Effect of tempering temperature on the mechanical properties and microstructures of 1500 MPa hot stamping steel after quenching

-

摘要: 针对1 500 MPa级热成形钢进行淬火和回火处理,利用金相显微镜、室温拉伸检测和扫描电镜等方法研究回火温度对材料显微组织和力学性能的影响。结果表明:Cr含量过高,会降低C的活度,抑制渗碳体的形成,因此钢中主要碳化物为M23C6和M7C3类,随着回火温度提高到400 ℃左右,碳化物会由M23C6类转化为M7C3类;抗拉强度、屈服强度和硬度随着回火温度的升高逐渐降低,当回火温度超过400 ℃之后强度会显著降低,延伸率随着回火温度的升高逐渐升高,而强塑积随着回火温度的升高呈现先增大后减小的趋势;板条马氏体中存在的高密度位错会随着回火温度的升高而下降,马氏体板条会相互吞噬、合并,逐渐模糊,基体中出现铁素体,此外碳化物也会析出并长大。

-

关键词:

- 1 500 MPa级热成形钢 /

- 回火 /

- 碳化物 /

- 马氏体板条

Abstract: Quenching and tempering treatment were carried out on a 1 500 MPa hot formed steel, and the effects of tempering temperature on the microstructures and mechanical properties were studied using methods such as metallographic microscopy, room temperature tensile testing, and scanning electron microscopy. The results show that if the Cr content is too high, it will reduce the activity of C and inhibit the formation of carbides. Therefore, the main carbides in the steel are M23C6 and M7C3. As the tempering temperature increases to around 400 ℃, the carbides will transform from M23C6 to M7C3, and the tensile strength, yield strength, and hardness will gradually decrease with the increase of tempering temperature. When the tempering temperature exceeds 400 ℃, the strength will significantly decrease, the elongation will gradually increase by enhancing tempering temperatures. The strength plastic product will first increase and then decrease with the increase of tempering temperature. The high-density dislocations in Flat noodles martensite will decrease, and the martensite will engulf and merge with each other, and then gradually blur with the increase of tempering temperature. Ferrites appear in the matrix. In addition, carbides will also precipitate and grow up.-

Key words:

- 1 500 MPa hot stamping steel /

- tempering /

- carbides /

- martensitic flat noodles

-

0. 引言

随着社会的进步和科技的发展,汽车行业内环保和安全问题逐渐凸显。为了满足汽车车身轻量化、低碳化,提高汽车车身安全性,因此汽车车身大多采用高强度汽车板。冷冲压高强钢因为冲压过程容易发生开裂及回弹,所以限制了冷冲压高强钢在汽车车身上面的使用。

现在汽车A柱、B柱等零部件大多使用热冲压技术。热成形工艺是将板料加热到奥氏体化温度以上并保温,使得奥氏体均匀化,然后转移到模具内进行模内淬火,把奥氏体转变成马氏体,使得零件强度得到大幅度提升[1−2]。淬火后零件虽然强度高,但是塑性较低、存在内应力,因此对零件进行回火处理是必要的。许多学者对于淬火后热成形钢回火温度以及回火时间进行研究,探究其力学性能以及组织转变规律。宋宁宏等[3]研究了回火时间对

1800 MPa级热成形钢组织和性能的影响,试验钢热处理工艺采用930 ℃保温4 min淬火,接着在200 ℃回火10~30 min,空冷至室温,经20 min回火后,马氏体亚晶粒尺寸最小;回火10 min后,组织中的小角度晶界最多,其强塑积也最高。徐德超等[4]研究了回火温度对淬火22MnB5热成形钢组织及性能的影响,试验钢采用900 ℃保温5 min淬火,然后100~500 ℃回火10 min,空冷至室温。随回火温度的升高,试验钢抗拉强度降低,断后伸长率增加。程俊业等[5]研究了回火温度对淬火后30MnB5热成形钢组织与性能的影响,30MnB5热成形钢经不同温度回火处理后发现在200 ℃保温2 min回火后得到的综合力学性能最佳。某钢厂新开发

1500 MPa热成形钢,相对于传统22MnB5热成形钢添加了大量合金元素,不仅提高了热成形钢淬透性,而且会在表面形成一层致密的氧化膜,提高抗氧化性能。由于材料属于新开发钢种,笔者对其进行热处理工艺探究,研究不同回火温度对淬火后组织和力学性能的影响,探究材料最佳回火工艺参数。1. 试验材料和方法

1500 MPa热成形钢原始板材组织主要是铁素体、珠光体。采用英国阿朗科技公司直读光谱仪(型号:ARTUS8)进行化学成分检测,测试标准依据为GB/T4336-2016,主要化学成分为0.21C、1.2Mn、Si+Cr≤5、0.029Al、0.029Ti、0.0033 B、0.067Nb,余量为 Fe。利用经验公式计算1500 MPa热成形钢$A_{\mathrm{C}_3} $、$A_{\mathrm{C}_1} $、MS点,见公式(1)~(3)[6-9]。$$ \begin{split} &M_{\mathrm{s}}\left({^ \circ {\mathrm{C}}}\right)=499-292 \mathrm{C}-32.4 \mathrm{Mn}-22 \mathrm{Cr}-\\ & 16.2 \mathrm{Ni}-10.8 \mathrm{Si}-10.8 \mathrm{Mo} \end{split}$$ (1) $$ \begin{split} &A_{\mathrm{C}_3}\left({^ \circ {\mathrm{C}}}\right)=910-203 \mathrm{C} - 15.2 \mathrm{Ni} + 44.7 \mathrm{Si} + \\ & 104 \mathrm{V} + 31.5 \mathrm{Mo} + 13.1 \mathrm{W} - (30 \mathrm{Mn} + 11 \mathrm{Cr}+20 \mathrm{Cu}-\\ & 700 \mathrm{P}-400 \mathrm{Al}-120 \mathrm{As}-400 \mathrm{Ti}) \end{split} $$ (2) $$ \begin{split} &A_{\mathrm{C}_1}\left({^ \circ {\mathrm{C}}}\right)=723 - 10.7 \mathrm{Mn} - 6.9 \mathrm{Ni} + 29.1 \mathrm{Si}+\\ & 16.9 \mathrm{Cr}+290 \mathrm{As}+6.38 \mathrm{W} \end{split} $$ (3) 计算得到Ms=317 ℃,$A_{\mathrm{C}_3} $=857 ℃,$A_{\mathrm{C}_1} $=801 ℃。

试验采用如下热加工工艺:先把马弗炉升温到930 ℃,然后把材料放入保温5 min,让其达到奥氏体化温度并奥氏体均匀化,随后取出水冷,再把马弗炉降温到500、400、300、200 ℃进行回火10 min处理(为防止材料在奥氏体化阶段及回火阶段被氧化,马弗炉在加热过程中全程都通入氮气作为保护气体,为保证试验准确性,3个为一组)。

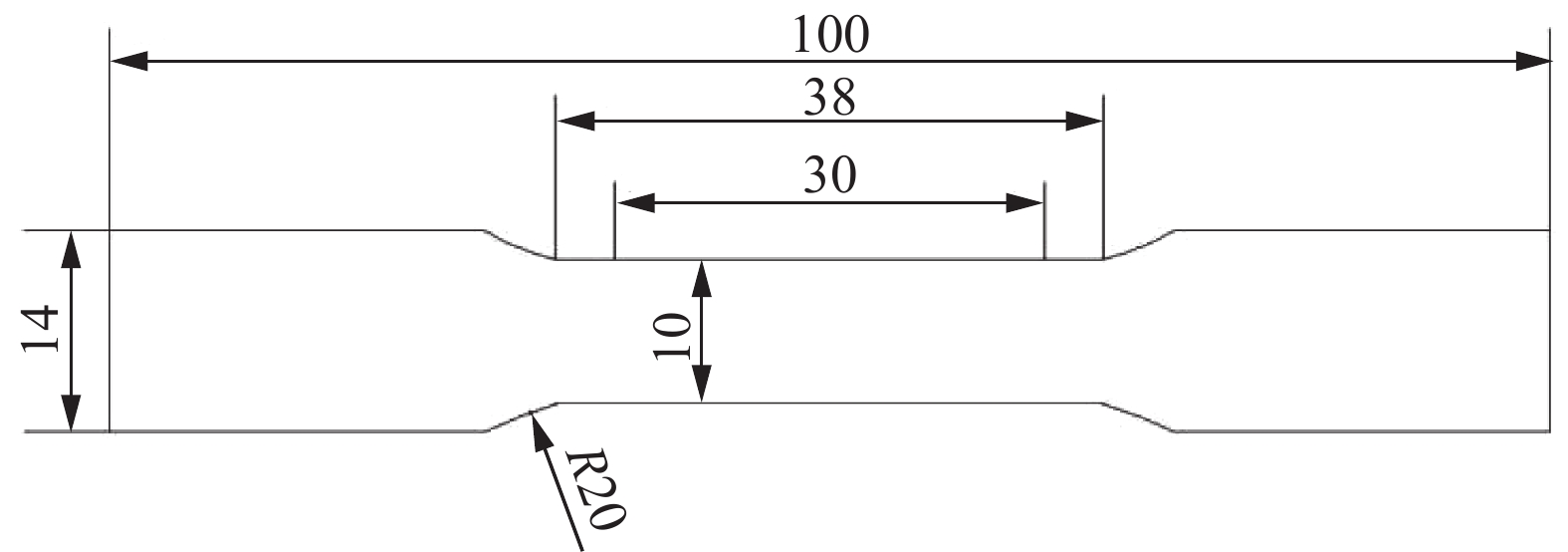

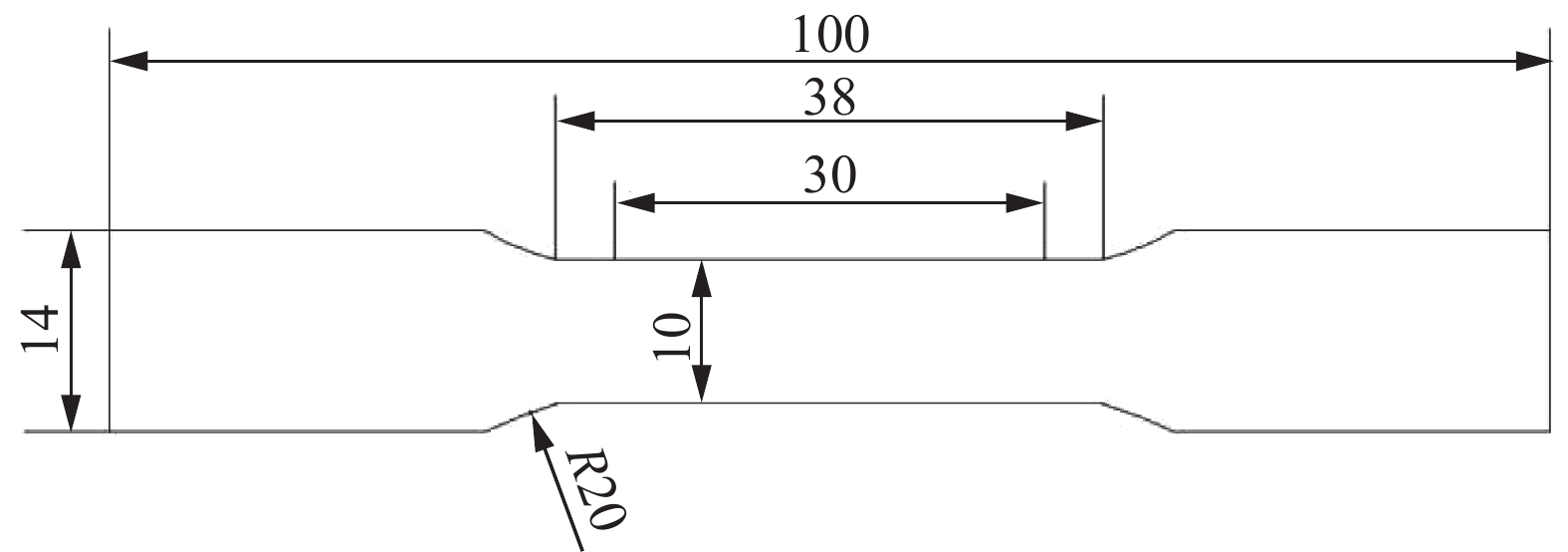

采用Instron3382型电子万能拉伸试验机进行力学性能测试,拉伸速率为3 mm/min,测试标准依据GB/T228.1-2010《金属材料拉伸试验第1部分:室温实验方法》,采用国标A30试样进行拉伸试验,拉伸试样在轧制方向上使用线切割进行切割,试样尺寸如图1所示。硬度测试采用HV-10小负荷维氏硬度计进行,每组试验均选取五个点的硬度,然后取平均值。金相试样采用DS-300金相显微镜进行拍照。

2. 试验结果和分析

2.1 热力学分析

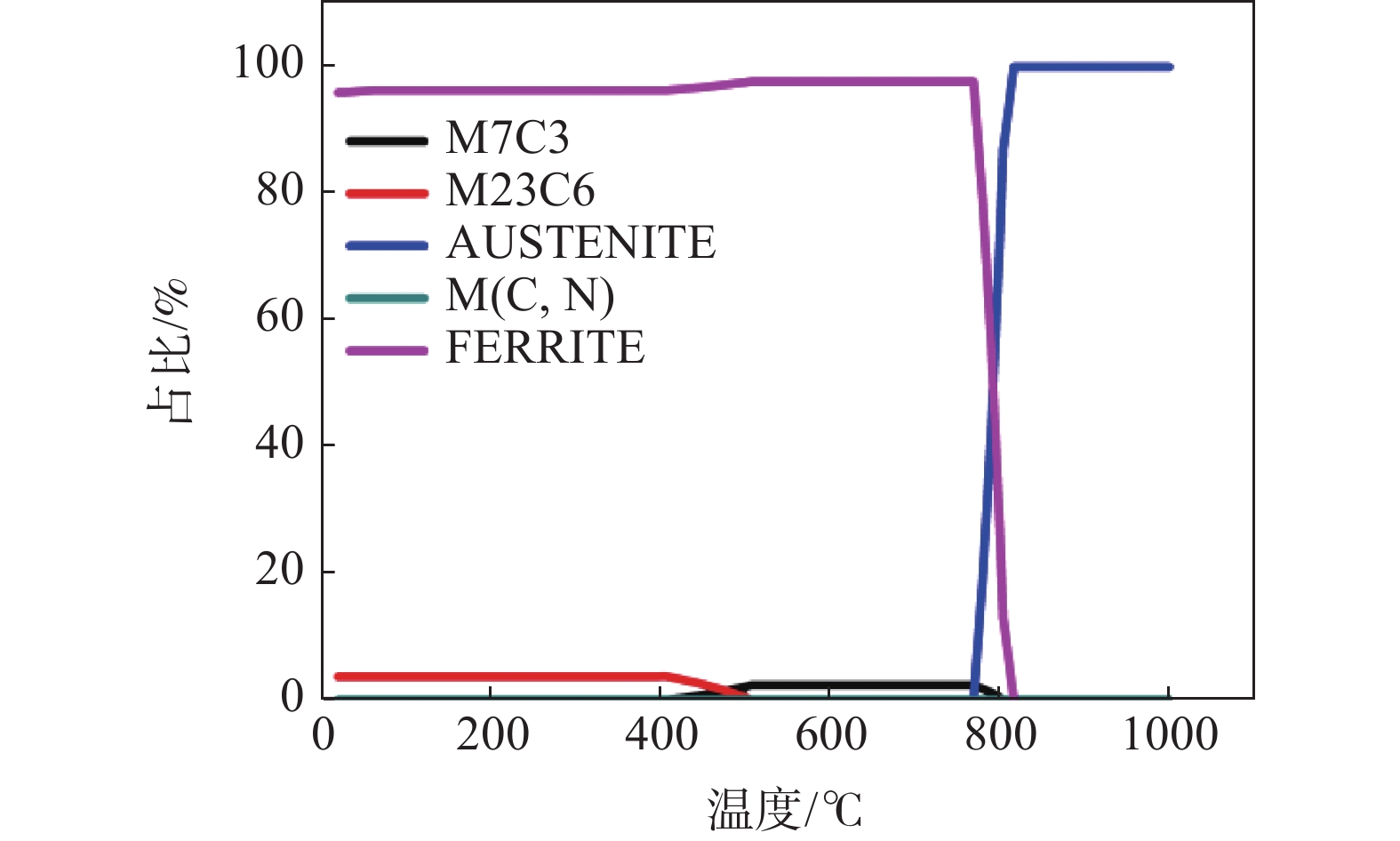

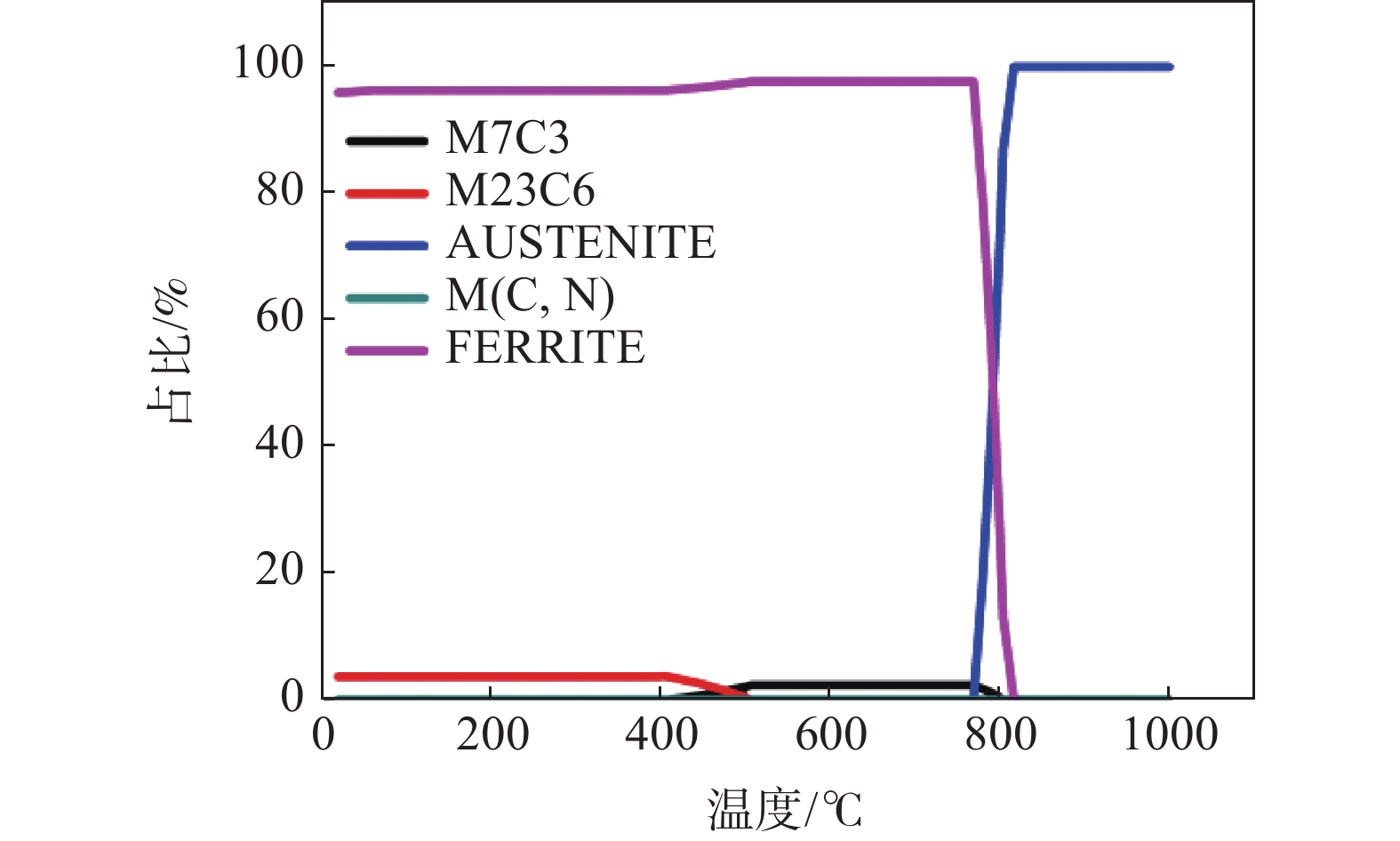

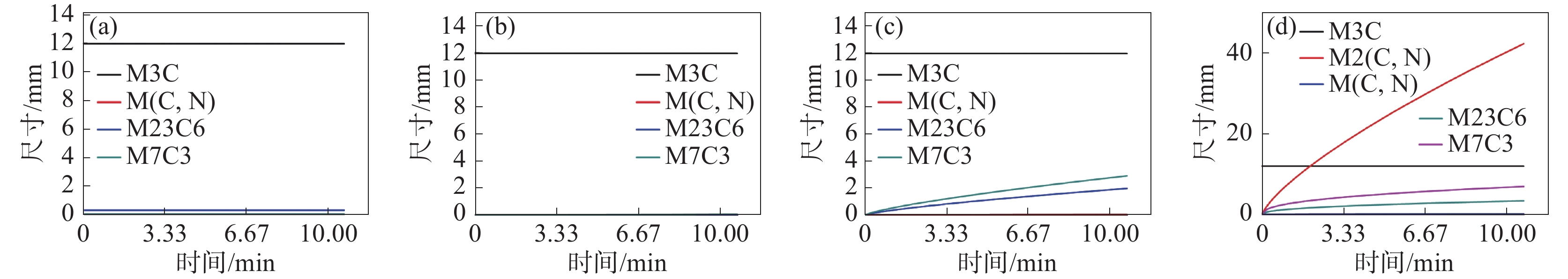

在JMatPro通用钢模块中输入材料化学成分计算平衡相图,如图2所示。当温度降低到850 ℃左右时,$ {\gamma} $奥氏体向$ {\alpha} $铁素体开始转变,碳固溶度会快速降低,因此钢中Cr、Ti等元素会以碳化物的形式从钢基体中析出。由于Cr含量过高会抑制C的活度,导致渗碳体不能稳定存在,所以钢基体中主要的碳化物是M23C6和M7C3。M7C3大约在800 ℃析出,随着温度的降低,在400 ℃转化成M23C6,并一直保持到室温。M23C6最大含量为3.67%,M7C3最大含量为2.3%。

2.2 力学性能

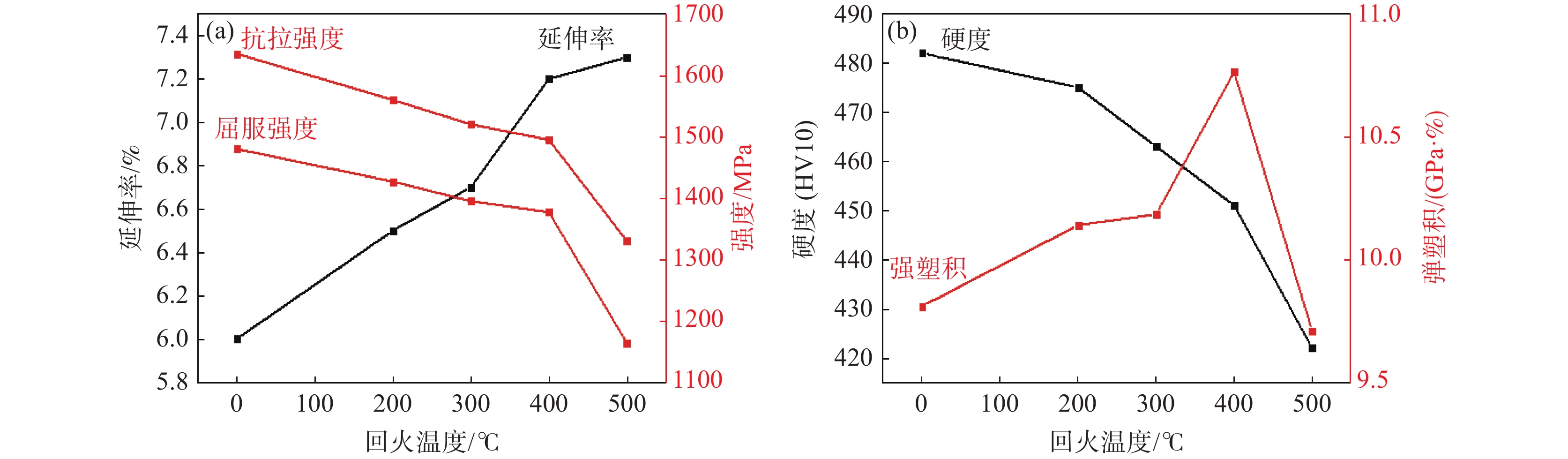

材料经过930 ℃完全奥氏体化并水淬后,再经过不同回火温度(200、300、400、500 ℃)保温10 min后的力学性能如图3(a)(b)所示,回火温度200~400 ℃时,马氏体中的碳随着回火温度的升高逐渐从基体中扩散出去,而马氏体的强度是由马氏体中的碳含量决定的,所以抗拉强度、屈服强度和硬度随着回火温度的升高而缓慢降低,且下降趋势呈现一致,当回火温度超过400 ℃时,由于马氏体组织中碳扩散速率增大、碳含量下降,导致马氏体组织出现分解情况,所以抗拉强度、屈服强度和硬度均快速降低;回火温度从0 ℃到500 ℃,延伸率与回火温度成正比,但强塑积先随着回火温度的升高而升高,达到400 ℃以后,强塑积随着回火温度的升高而下降。此时因为回火温度较高,同时还存在塑性的作用,导致位错增殖和攀移的阻力较小,在变形过程中,应力增加幅度较小,加工硬化率急剧下降,裂纹扩展导致断裂[5]。因此综合对比不同回火温度下的力学性能可以发现,当回火温度为400 ℃时,材料力学性能最优。

2.3 显微组织

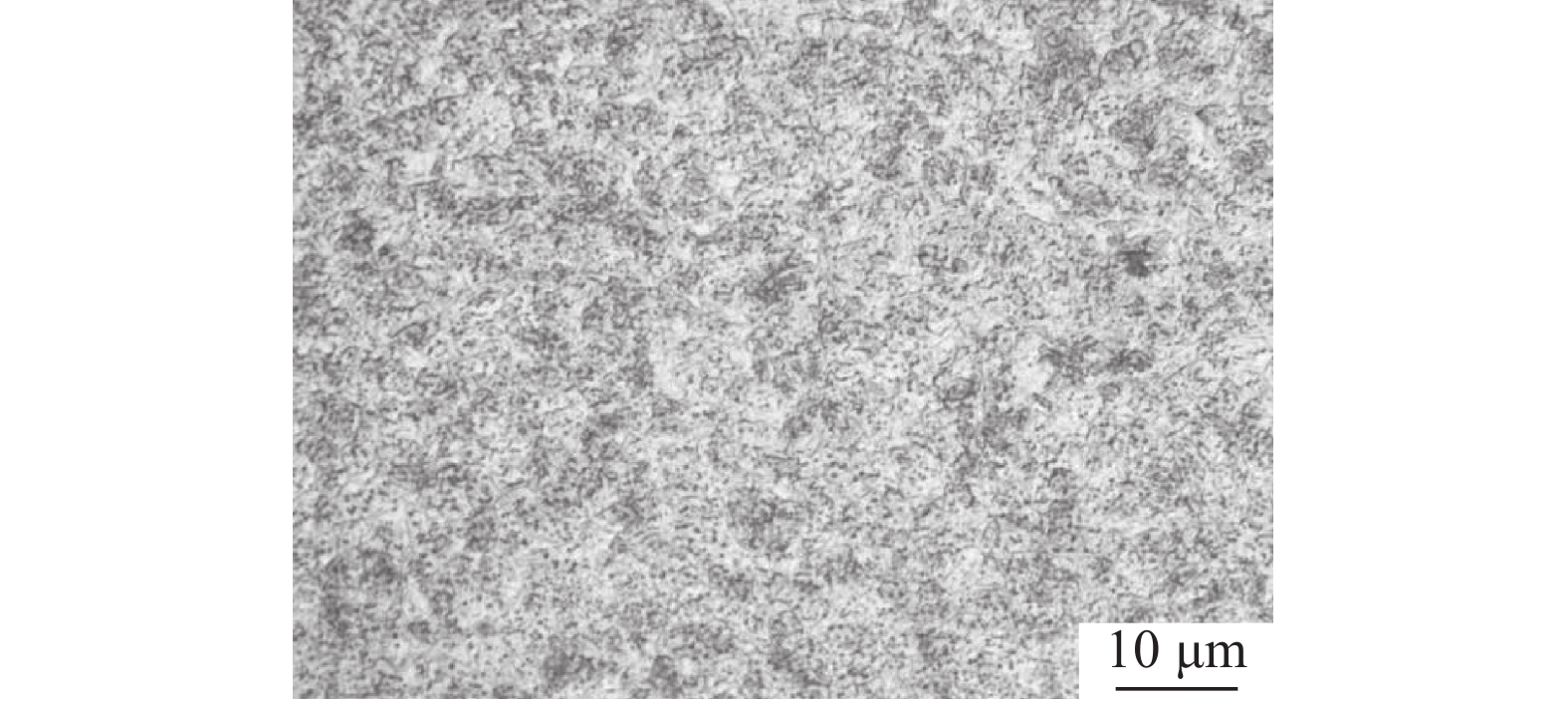

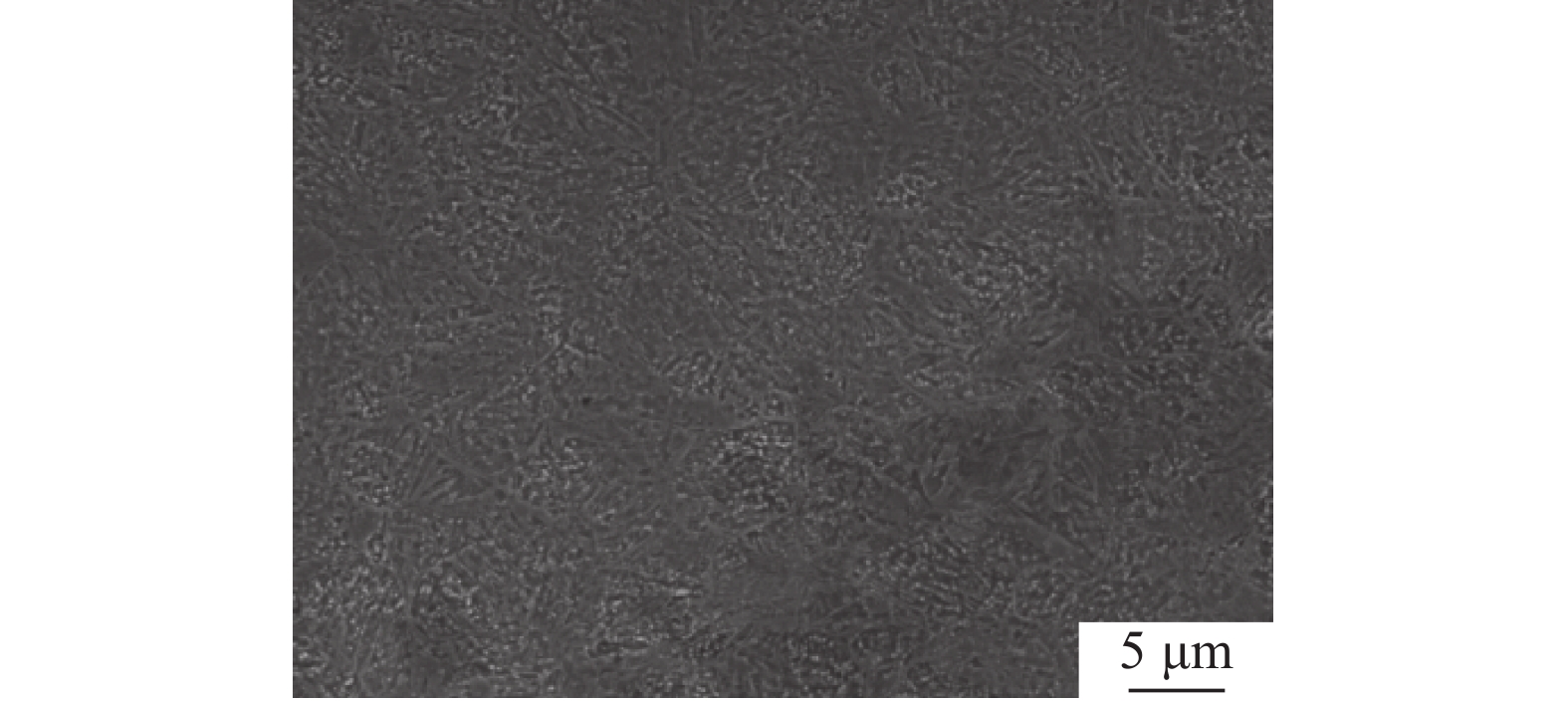

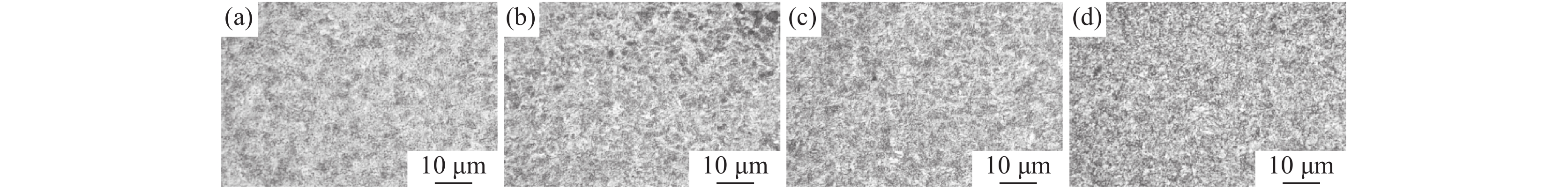

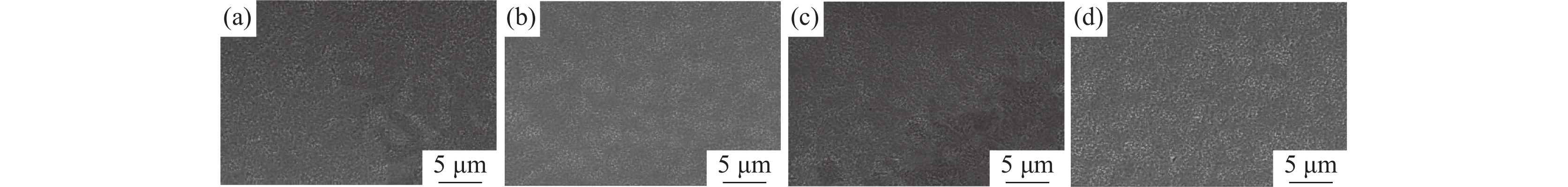

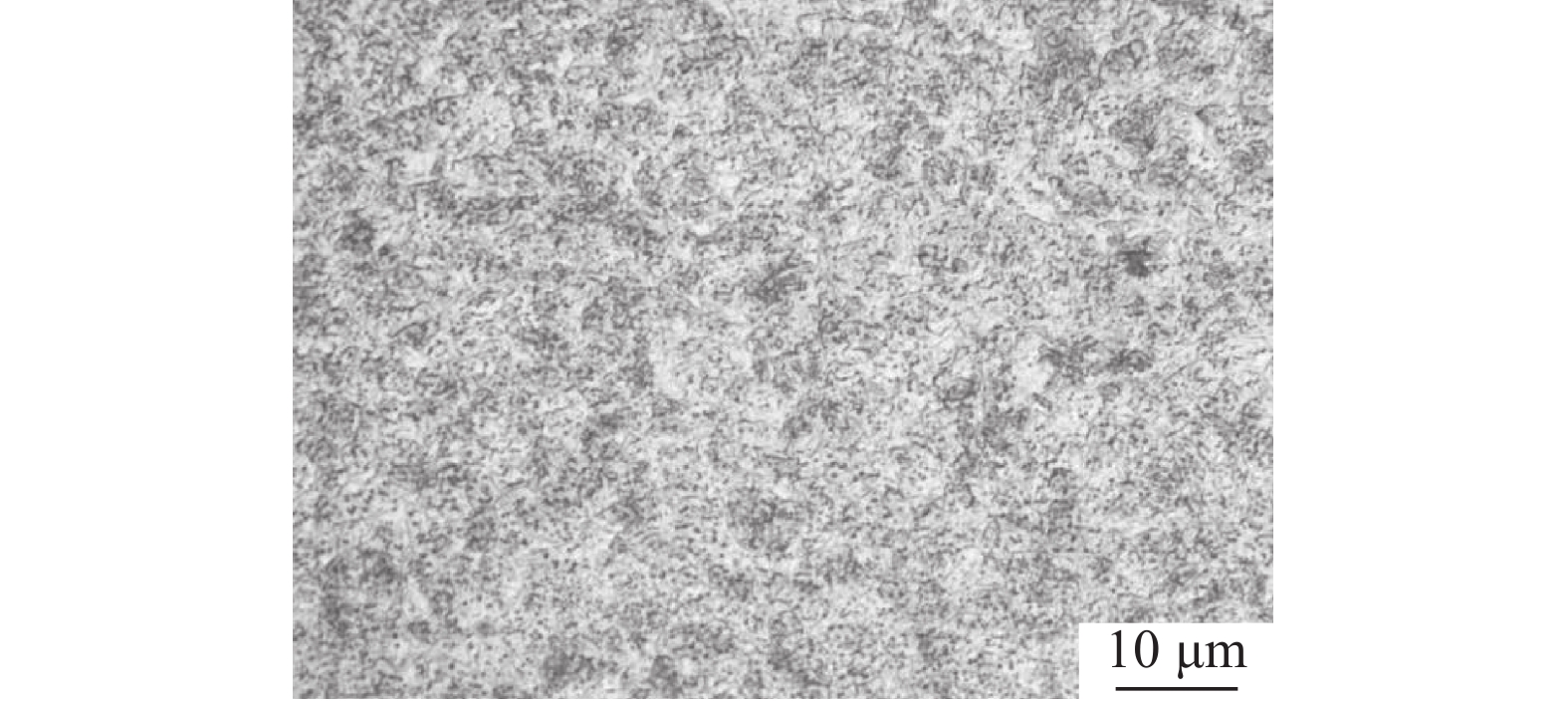

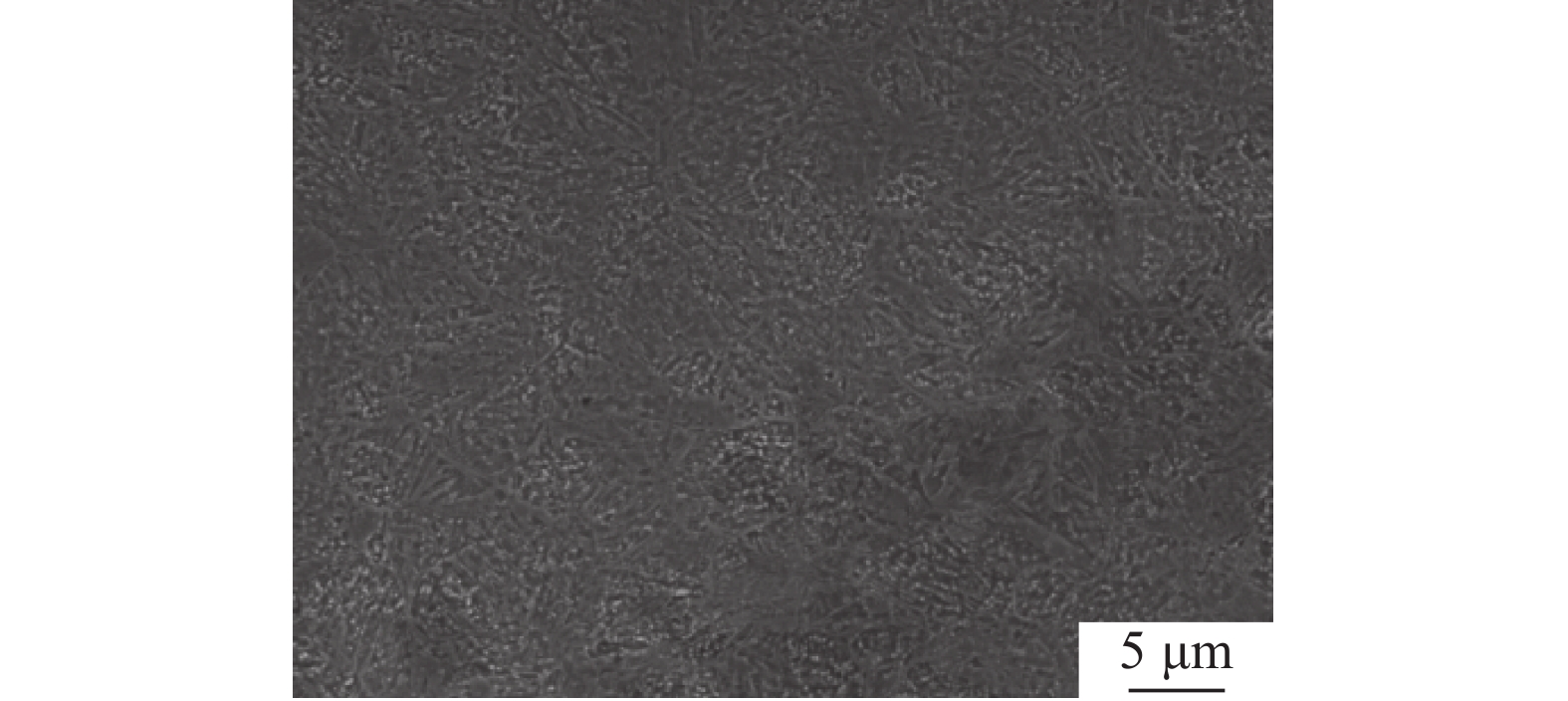

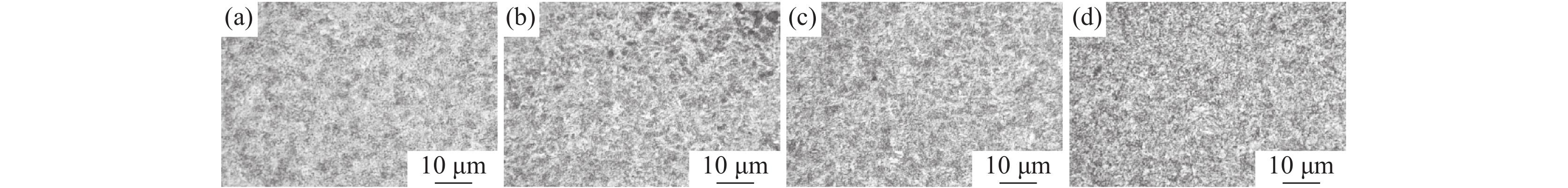

图4、5为淬火后金相和SEM照片,淬火态的马氏体组织主要呈板条状,基体中存在大量第二相粒子,这是材料相较于普通22MnB5钢力学性能提升的原因。图6、7为回火处理后金相和SEM照片,随着回火温度的升高,位错、滑移逐渐剧烈,马氏体从饱和亚稳态向平衡态转化,而且马氏体中碳含量降低,碳化物大量析出长大,从而表现出强度降低、塑性提高的情况。

如图7(a)所示,经200 ℃回火后的显微组织为回火马氏体,马氏体内部主要发生碳的扩散、聚集和重新分布,淬火内应力得到部分消除,位错密度降低[10]。因为是较低温度回火处理,所以马氏体板条形态仍被保留,但是位错密度略有降低,存在碳化物粒子的析出行为,导致基体内固溶碳的减少。基体中固溶碳的扩散和位错密度的降低会使得强度降低,而位错周围析出的碳化物容易和位错发生钉扎作用[11],使得位错减少。如图7(c)所示,随着回火温度的升高,板条马氏体回复程度增加,部分马氏体板条边界消失,随着基体中碳的扩散,碳化物逐渐长大粗化,固溶强化作用降低[12]。如图7(d)所示,500 ℃回火后大部分马氏体板条消失,基体中出现铁素体,这是经500 ℃回火后强度显著下降的主要原因,碳化物则进一步长大、球化。

2.4 讨论

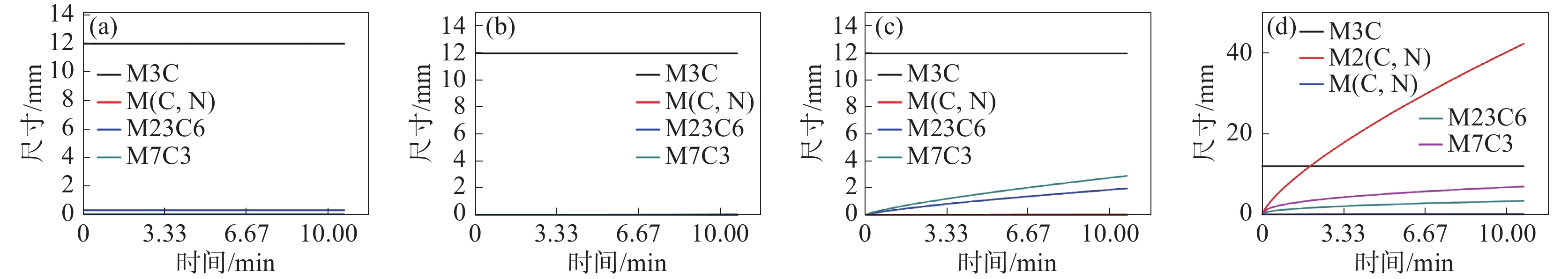

如图5、7所示,材料通过淬火和回火处理后,强度随着回火温度的升高而降低,延伸率随着回火温度的升高而增加,马氏体板条中碳含量下降,而且有部分马氏体板条的边界消失,碳化物也会逐渐粗化、球化。这种情况是基于显微组织变化的结果,主要表现为板条马氏体的回复和再结晶、基体固溶碳和位错等缺陷的减少、残余奥氏体分解以及第二相粒子的形核、长大和粗化[13]。而且由于合金含量较高会抑制渗碳体的形成,因此基体中主要存在的碳化物为M23C6和M7C3类。如图8所示,回火温度小于400 ℃时,主要碳化物为M23C6类,而且碳化物尺寸几乎没有发生长大,基体中存在一定碳化物扩散,所以强度有所下降;当回火温度大于400 ℃时,主要碳化物由M23C6类转化为M7C3类,而且总碳化物含量由3.67%降低到2.3%,碳化物尺寸也增大2~3倍,所以此时钢的强度迅速下降。

3. 结论

1)Cr含量过高会降低C的活度,抑制渗碳体的形成,因此主要碳化物为M23C6和M7C3类,随着回火温度提高到400 ℃左右时,碳化物会由M23C6类转化为M7C3类。

2)随回火温度的升高,抗拉强度和屈服强度降低,延伸率增加,强塑积则呈现先升高后下降趋势。综合对比各个回火温度下力学性能,当回火温度为400 ℃时,抗拉强度和屈服强度为

1495 MPa和1377 MPa,对比淬火试样变化幅度不大,而塑性得到明显改善,延伸率为7.2%,强塑积为10.764 GPa·%,是不同回火温度下最高的强塑积。3)材料淬火组织主要为板条马氏体,随着回火温度的升高,板条马氏体中存在的高密度位错会随着回火温度的升高而下降,此外碳化物也会析出并长大。

-

-

[1] Turetta A, Bruschi S, Ghiotti A. Investigation of 22MnB5 formability in hot stamping operations[J]. Journal of Materials Processing Technology , 2006, 177(1-3): 396-400. [2] Nikravesh M, Naderi M, Akbari G H. Influence of hot plastic deformation and cooling rate on martensite and bainite start temperatures in 22MnB5 steel[J]. Materials Science and Engineering: A, 2012,540:24-29. doi: 10.1016/j.msea.2012.01.018 [3] Song Ninghong, Lin Chao, Bi Wenzhen, et al. The effect of tempering time on the microstructure and properties of 1800 MPa hot formed steel[J]. Metal Heat Treatment, 2022,47(08):112-117. (宋宁宏, 林超, 毕文珍, 等. 回火时间对1800 MPa级热成形钢组织和性能的影响[J]. 金属热处理, 2022,47(8):112-117.Song Ninghong, Lin Chao, Bi Wenzhen, et al. The effect of tempering time on the microstructure and properties of 1800 MPa hot formed steel[J]. Metal Heat Treatment, 2022, 47(08): 112-117. [4] Xu Dechao, Zhao Haifeng, Li Xuetao, et al. The effect of tempering temperature on the microstructure and properties of quenched 22MnB5 hot formed steel[J]. Journal of Materials Heat Treatment, 2018,39(8):88-94. (徐德超, 赵海峰, 李学涛, 等. 回火温度对淬火22MnB5热成形钢组织及性能的影响[J]. 材料热处理学 报, 2018,39(8):88-94.Xu Dechao, Zhao Haifeng, Li Xuetao, et al. The effect of tempering temperature on the microstructure and properties of quenched 22MnB5 hot formed steel[J]. Journal of Materials Heat Treatment, 2018, 39(8): 88-94. [5] Cheng Junye, Zhao Aimin, Chen Yinli, et al. Effect of tempering temperature on the microstructure and properties of quenched 30MnB5 hot formed steel[J]. Journal of Beijing University of Science and Technology, 2013,35(9):1150-1157. (程俊业, 赵爱民, 陈银莉, 等. 回火温度对淬火后30MnB5热成形钢组织与性能影响[J]. 北京科技大学学报, 2013,35(9):1150-1157.Cheng Junye, Zhao Aimin, Chen Yinli, et al. Effect of tempering temperature on the microstructure and properties of quenched 30MnB5 hot formed steel[J]. Journal of Beijing University of Science and Technology, 2013, 35(9): 1150-1157. [6] Liu Cheng, Zhao Zhenbo, Northwood Derek O, et al. A new empirical formula for the calculation of MS temperatures in pure iron and super-low carbon alloy steels[J]. Journal of Materials Processing Technology, 2001,113(1-3):556-562. doi: 10.1016/S0924-0136(01)00625-2 [7] Trzaska J. Calculation of critical temperatures by empirical formulae[J]. Archives of Metallurgy and Materials, 2016,61(2):981-986. doi: 10.1515/amm-2016-0167 [8] Sabih A, Elwazri A M, Nemes J A, et al. A workability criterion for the transformed adiabatic shear band phenomena during cold heading of 1038 steel[J]. Journal of Failure Analysis and Prevention, 2006,6:97-105. doi: 10.1007/BF03197706 [9] Daniel Alexandre da Costa Ximenes, Luciano Pessanha Moreira, José Eduardo Ribeiro de Carvalho, et al. Phase transformation temperatures and Fe enrichment of a 22MnB5 Zn-Fe coated steel under hot stamping conditions[J]. Journal of Materials Research and Technology, 2020,9(1):629-635. doi: 10.1016/j.jmrt.2019.11.003 [10] Wang Lijun, Cai Qingwu, Wu Huibin, et al. Effect of tempering temperature on the microstructure and properties of 1500 MPa grade directly quenched steel[J]. Journal of Beijing University of Science and Technology, 2010, 32 (9):1150-1156. (王立军, 蔡庆伍, 武会宾, 等. 回火温度对1500 MPa级直接淬火钢组织与性能的影响[J]. 北京科技大学学报, 2010, 32(9):1150-1156.Wang Lijun, Cai Qingwu, Wu Huibin, et al. Effect of tempering temperature on the microstructure and properties of 1500 MPa grade directly quenched steel[J]. Journal of Beijing University of Science and Technology, 2010, 32 (9): 1150-1156. [11] Liu Yazheng. Fundamentals of material forming theory[M]. Beijing: National Defense Industry Press, 2004:326. (刘雅政. 材料成形理论基础[M]. 北京: 国防工业出版社, 2004:326.Liu Yazheng. Fundamentals of material forming theory[M]. Beijing: National Defense Industry Press, 2004: 326. [12] Chi Hongxiao, Ma Dangsheng, Xu Huiya, et al. Phase transformation of a cold work tool steel during tempering[J]. Journal of Iron and Steel Research, International, 2016(5):484-488. [13] Liu Qingdong, Liu Wenqing, Wang Zemin, et al. 3D atomic probe characterization of alloy carbides in tempered martensite I Nucleation [J] Journal of Metals, 2009, 45 (11): 1281-1287. (刘庆冬, 刘文庆, 王泽民, 等. 回火马氏体中合金碳化物的 3D 原子探针表征Ⅰ. 形核[J]. 金属学报, 2009, 45(11): 1281-1287.Liu Qingdong, Liu Wenqing, Wang Zemin, et al. 3D atomic probe characterization of alloy carbides in tempered martensite I Nucleation [J] Journal of Metals, 2009, 45 (11): 1281-1287. -

下载:

下载:

下载:

下载: