T. The establishment of a titanium alloy recycling plant in Europe reduces dependence on imported titanium alloys[J]. Iron Steel Vanadium Titanium, 2016, 37(5): 79. [11] HUANG Y G. The actuality of callback and reutilization of titanium and its alloy wastes in China[J]. Titanium Industry Progress, 2007,24:1-3. (黄永光. 我国钛废料回收利用现状[J]. 钛工业进展, 2007,24:1-3 doi: 10.3969/j.issn.1009-9964.2007.02.001HUANG Y G. The actuality of callback and reutilization of titanium and its alloy wastes in China[J]. Titanium Industry Progress, 2007, 24: 1-3. doi: 10.3969/j.issn.1009-9964.2007.02.001 [12] YUN P F, LIAO Q, WU H, et al. Chemical constituents of residual material recovered ingot TC4[J]. Mechanical Engineering & Automation, 2015,3:128-129, 131. (贠鹏飞, 廖强, 吴华, 等. 碎钛回收TC4铸锭成分研究[J]. 机械工程与自动化, 2015,3:128-129, 131. doi: 10.3969/j.issn.1672-6413.2015.06.054YUN P F, LIAO Q, WU H, et al. Chemical constituents of residual material recovered ingot TC4[J]. Mechanical Engineering & Automation, 2015, 3: 128-129, 131. doi: 10.3969/j.issn.1672-6413.2015.06.054 [13] ZHANG S Y. Investigation of solidification behavior and microstructure evolution in ZTC4 alloys[D]. Xi’an: Northwestern Polytechnical University, 2016. (张守银. ZTC4钛合金凝固行为及组织演化研究[D]. 西安: 西北工业大学, 2016.ZHANG S Y. Investigation of solidification behavior and microstructure evolution in ZTC4 alloys[D]. Xi’an: Northwestern Polytechnical University, 2016. [14] LIU L, KANG D D, WANG G J. Effect of melting process parameters on principal component uniformity of Ti6Al4V-0.15B titanium alloy[J]. World Nonferrous Metals, 2021,22:147-149. (刘丽, 康丹丹, 王高见. 熔炼工艺参数对Ti6Al4V-0.15B钛合金主成分均匀性的影响研究[J]. 世界有色金属, 2021,22:147-149.LIU L, KANG D D, WANG G J. Effect of melting process parameters on principal component uniformity of Ti6Al4V-0.15B titanium alloy[J]. World Nonferrous Metals, 2021, 22: 147-149. [15] WANG G J, LIU L, KANG D D. Effect of melting parameters on chemical composition of Ti6Al4V-0.15B titanium alloy[J]. Nonferrous Metals Processing, 2022,51(5):30-33. (王高见, 刘丽, 康丹丹. 熔炼工艺参数对Ti6Al4V-0.15B钛合金化学成分的影响研究[J]. 有色金属加工, 2022,51(5):30-33. doi: 10.3969/j.issn.1671-6795.2022.05.008WANG G J, LIU L, KANG D D. Effect of melting parameters on chemical composition of Ti6Al4V-0.15B titanium alloy[J]. Nonferrous Metals Processing, 2022, 51(5): 30-33. doi: 10.3969/j.issn.1671-6795.2022.05.008 [16] CABIBBO M, ZHEREBTSOV S, MIRONOV S, et al. Loss of coherency and interphase α/β angular deviation from the Burgers orientation relationship in a Ti-6Al-4V alloy compressed at 800 ℃[J]. Journal of Materials Science, 2012,48(3):1100-1110. [17] YANG J H. Research on deformation behavior and microstructure and mechanical properties of (TiB+TiC+Y2O3)/α-Ti composites[D]. Harbin: Harbin Institute of Technology, 2020. (杨建辉. (TiB+TiC+Y2O3)/α-Ti复合材料变形行为及组织性能研究[D]. 哈尔滨: 哈尔滨工业大学, 2020.YANG J H. Research on deformation behavior and microstructure and mechanical properties of (TiB+TiC+Y2O3)/α-Ti composites[D]. Harbin: Harbin Institute of Technology, 2020. [18] SU Y, KONG F T, YOU F H, et al. The high-temperature deformation behavior of a novel near-α titanium alloy and hot-forging based on the processing map[J]. Vacuum, 2020,173:109135. doi: 10.1016/j.vacuum.2019.109135 [19] WU J X, CHEN Y Y, DU Z M, et al. Enhancing the elevated temperature strength of titanium matrix composites through a novel (α + β) TRIPLEX heat treatment[J]. Materials Science & Engineering A, 2024,890:145884. [20] BHATTACHARYYA D, VISWANATHAN G B, Denkenberger R, et al. The role of crystallographic and geometrical relationships between α and β phases in an α/β titanium alloy[J]. Acta Materialia, 2003,51:4679-4691. doi: 10.1016/S1359-6454(03)00179-4 [21] BOHEMEN S M C V, KAMP A, PETROV R H, et al. Nucleation and variant selection of secondary α plates in a β Ti alloy[J] Acta Materialia, 2008, 56: 5907-5914. [22] LU K K, LI M N, ZHOU L P, et al. Study on bright speck of low power microstructure of TC4 titanium alloy bars[J]. Hot Working Technology, 2019,48:96-98. (卢凯凯, 李敏娜, 周立鹏, 等. TC4钛合金棒材低倍组织亮斑分析[J]. 热加工工艺, 2019,48:96-98.LU K K, LI M N, ZHOU L P, et al. Study on bright speck of low power microstructure of TC4 titanium alloy bars[J]. Hot Working Technology, 2019, 48: 96-98. [23] ZHANG J, WEN N, LIAO Q. Defect analysis of TC4 titanium alloy bar[J]. Special Steel Technology, 2014,20:15-18. (张杰, 文宁, 廖强. TC4钛合金棒材缺陷分析[J]. 特钢技术, 2014,20:15-18.ZHANG J, WEN N, LIAO Q. Defect analysis of TC4 titanium alloy bar[J]. Special Steel Technology, 2014, 20: 15-18. [24] LIU H Y. The effect of interstitial elements (H, N, O) on the microstructure and mechanical properties of the casting titanium alloy[D]. Beijing: China Academy of Machinery Science and Technology Group, 2008. (刘宏宇. 间隙元素(H、N、O)对铸造钛合金组织和力学性能的影响[D]. 北京: 机械科学研究总院, 2008.LIU H Y. The effect of interstitial elements (H, N, O) on the microstructure and mechanical properties of the casting titanium alloy[D]. Beijing: China Academy of Machinery Science and Technology Group, 2008. [25] FAN C L. On the effect of microstructure and interstitial element on the plasticity and toughness of near α titanium alloy at cryogenic temperature[D]. Xi’an: Xi’an University of Architecture and Technology, 2004. (范承亮. 显微组织和间隙元素对近α钛合金低温塑韧性的影响[D]. 西安: 西安建筑大学, 2004.FAN C L. On the effect of microstructure and interstitial element on the plasticity and toughness of near α titanium alloy at cryogenic temperature[D]. Xi’an: Xi’an University of Architecture and Technology, 2004. [26] AHMAD M A, JABIR M, JOHARI N, et al. The effect of impurities elements on titanium alloy (Ti-6Al-4V) MIM sintered part properties[J]. Aip Conference Proceedings, 2017,1901:040007. [27] OMIDBAKHSH F, EBRAHIMI A R, MOUSAVI S H, et al. Effect of oxygen boost diffussion treatment on fatigue behavior of Ti-4A1-2V alloy[J]. Surface & Coating Technology, 2011,205(8-9):2954-2963. [28] SENEMMAR A, CHRIST H J. Effect of hydrogen on the mechanical properties of the β titanium alloy Timetal® 21S[J]. International Journal of Materials Research, 2002,93:614-919. [29] CHU C L, WU S K. Ion nitriding of titanium aluminides with 25−53 at. % Al: nitriding parameters and microstructure characterization[J]. Surface & Coatings Technology, 1996,78:211-218. [30] MA F C, ZHOU J J, LIU P, et al. Strengthening effects of TiC particles and microstructure refinement in in situ TiC-reinforced Ti matrix composites[J]. Materials Characterization, 2017,127:27-34. doi: 10.1016/j.matchar.2017.02.004 [31] LU J H, MIN Y A, YUE J J, et al. Uniformity of properties and cracking mechanism of large-scale aluminum alloy casting die[J]. Transactions of Materialsand Heat Treatment, 2019,40:62-69. (陆佳晖, 闵永安, 岳加佳, 等. 大型铝合金压铸模的性能均匀性与开裂机理[J]. 材料热处理学报, 2019,40:62-69.LU J H, MIN Y A, YUE J J, et al. Uniformity of properties and cracking mechanism of large-scale aluminum alloy casting die[J]. Transactions of Materialsand Heat Treatment, 2019, 40: 62-69. [32] LIU X M, SONG X Y, WANG K, et al. Inhomogeneous distribution of grain size and hardness of large size cemented carbides bulks prepared by SPS[J]. Chinese Journal of Stereology and Image Analysis, 2011,16:137-140. (刘雪梅, 宋晓艳, 王凯, 等. SPS制备的大尺寸WC-Co硬质合金试样晶粒尺寸与硬度的不均匀性研究[J]. 中国体视学与图像分析, 2011,16:137-140.LIU X M, SONG X Y, WANG K, et al. Inhomogeneous distribution of grain size and hardness of large size cemented carbides bulks prepared by SPS[J]. Chinese Journal of Stereology and Image Analysis, 2011, 16: 137-140. [33] ZHENG Z Z, KONG F T, WANG X P, et al. Microstructure evolution, mechanical properties and strengthening mechanism of titanium matrix composite sheets[J]. Materials Science & Engineering A, 2022,860:144256. -

下载:

下载: