Effect of annealing process on microstructure and properties of 2Cr12Ni4Mo3VNbN blade steel

-

摘要: 针对2Cr12Ni4Mo3VNbN工业棒材退火硬度偏高问题,系统研究了不同退火工艺对2Cr12Ni4Mo3VNbN叶片钢组织和硬度的影响。结果表明:相较于两相区加热退火和不完全退火的一段式退火,完全退火具有更好的退火效果,退火后硬度最低,且炉冷可使硬度进一步降低。采用两段式退火和三段式退火可改善组织均匀性,显著降低硬度,而三段式退火工艺优于一段式退火和两段式退火工艺。Abstract: In order to solve the problem of high annealing hardness of 2Cr12Ni4Mo3VNbN industrial bar, the effects of different annealing processes on the microstructure and hardness of 2Cr12Ni4Mo3VNbN blade steel were systematically studied. The results show that compared with two-phase zone heating annealing and incomplete annealing, complete annealing has better annealing effect, the hardness is the lowest after annealing, and the hardness can be further reduced by furnace cooling. The two-stage annealing and three-stage annealing can improve structure uniformity and significantly reduce the hardness. The multi-stage annealing process is better than the one-stage annealing and two-stage annealing with regards to hardness reduction through annealing.

-

Key words:

- blade steel /

- annealing temperature /

- annealing time /

- multi-stage annealing

-

0. 引言

2Cr12Ni4Mo3VNbN是一种新型叶片钢,应用于汽轮机末级叶片,叶片钢在服役过程中,因环境中含有的氯、硫等腐蚀介质,会在应力集中处发生点蚀,继而导致开裂[1-2]。2Cr12Ni4Mo3VNbN在2Cr12的基础上添加Ni、Mo、V、Nb、N等元素进行性能调控,优化组织。王刚健[3]认为,无论是1Cr12还是2Cr12,在退火过程中都存在退火时间过长,退火过程中产生碳排放过高的问题,延长退火时间是一种简单的退火工艺,进一步优化退火工艺,能够降低生产成本,提高产品的竞争力[4-6]。闫扶摇等[7]采取退火工艺优化,利用两步退火软化工艺将CTHQ25钢硬度从276降至240,其中杨钢等[8]对1Cr12的退火研究表明,1Cr12Ni3Mo2VN钢最优的退火工艺为两相区退火加再结晶退火的二段式退火,并认为退火过程中的软化程度主要受碳化物的影响。

目前国内外对2Cr12Ni4Mo3VNbN叶片钢的研究较少,高圆等[9]对2Cr12Ni4Mo3VNbN高频淬火后的显微组织和疲劳性能进行研究,发现高频淬火后晶粒得到细化,可以提高疲劳裂纹扩展抗力。刘帅等[10]对2Cr12Ni4Mo3VNbN进行了前期的热力学计算,表明该钢中主要的析出相为MX相、M23C6和M6C,2Cr12Ni4Mo3VNbN由于具有高强度,其抗拉强度可达

1400 MPa,其具有难加工性,退火后可降低硬度[11-12],便于机械加工的精确性,且样品易于加工,有利于降低生产成本。有关该钢种退火工艺对硬度及组织的影响的研究相对匮乏,为此,笔者结合试验数据对退火工艺进行研究,探究退火工艺对硬度和组织的影响。1. 试验材料及方法

对2Cr12Ni4Mo3VNbN试验钢采用EBT+AOD+LF+VD的工艺进行冶炼,其主要化学成分见表1,经过墩拔工艺后将样品加工成Ø135 mm棒材样品,在样品的中心半径位置取金相样以及硬度样块,金相样尺寸为10 mm×10 mm×10 mm,硬度样尺寸为10 mm×10 mm×8 mm,将试样采用退火试验工艺后再加工,利用gleeble热模拟仪对样品进行CCT曲线测试试验,随后对样品进行硬度、金相试验。利用砂纸对样品进行打磨,抛光后用FeCl3溶液进行侵蚀,观察其微观组织,并进行硬度检测和物相分析,将机械抛光后样品在6%高氯酸酒精溶液中进行电解抛光,电压为20 V,电解时间为20 s,获得EBSD(Electron Backscatter Diffraction)样品。

表 1 试验料的主要化学成分Table 1. Main chemical composition of test materials% C Cr Ni Mo V Nb N 0.2 12 4 3 0.25 0.15 0.06 2. 试验结果分析

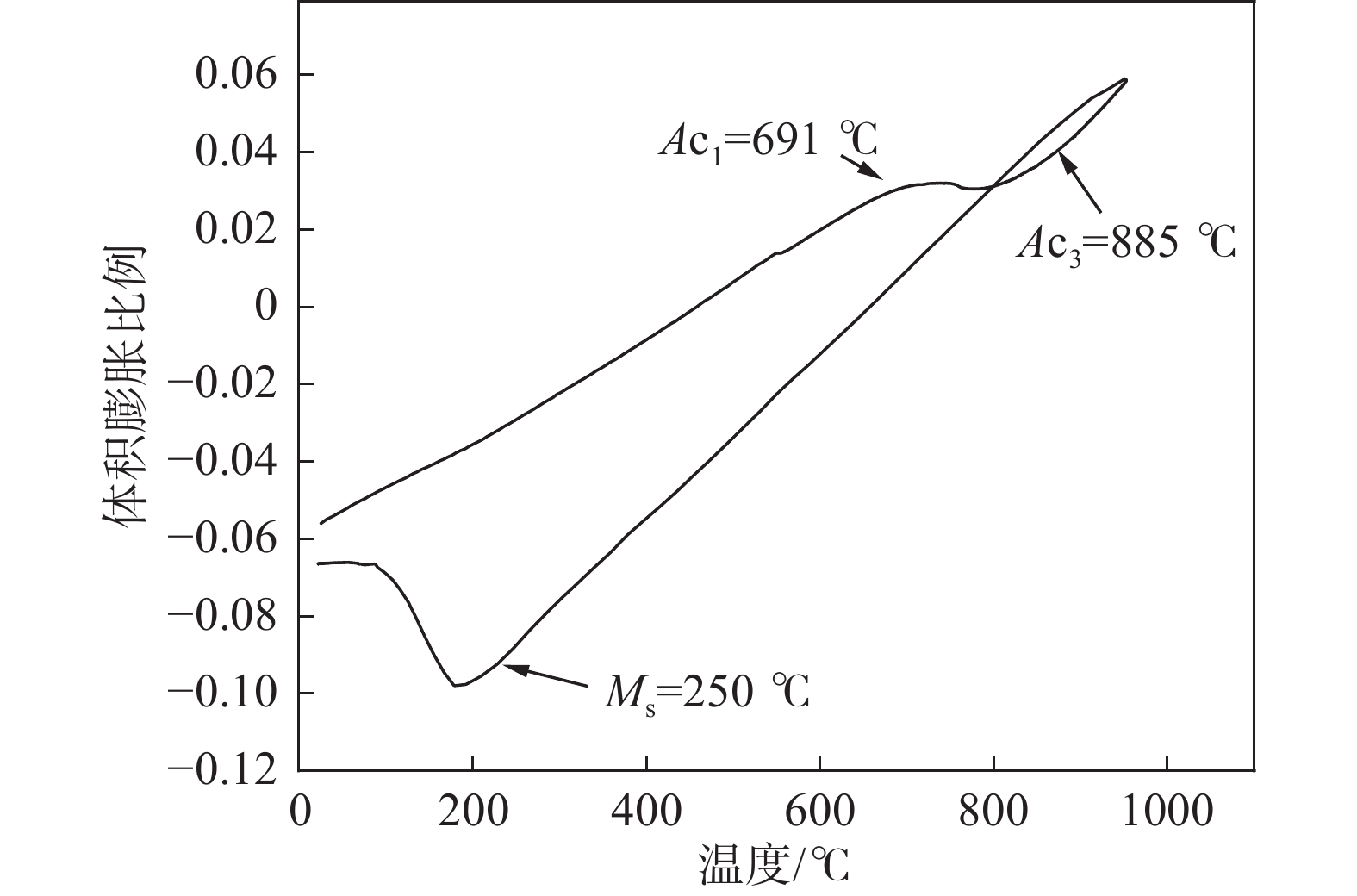

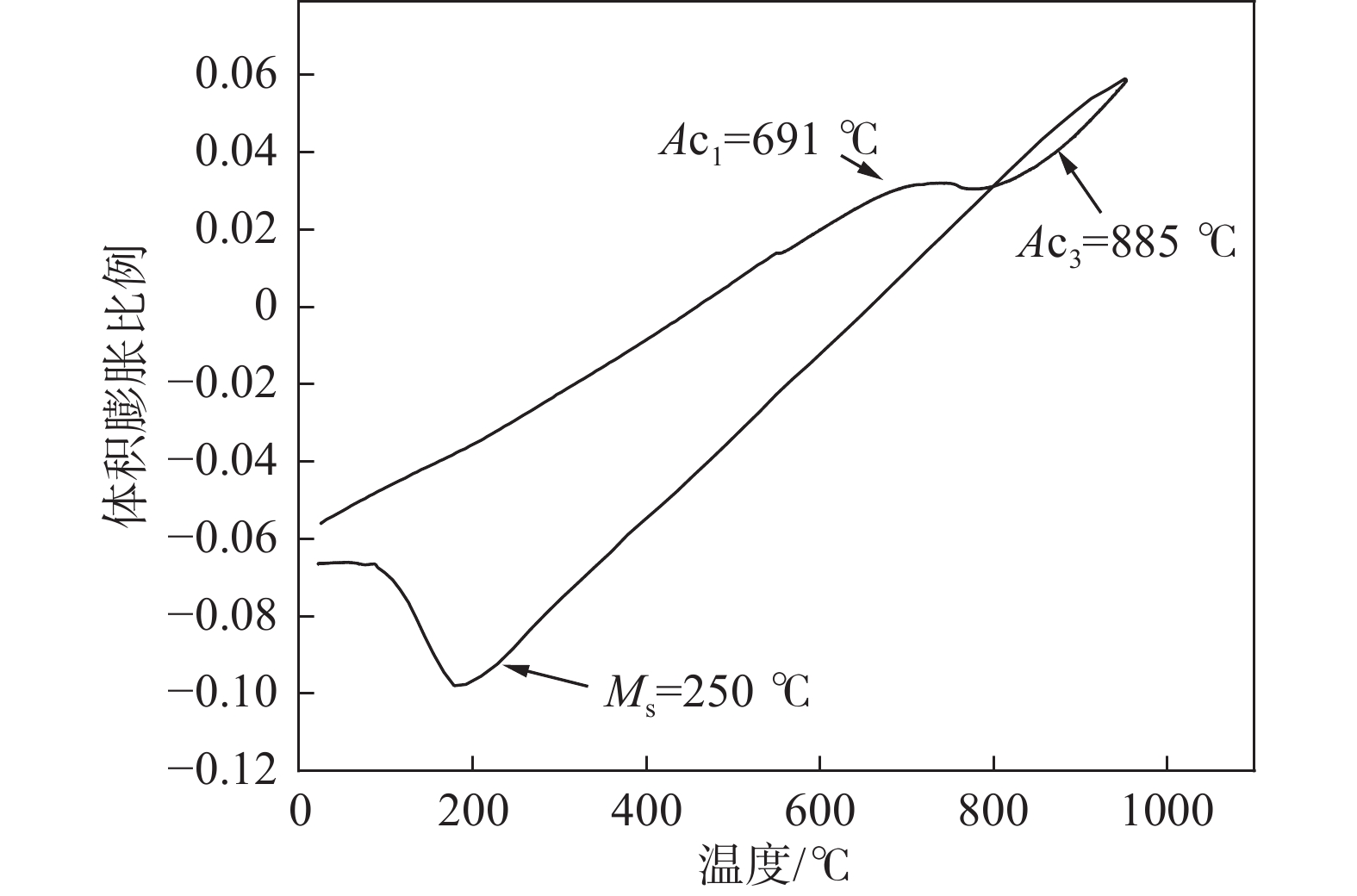

对于马氏体钢来说,奥氏体的含量及碳化物析出是影响其性能的重要因素,少量的奥氏体尤其是逆转变奥氏体可以提高钢的韧性,但过多的奥氏体会导致强度显著下降。通过测量热膨胀曲线来确定Ac1、Ac3、Ms、Mf点,如图1所示,2Cr12Ni4Mo3VNbN的奥氏体转变开始温度Ac1为691 ℃、奥氏体转变结束温度Ac3为886 ℃,马氏体转变点Ms是250 ℃,马氏体转变结束点Mf在室温以下。

依据Ac1、Ac3设计不同温度、不同退火时间对硬度和组织的影响,不同退火温度为完全退火(930 ℃×4 h)、不完全退火(770 ℃×4 h)以及再结晶退火(680 ℃×4 h),并探究不同退火时间对组织的影响,一段式退火工艺试验方案如表2所示。

表 2 一段式退火工艺试验方案Table 2. One-stage annealing practice of samples试验方案 退火温度/℃ 退火时间/h 冷却方式 试验目的 1 770 4,12,24,30,40,50 FC 退火时间对

组织的影响2 680,770,930 4 AC 退火温度对

组织的影响2.1 退火温度对硬度和组织的影响

分别对样品钢进行680 ℃×4 h、770 ℃×4 h、930 ℃×4 h退火试验,进行布氏硬度检测,结果如表3所示,通过对比退火温度对硬度的影响可知,随着退火温度的增加,样品的硬度增加,这是由于样品达到奥氏体化温度以后,在冷却的过程中产生了新的马氏体,且析出了碳化物,碳化物的析出区间为770~930 ℃,导致硬度提高,与退火前的样品相比较,退火后硬度均降低。

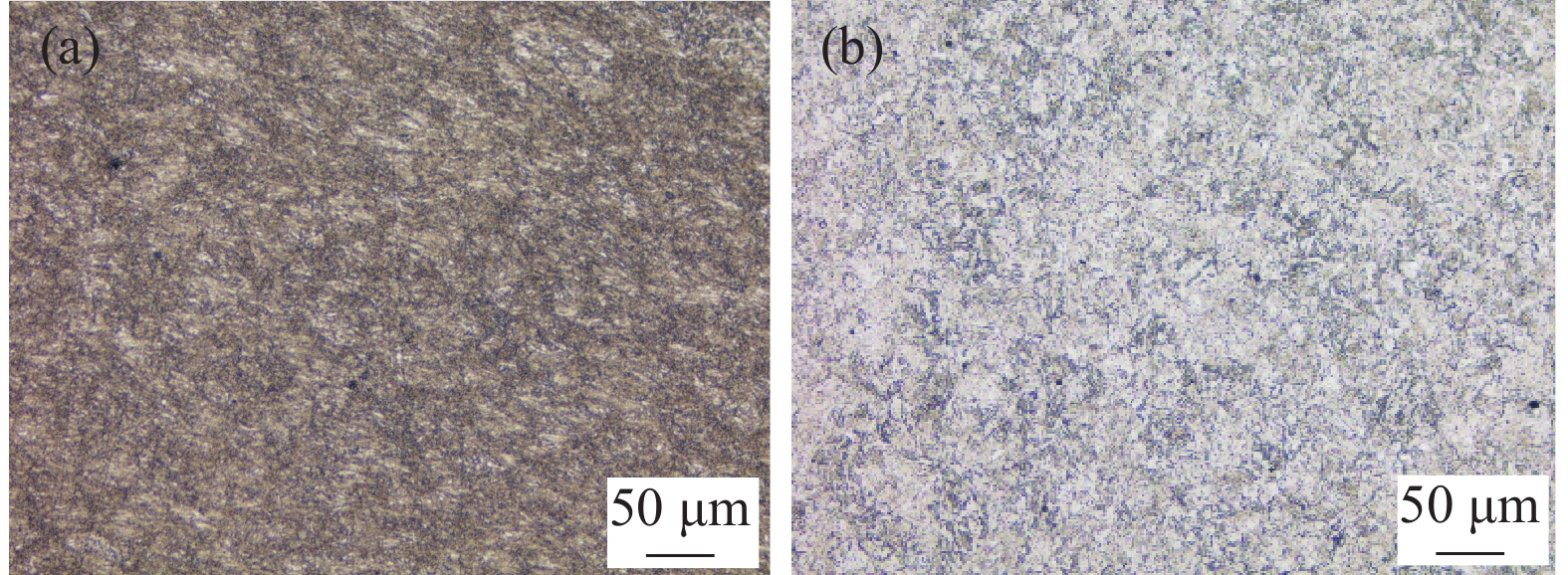

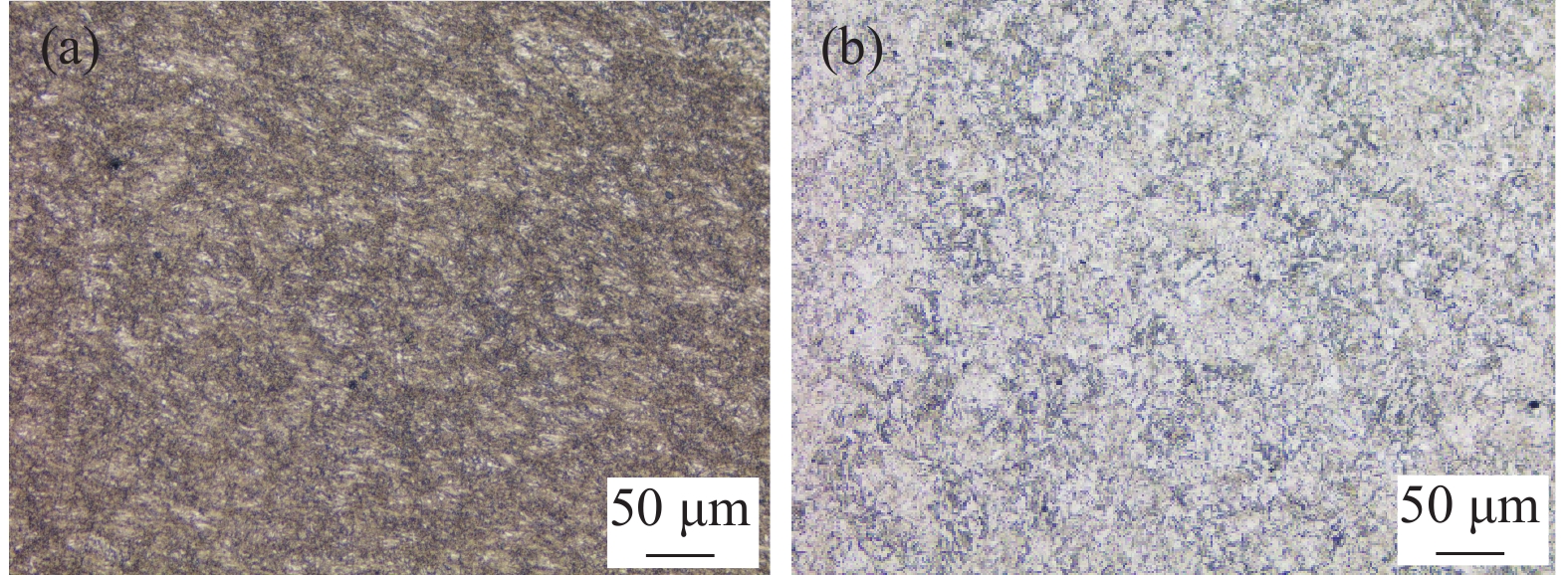

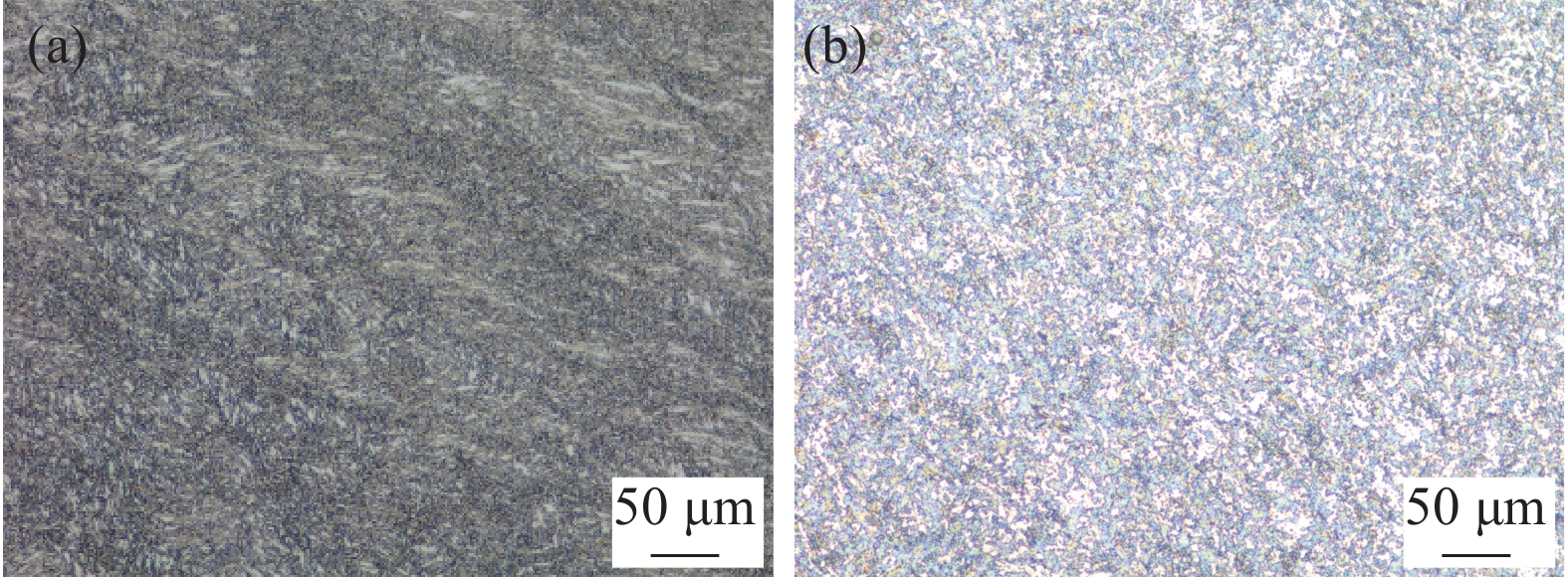

表 3 不同退火温度下的硬度值Table 3. Hardness values of samples after being annealed at different temperatures温度/ ℃ 退火时间/h 布氏硬度 680 4 347 770 4 346 930 4 442 通过对比退火温度对组织的影响可知,随着退火温度的增加,不同温度下完全退火和再结晶退火组织差异较大,再结晶温度退火的组织较为细小,为片层状贝氏体加块状铁素体组织,如图2所示,完全退火后样品的奥氏体化更完全,冷却过程中产生板条马氏体,并且在样品表面析出碳化物,导致硬度升高。

2.2 退火时间对硬度和组织的影响

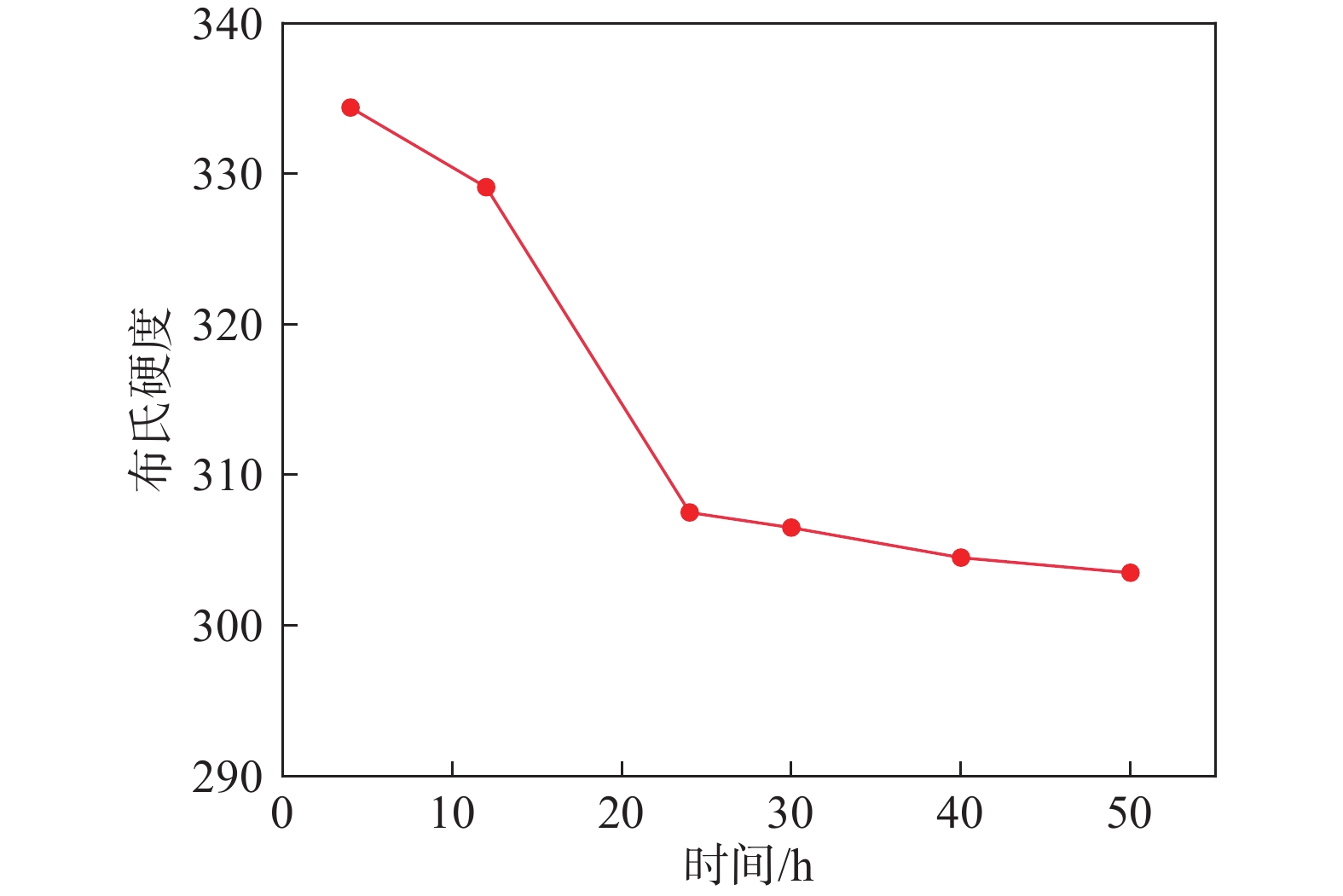

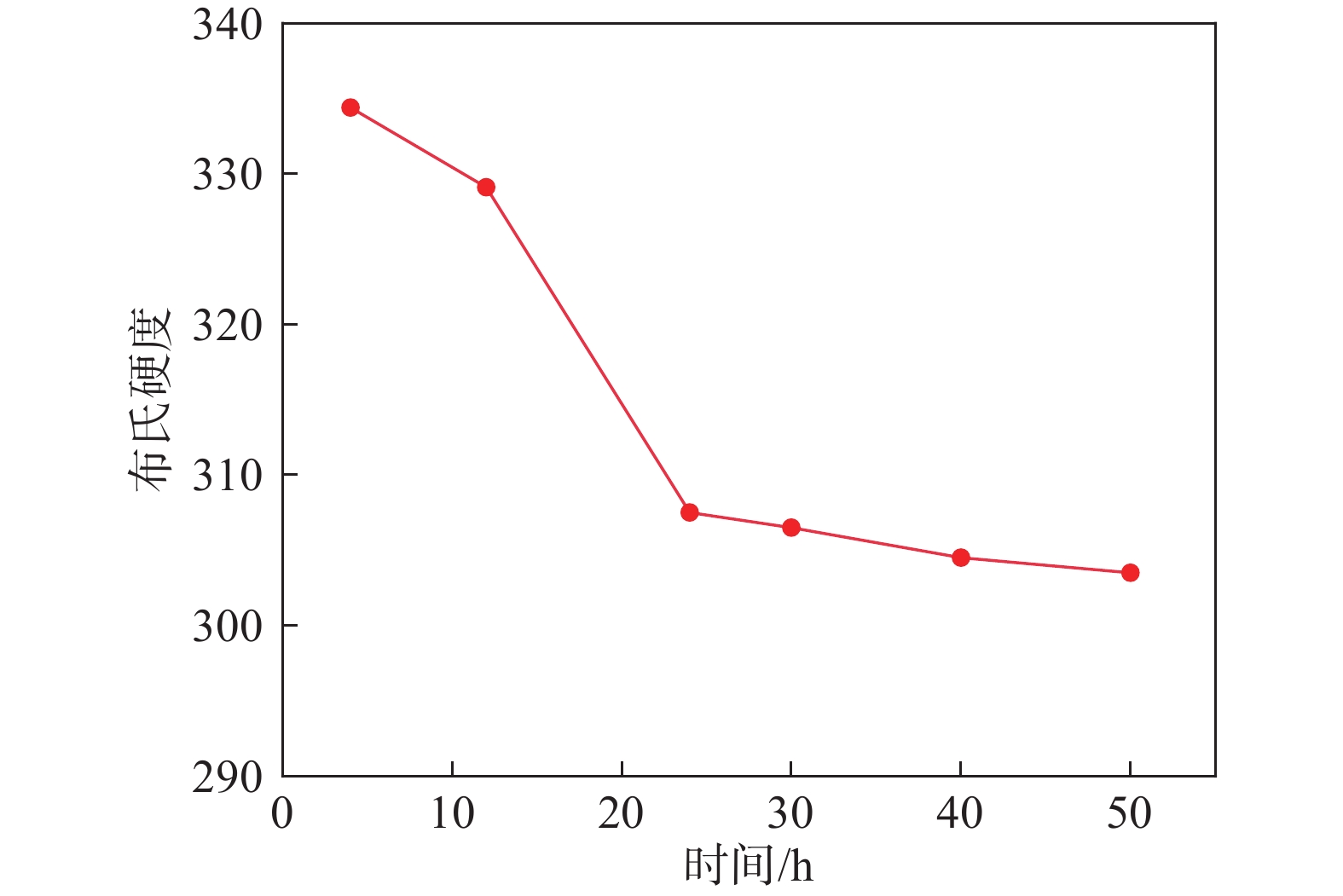

对770 ℃退火样品进行不同退火时间试验,对比短时和长时样品硬度发现,长时退火样品的硬度小于短时退火样品,如图3所示。由图3可知,随着退火时间延长,样品硬度不断降低,而对于30、50 h的样品,随着退火时间的延长,样品的硬度变化不大,说明在长时退火的过程中,碳化物析出完全。

短时退火过程中,样品的微观组织形貌形成差异,而长时退火样品与短时退火样品也存在差异,其中770 ℃×4 h样品和770 ℃×50 h样品组织差异明显,如图4所示,但是继续延长退火时间的样品则差异不大,这与硬度规律一致。短时退火样品为回火的板条马氏体组织,经过长时间退火后,样品的组织转变成了粒状珠光体组织,相较于短时退火的回火马氏体组织,样品硬度没有明显的再次下降,故无法仅通过延长退火时间进一步降低样品硬度。

2.3 不同退火工艺下的组织和性能分析

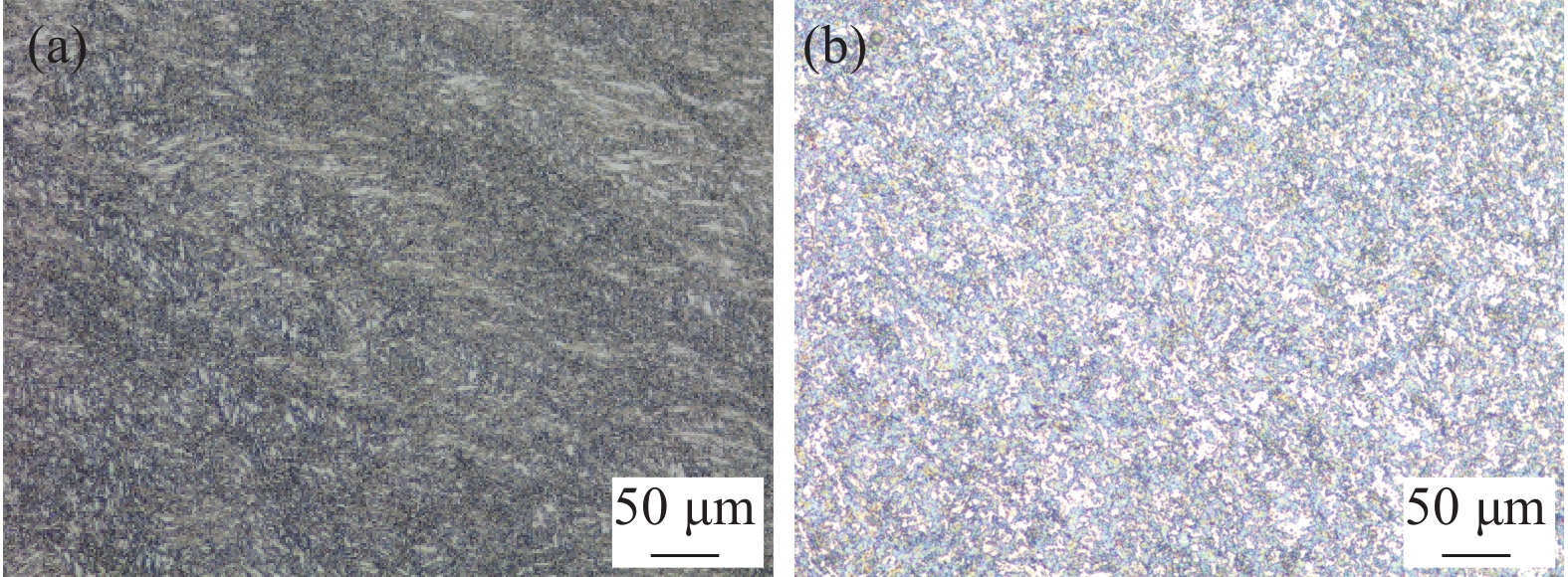

一段式退火中,再结晶退火(680 ℃×4 h)的效果最好,单从高温冷却的过程,样品中会存在少量的残余应力,会导致在后续的加工过程或淬火过程中出现样品开裂的情况,为消除样品中的残余应力,并保持退火的效果,对退火工艺进行优化,在完全退火(930 ℃×6 h)的基础上进行一次和二次的再结晶退火,采用二段式退火和三段式退火的工艺,具体工艺如表4所示,对比不同退火工艺的硬度后发现,多段式退火的样品硬度更低,性能更好。

表 4 五种不同退火工艺样品性能Table 4. Microstructure and hardness samples after being annealed with different annealing processes序号 状态 工艺 组织 布氏硬度 1 退火前 墩拔态 马奥双相组织 523.2 2 完全退火 完全退火 板条马氏体组织 401.1 3 再结晶退火 再结晶退火 片层贝氏体组织 330.2 4 二段式退火 完全退火+再结晶退火 片层贝氏体组织 308.2 5 三段式退火 完全退火+再结晶退火+再结晶退火 片层贝氏体组织 274.5 表4为五种不同退火工艺的样品的性能,为获得较低的硬度,不断优化退火工艺,完全退火在高温时为奥氏体,冷却至室温时为马氏体,并且有碳化物析出,再结晶退火为珠光体,且没有碳化物析出。将样品进行完全退火,使样品析出碳化物,再通过两次再结晶退火使碳化物充分长大,通过样品析出碳化物后长大的过程,降低了基体的碳含量,大颗粒碳化物失去了弥散强化和钉扎效果,继而使硬度进一步降低。

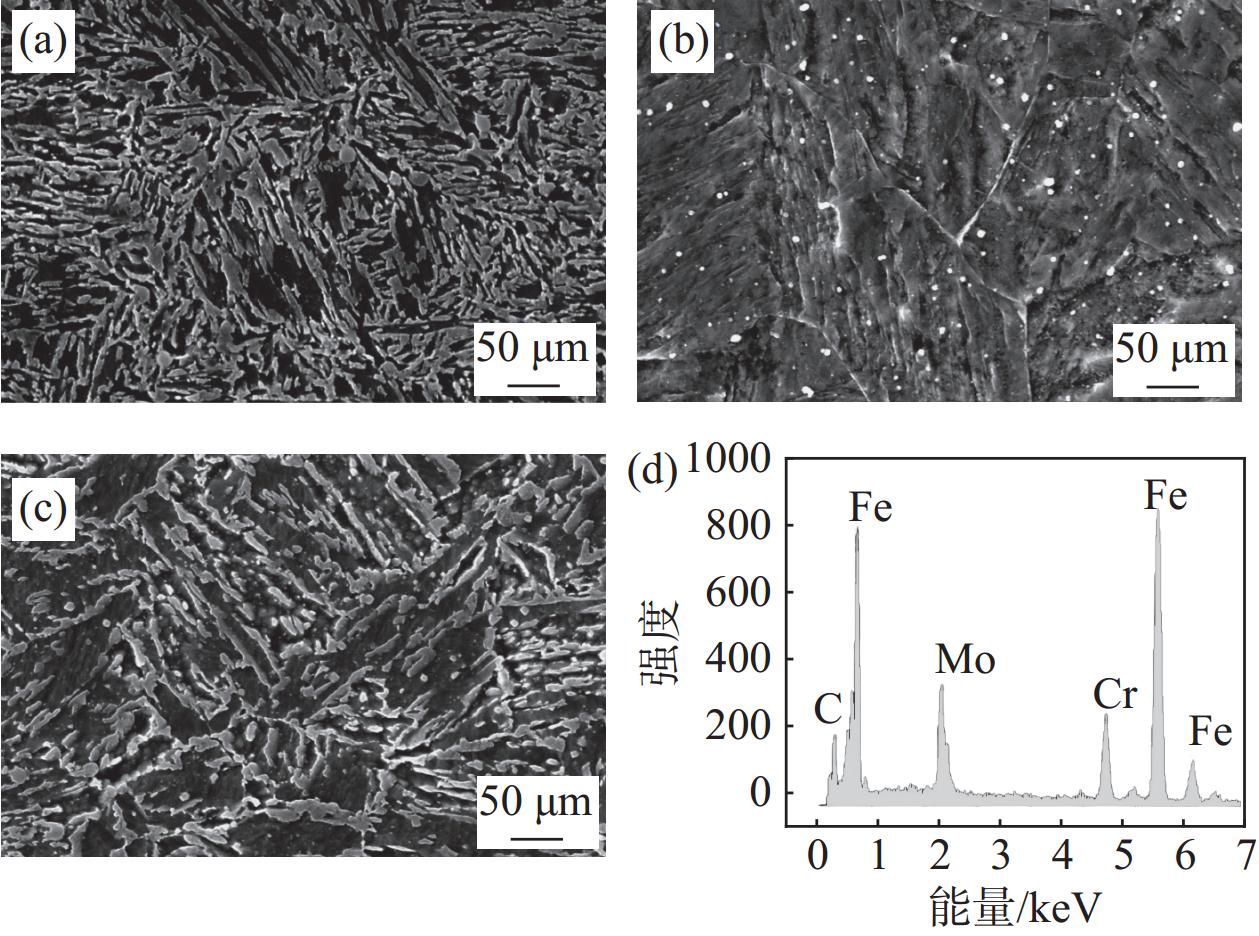

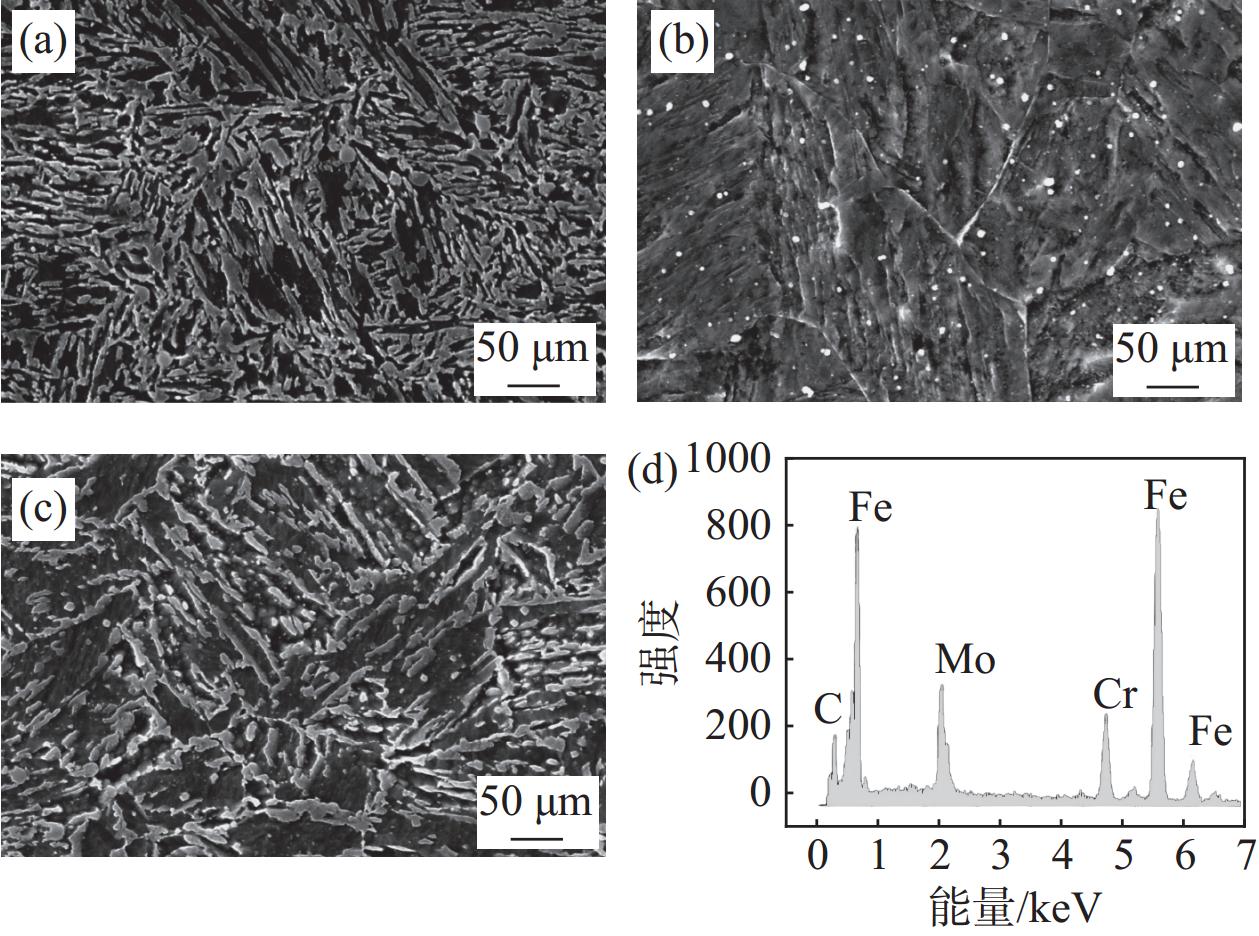

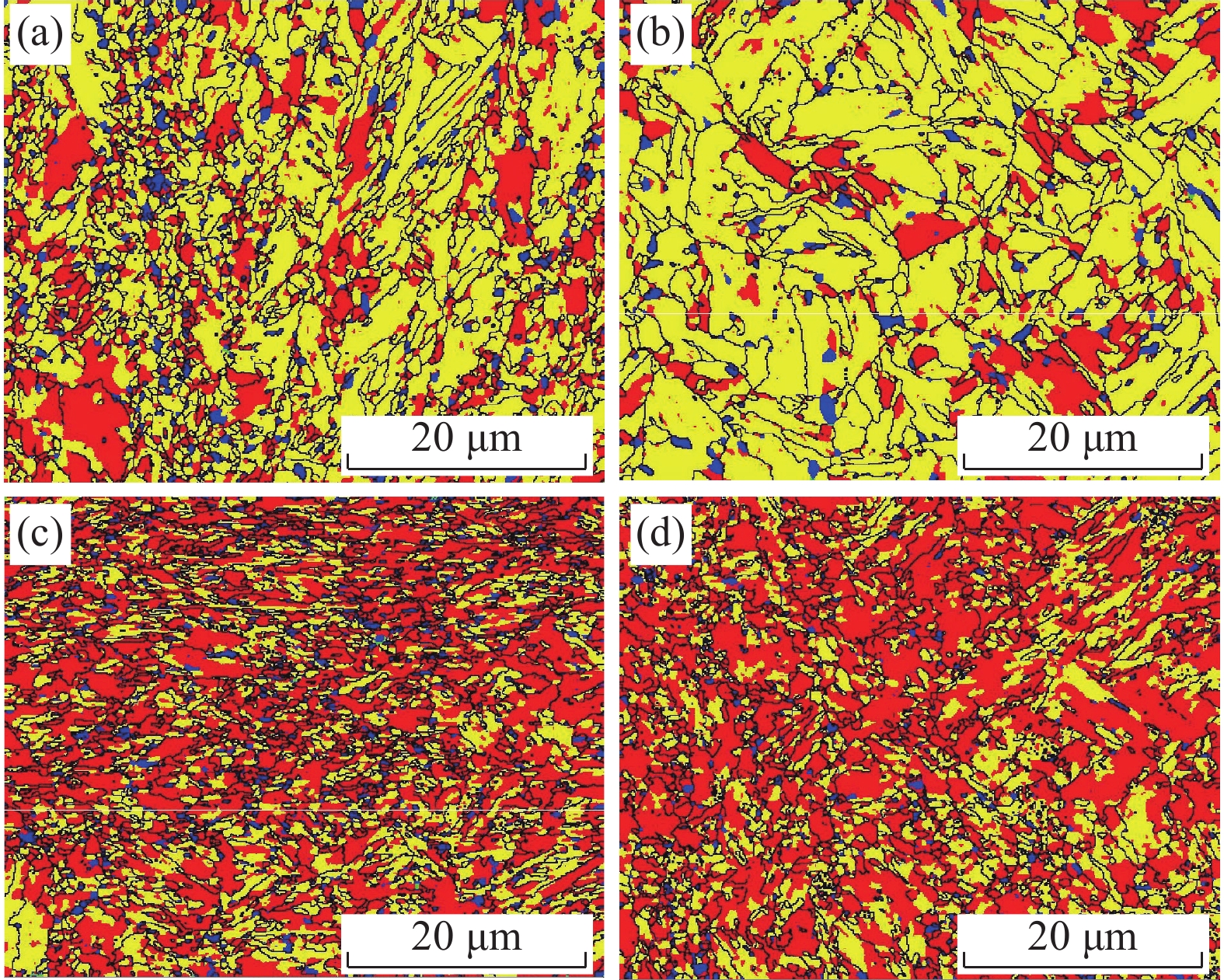

图5(a)为再结晶退火扫描,从图5(a)中可以看出,再结晶退火样品为片层状贝氏体加板条状马氏体加残余奥氏体组织,碳化物析出较少。图5(b)为完全退火样品的微观组织形貌,样品为白色析出碳化物分布在板条状马氏体上,图5(c)为三段式退火样品的微观组织形貌,样品为贝氏体组织,且贝氏体的层状组织更大,间距更宽,退火后样品表面析出的白色碳化物为NbC颗粒。

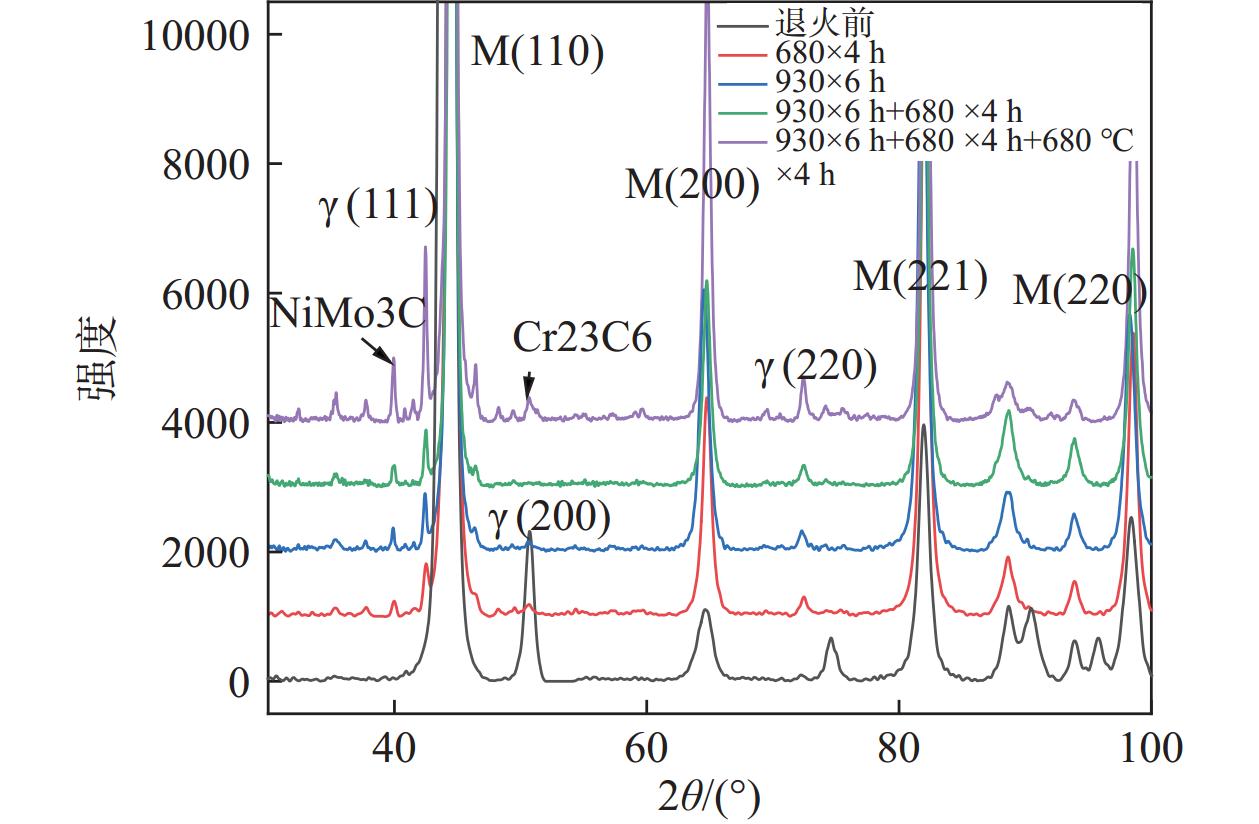

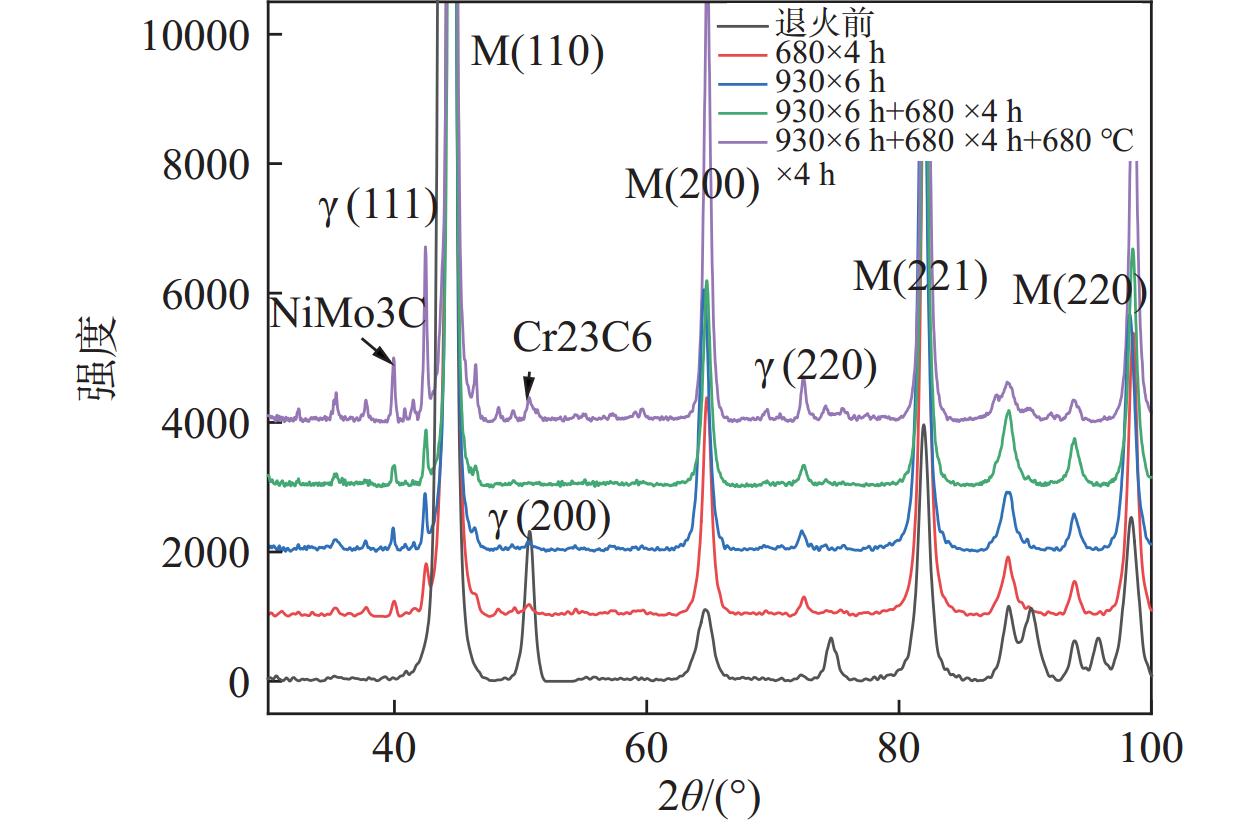

五种不同工艺样品的XRD衍射图如图6所示,从XRD数据可以看出,样品在退火前为两相组织,由于退火前样品组织不均匀,马氏体转化不完全,故由部分残余奥氏体和马氏体组成,经过退火后优化了样品组织,消除了部分奥氏体,并且多段式退火后,样品中的碳化物含量增加,衍射峰增多,碳化物的析出也导致了基体中的碳含量减少。而完全退火的试样经过进一步再结晶退火后,新形成的马氏体中开始析出碳化物,细小的碳化物开始粗化,由于完全退火的样品在冷却过程中产生的马氏体更完全,残余奥氏体少,故碳化物形成更多,多段式退火后软化的效果优于两相区温度的多段式退火。

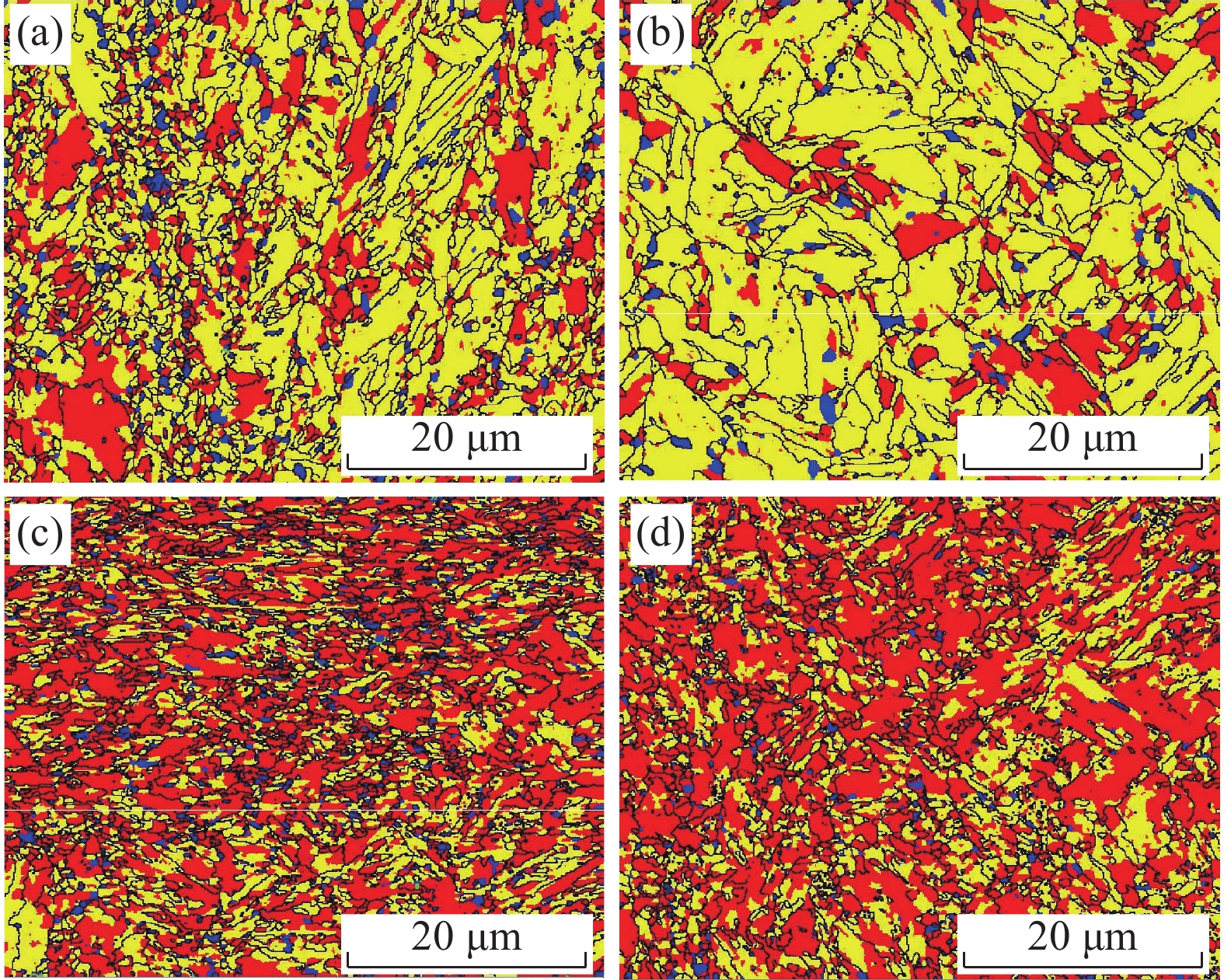

对再结晶退火、完全退火、三段式退火和长时退火的样品进行EBSD后,观察样品的再结晶情况,如图7所示,完全退火的样品主要为板条马氏体,其中残余奥氏体含量为0.23%,再结晶较少,再结晶退火中产生了较多的形变组织和再结晶组织,并且晶粒发生了细化,为马氏体和细小贝氏体组织,残余奥氏体含量为0.39%,这也是再结晶退火硬度小于完全退火的原因,对比图7(c)(d)可知,三段式退火达到了长时退火的效果,二者组织相仿,残余奥氏体含量为0.39%和0.35%,并且三段式退火的组织更加细小。

2Cr12Ni4Mo3VNbN具有较强的自硬性,在炉冷和空冷的情况下都能获得马氏体组织,冷却方式对退火后硬度与组织影响不大,出炉温度对退火后性能以及淬火、回火后性能影响不大,延长退火时间会导致样品的硬度降低,达到30 h以后对样品的软化效果变弱,退火工艺对样品的影响最大,再结晶退火会发生马氏体回复和少量再结晶,碳化物析出较少,对硬度的降低有限,完全退火会导致样品奥氏体化,在冷却的过程中产生二次马氏体,并析出大量弥散细小的碳化物,该碳化物起到了一定的弥散强化作用,并且阻碍位错运动,所以完全退火后样品硬度依然较高,完全退火后进行再结晶温度的二次退火,马氏体向贝氏体转变,基体组织变软,三次退火后基体中碳化物会继续长大,导致基体中的碳含量下降,并且弥散强化效果减弱,导致硬度的大幅下降,硬度采用三段式退火的工艺最优。

3. 结论

1)退火温度升高导致样品的硬度升高,退火时间延长导致样品的硬度降低,再结晶退火会发生马氏体回复和少量再结晶,降低硬度,完全退火在冷却过程中会生成二次马氏体,软化效果不如再结晶退火。

2)采用短时退火时,可适当延长退火时间,采用长时退火时,延长退火时间意义不大。

3)三段式退火相较于一段式和两段式具有更优异的力学性能,推荐采用三段式退火,其中完全退火加再结晶退火可使样品在表面析出碳化物,并使碳化物长大,软化效果最好。

-

表 1 试验料的主要化学成分

Table 1. Main chemical composition of test materials

% C Cr Ni Mo V Nb N 0.2 12 4 3 0.25 0.15 0.06 表 2 一段式退火工艺试验方案

Table 2. One-stage annealing practice of samples

试验方案 退火温度/℃ 退火时间/h 冷却方式 试验目的 1 770 4,12,24,30,40,50 FC 退火时间对

组织的影响2 680,770,930 4 AC 退火温度对

组织的影响表 3 不同退火温度下的硬度值

Table 3. Hardness values of samples after being annealed at different temperatures

温度/ ℃ 退火时间/h 布氏硬度 680 4 347 770 4 346 930 4 442 表 4 五种不同退火工艺样品性能

Table 4. Microstructure and hardness samples after being annealed with different annealing processes

序号 状态 工艺 组织 布氏硬度 1 退火前 墩拔态 马奥双相组织 523.2 2 完全退火 完全退火 板条马氏体组织 401.1 3 再结晶退火 再结晶退火 片层贝氏体组织 330.2 4 二段式退火 完全退火+再结晶退火 片层贝氏体组织 308.2 5 三段式退火 完全退火+再结晶退火+再结晶退火 片层贝氏体组织 274.5 -

[1] Zhang Wei, Ni Jinfei, You Jin, et al. Analysis on cracking cause of 1Cr12Ni3Mo2VN stainless steel blade in low pressure rotor of steam turbine[J]. Material Protection, 2022,55(4):203-209. (张炜, 倪进飞, 尤晋, 等. 汽轮机低压转子1Cr12Ni3Mo2VN不锈钢叶片的开裂原因分析[J]. 材料保护, 2022,55(4):203-209.Zhang Wei, Ni Jinfei, You Jin, et al. Analysis on cracking cause of 1Cr12Ni3Mo2VN stainless steel blade in low pressure rotor of steam turbine[J]. Material Protection, 2022, 55(4): 203-209. [2] Zeng Xiao, Zhao Jiqing, Gan Guoyou, et al. Influence of isothermal annealing on microstructure homogenization of COST-FB2 steel[J]. Heat Treatment of Metals, 2018,43(3):128-134. (曾骁, 赵吉庆, 甘国友, 等. 等温退火对COST-FB2钢组织均匀化的影响[J]. 金属热处理, 2018,43(3):128-134.Zeng Xiao, Zhao Jiqing, Gan Guoyou, et al. Influence of isothermal annealing on microstructure homogenization of COST-FB2 steel[J]. Heat Treatment of Metals, 2018, 43(3): 128-134. [3] Wang Gangjian. Study on anneal process and anneal hardness of 1~2Cr13[J]. Special Steel Technology, 2011,17(1):28-30. (王刚健. 1~2Cr13退火工艺操作与退火硬度的研究[J]. 特钢技术, 2011,17(1):28-30.Wang Gangjian. Study on anneal process and anneal hardness of 1~2Cr13[J]. Special Steel Technology, 2011, 17(1): 28-30. [4] Du Simin. Effect of annealing on microstructure and hardness of ultra-high strength low alloy bainitic steel[J]. Iron Steel Vanadium Titanium, 2020,41(5):130-135. (杜思敏. 退火工艺对低合金超高强度贝氏体钢组织和硬度的影响[J]. 钢铁钒钛, 2020,41(5):130-135.Du Simin. Effect of annealing on microstructure and hardness of ultra-high strength low alloy bainitic steel[J]. Iron Steel Vanadium Titanium, 2020, 41(5): 130-135. [5] Lu Qianqian, Gu Hairong, Cui Lei, et al. Effect of annealing temperature on microstructure, mechanical properties and retained austenite of 1 000 MPa Q&P steel[J]. Iron Steel Vanadium Titanium, 2020,41(6):130-134. (卢茜倩, 谷海容, 崔磊, 等. 退火温度对1000 MPa级Q&P钢组织性能及残余奥氏体的影响[J]. 钢铁钒钛, 2020,41(6):130-134.Lu Qianqian, Gu Hairong, Cui Lei, et al. Effect of annealing temperature on microstructure, mechanical properties and retained austenite of 1 000 MPa Q&P steel[J]. Iron Steel Vanadium Titanium, 2020, 41(6): 130-134. [6] Peng Tao, Zhao Jiqing, Cao Jianchun, et al. Influence of annealing process on hardness and microstructure of AMS 6308 steel[J]. Journal of Iron and Steel Research, 2016,28(4):58-63. (彭涛, 赵吉庆, 曹建春, 等. 退火工艺对AMS 6308钢硬度及组织的影响[J]. 钢铁研究学报, 2016,28(4):58-63.Peng Tao, Zhao Jiqing, Cao Jianchun, et al. Influence of annealing process on hardness and microstructure of AMS 6308 steel[J]. Journal of Iron and Steel Research, 2016, 28(4): 58-63. [7] Yan Fuyao, Zhu Lei, Chen Hongtao, et al. Annealing process and stacking method for reducing hardness of as rolled/forged high quality special steel[J]. Iron Steel Vanadium Titanium, 2021,42(2):152-160. (闫扶摇, 朱磊, 陈宏涛, 等. 轧/锻态高品质特殊钢退火软化工艺与布料方式[J]. 钢铁钒钛, 2021,42(2):152-160.Yan Fuyao, Zhu Lei, Chen Hongtao, et al. Annealing process and stacking method for reducing hardness of as rolled/forged high quality special steel[J]. Iron Steel Vanadium Titanium, 2021, 42(2): 152-160. [8] Yang Gang, Xie Xuelin, Liu Xinquan, et al. Investigation on annealing practice of 1Cr12Ni3Mo2VN heat-resistant steel[J]. Journal of Iron and Steel Research, 2010,22(3):23-28. (杨钢, 谢学林, 刘新权, 等. 1Cr12Ni3Mo2VN耐热钢退火工艺研究[J]. 钢铁研究学报, 2010,22(3):23-28.Yang Gang, Xie Xuelin, Liu Xinquan, et al. Investigation on annealing practice of 1Cr12Ni3Mo2VN heat-resistant steel[J]. Journal of Iron and Steel Research, 2010, 22(3): 23-28. [9] Gao Yuan, Xi Shengqi, Wang Hong, et al. Microstructure and fatigue properties of 2Cr12Ni4Mo3VNbN new blade steel after high frequency quenching[J]. Transactions of Materials and Heat Treatment, 2020,41(2):75-81. (高圆, 席生岐, 王虹, 等. 2Cr12Ni4Mo3VNbN新型叶片钢高频淬火后的显微组织与疲劳性能[J]. 材料热处理学报, 2020,41(2):75-81.Gao Yuan, Xi Shengqi, Wang Hong, et al. Microstructure and fatigue properties of 2Cr12Ni4Mo3VNbN new blade steel after high frequency quenching[J]. Transactions of Materials and Heat Treatment, 2020, 41(2): 75-81. [10] Liu Shuai, Lü Zhiqing, Zhao Jiqing, et al. Thermodynamic calculation and experimental analysis on equilibrium precipitates phase in 2Cr12Ni4Mo3VNbN steel[J]. Iron & Steel, 2022,57(5):129-136. (刘帅, 吕知清, 赵吉庆, 等. 2Cr12Ni4Mo3VNbN钢中析出相的热力学计算与试验分析[J]. 钢铁, 2022,57(5):129-136.Liu Shuai, Lü Zhiqing, Zhao Jiqing, et al. Thermodynamic calculation and experimental analysis on equilibrium precipitates phase in 2Cr12Ni4Mo3VNbN steel[J]. Iron & Steel, 2022, 57(5): 129-136. [11] Yu Cansheng, Zhang Longchao, Zheng Zhiwang, et al. Effect of annealing temperature on microstructure and mechanical properties of vanadium microalloyed 780 MPa cold rolled dual phase steel[J]. Iron Steel Vanadium Titanium, 2021,42(5):158-163. (余灿生, 张龙超, 郑之旺, 等. 退火温度对钒微合金化780 MPa级冷轧双相钢组织性能的影响[J]. 钢铁钒钛, 2021,42(5):158-163.Yu Cansheng, Zhang Longchao, Zheng Zhiwang, et al. Effect of annealing temperature on microstructure and mechanical properties of vanadium microalloyed 780 MPa cold rolled dual phase steel[J]. Iron Steel Vanadium Titanium, 2021, 42(5): 158-163. [12] Zeng Xiao, Zhao Jiqing, Gan Guoyou, et al. Influence of annealing process on hardness and microstructure of COST- FB2 steel[J]. Heat Treatment of Metals, 2017,42(10):75-80. (曾骁, 赵吉庆, 甘国友, 等. 退火工艺对COST-FB2钢组织和硬度的影响[J]. 金属热处理, 2017,42(10):75-80.Zeng Xiao, Zhao Jiqing, Gan Guoyou, et al. Influence of annealing process on hardness and microstructure of COST- FB2 steel[J]. Heat Treatment of Metals, 2017, 42(10): 75-80. -

下载:

下载:

下载:

下载: