Thermodynamic calculation of sulfide and nitride precipitation in high grade non-oriented silicon steel

-

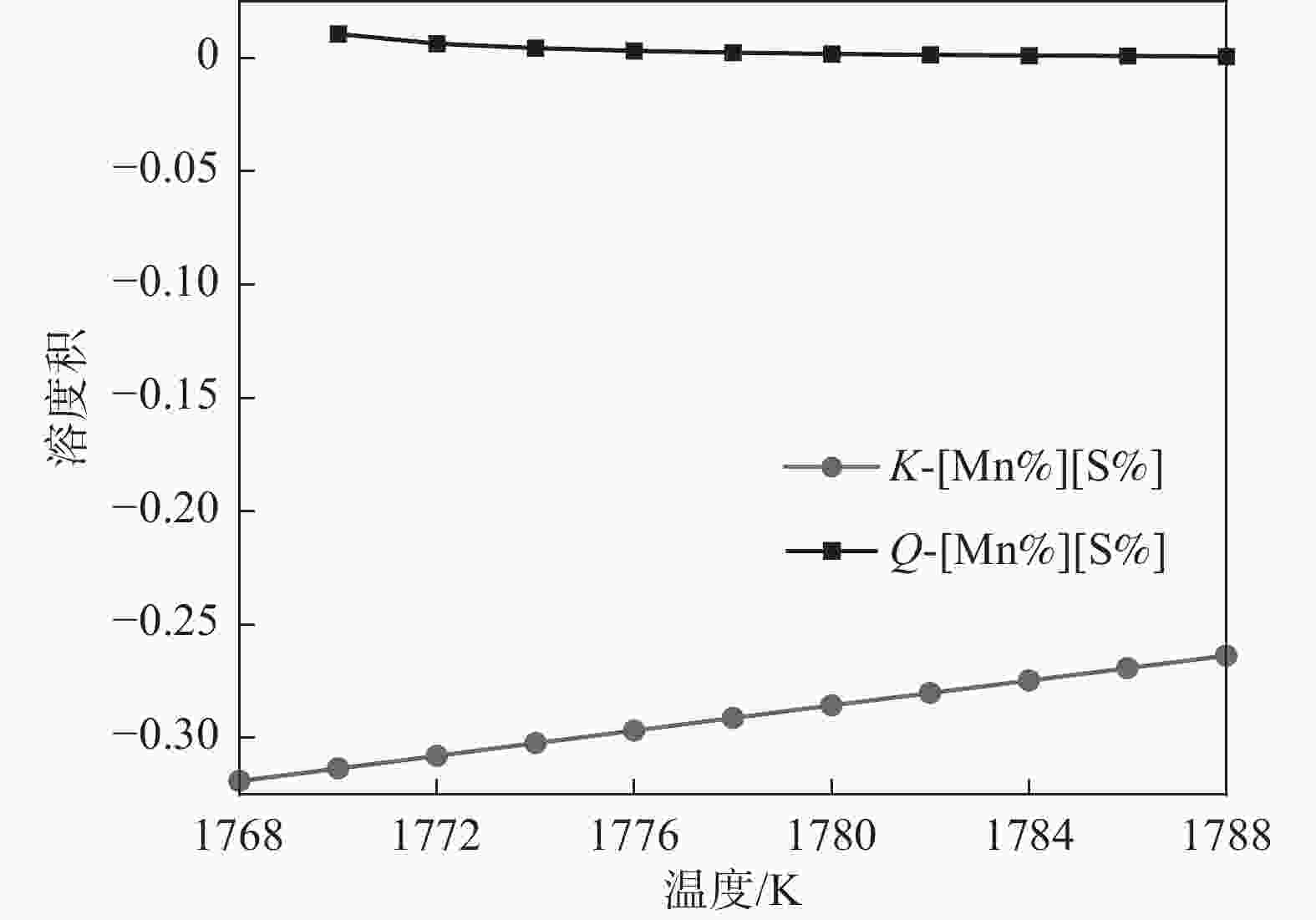

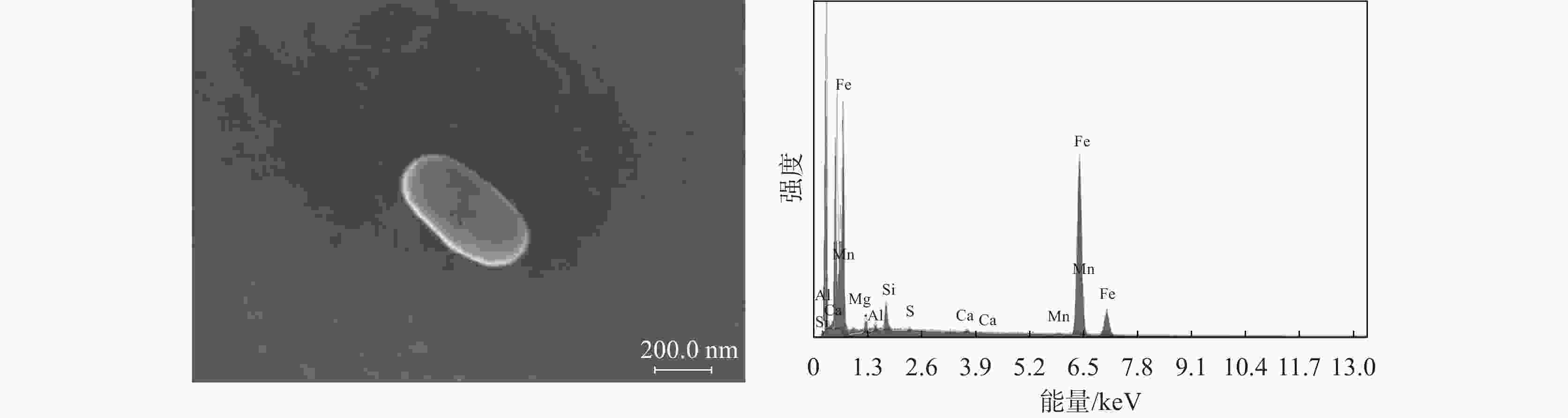

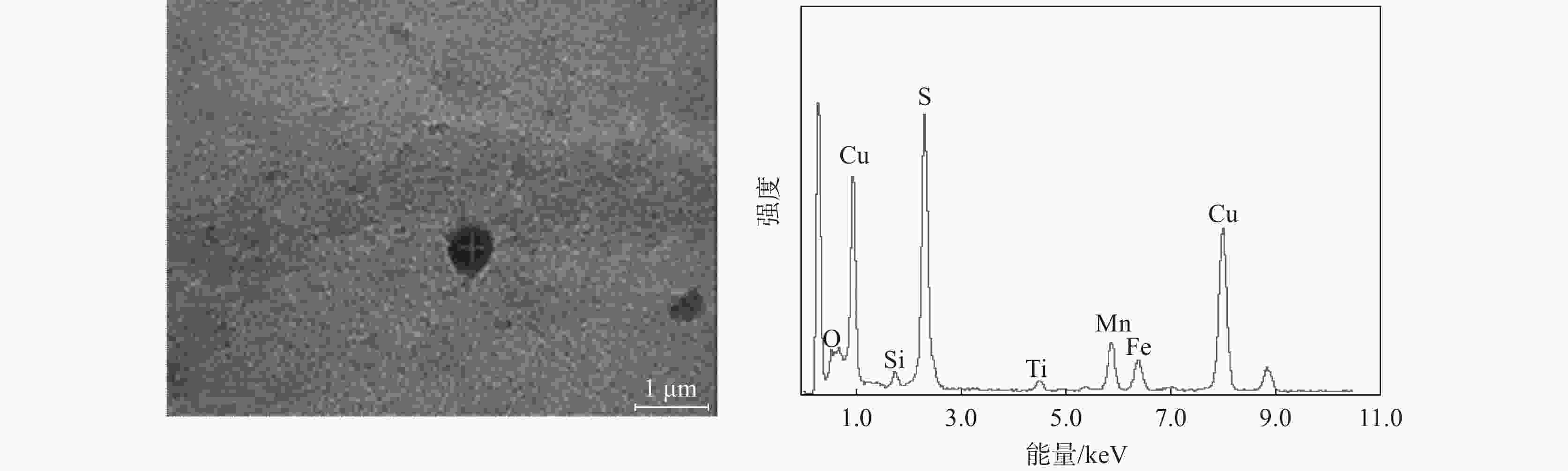

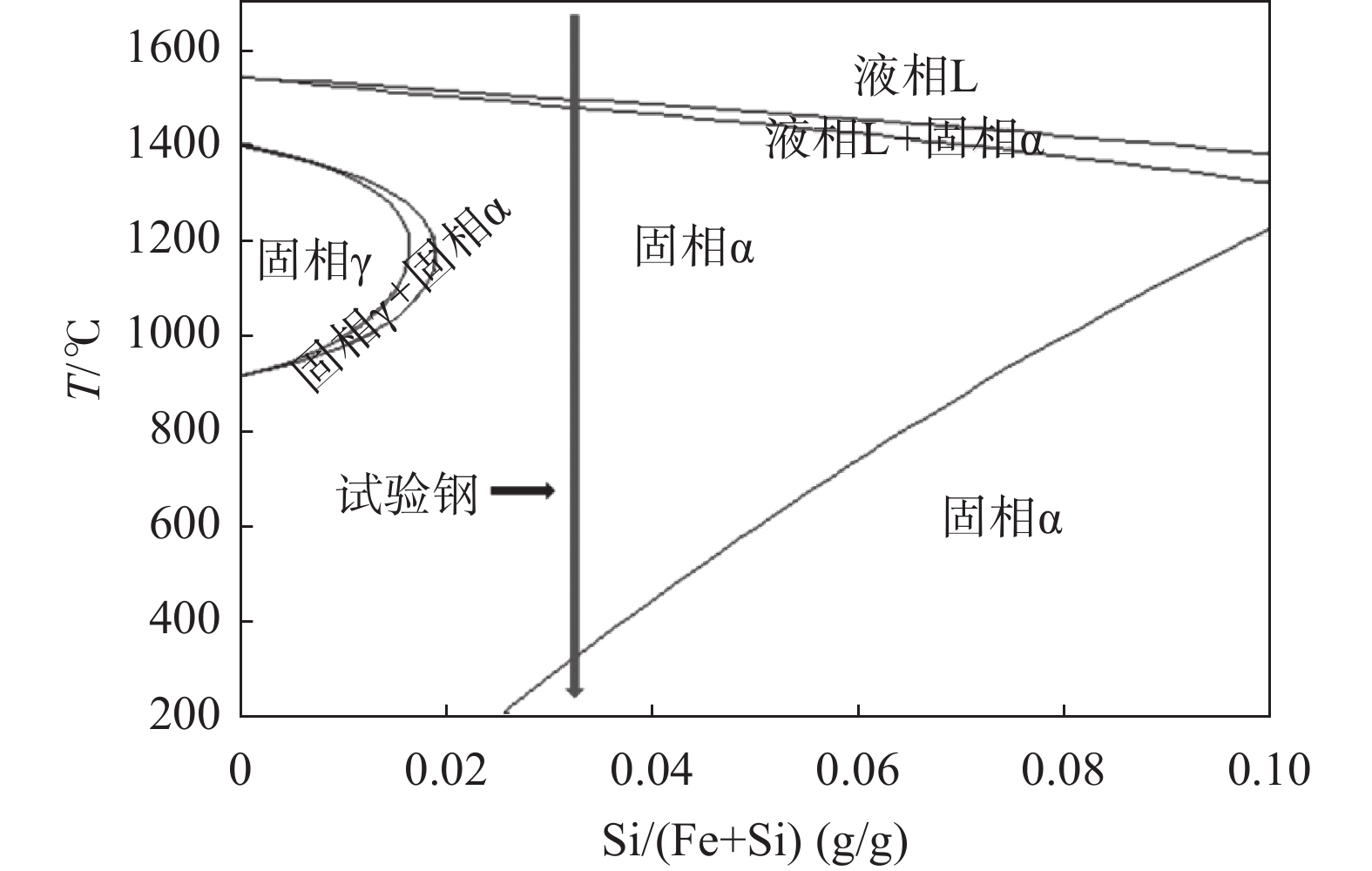

摘要: 通过对高牌号无取向电工钢 50W350硫化物、氮化物的热力学计算,获得了析出物的平衡浓度关系。液相线温度以下,AlN在

1700 ~1788 K温度区间析出,TiN的析出温度区间为1588 ~1788 K,MnS的析出温度区间在1768 ~1788 K范围内,Cu2S的析出温度范围为1420 ~1768 K,并通过实际检测,证实了各温度区间析出物的存在。Abstract: The equilibrium concentration relationship of precipitates was obtained by thermodynamic calculation of sulfide and nitride of the high grade non-oriented electrical steel 50W350. Below the liquidus temperature, AlN precipitates in the range of 1 700-1 788 K, TiN in the range of 1 588-1 788 K, MnS in the range of 1 768-1 788 K, Cu2S in the range of 1 420-1 768 K. The existence of precipitates in each temperature range has been confirmed through detection.-

Key words:

- non-oriented silicon steel /

- liquidus temperature /

- solidus temperature /

- sulfide /

- nitride /

- solubility product

-

化合物 K Q 相 AlN 6.334- 14069 /T[%Al][%N] 液相 MnS 4.63- 8750 /T[%Mn][%S] 液相 AlN 5.37- 14640 /T[%Al][%N] δ相 AlN 2.27- 10590 /T[%Mn][%S] δ相 Cu2S 26.31- 44791 /T[%Cu]2[%S] 液相+δ相 TiN 5.56- 17025 /T[%Ti][%N] 液相+δ相 表 2 试验钢的主要化学成分

Table 2. Main chemical composition of the tested steel

% C Mn Si S P Als N Ti Cu 0.0019 0.32 2.72 0.0023 0.014 0.5016 0.0015 0.0026 0.046 -

[1] Li Wenquan, Gao Zhenyu, Luo Li, et al. Elementary analysis on influence of inclusion on magnetic performance of electric steel[J]. Angang Technology, 2004 (1): 18-21. (李文权, 高振宇, 罗理, 等. 夹杂物对电工钢磁性能影响的初步分析[J]. 鞍钢技术, 2004(1): 18-21.Li Wenquan, Gao Zhenyu, Luo Li, et al. Elementary analysis on influence of inclusion on magnetic performance of electric steel[J]. Angang Technology, 2004 (1): 18-21. [2] Wu Yuan. Characteration of inclusion/precipitate and the effect of sulfide on the microstructure of the high-grade non-oriented silicon steel[D].Shanghai: Shanghai University, 2017. (吴媛. 高牌号无取向硅钢中夹杂物/析出物的表征及硫化物对组织影响的研究[D]. 上海:上海大学,2017.Wu Yuan. Characteration of inclusion/precipitate and the effect of sulfide on the microstructure of the high-grade non-oriented silicon steel[D].Shanghai: Shanghai University, 2017. [3] Wu Derun, Tang Hongle, Li Yuhua, et al. Effects of ladle top slag modification treatment on inclusion and electromagnetic properties of non-oriented electrical steels[J]. Electrical Materials, 2016(1):5-16. (吴德润, 唐洪乐, 李玉华, 等. 钢包顶渣改性对无取向电工钢夹杂物和磁性能的影响[J]. 电工材料, 2016(1):5-16.Wu Derun, Tang Hongle, Li Yuhua, et al. Effects of ladle top slag modification treatment on inclusion and electromagnetic properties of non-oriented electrical steels[J]. Electrical Materials, 2016(1): 5-16. [4] Wu Shuang, Fan Lifeng, Mao Yibiao, et al. Thermodynamics of sulfide and nitride precipitation in high-grade non-oriented electrical steel[J]. Metallurgical Collections, 2009(2):3-12. (吴爽, 樊立峰, 毛一标, 等. 高牌号无取向电工钢中硫化物、氮化物析出的热力学分析[J]. 冶金丛刊, 2009(2):3-12.Wu Shuang, Fan Lifeng, Mao Yibiao, et al. Thermodynamics of sulfide and nitride precipitation in high-grade non-oriented electrical steel[J]. Metallurgical Collections, 2009(2): 3-12. [5] Li Daizhong. Non-metallic inclusions in steel[M]. Beijing:Science Press, 1983. (李代钟. 钢中的非金属夹杂物[M]. 北京:科学出版社, 1983.Li Daizhong. Non-metallic inclusions in steel[M]. Beijing:Science Press, 1983. [6] He Zhongzhi, Zhao Yu, Luo Haiwen. Electrical Steel[M].Beijing:Metallurgical Industry Press,2012. (何忠治, 赵宇, 罗海文. 电工钢[M]. 北京:冶金工业出版社,2012.He Zhongzhi, Zhao Yu, Luo Haiwen. Electrical Steel[M].Beijing:Metallurgical Industry Press, 2012. [7] Boc I. Analysis of inclusion in cold rolled Si-Fe strips[J]. Joumal of Magnetism and Magnetic Materials, 1990,83:38l-383. [8] Darja Steiner Petrovič, Boštjan Arh, Franc Tehovnic, et al. Magnesium non-metallic inclusions in non-oriented electrical steel sheets[J]. ISIJ International, 2011,51(12):2069-2075. doi: 10.2355/isijinternational.51.2069 [9] Wu Shaojie, Wan Yong, Chen Weiqing, et al. Examination and study on cleanliness of non-oriented silicon steel XG800WR in 210 t BOF-RH-CC steelmaking process[J]. Special Steel, 2011,32(5):56-59. (吴绍杰, 万勇, 陈伟庆, 等. 210 t BOF-RH-CC炼钢流程无取向硅钢XG800WR洁净度的试验研究[J]. 特殊钢, 2011,32(5):56-59. doi: 10.3969/j.issn.1003-8620.2011.05.017Wu Shaojie, Wan Yong, Chen Weiqing, et al. Examination and study on cleanliness of non-oriented silicon steel XG800WR in 210 t BOF-RH-CC steelmaking process[J]. Special Steel, 2011, 32(5): 56-59. doi: 10.3969/j.issn.1003-8620.2011.05.017 [10] Peng Qichun, Qiu Lei, Zou Jian, et al. Evolution of inclusions in non-oriented silicon steel W800 in 210 t during production process[J]. Iron and Steel, 2015,50(8):34-38. (彭其春, 邱雷, 邹健, 等. 无取向硅钢W800生产过程中夹杂物演变规律[J]. 钢铁, 2015,50(8):34-38.Peng Qichun, Qiu Lei, Zou Jian, et al. Evolution of inclusions in non-oriented silicon steel W800 in 210 t during production process[J]. Iron and Steel, 2015, 50(8): 34-38. [11] Lü Xuejun, Zhang Feng, Wang Bo, et al. Effects of inclusions on magnetic properties of non-oriented silicon steel[J]. Special Steel, 2012(4):22-25. (吕学钧, 张峰, 王波, 等. 夹杂物对无取向硅钢磁性能的影响[J]. 特殊钢, 2012(4):22-25. doi: 10.3969/j.issn.1003-8620.2012.04.006Lü Xuejun, Zhang Feng, Wang Bo, et al. Effects of inclusions on magnetic properties of non-oriented silicon steel[J]. Special Steel, 2012(4): 22-25. doi: 10.3969/j.issn.1003-8620.2012.04.006 -

下载:

下载: