Microstructure, mechanical properties and corrosion resistance of the Ni-based alloy NS1402 TIG welded joints

-

摘要: 采用TIG焊接方式,以镍基焊丝ERNiFeCr-1作为填充材料对国产镍基合金NS1402进行焊接性研究,并与国外Incoloy825合金进行对比,分析其接头的显微组织和力学性能。同时对比了普通低合金钢焊丝ER50-6对国内外两种合金的焊接性的影响,并研究其接头的耐腐蚀性能。结果表明,镍基合金NS1402接头成型良好,焊缝区组织由大片等轴晶和少量柱状晶组成;拉伸试样从NS1402焊缝处断裂,焊缝接头抗拉强度达到570 MPa,达到母材抗拉强度的89.1%,NS1402的强度及延伸率均略低于进口825合金;对接头拉伸后的断口形貌进行观察和分析,发现镍基合金NS1402焊接接头断口类型为延性断裂,接头断口韧窝的尺寸较小、数量偏多;镍基焊丝ERNiFeCr-1接头的耐腐蚀性能优于普通ER50-6焊丝接头,腐蚀试验结果表明,国产镍基合金NS1402接头耐腐蚀性能与国外Incoloy825接头相当。

-

关键词:

- 镍基合金NS1402 /

- TIG焊接 /

- 力学性能 /

- 耐蚀性能

Abstract: The weldability of domestic nickel-based alloy NS1402 by TIG welding with nickel-based wire ERNiFeCr-1 as the filler material was studied. The microstructures and mechanical properties of the joints were analyzed compared with the foreign Incoloy825 alloy. At the same time, the effect of common low alloy steel wire ER50-6 on the weldability of the two alloys at home and abroad was compared, and the corrosion resistance of the joints was investigated. The results show that the nickel-based alloy NS1402 joints are well formed, and the weld zone consists of a large area of equiaxial crystals and a small number of columnar crystals. Tensile specimens are broken at the NS1402 welding seam, and the welded joints have a tensile strength of 570 MPa, which is 89.1% of the tensile strength of base metal. The strength and elongation of NS1402 are slightly lower than that of the imported 825 alloy. The fracture morphology of the joints after tensile testing is observed and analyzed. It is found that the fracture morphology of nickel-based alloy NS1402 welded joint exhibits ductile fracture, with a higher number of small-sized dimples on the fracture joints. The corrosion resistance of nickel-based wire ERNiFeCr-1 joint is better than the common ER50-6 wire joints. The corrosion test results show that the corrosion resistance of the domestic nickel-based alloy NS1402 joints and foreign Incoloy825 joints is comparable.-

Key words:

- nickel-based alloy NS1402 /

- TIG welding /

- mechanical property /

- corrosion resistance

-

0. 引言

耐腐蚀性是考量材料性能的一个重要指标。镍基合金拥有比不锈钢等材料更优越的耐腐蚀性能,是耐腐蚀性材料开发的热点,同时镍基合金还具有良好的高温及低温力学性能,因此它被广泛应用于石油化工、涡轮发动机、核能以及航空航天等领域[1−3],通常服役于高温高压的疲劳条件,因此对其材料焊接性提出了更高的要求。

镍基合金Incoloy825是由美国超合金公司研制(简称825合金),是一种添加Mo、Cu和Ti等元素的铁-镍-铬固溶强化型镍基耐蚀合金,在国内耐蚀合金市场使用占比大。目前,国内外学者对进口825合金在焊接领域的研究较多,而对国产825(NS1402)镍基合金在其焊接性以及接头热裂纹产生机理等方面的研究鲜有报道,缺乏系统性理论研究。大量国内外学者研究了焊接参数对825合金焊缝成型的影响,不同试验条件下Incoloy825合金的显微组织及力学性能,不同填充材料对高温镍基合金的热裂敏感性[4−9]。郎宇平[10]通过开展拉伸试验、热模拟和晶间腐蚀试验对镍基耐蚀合金NS1402的力学性能、热加工性能以及晶间腐蚀性能进行了研究。为了打破Incoloy825合金对国内市场的技术封锁和垄断,攀钢集团开发了镍基合金NS1402替代Incoloy825合金,以实现国产镍基合金的技术自主与国产化。因此,对镍基合金NS1402开展其焊接性、热裂性、耐腐蚀性等研究具有十分重要的意义,同时推广该材料在各领域的应用,也迫切需要对NS1402展开大量焊接方面的试验及理论研究。

为促进国产825(NS1402)合金的应用,同时为我国相关同类钢优化提供参考依据,笔者采用TIG填丝对镍基合金NS1402与Incoloy825合金进行焊接,选用镍基焊丝ERNiFeCr-1作为焊接填充金属,探究了镍基合金NS1402与焊丝的匹配性对焊接接头的显微组织和力学性能的影响,同时对接头的腐蚀性进行研究,对比了Incoloy825合金接头性能,从冶金角度与力学角度出发,对镍基合金NS1402焊接性及其接头组织性能进行探索,为我国相关钢厂优化NS1402材料的性能提供参考依据。

1. 试验材料及方法

试验母材采用攀钢集团生产的镍基耐蚀合金NS1402和进口Incoloy825合金,选用进口镍基合金ERNiFeCr-1焊丝,各化学成分如表1所示。

表 1 母材及焊丝化学成分Table 1. Chemical compositions of the base material and welding wires% 材料 C Cr Fe Mn Ni Mo Al P S NS1402 0.05 19.5~23.5 余量 1.0 38~46 2.5~3.5 0.2 0.03 0.03 Incoloy825 0.05 19.5~23.5 余量 1.0 38~46 2.5~3.5 0.2 0.03 0.03 ERNiFeCr-1 0.03 20.89 31.16 0.53 40.01 3.23 0.14 0.02 0.01 焊机选用松下YC-300WX-4,采用TIG填丝方式进行焊接,焊接电流为80~90 A,电弧电压为12 V,焊接速度为180 mm/min,氩气流量为15 L/min。选用岛津AG-Xplus型万能拉伸试验机进行拉伸试验。金相试样腐蚀液的配比为无水硫酸铜2 g、盐酸10 mL、蒸馏水10 mL。按照GB/T 15260-2016方法A进行晶间腐蚀试验,腐蚀液的配比为400 mL蒸馏水、236 mL符合GB/T625规定的硫酸、25 g硫酸铁(粉末状),在腐蚀液微沸状态下对试件持续腐蚀120 h,并采用称重法测量及计算其腐蚀率。

2. 结果与分析

2.1 焊接试验

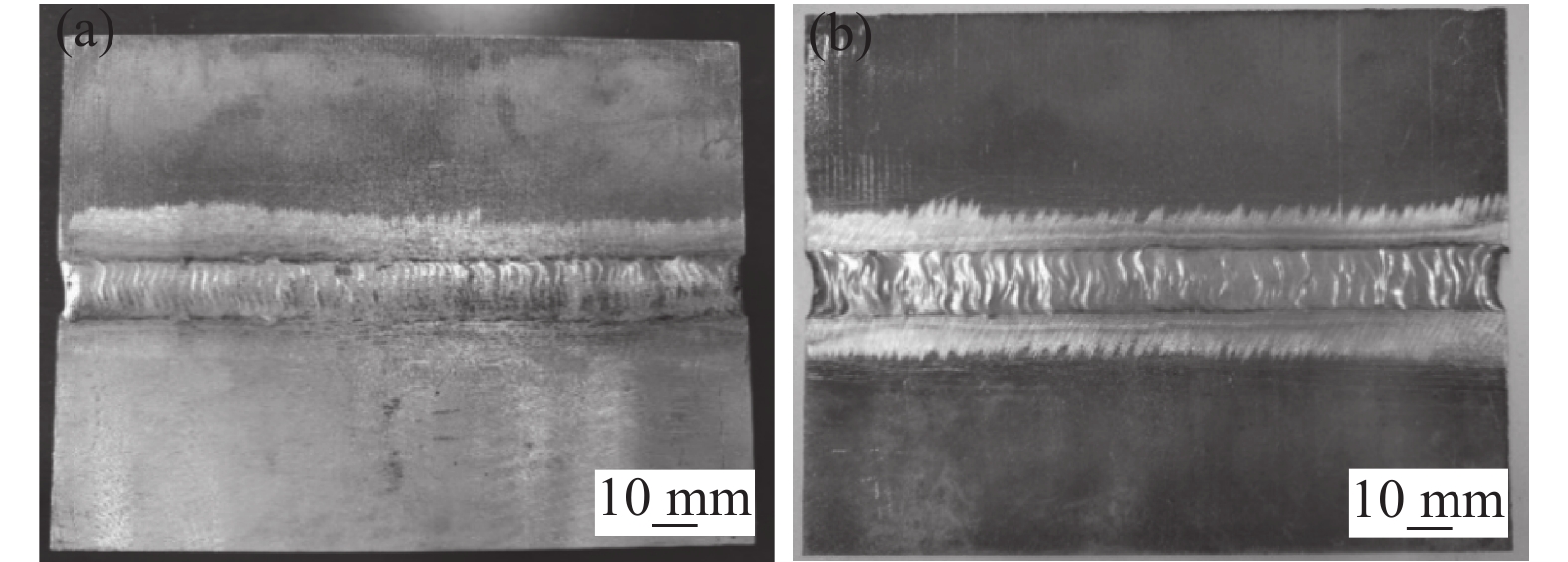

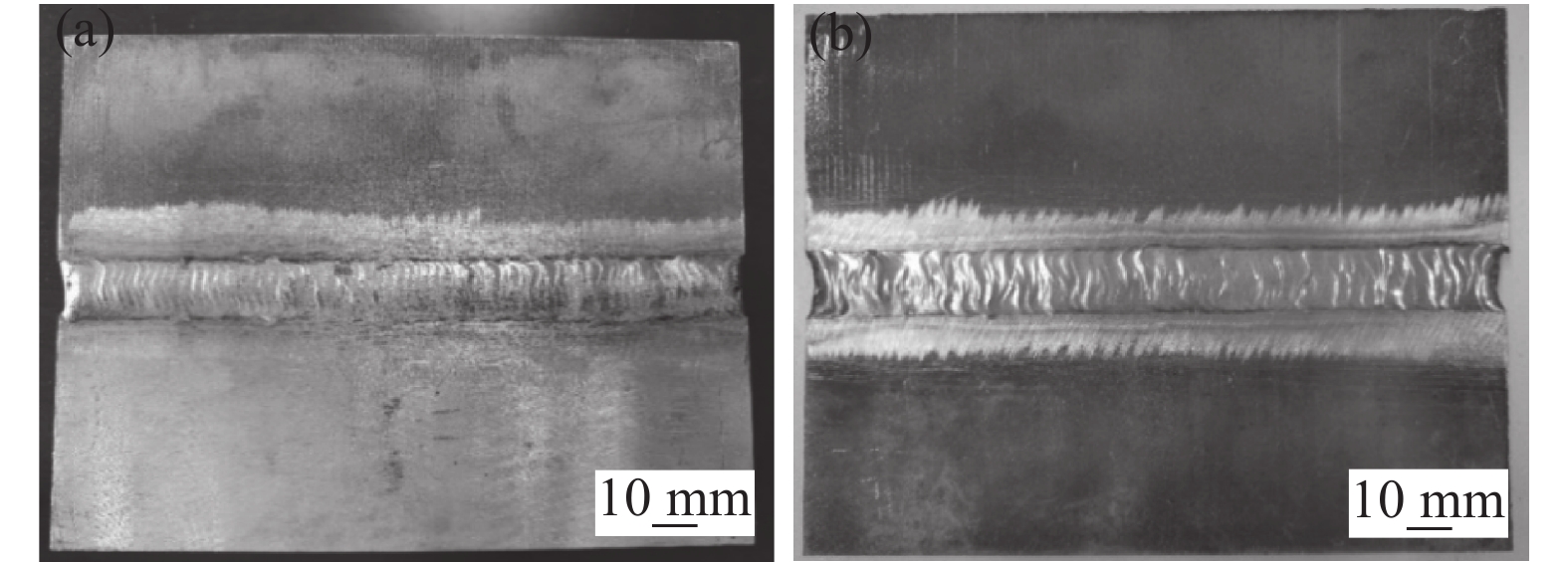

焊接试件尺寸为150 mm×60 mm×10 mm,底部钝边尺寸为2 mm,开设坡口角度为60°,采用多层多道焊方式施焊,对层间进行清理,共焊接四层。焊接过程母材及焊丝熔化后流动性较好,焊缝成形良好,无变形、咬边、气孔、裂纹等缺陷,实现了较好的冶金结合,接头宏观形貌如图1所示。

2.2 接头显微组织

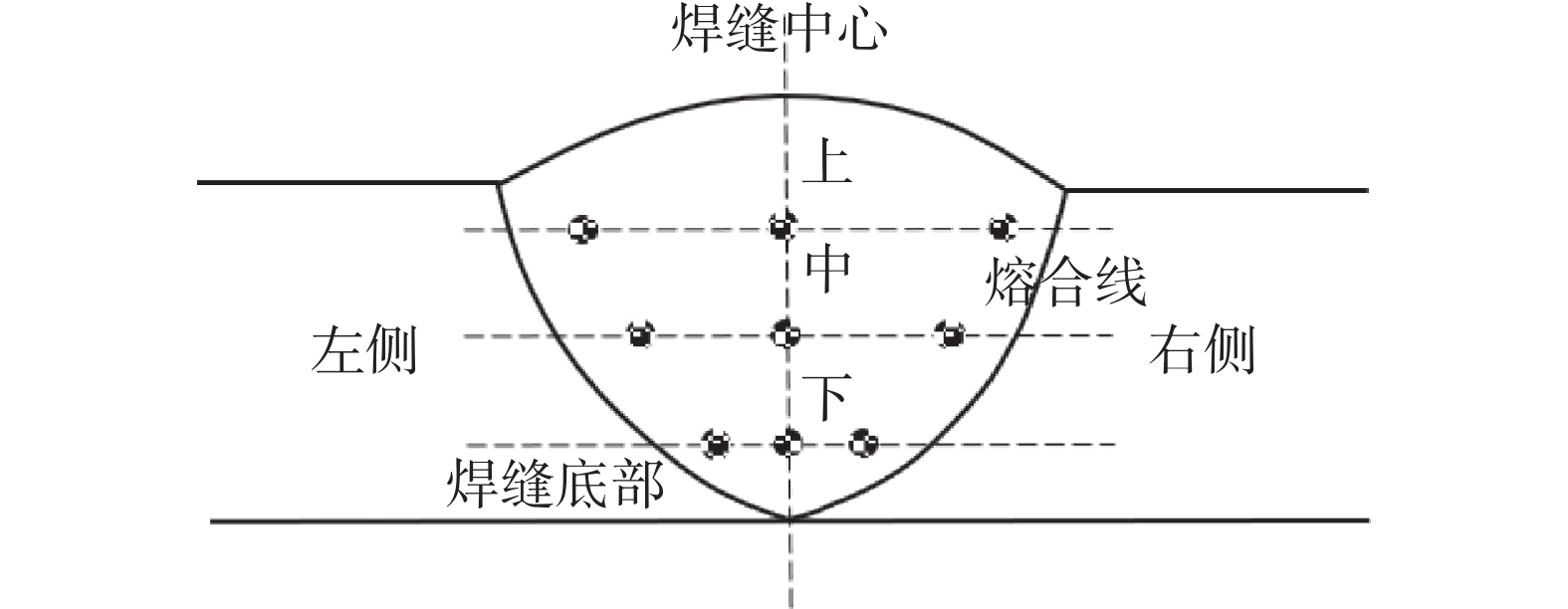

对镍基合金NS1402及Incoloy825焊接接头的显微组织进行微观分析,图2为接头组织观察的取点位置示意图,分别在焊缝中心上部、中部、下部、焊缝底部、熔合线、热影响区等位置进行取点观察。

2.2.1 NS1402焊缝微观组织

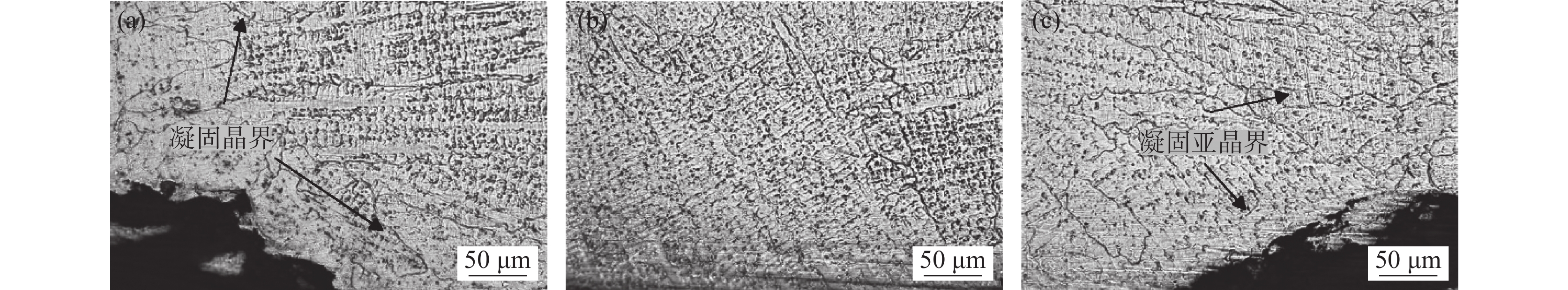

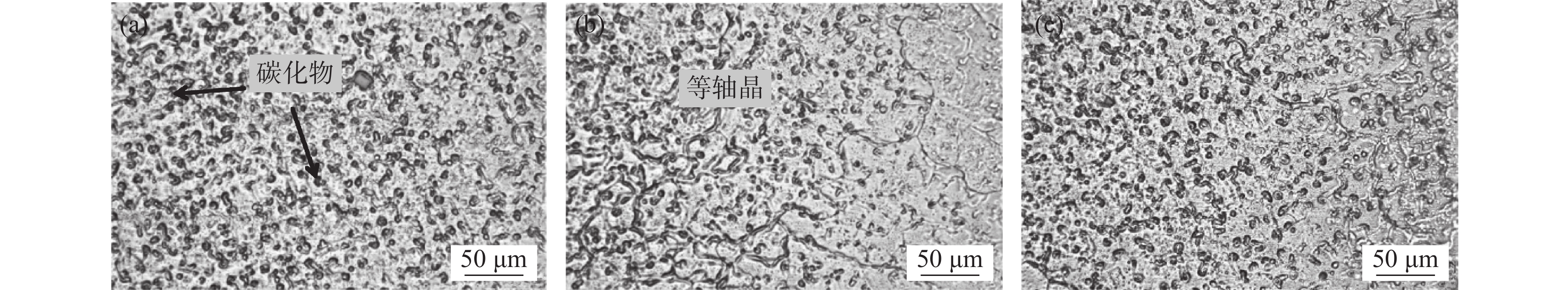

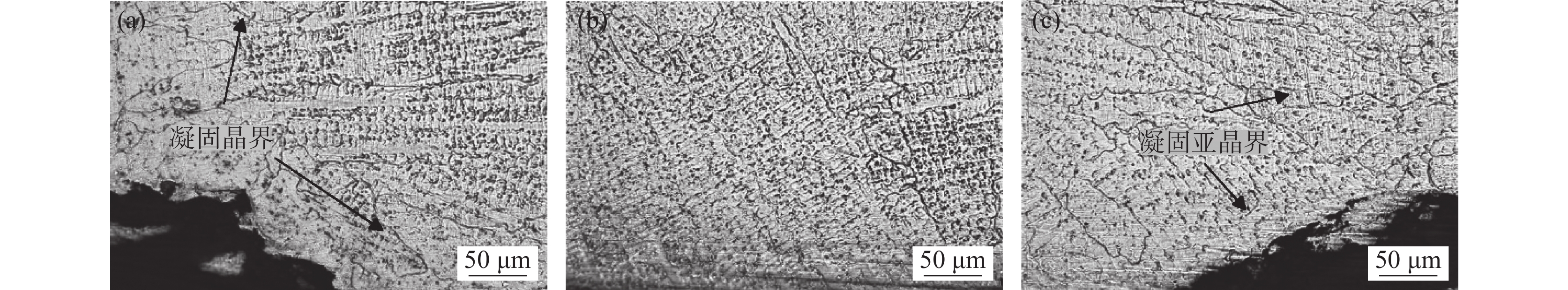

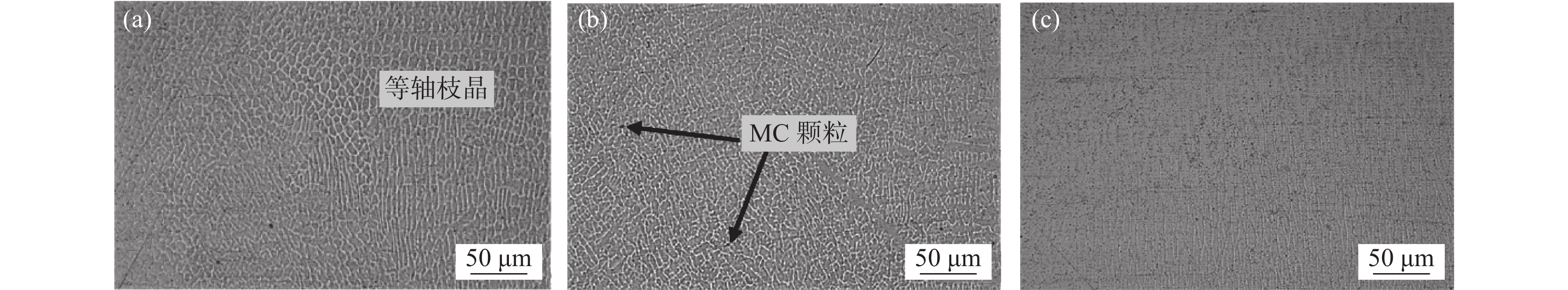

图3为NS1402焊接接头焊缝底部左侧、中心、右侧的金相组织,由图3(b)可知,焊缝金属以联生结晶方式、固液界面的晶粒为核生成柱状晶,指向焊缝中心,呈对称分布,同时还发现碳化物及二次相粒子大多固溶于晶粒内部,晶粒表面颜色较深,在焊缝底部成片分布。在焊缝底部左侧、右侧接邻熔合线处组织为奥氏体,经抛光和腐蚀处理后,晶粒边界特别明显,能清晰分辨出凝固晶界以及凝固亚晶界,多束亚晶粒相交成凝固晶界,成为相邻柱状晶的边界,如图3(a)(c)所示。

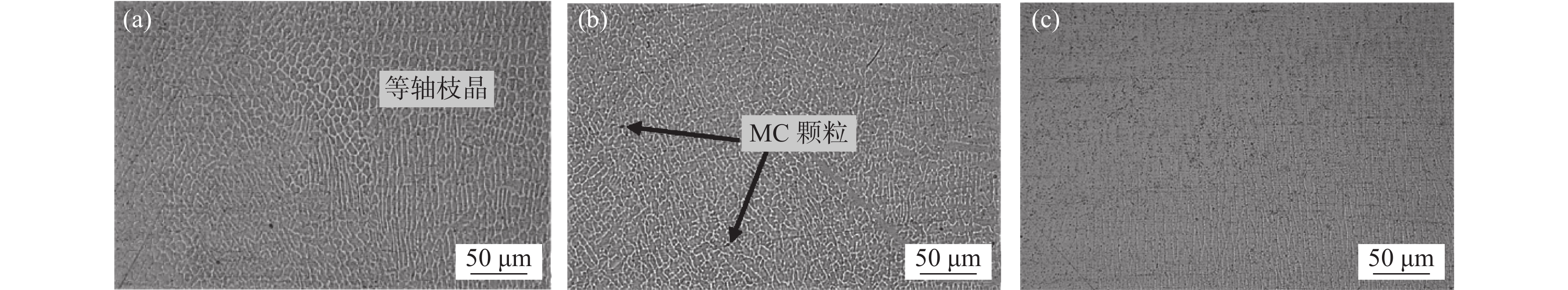

图4为NS1402焊缝中心上部、中部以及下部的金相组织,由图4(a)(b)可以看出,焊缝中部组织多为等轴枝晶,仍为奥氏体相,以亚晶界和迁移晶界为主。随着焊缝金属温度的逐渐降低,溶解度明显下降,在焊缝中心的上、中、下三个区域处有明显的杂质偏析现象,最终以M23C6、MC等碳化物颗粒形式分布于晶粒内部及枝状晶间位置处,如图4(b)所示。

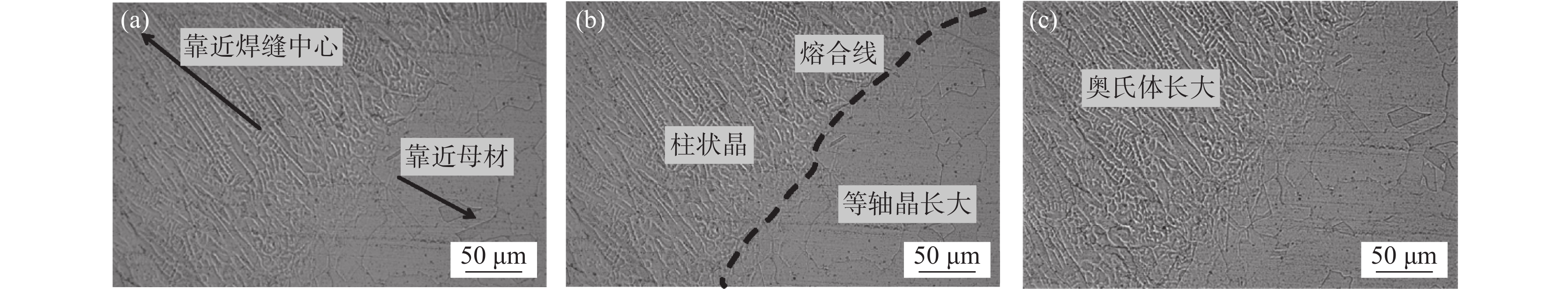

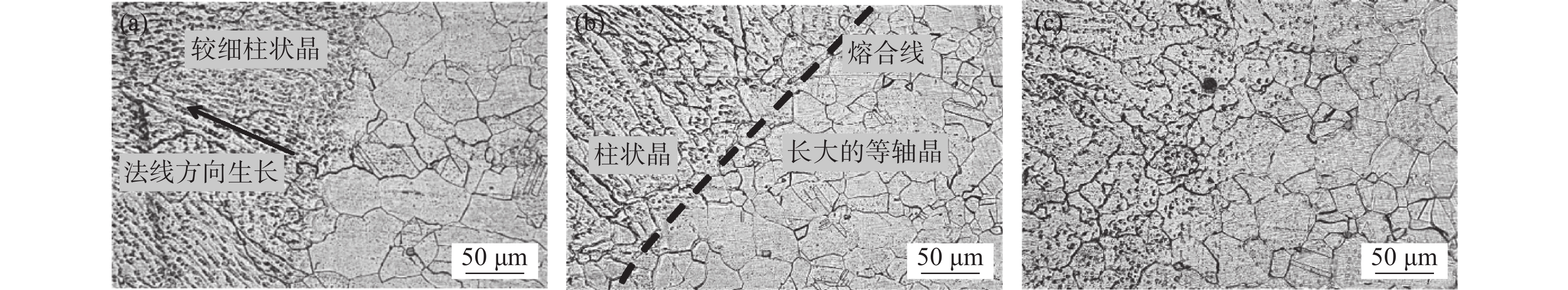

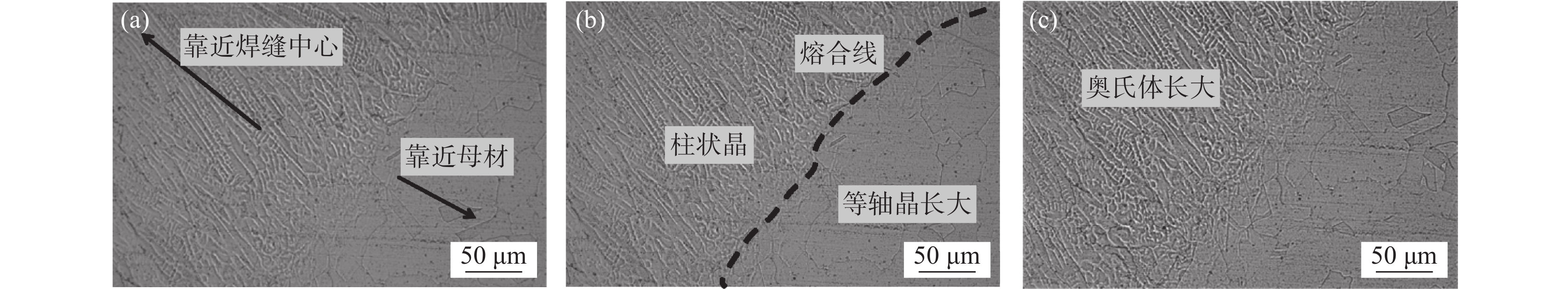

图5为镍基合金NS1402右侧熔合线上部、中部、下部的金相组织,由图5(b)可以看出,熔合线中部左侧组织为明显的柱状晶,以一定角度指向焊缝中心,熔合线右侧为热影响区(HAZ),组织为等轴晶。靠近焊缝侧奥氏体晶粒发生明显长大,这是由于靠近母材侧金属温度持续较高,晶界能减小引起小晶粒融入大晶粒造成的,如图5(a)(c)。

2.2.2 Incoloy825焊缝微观组织

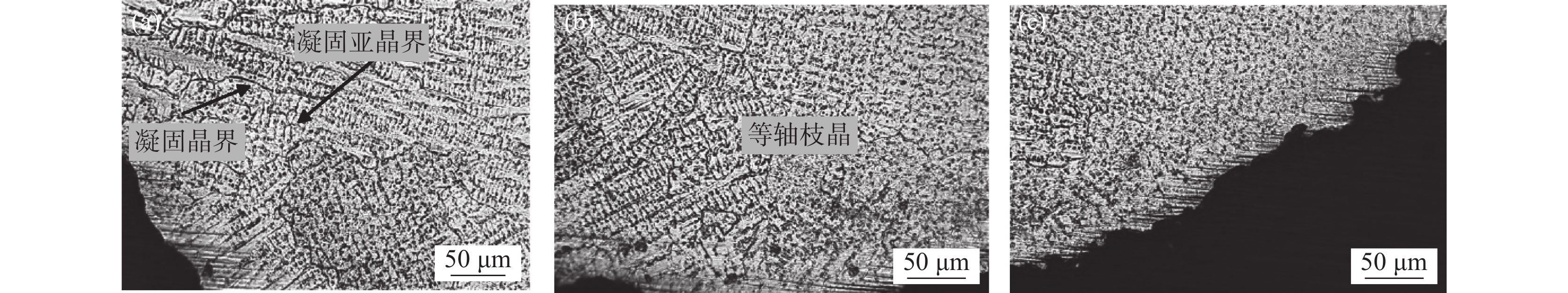

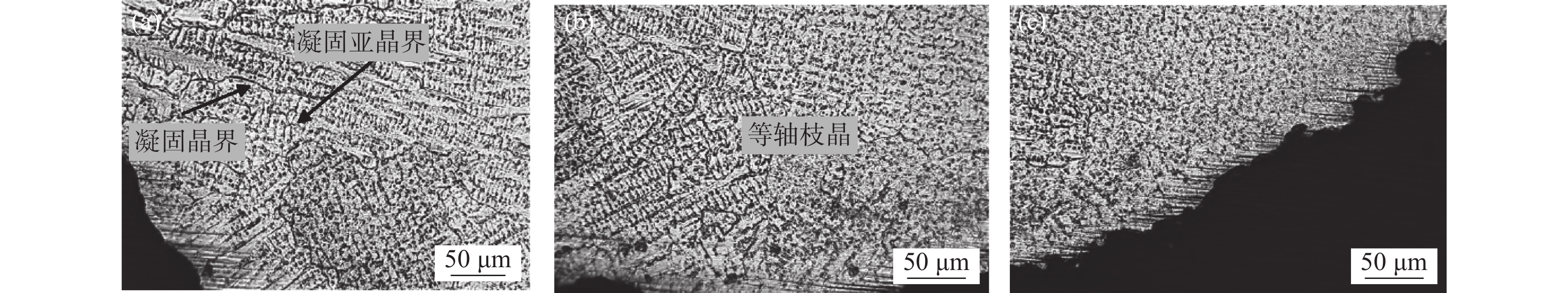

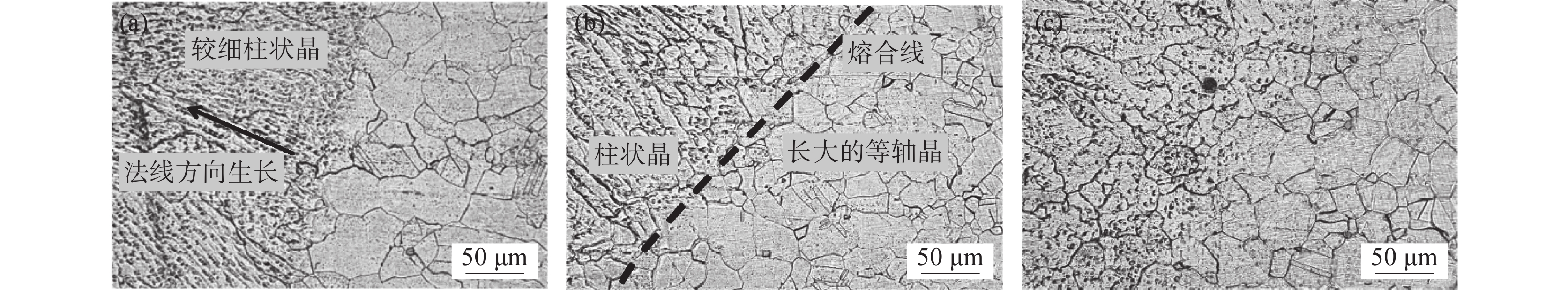

图6为进口Incoloy825合金焊缝底部左侧、底部中心、底部右侧的金相组织,如图6(a)所示,焊缝中可以清晰看到凝固晶界和凝固亚晶界,二次相更加均匀地分布在枝状晶内部,少量位于晶界处,亚晶界更加清晰,表明焊缝液态金属发生了溶质再分布,在底部左、右两侧,如图6(a)(c)所示,柱状晶呈簇状沿熔合线的法线向焊缝中心蔓延。

焊缝中心上部、中部、底部的金相组织见图7,表明焊缝中心组织为等轴晶。焊缝中心中部为奥氏体组织,如图7(b)所示。从图7(a)可以发现碳化物颗粒存在于晶粒内,少量在亚晶界上,晶界结合较为紧密,中心上部的晶粒尺寸较中部、下部稍小,相比国内NS1402,焊缝处的等轴枝晶更加细密,晶界内析出相对均匀,偏析相对较弱。

焊缝熔合线上部、中部、底部的金相组织如图8所示,熔合区为焊缝与处于半熔化态的母材交界处,固态晶粒作为形核中心。由于Incoloy825的过热区晶粒小于NS1402,所以熔合线处的柱状晶较细,向焊缝内部伸长距离也较长,枝晶方向更加明显,沿熔合线法线方向生长,指向焊缝中截面,如图8(a)(b)所示。

NS1402及进口Incoloy825合金的显微组织特征均为γ型奥氏体相,两者的差异主要表现在晶粒的尺寸以及碳化物在晶粒中的分布位置不同。分析国产NS1402及进口Incoloy825合金不同焊缝区域的结晶及组织特征,发现两种材料焊缝金属均以联生结晶方式、固液界面的晶粒为核生成柱状晶,指向焊缝中心,二次相大多固溶于晶粒内,相比于国内NS1402,进口Incoloy825合金的焊缝等轴枝晶更为细密,晶内析出相对均匀,偏析相对较弱,使得Incoloy825合金接头的拉伸强度优于国产NS1402合金接头。

2.3 焊接接头力学性能

2.3.1 拉伸性能

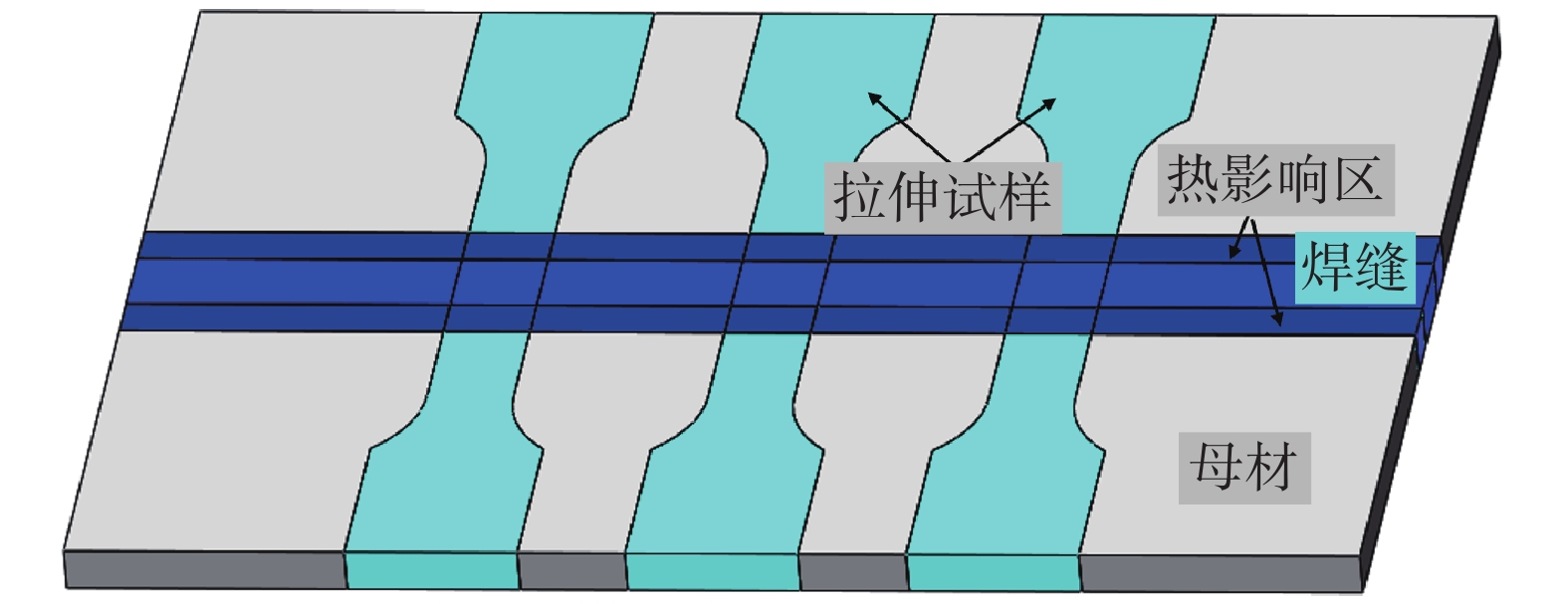

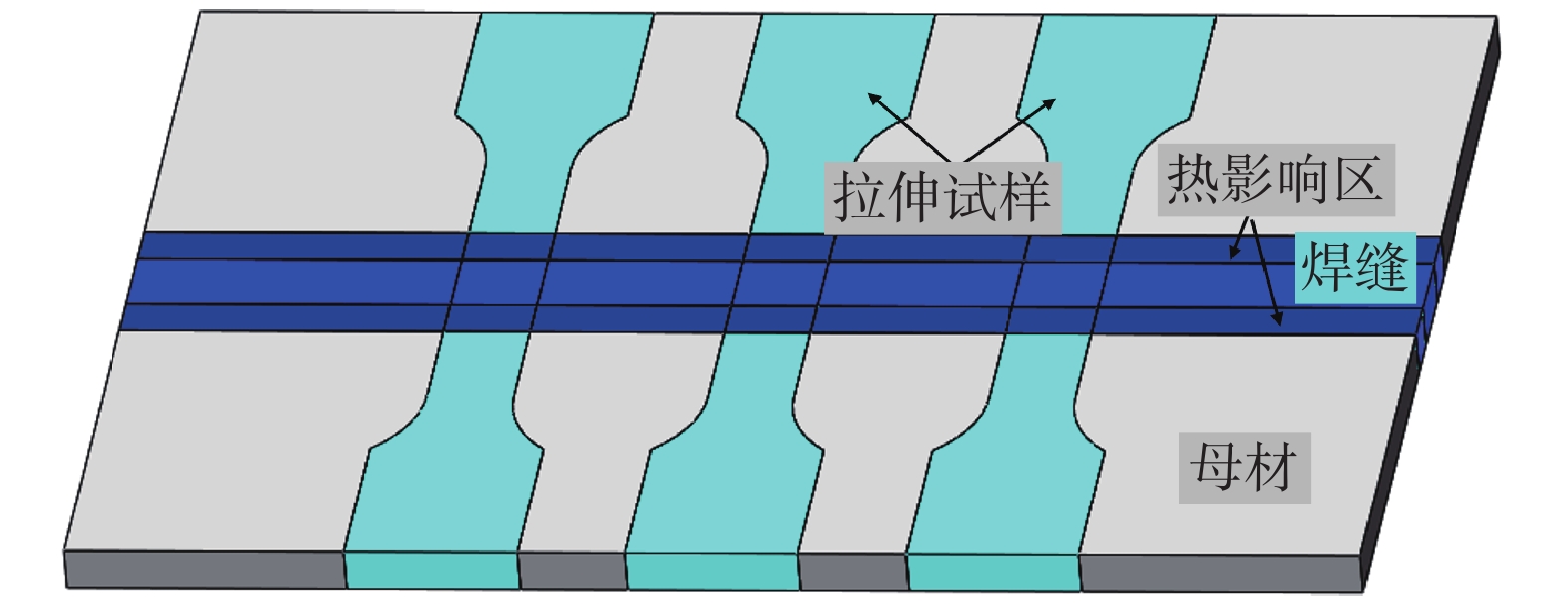

图9为焊接件拉伸试样取样示意,为避免焊接开始及结束时的焊缝缺陷,在试样中心沿垂直焊缝方向取三份试样,用于焊接接头拉伸试验。

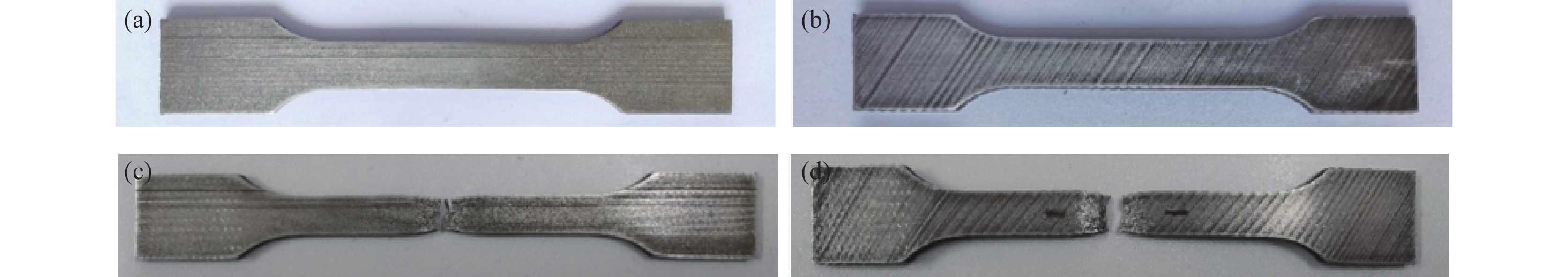

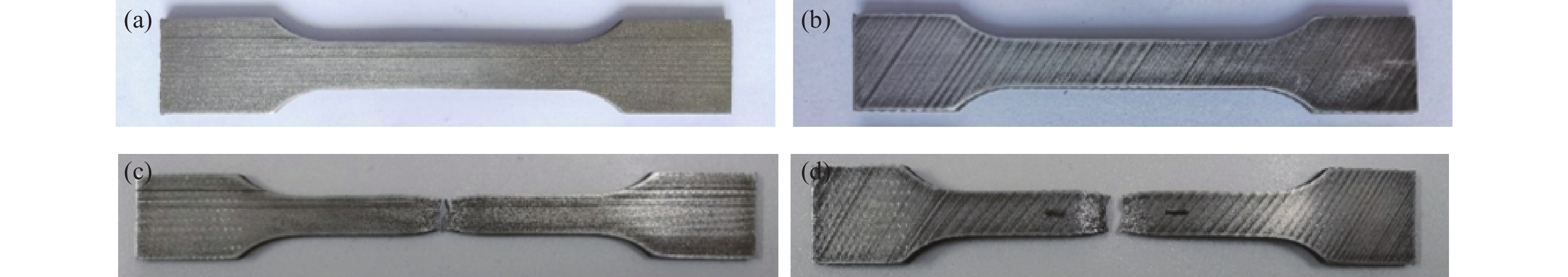

图10为国内外镍基合金焊接件拉伸试验中拉伸前、拉伸后的试样图,从图10中可知,镍基合金NS1402及Incoloy825焊接拉伸试样的断裂位置均出现在焊缝区域,撕裂面与水平面呈45°,断口处出现缩颈特征,断裂类型为明显的延性断裂,表明这两种材料的塑性较好。

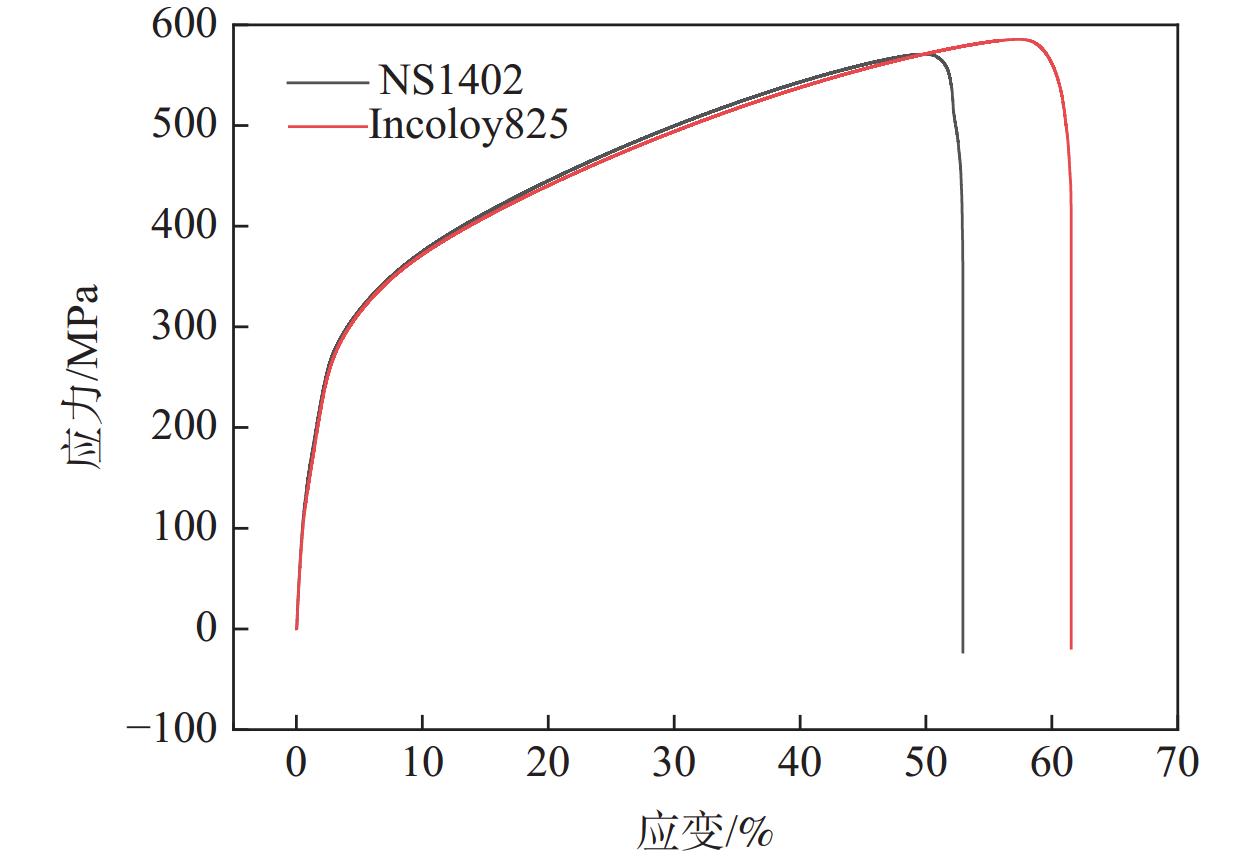

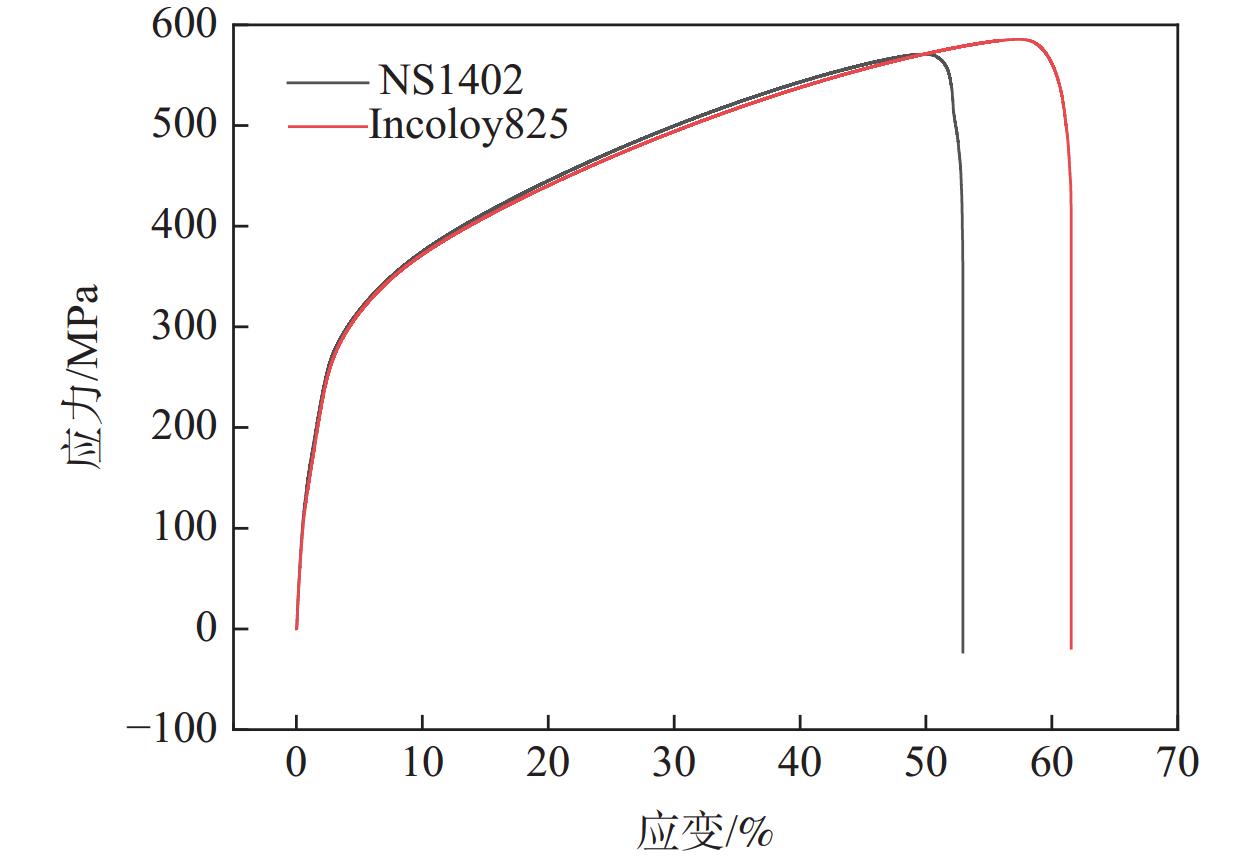

焊接接头拉伸应力-应变值分别取其三份试样的平均值,图11为国产NS1402及进口Incoloy825合金焊接接头的拉伸应力-应变曲线,由图11可知,国产NS1402接头的强度为570 MPa,进口Incoloy825接头的强度为590 MPa。两者接头的抗拉强度分别达到母材强度的89.1%、91.9%,NS1402的强度及延伸率均略低于进口Incoloy825。

2.3.2 断口形貌

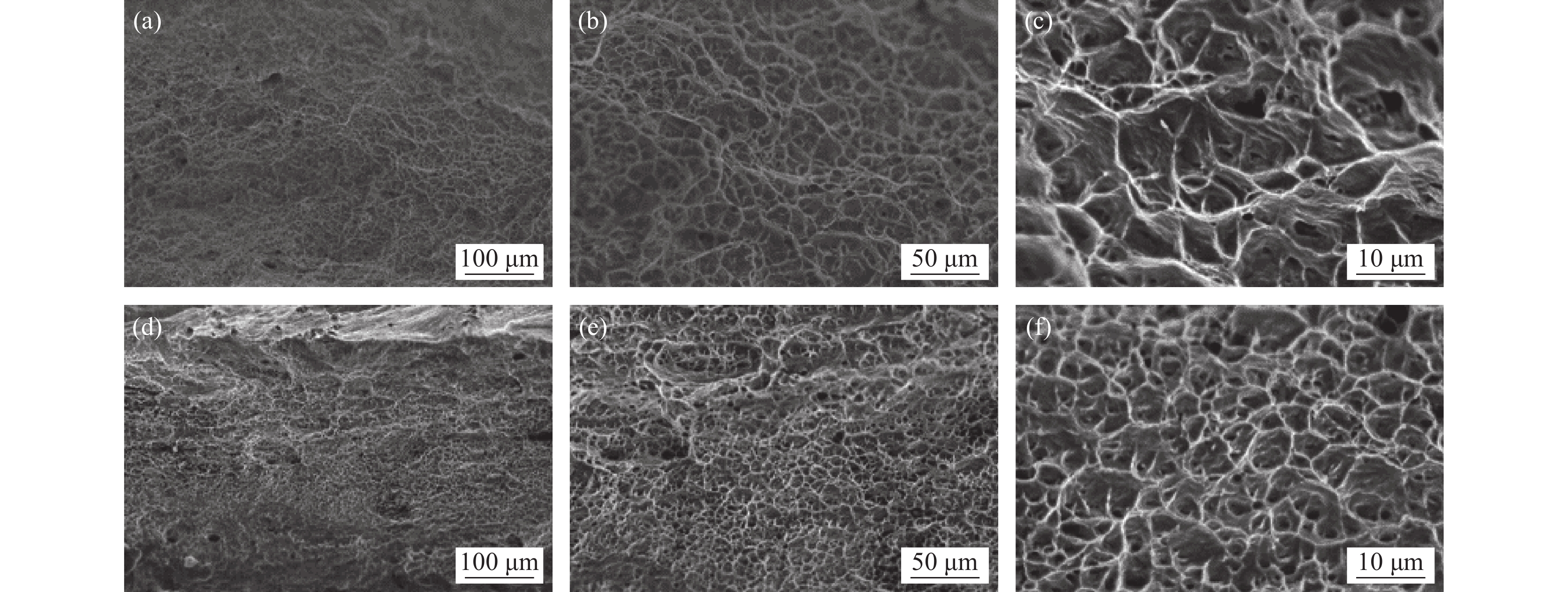

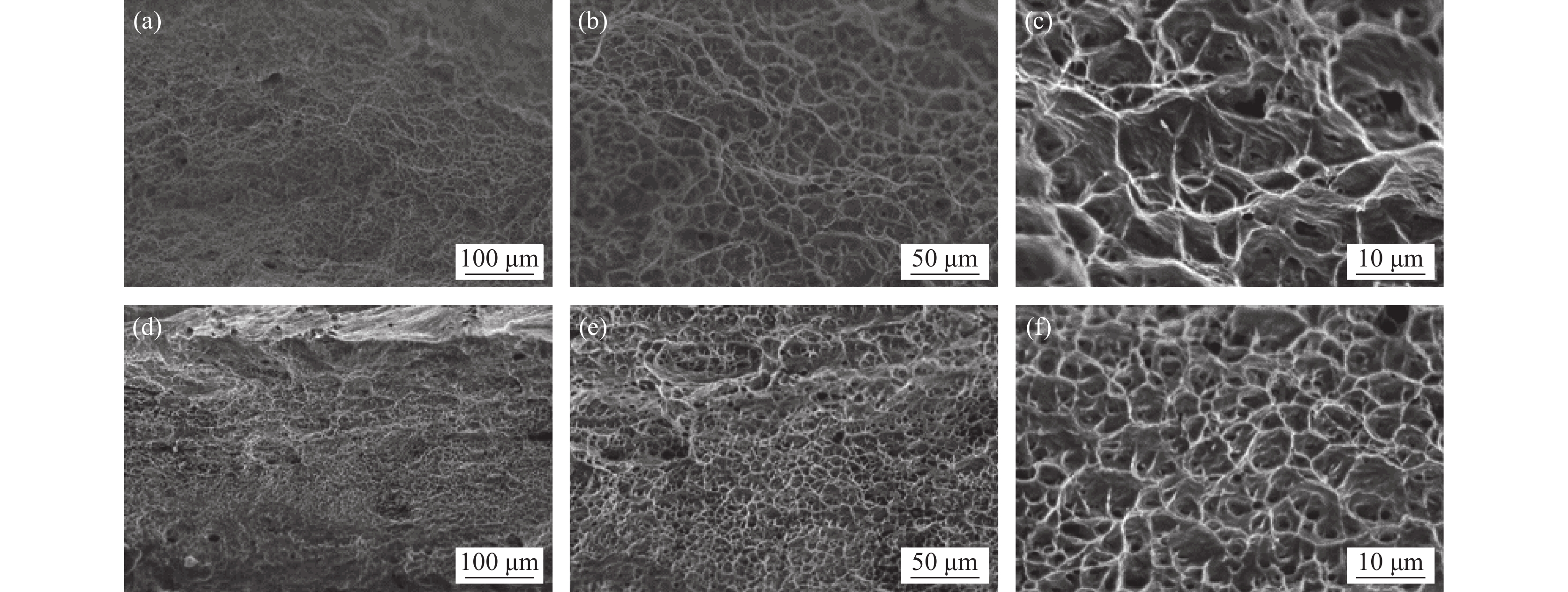

图12(a)~(c)为镍基合金NS1402焊接接头拉伸后的断口形貌,图12(d)~(f)为镍基合金Incoloy825焊接接头拉伸后的断口形貌,发现NS1402及Incoloy825合金接头的断口特征均为延性断裂,韧窝较为细密,表现出一定的塑性。但与NS1402相比,Incoloy825的韧窝尺寸较小且韧窝数量偏多,并且韧窝形貌也发生变化,微孔聚集时在韧窝内部也出现撕裂棱,韧窝内壁出现涟漪波纹状,表明Incoloy825合金的塑性要优于NS1402。

2.3.3 硬度测试

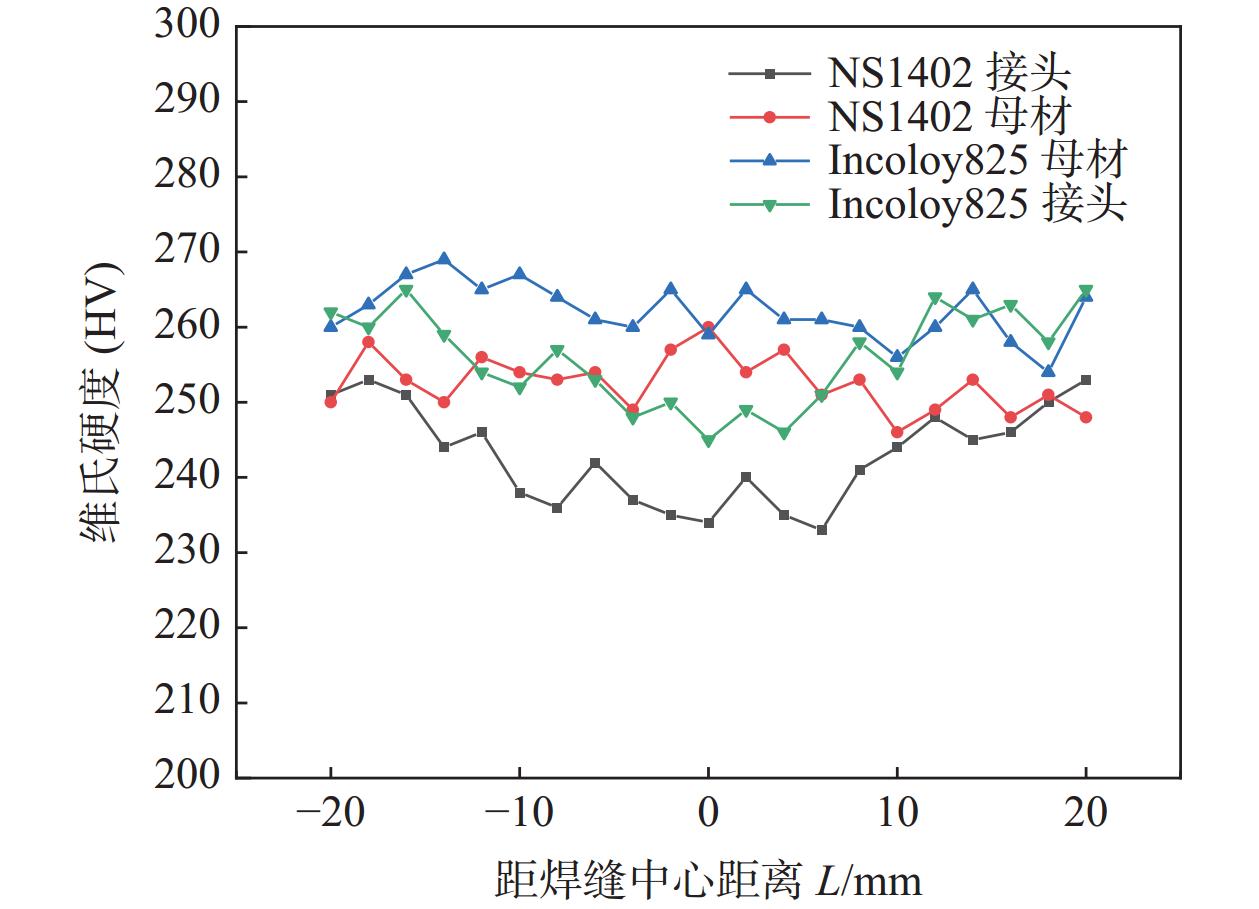

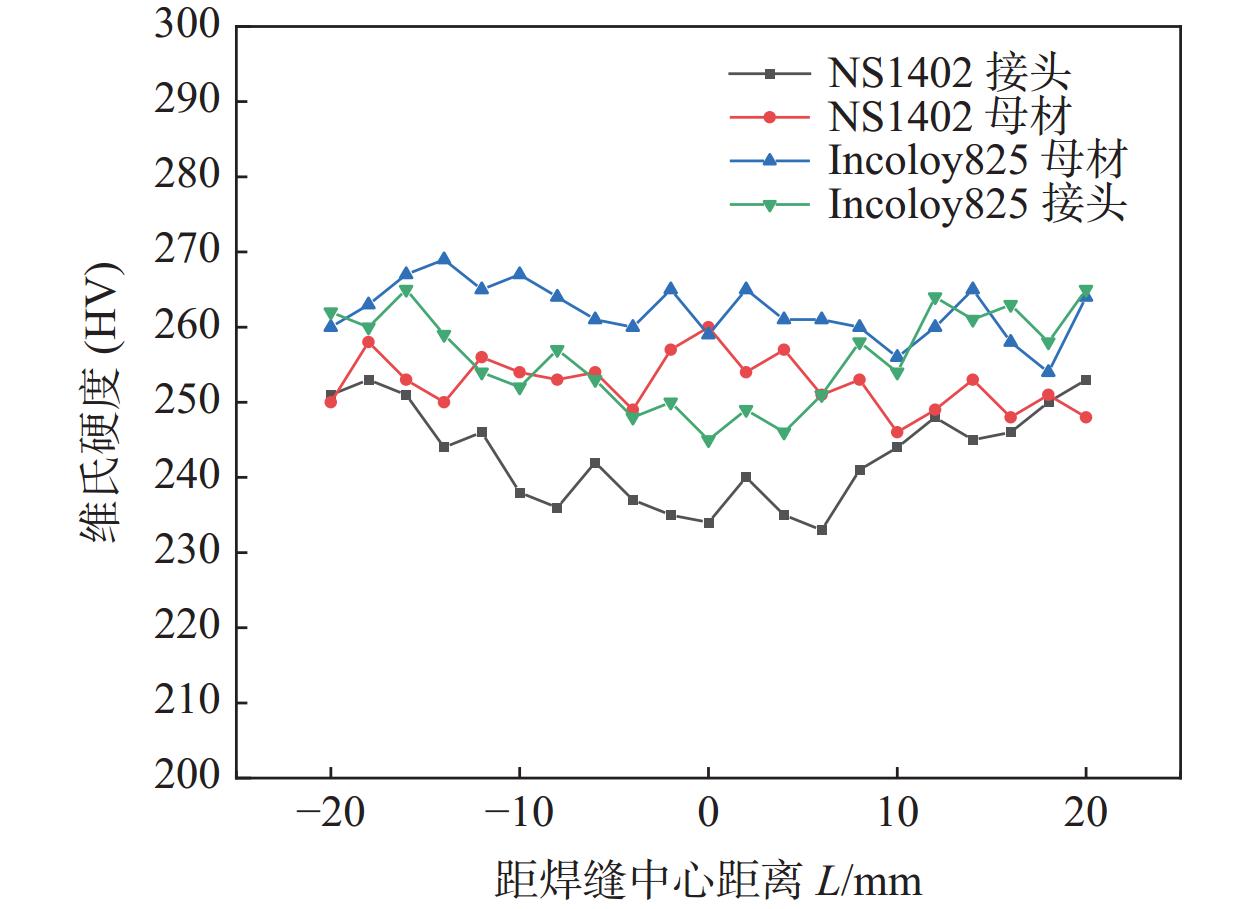

沿焊缝横截面中心位置左右依次取等距测试点,测试点间距为2 mm。图13为NS1402、Incoloy825合金及其接头维氏硬度对比,国产NS1402的维氏硬度(HV)平均值在252左右,进口Incoloy825合金的维氏硬度(HV)平均值在261左右,比国产NS1402硬度略高。接头硬度分布情况呈两边高、中间低的趋势,靠近焊缝中心区域其硬度较母材略微降低,熔合线区域硬度接近母材硬度。NS1402和Incoloy825合金焊接接头的维氏硬度(HV)平均值分别在243、255左右,其硬度分别达到母材的96.4%、97.7%,TIG焊得到的焊缝接头硬度与母材硬度相差较小,满足母材硬度性能要求。

2.4 耐腐蚀性能测试

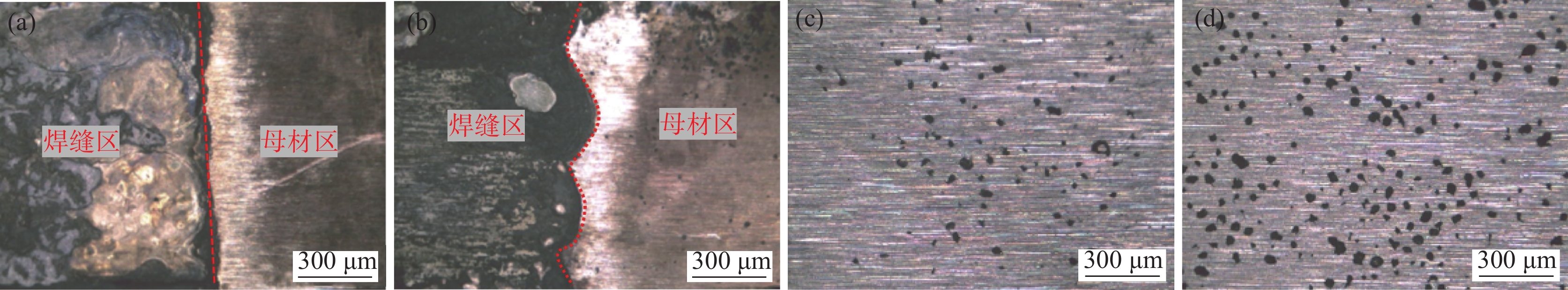

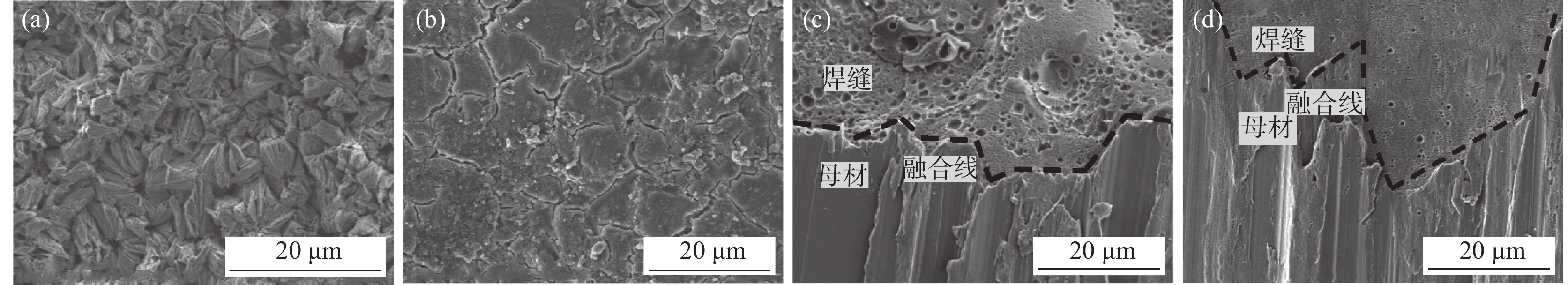

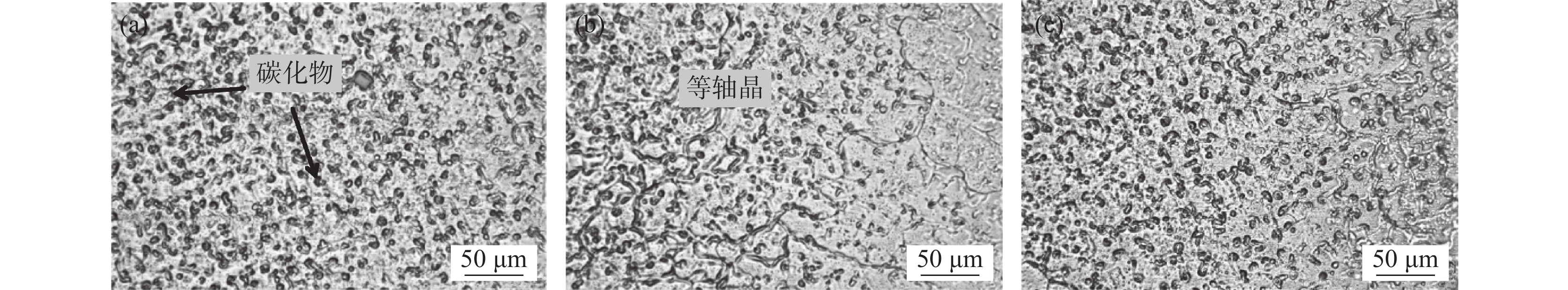

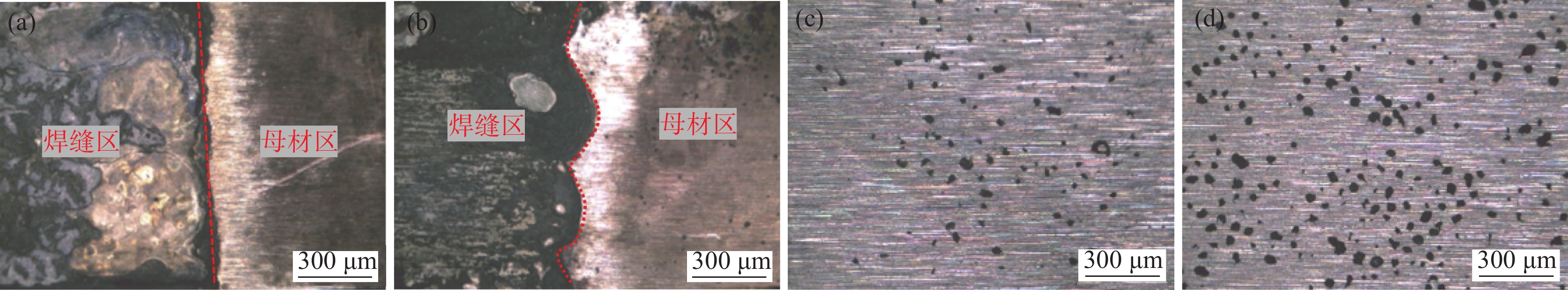

试样按照GB/T 15260-2016方法A进行晶间腐蚀试验,接头宏观腐蚀结果如图14(a)~(d)所示,ER50-6接头与ERNiFeCr-1接头耐晶间腐蚀性能结果如表2所示。腐蚀结果表明,接头的耐腐蚀性能相对母材要更差;NS1402与Incoloy825的ERNiFeCr-1接头耐腐蚀性能都要优于ER50-6接头;国产NS1402的ER50-6接头和ERNiFeCr-1接头耐腐蚀性能与Incoloy825所对应的接头耐腐蚀性能相当。

表 2 接头晶间腐蚀结果Table 2. Results of intergranular corrosion of joints焊丝 母材 腐蚀前/g 腐蚀后/g 差值/g 腐蚀率/% ER50-6 NS1402

Incoloy82513.344

13.47212.288

12.6471.056

0.8257.91

6.12ERNiFeCr-1 NS1402

Incoloy82544.906

43.00744.902

43.0020.004

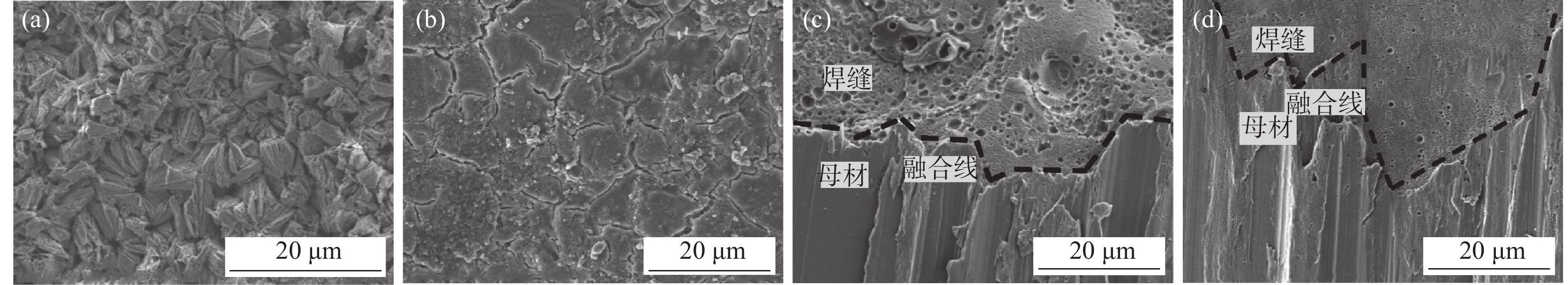

0.0050.0089 0.0116 采用SEM对试验完成后样品焊缝区、热影响区及母材形貌进行分析,如图15(a)~(d)所示,ERNiFeCr-1接头耐腐蚀性能都要优于ER50-6接头。由图15(a)(b)可知,在相同腐蚀环境下,ER50-6焊丝Incoloy825接头晶界腐蚀程度比ER50-6焊丝NS1402接头晶界腐蚀程度更浅;由图15(c)(d)可知,ERNiFeCr-1接头焊缝区和热影响区的腐蚀程度高于母材,焊缝表面有少量的浅凹坑分布,焊缝腐蚀后表面呈多孔状形貌。

3. 结论

1)镍基合金NS1402接头成型良好,焊缝区组织由大片等轴晶和少量柱状晶组成,相比于国内NS1402,进口Incoloy825合金的焊缝等轴枝晶更为细密,晶内析出相对均匀,偏析相对较弱。

2)拉伸断口特征均为延性断裂,韧窝较为细密,表现出一定的塑性,国产NS1402接头的强度为570 MPa,进口Incoloy825接头的强度为590 MPa,两者接头的抗拉强度分别达到母材强度的89.1%、91.9%,NS1402的强度及延伸率均略低于进口Incoloy825。

3)国产NS1402和进口Incoloy825合金焊接接头的维氏硬度(HV)平均值分别在243、255左右,其硬度分别达到母材的96.4%、97.7%,TIG焊得到的焊缝接头硬度与母材硬度相差较小,满足母材硬度性能要求。

4)普通ER50-6接头耐晶间腐蚀性能比镍基焊丝ERNiFeCr-1接头差,国产NS1402接头耐晶间腐蚀性能与Incoloy825接头相当。

-

表 1 母材及焊丝化学成分

Table 1. Chemical compositions of the base material and welding wires

% 材料 C Cr Fe Mn Ni Mo Al P S NS1402 0.05 19.5~23.5 余量 1.0 38~46 2.5~3.5 0.2 0.03 0.03 Incoloy825 0.05 19.5~23.5 余量 1.0 38~46 2.5~3.5 0.2 0.03 0.03 ERNiFeCr-1 0.03 20.89 31.16 0.53 40.01 3.23 0.14 0.02 0.01 表 2 接头晶间腐蚀结果

Table 2. Results of intergranular corrosion of joints

焊丝 母材 腐蚀前/g 腐蚀后/g 差值/g 腐蚀率/% ER50-6 NS1402

Incoloy82513.344

13.47212.288

12.6471.056

0.8257.91

6.12ERNiFeCr-1 NS1402

Incoloy82544.906

43.00744.902

43.0020.004

0.0050.0089 0.0116 -

[1] Zhang Shulang, Zhang Hongbin. Incoloy825 corrosion resistant alloy[J]. Special Steel Technology, 2005,10(3):64-66. (张菽浪, 张红斌. Incoloy 825耐蚀合金[J]. 特钢技术, 2005,10(3):64-66.Zhang Shulang, Zhang Hongbin. Incoloy825 corrosion resistant alloy[J]. Special Steel Technology, 2005, 10(3): 64-66. [2] Yao Caiyan, Zhang Linxian. Research on welding process of incoloy alloy 825 iron-nickel-based alloy[J]. Welding Technology, 2002,31(6):19-20. (姚彩艳, 张林贤. Incoloy Alloy 825铁镍基合金的焊接工艺研究[J]. 焊接技术, 2002,31(6):19-20. doi: 10.3969/j.issn.1002-025X.2002.06.009Yao Caiyan, Zhang Linxian. Research on welding process of incoloy alloy 825 iron-nickel-based alloy[J]. Welding Technology, 2002, 31(6): 19-20. doi: 10.3969/j.issn.1002-025X.2002.06.009 [3] Xiong Yong, Cheng Fasong, Li Yongbin, et al. Failure analysis of a GH4033 nickel-based alloy bond ring of an aero-engine[J]. Mechanical Engineering Materials, 2019,43(9):78-82. (熊勇, 程法嵩, 李永斌, 等. 某航空发动机GH4033镍基合金结合环的失效分析[J]. 机械工程材料, 2019,43(9):78-82. doi: 10.11973/jxgccl201909015Xiong Yong, Cheng Fasong, Li Yongbin, et al. Failure analysis of a GH4033 nickel-based alloy bond ring of an aero-engine[J]. Mechanical Engineering Materials, 2019, 43(9): 78-82. doi: 10.11973/jxgccl201909015 [4] Kim P S, Choi S Y, Kim Y S, et al. A study on the weldability of Incoloy 825 alloys and STS316L alloys[J]. Advanced Materials Research, 2015,1110:118-124. doi: 10.4028/www.scientific.net/AMR.1110.118 [5] Nagaraj B, Ramana V V. Empirical modelling and investigations of process parameters on a super alloy[J]. Materials Today : Proceedings, 2019, 19: 213-217. [6] Wang Tao, Zheng Zhentai, Dong Tianshun, et al. Effect of pulsed TIG welding process parameters on the grain size of Inconel601H nickel-based alloy welds[J]. Journal of Welding, 2015,36(4):109-112. (王涛, 郑振太, 董天顺, 等. 脉冲TIG焊接工艺参数对Inconel601H镍基合金焊缝晶粒大小的影响[J]. 焊接学报, 2015,36(4):109-112.Wang Tao, Zheng Zhentai, Dong Tianshun, et al. Effect of pulsed TIG welding process parameters on the grain size of Inconel601H nickel-based alloy welds[J]. Journal of Welding, 2015, 36(4): 109-112. [7] Hu Xianjun, Hong Huimin, Zhang Ke, et al. Microstructure and properties of Incoloy 825 alloy after solid solution at different temperatures[J]. Mechanical Engineering Materials, 2017,41(8):23-26. (胡显军, 洪慧敏, 张珂, 等. 不同温度固溶后Incoloy825合金的显微组织与性能[J]. 机械工程材料, 2017,41(8):23-26. doi: 10.11973/jxgccl201708005Hu Xianjun, Hong Huimin, Zhang Ke, et al. Microstructure and properties of Incoloy 825 alloy after solid solution at different temperatures[J]. Mechanical Engineering Materials, 2017, 41(8): 23-26. doi: 10.11973/jxgccl201708005 [8] Al-Saadi M, Sandberg F, Kasarav A, et al. Microstructure characterisation in alloy 825[J]. Procedia Manufacturing, 2018,15:1626-1634. doi: 10.1016/j.promfg.2018.07.294 [9] Sayyar N, Shamanian M, Niroumand B, et al. EBSD observations of microstructural features and mechanical assessment of Incoloy 825 alloy/AISI 321 stainless steel dissimilar welds[J]. Journal of Manufacturing Processes, 2020,60:86-95. doi: 10.1016/j.jmapro.2020.10.042 [10] Lang Yuping, Zhang Guoxin, Fang Yi, et al. Heat distortion behavior, mechanical and intergranular corrosion properties of NS1402 alloy[J]. Special Steel Technology, 2013, 19(1): 11-15. (郎宇平, 张国信, 方轶, 等. NS1402合金的热变形行为、力学和晶间腐蚀性能[J] 特钢技术, 2013, 19(1): 11-15.Lang Yuping, Zhang Guoxin, Fang Yi, et al. Heat distortion behavior, mechanical and intergranular corrosion properties of NS1402 alloy[J]. Special Steel Technology, 2013, 19(1): 11-15. -

下载:

下载:

下载:

下载: