Study on the inclusion distribution behavior of U71Mn heavy rail steel after rolling

-

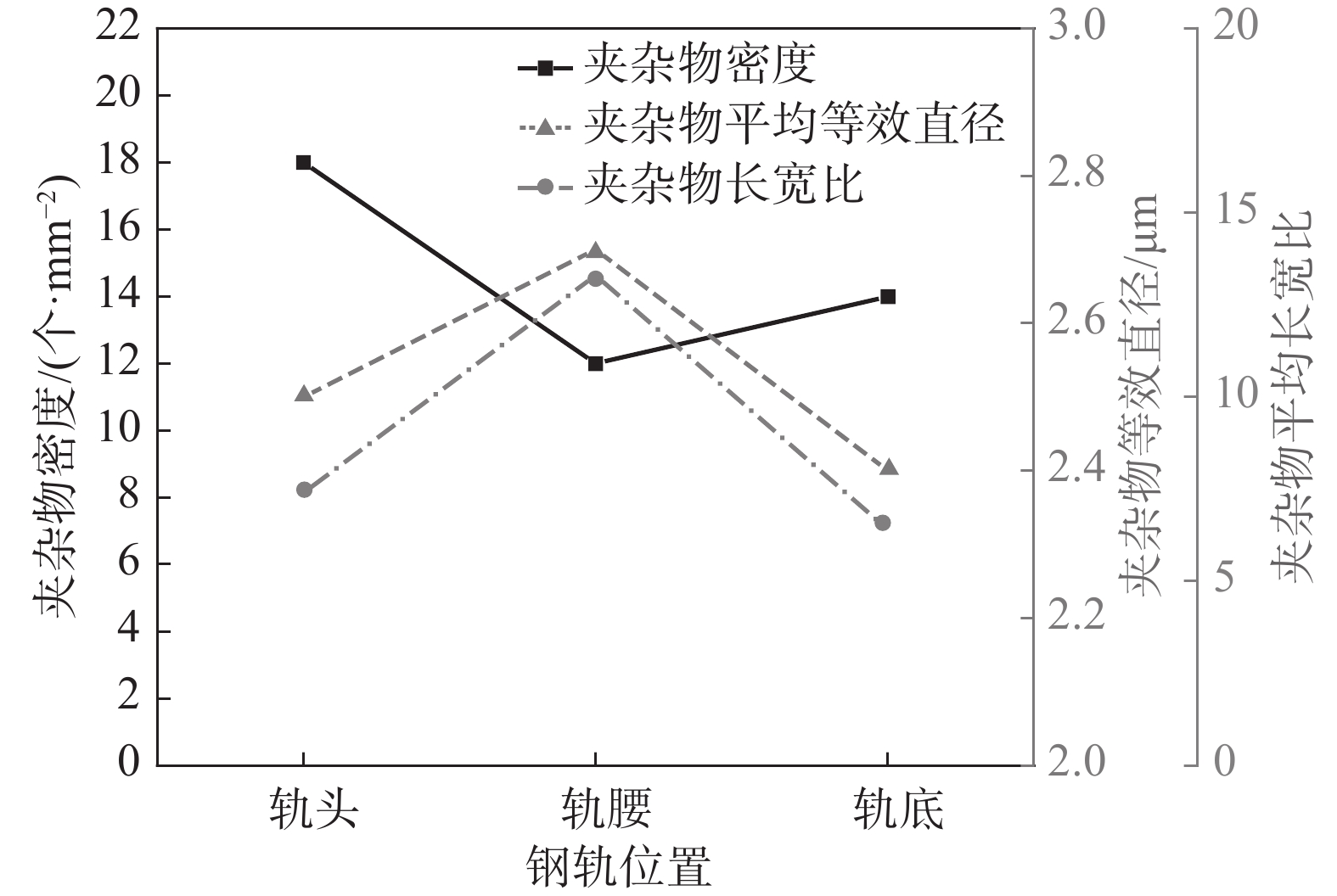

摘要: 非金属夹杂物的形态和分布对重轨钢的性能具有显著影响。采用光学显微镜、扫描电镜、夹杂物三维刻蚀仪、Thermo-calc软件对某厂生产的U71Mn重轨钢中的夹杂物进行了研究。结果表明,U71Mn重轨钢中轨腰处夹杂物的平均等效直径、长宽比最大,数量密度最小。轨头、轨腰、轨底的夹杂物密度分别为18、12、14 个/mm2,平均等效直径分别为2.5 、2.7、2.4 μm,平均长宽比分别为7.4、13.3、6.4。钢中夹杂物以单独存在的MnS和CaO·Al2O3·SiO2·MgO复合夹杂物为主。轨头和轨底处的MnS尺寸较小,集中分布在10~50 μm;轨腰处的MnS夹杂物尺寸较大,多在20~80 μm,且存在多条大尺寸的MnS被轧制在同一条水平线上。CaO·Al2O3·SiO2·MgO复合夹杂物沿轧制方向普遍呈近球形和不规则形。Abstract: The morphology and distribution of non-metallic inclusions significantly affect the performance of heavy rail steels. This study employed optical microscopy, scanning electron microscopy, a three-dimensional etching instrument for inclusions, and Thermo-calc software to investigate the inclusions in U71Mn heavy rail steel produced by a certain factory. The results show that the average equivalent diameter and aspect ratio of inclusions at the waist of the U71Mn heavy rail steel are the largest, while the number density is the smallest. The inclusion densities in the rail head, waist, and base are 18, 12, and 14/mm2, respectively, with the average equivalent diameters of 2.5, 2.7, and 2.4 μm, and the average aspect ratios of 7.4, 13.3, and 6.4, respectively. The main inclusions in the steel are individual MnS and complex inclusions of CaO·Al2O3·SiO2·MgO. The sizes of MnS at the rail head and base are relatively small, mainly distributed between 10~50 μm. The sizes of MnS inclusions at the rail waist are larger, mostly between 20~80 μm, with several large-sized MnS rolled on the same horizontal line. The complex inclusions of CaO·Al2O3·SiO2·MgO generally appear near-spherical or irregular along the rolling direction.

-

Key words:

- U71Mn heavy rail steel /

- inclusions /

- rolling deformation /

- thermodynamic analysis

-

0. 引言

U71Mn重轨钢是一种铁路用热轧钢轨,具有耐磨、耐压、耐疲劳等性能特点[1-2],由于应用的特殊性,重轨钢必须满足高强度、高硬度,以确保能适应铁路的重载和高速运营需求。在生产过程中,U71Mn重轨钢的钢液洁净度有严格要求,钢中夹杂物是造成重轨钢内部损伤、使用中产生疲劳破坏的主要原因[3−5]。非金属夹杂物作为应力集中源,是疲劳裂纹的起源地,会降低钢的塑性、韧性和抗腐蚀性能,严重影响重轨钢的机械加工性能[6−10]。深入分析和研究U71Mn重轨钢夹杂物的种类、来源、影响及控制方法,可为进一步提高U71Mn重轨钢的质量提供理论依据和技术支持。

过去的几十年里,众多研究学者对钢轨铸坯中的非金属夹杂物特征进行了深入研究,Liu H等[11]研究了LF-RH精炼过程中U75V重轨钢夹杂物的分布,分析发现从LF到VD,钢中夹杂物从MnO-Al2O3-SiO2转变为CaO-Al2O3-SiO2,夹杂物形貌不规则,尺寸较大,夹杂物的数量较多,RH处理可以明显减小大尺寸夹杂物。Zhang Y等[12]利用高温管式炉分析了重轨钢中夹杂物的转变,研究表明在

1000 ~1300 ℃时,钢中的CaO-SiO2-Al2O3-MgO夹杂转化为MgO·Al2O3-CaS-(CaO-SiO2)型复合夹杂,随着温度的升高,夹杂物组分趋于稳定。卓超[13]以高速重轨钢U75V为研究对象,分析发现铸坯中典型夹杂物为CaO-Al2O3-SiO2-MgO和MnS,其中氧化物夹杂的平均尺寸在4~7 μm,轧制后这两种夹杂物可能导致C类和A类夹杂物评级较高甚至超标;储焰平等[14]结合热力学计算以及显微分析,发现重轨钢中夹杂物主要有尖晶石和钙铝酸盐两类,钙铝酸盐夹杂物在降温冷却中析出,容易引起超声波探伤不合适;樊志明等[15]使用扫描电镜对真空感应炉冶炼的重轨钢进行分析,发现夹杂物类型主要有3种,分别为大尺寸长条形的MnS、尖锐不规则形的Al2O3及近球形的MnS-Al2O3复合夹杂物。目前,国内外对重轨钢中非金属夹杂物进行的广泛研究多局限于铸坯,且以MnS夹杂和铝脱氧钢的研究为主,对采用非铝脱氧冶炼轧制后的钢中夹杂物特征研究甚少。不同类型的夹杂物(如硫化物、氧化物等)在轧制过程中的行为可能不同,对钢材性能的影响也有所差异。因此,为了更全面地揭示钢轨中的夹杂物特性,以某厂采用非铝脱氧冶炼工艺轧制后的U71Mn重轨钢为研究对象,利用Thermo-calc热力学软件对U71Mn重轨钢中夹杂物的析出行为进行了计算,采用金相和电子显微分析等技术观察了U71Mn重轨钢中典型夹杂物的二维形貌特征,使用夹杂物三维蚀刻仪分析了钢轨中夹杂物的三维形貌和分布规律,为进一步提高重轨钢的洁净度提供了理论依据。

1. 生产工艺及分析方法

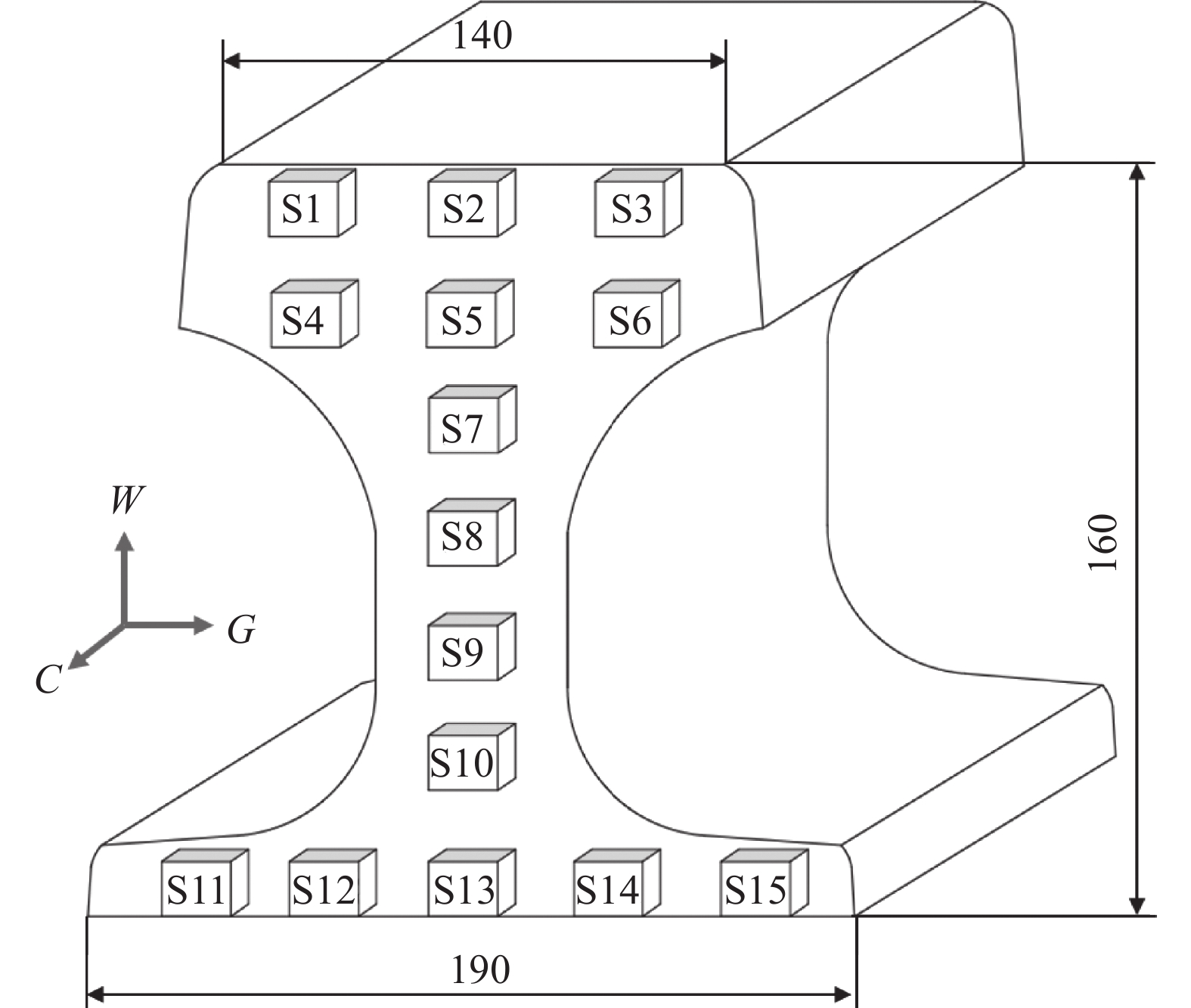

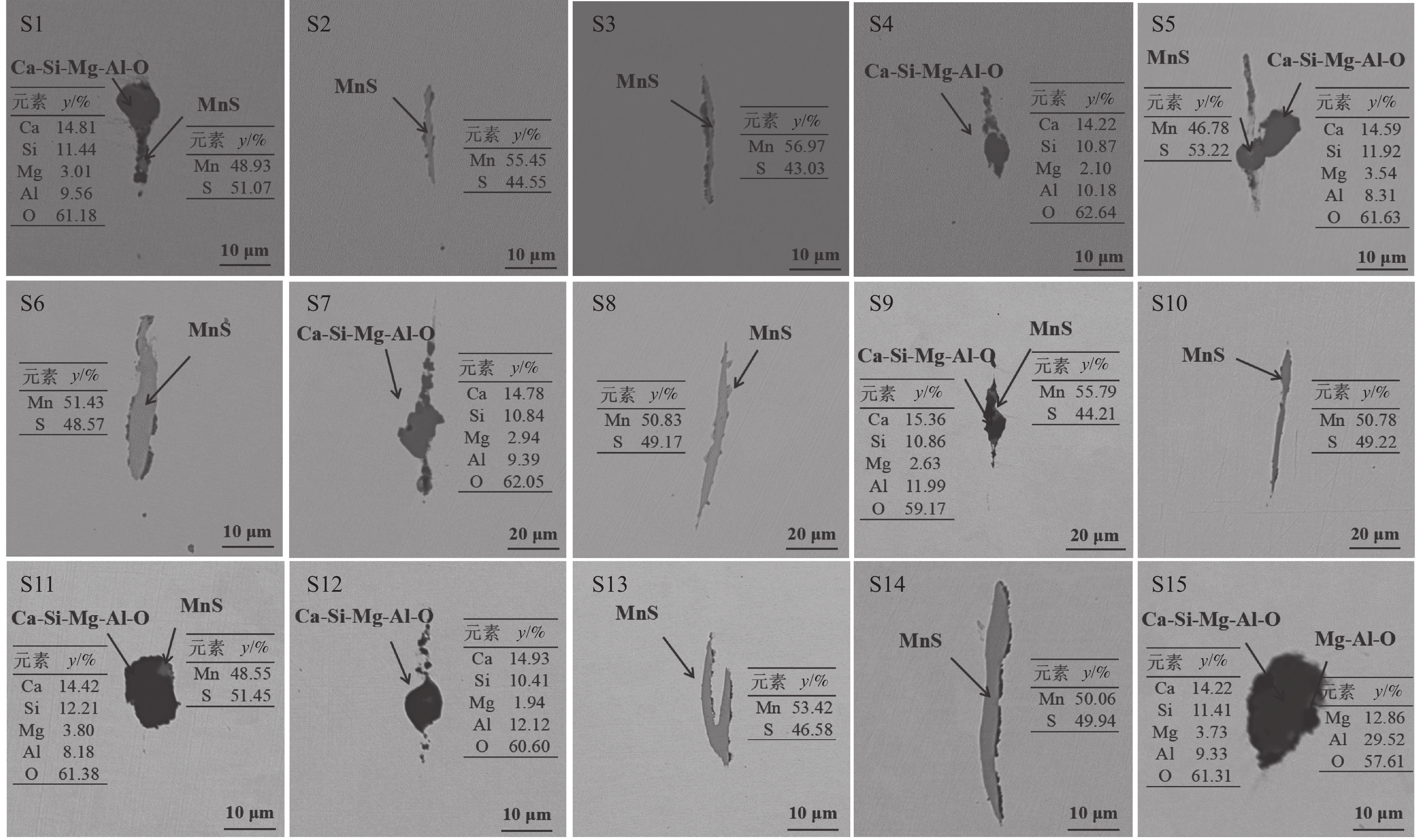

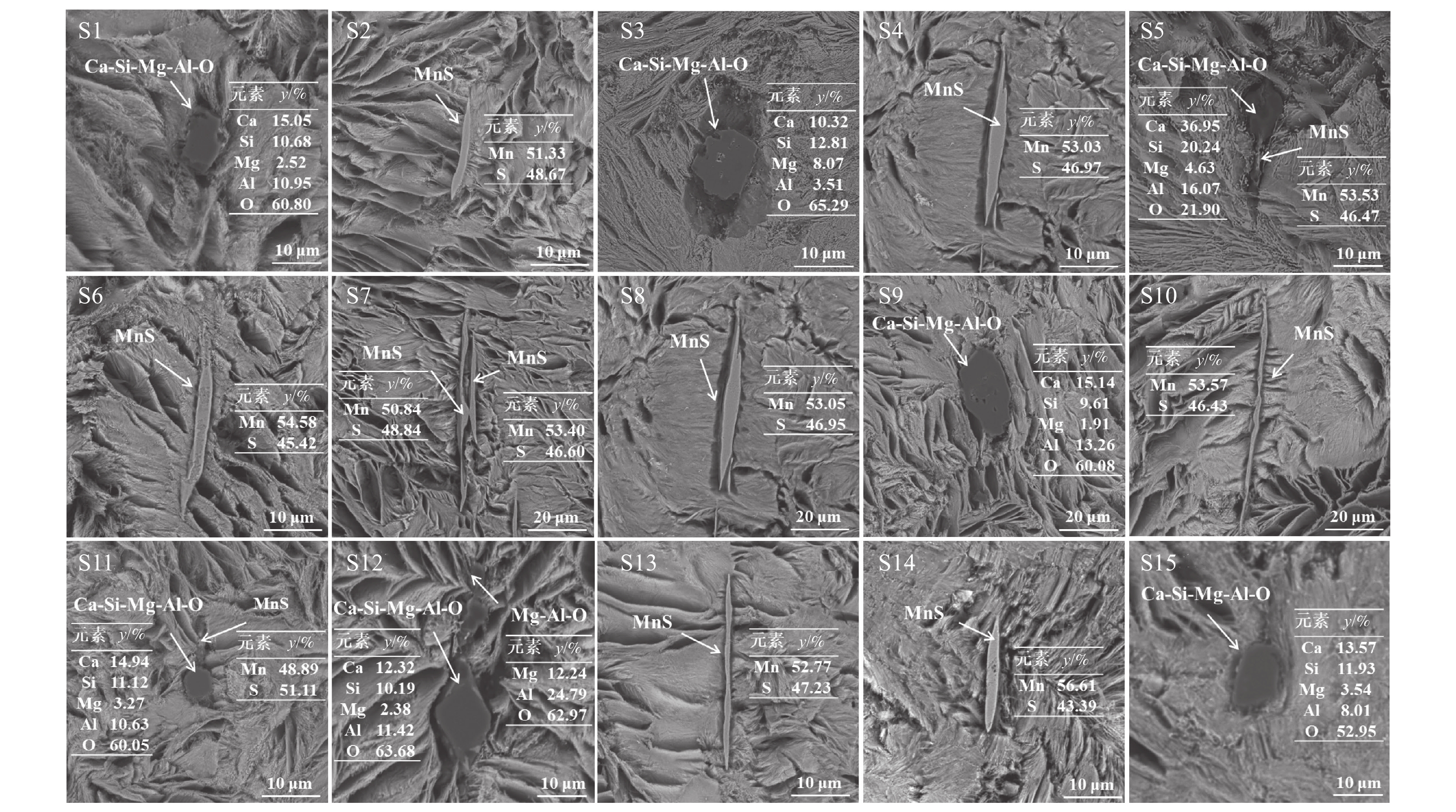

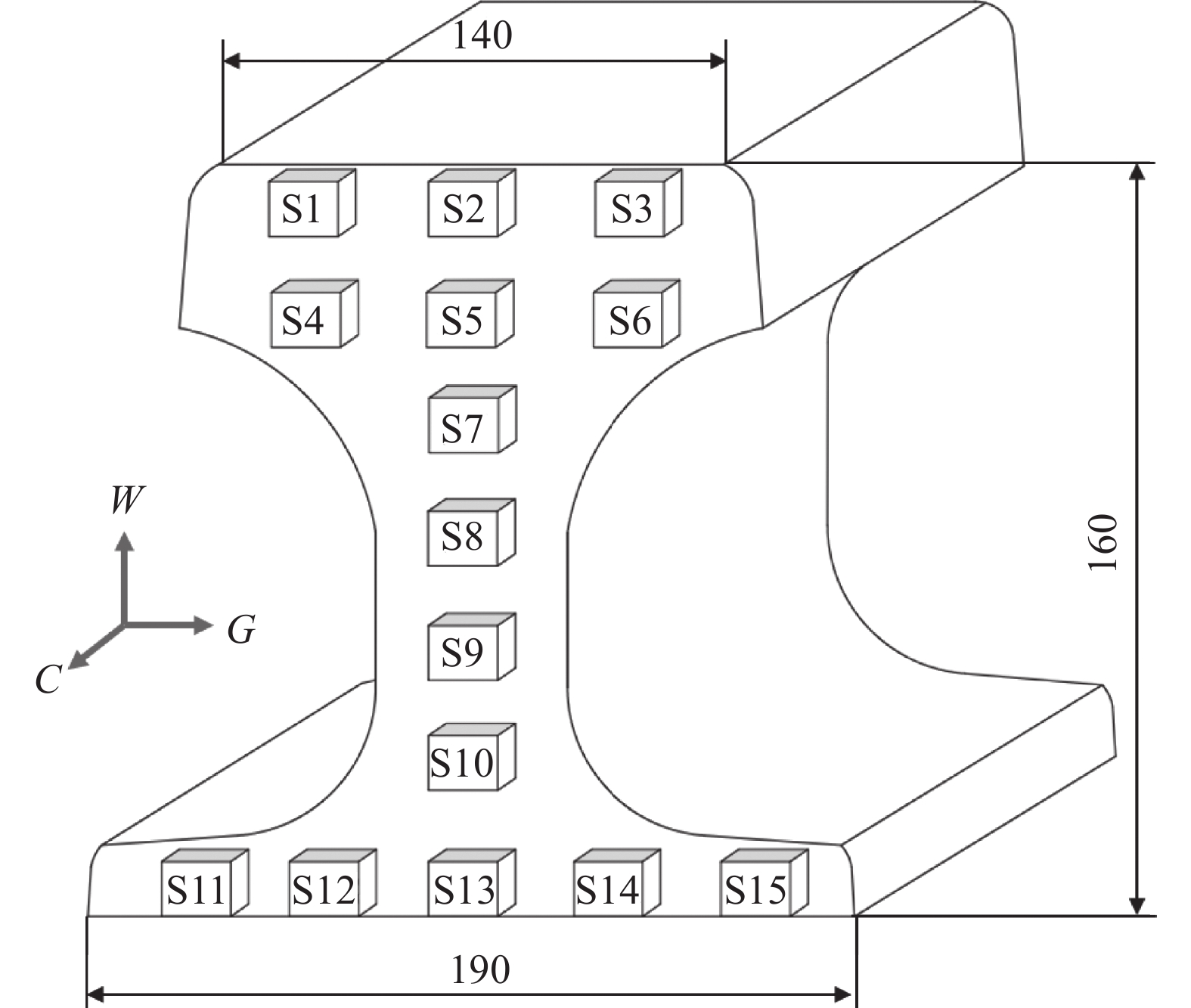

某厂U71Mn重轨钢的生产工艺流程为转炉冶炼→LF炉精炼→真空脱气(VD)→方坯连铸→轧制。其中,为了避免钢液中生成大量Al2O3夹杂,采用无铝脱氧工艺,脱氧剂为硅钙钡。钢轨的化学成分如表1所示,采用线切割的方法按照图1所示切取15个长宽高20 mm×10 mm×15 mm的矩形块,颜色标黄的为观测面,其中S1~S6为轨头试样,S7~S10为轨腰试样,S11~S15为轨底试样。将15个试样分别使用61~6.5 μm的砂纸依次打磨、抛光,酒精喷洗吹干后采用蔡司金相显微镜(Zeiss)对试样不同部位进行观测,利用配备能谱分析仪的Phenom-Word台式扫描电镜对夹杂物进行分析。

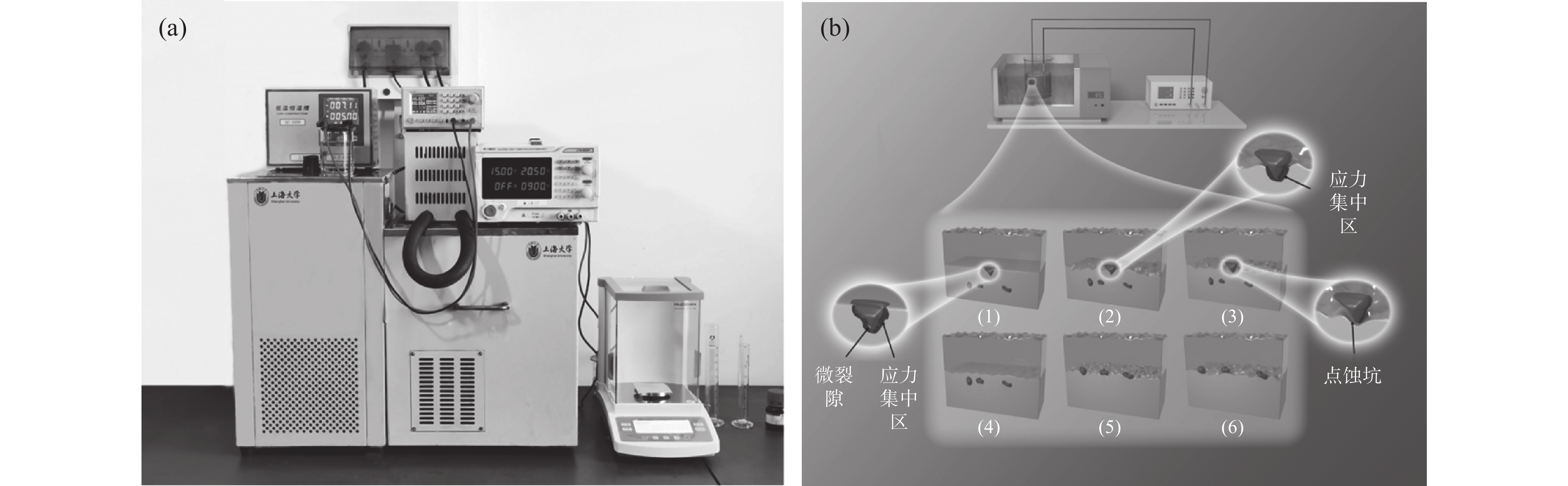

表 1 U71Mn重轨钢化学成分Table 1. U71Mn heavy rail steel composition% C Si Mn P S Al Ca V O Fe 0.73 0.35 0.95 0.012 0.002 0.003 0.0012 0.004 0.0009 余量 为解析U71Mn重轨钢中夹杂物的三维形貌及空间分布,对15个试样依次进行电解,电解装置及原理如图2所示。在电解过程中,试样作为阳极发生氧化反应,不锈钢片作为阴极发生还原反应,通电后钢基体逐渐溶解,夹杂物暴露出来。电解结束后利用扫描电镜和能谱仪对钢中的夹杂物进行三维形貌和成分解析。

2. 结果与讨论

2.1 钢轨典型夹杂物特征分析

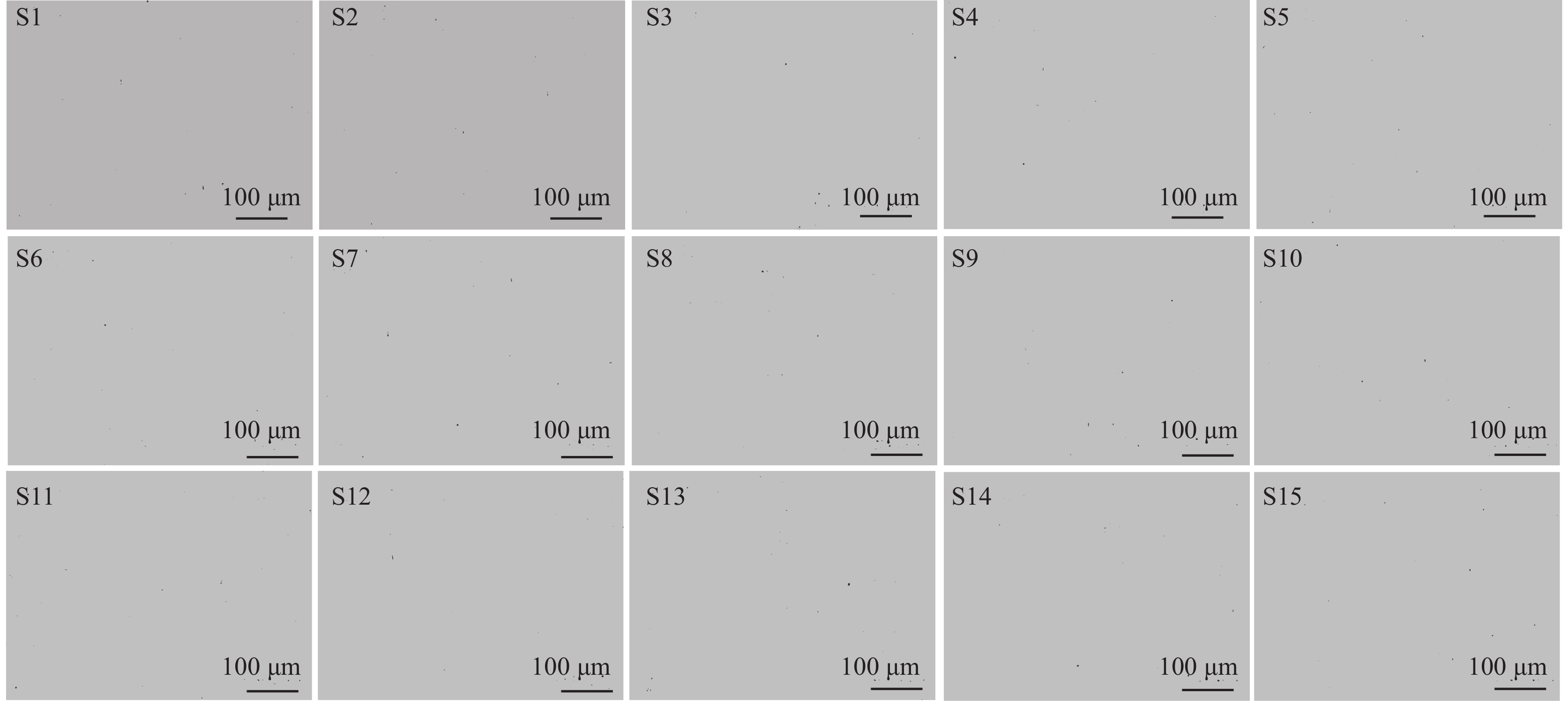

图3为U71Mn不同部位对应的100倍典型金相显微组织。可以看出,夹杂物整体数量较少、分布均匀。

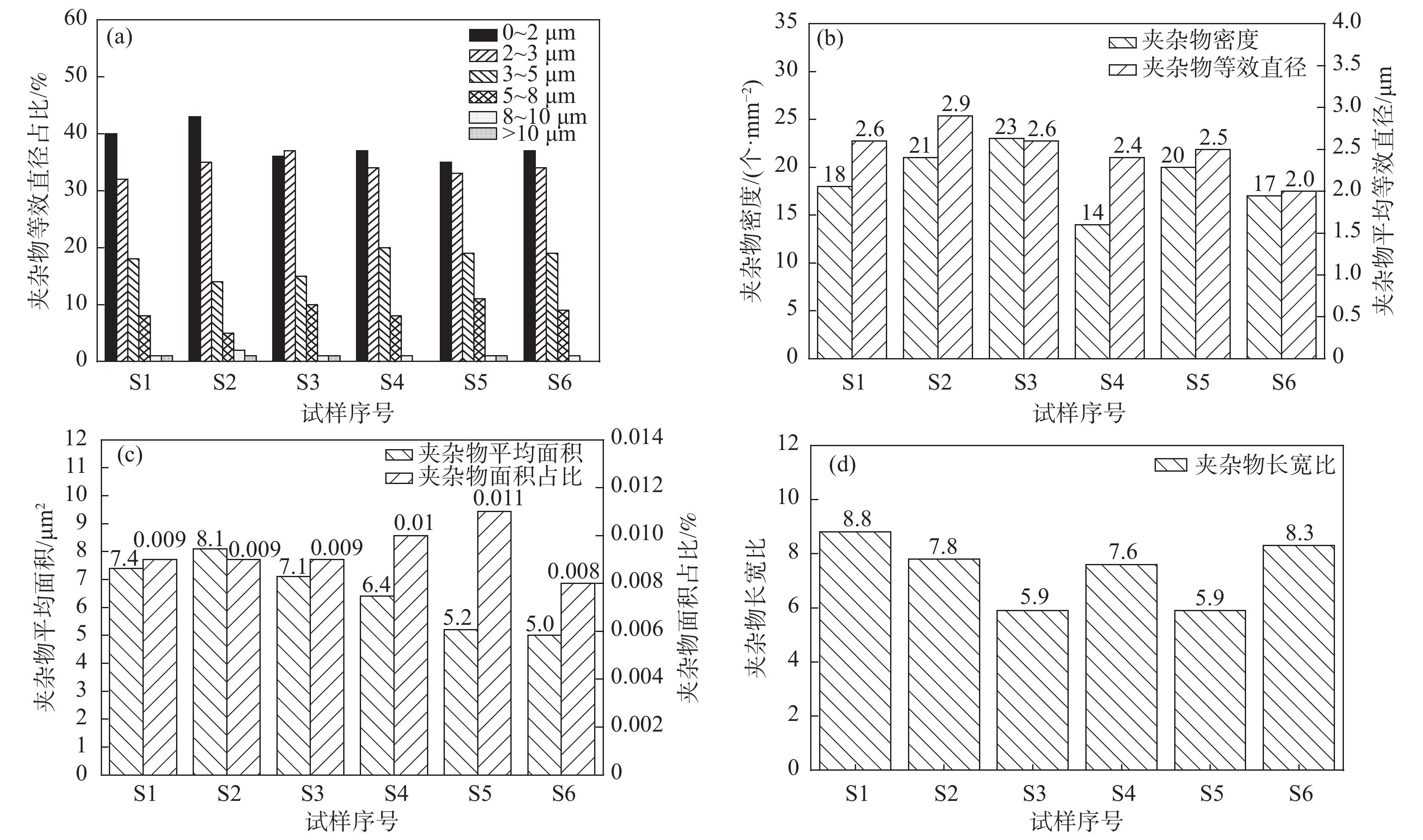

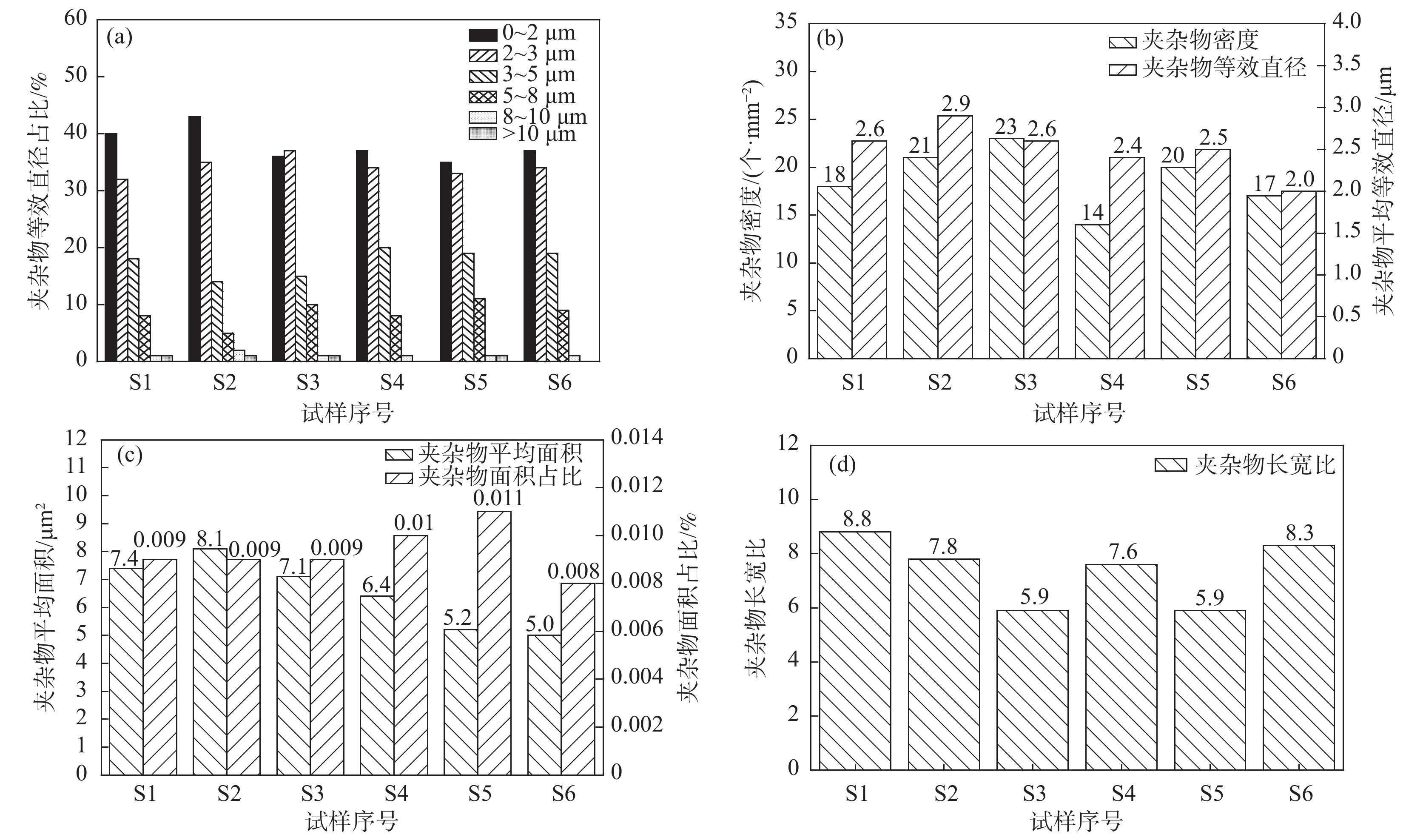

利用Image Pro Plus软件对金相下的夹杂物数量密度和等效直径分布、平均面积及夹杂物面积比例进行统计,结果如图4、5、6所示。图4为轨头的夹杂物相关尺寸特征。由图4(a)~(d)可知,轨头夹杂物的等效直径集中分布在0~3 μm,占比为72.1%,等效直径大于10 μm的大尺寸夹杂物平均占比为0.6%;夹杂物数量密度分布在14~23 个/mm2,夹杂物平均等效直径分布在2.0~2.9 μm;夹杂物平均面积分布在5.0~8.1 μm2,面积占比分布在0.008%~0.011%;夹杂物长宽比分布在5.9~8.8,平均长宽比为7.4。

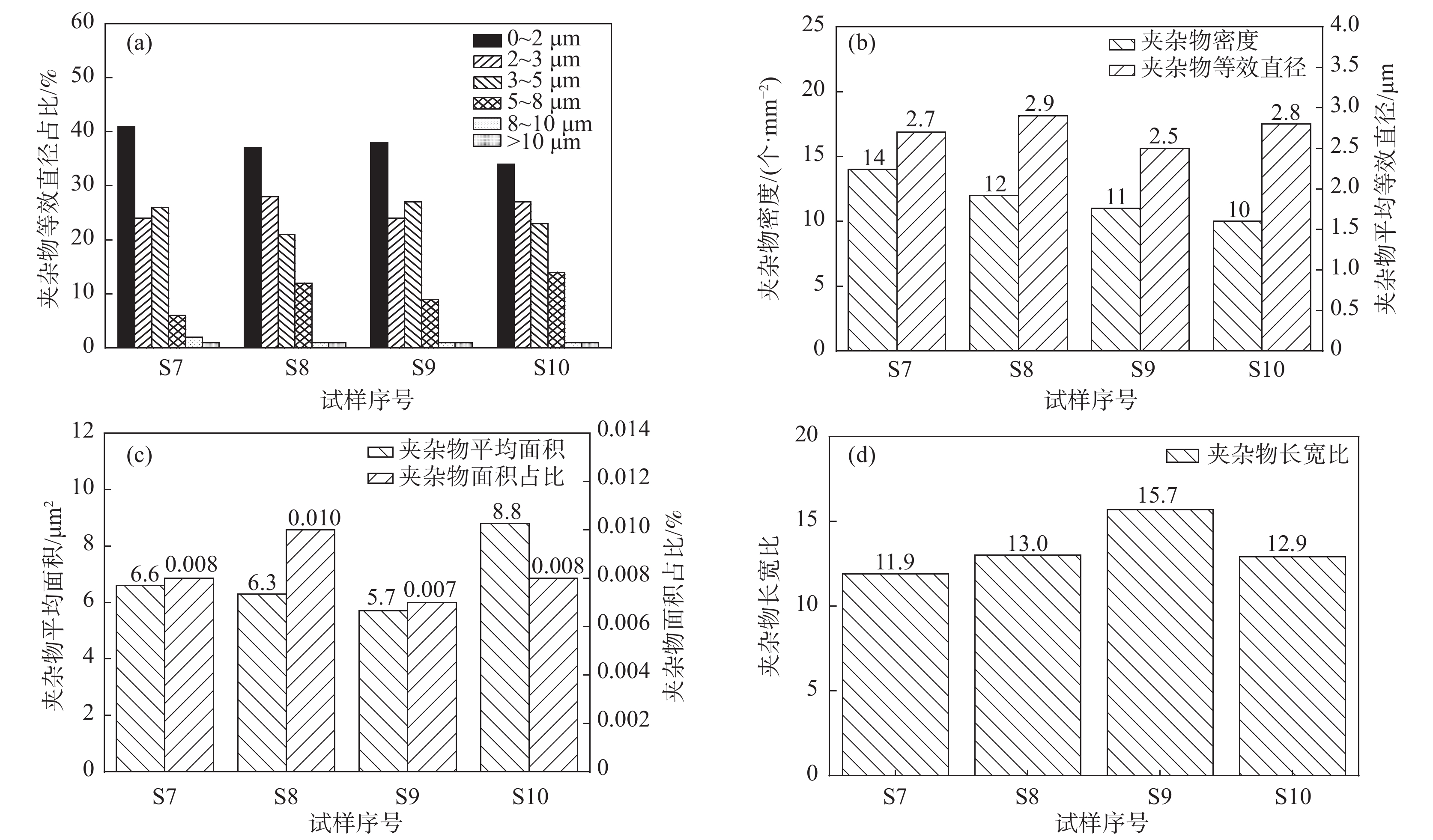

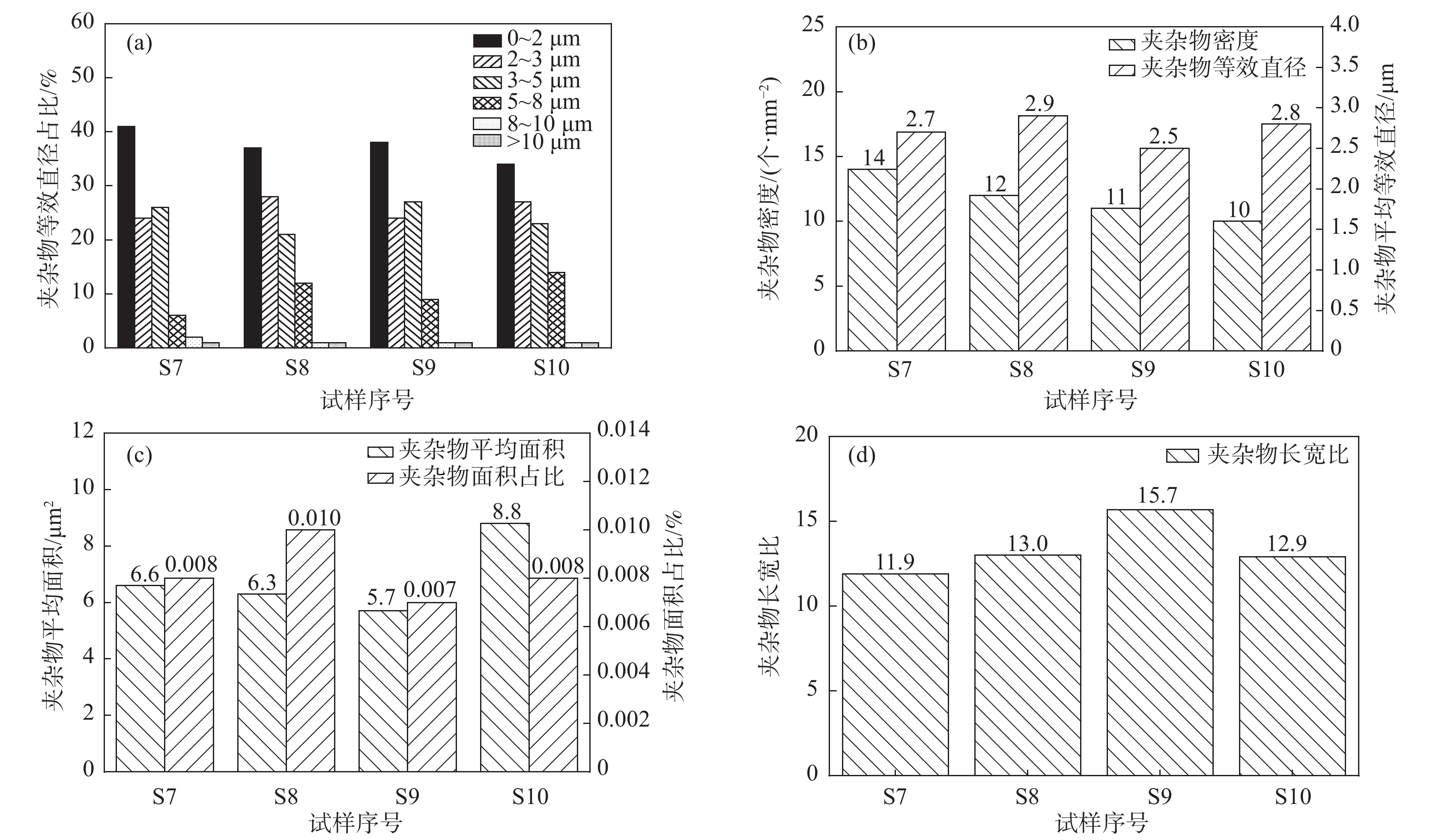

图5展示了轨腰夹杂物相关尺寸特征。从图5(a)~(d)可知,轨腰的夹杂物等效直径同样集中分布在0~3 μm,平均占比为63.2%,等效直径大于10 μm的夹杂物平均占比为1.0%;夹杂物数量密度分布在10~14 个/mm2,夹杂物平均等效直径分布在2.5~2.8 μm;夹杂物平均面积分布在5.7~8.8 μm2,面积占比分布在0.007%~0.010%;夹杂物长宽比分布为11.9~15.7,平均长宽比为13.4。

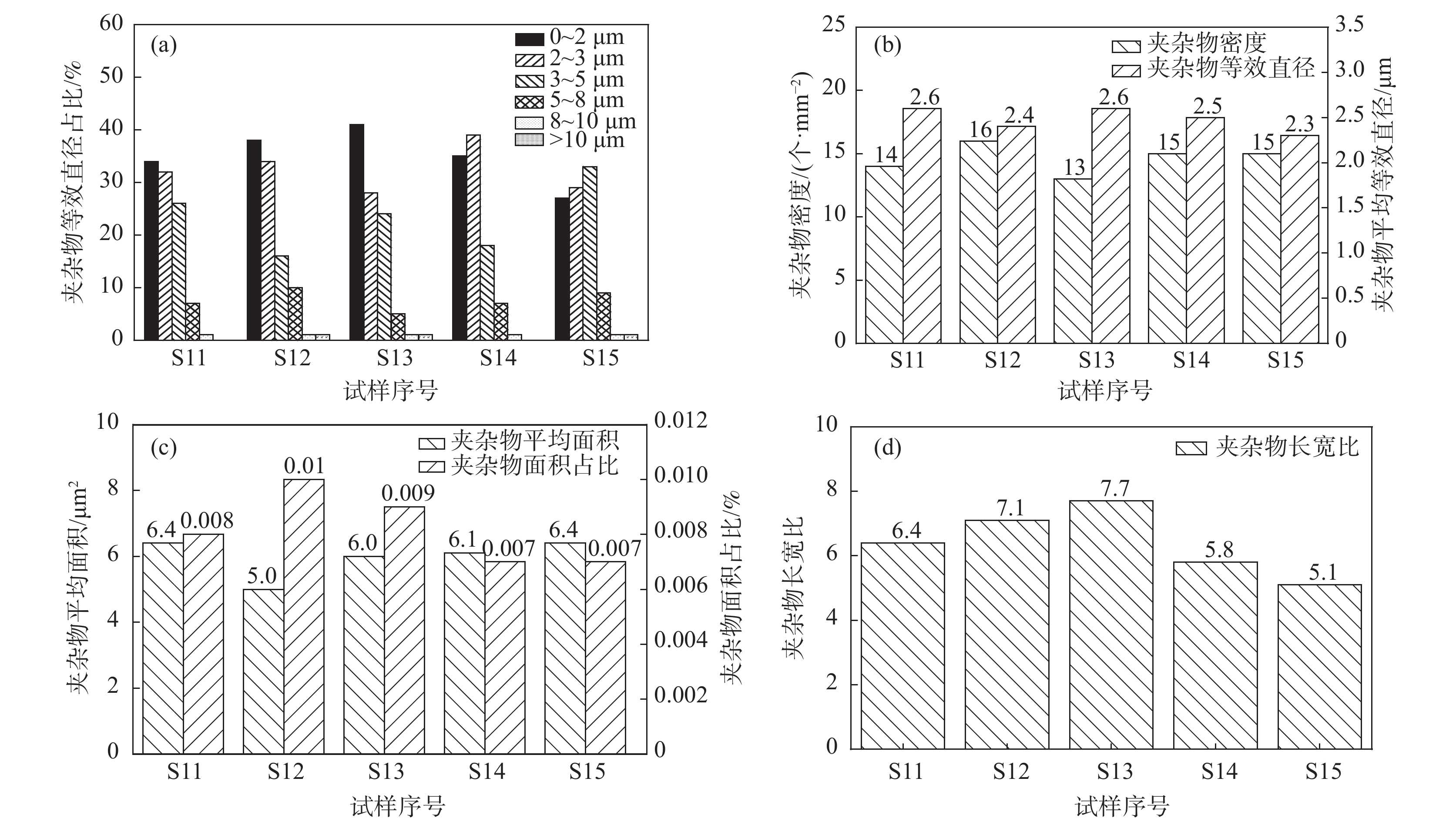

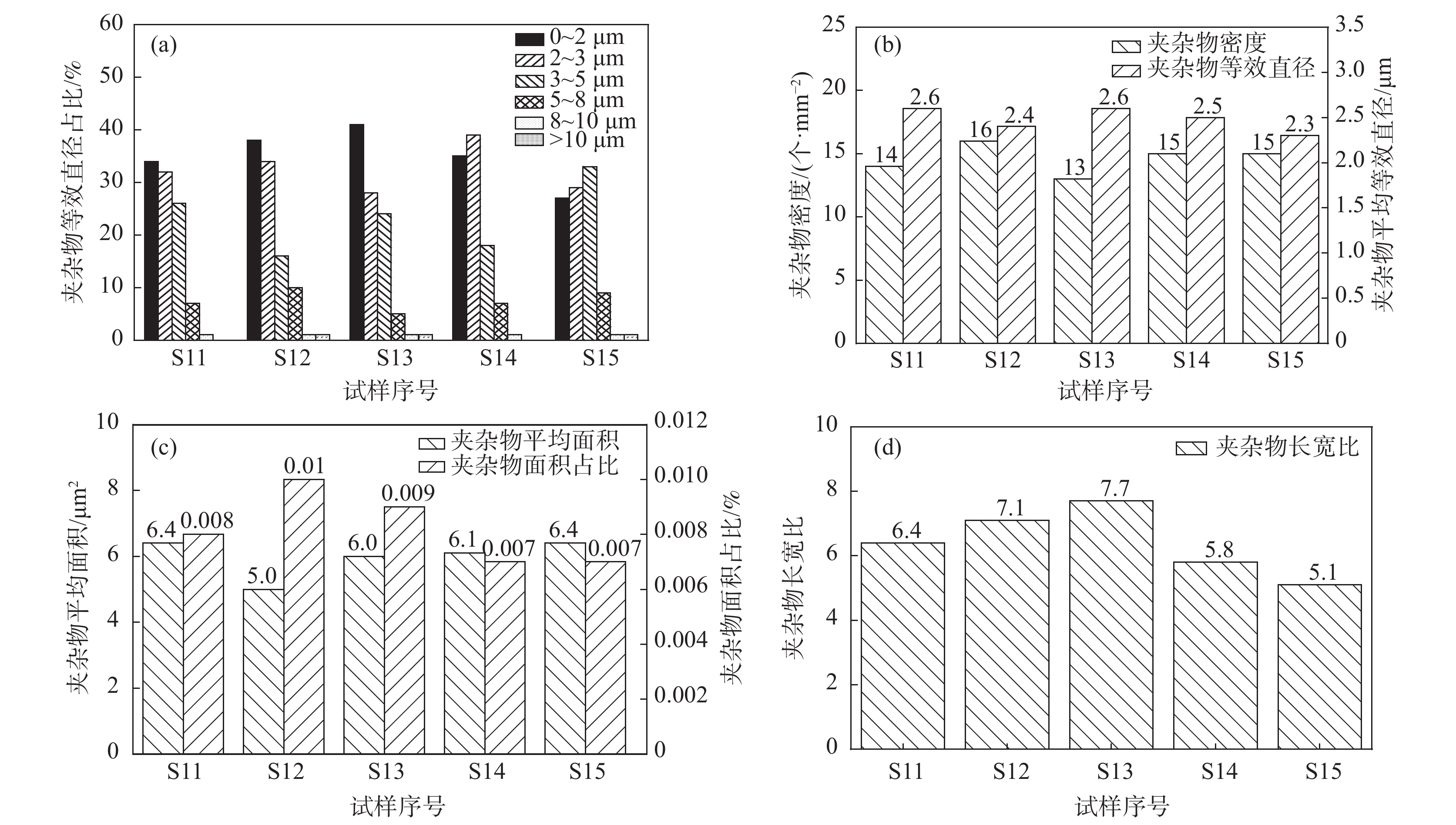

图6显示了轨底夹杂物相关尺寸特征。从图6(a)~(d)可知,轨底的夹杂物等效直径集中分布在0~3 μm,平均占比为67.4%,等效直径大于10 μm的夹杂物平均占比为0.6%;夹杂物数量密度分布在13~16 个/mm2,夹杂物平均等效直径分布在2.3~2.6 μm;夹杂物平均面积分布在5.0~6.4 μm2,面积占比分布在0.007%~0.010%;夹杂物长宽比分布在5.1~7.7,平均长宽比为6.4。

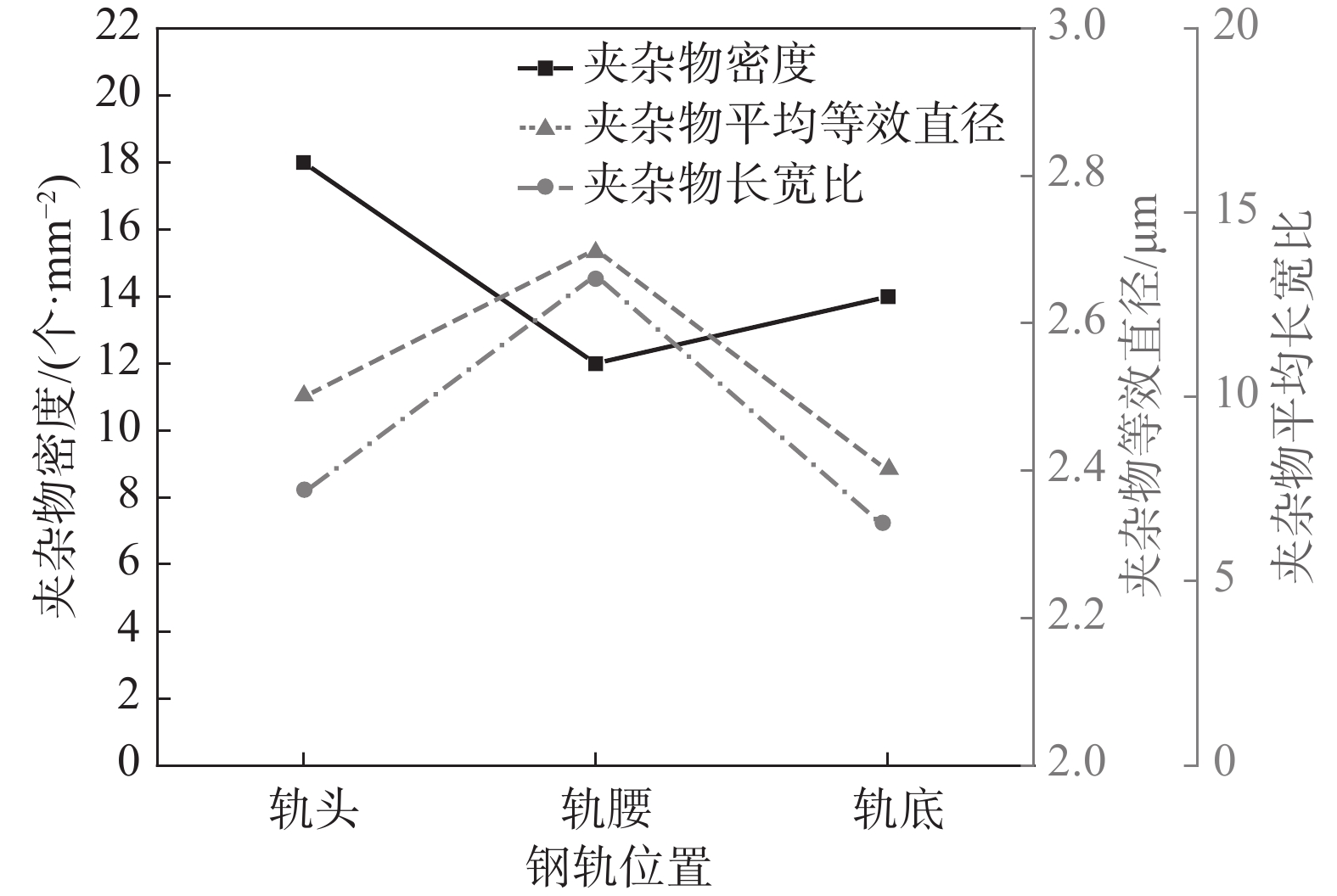

为了全面了解U71Mn重轨中不同部位的夹杂物分布情况,对从轨头、轨腰和轨底部位取得的试样进行了综合分析。图7为三个部位夹杂物的密度、平均等效直径和长宽比的统计对比结果。可以看出,从轨头到轨腰再到轨底,夹杂物的数量密度先减小后增大,夹杂物平均等效直径、长宽比先增大后减小,轨腰的夹杂物数量密度最小,而平均等效直径、长宽比最大,这说明在轨腰处存在着较多的大尺寸夹杂物,而轨头和轨底部位则相对较少。具体而言,轨头、轨腰、轨底的夹杂物密度分别为18、12、14 个/mm2,平均等效直径分别为2.5、2.7、2.4 μm,平均长宽比分别为7.4、13.3、6.4。

2.2 夹杂物析出热力学分析

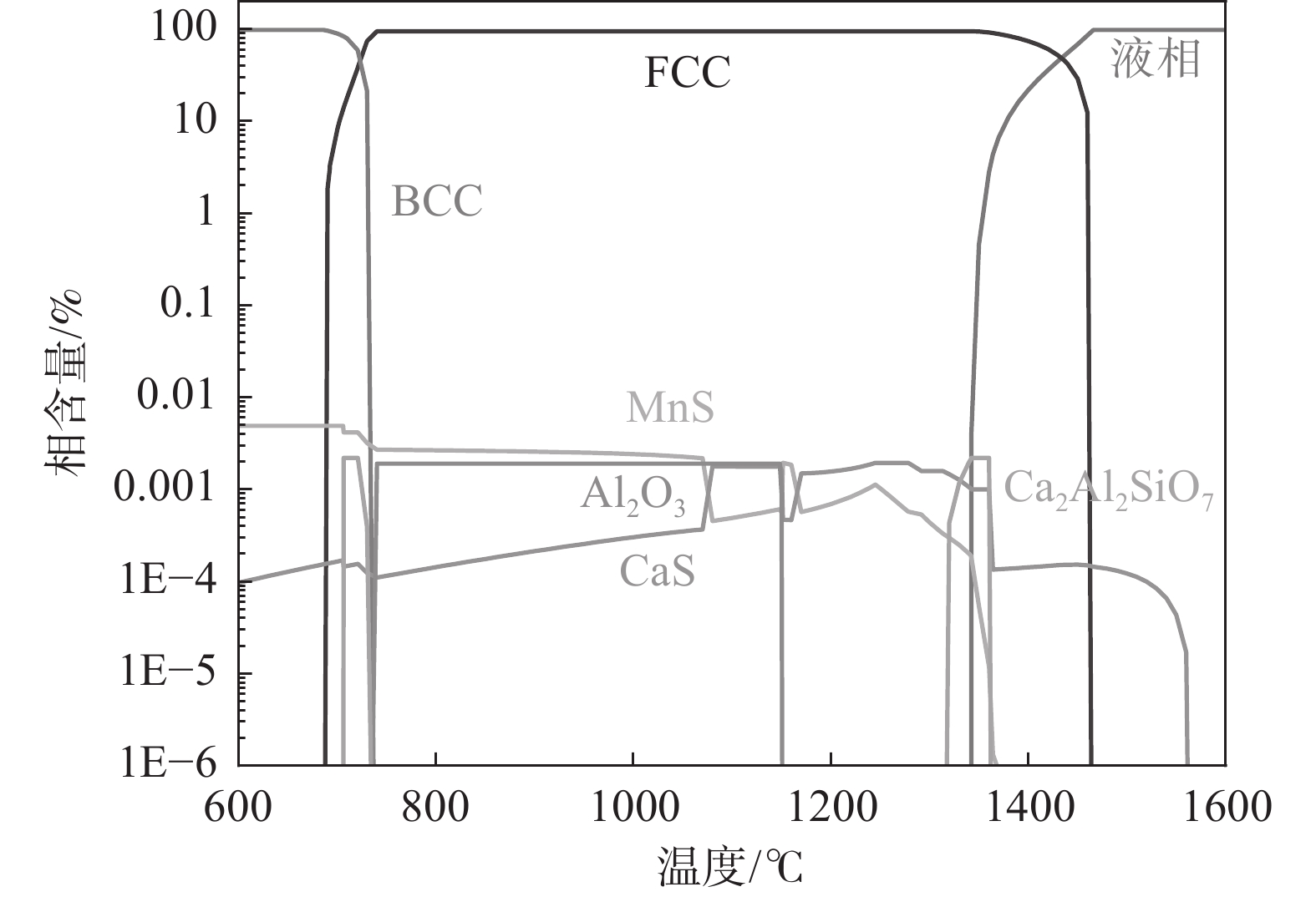

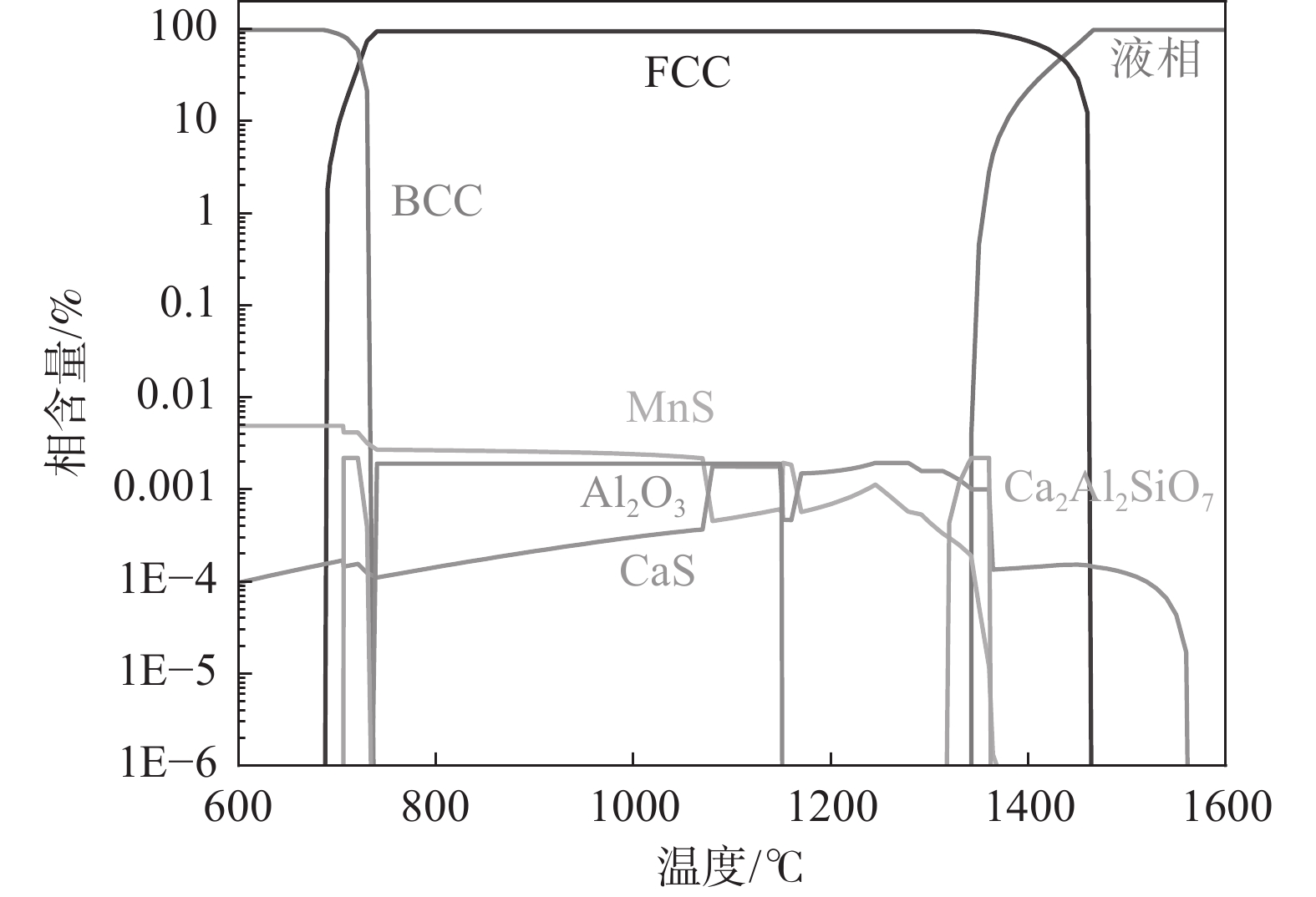

为研究U71Mn重轨钢凝固及冷却过程中的相转变行为及平衡相组成,采用Thermo-calc软件计算表1成分的U71Mn重轨钢由

1600 ℃高温液相至600 ℃的平衡相组成,结果如图8所示。从图8中可以观察到,U71Mn的液相线温度为1460 ℃,固相线温度为1342 ℃。在1460 ℃时,FCC相开始析出,发生了从液相到FCC相的转变。当温度降至1342 ℃时,所有的液相都已经转变为FCC相。进一步冷却至730 ℃时,BCC相开始析出,发生了从FCC相到BCC相的转变。到了690 ℃时,FCC相转变为BCC相。夹杂物相主要有CaS、MnS、Ca2Al2SiO7、Al2O3,它们对应的析出温度分别为1560 、1364 、1360 、1140 ℃,其中,Ca2Al2SiO7在730 ℃时二次析出。2.3 钢轨典型夹杂物形态分析

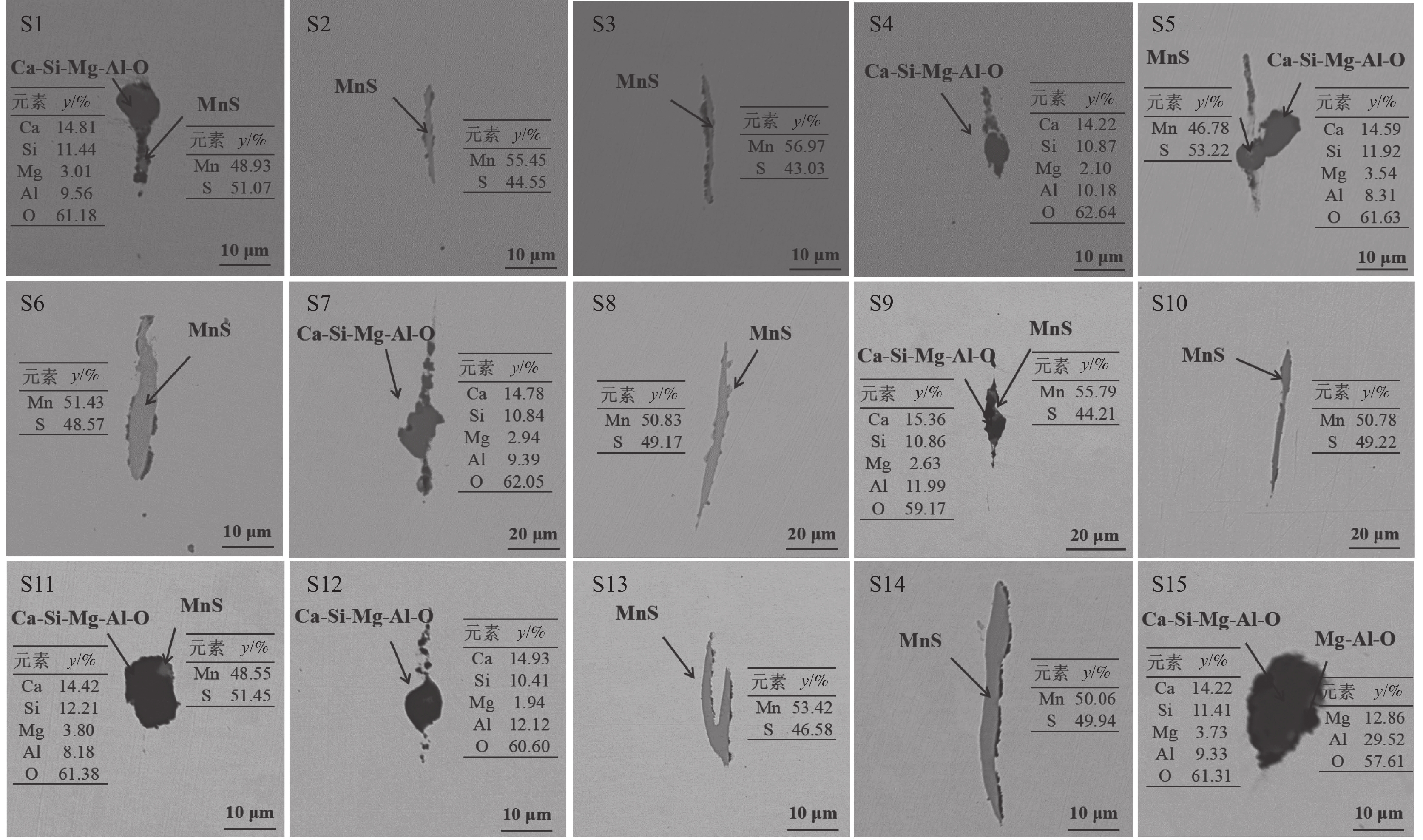

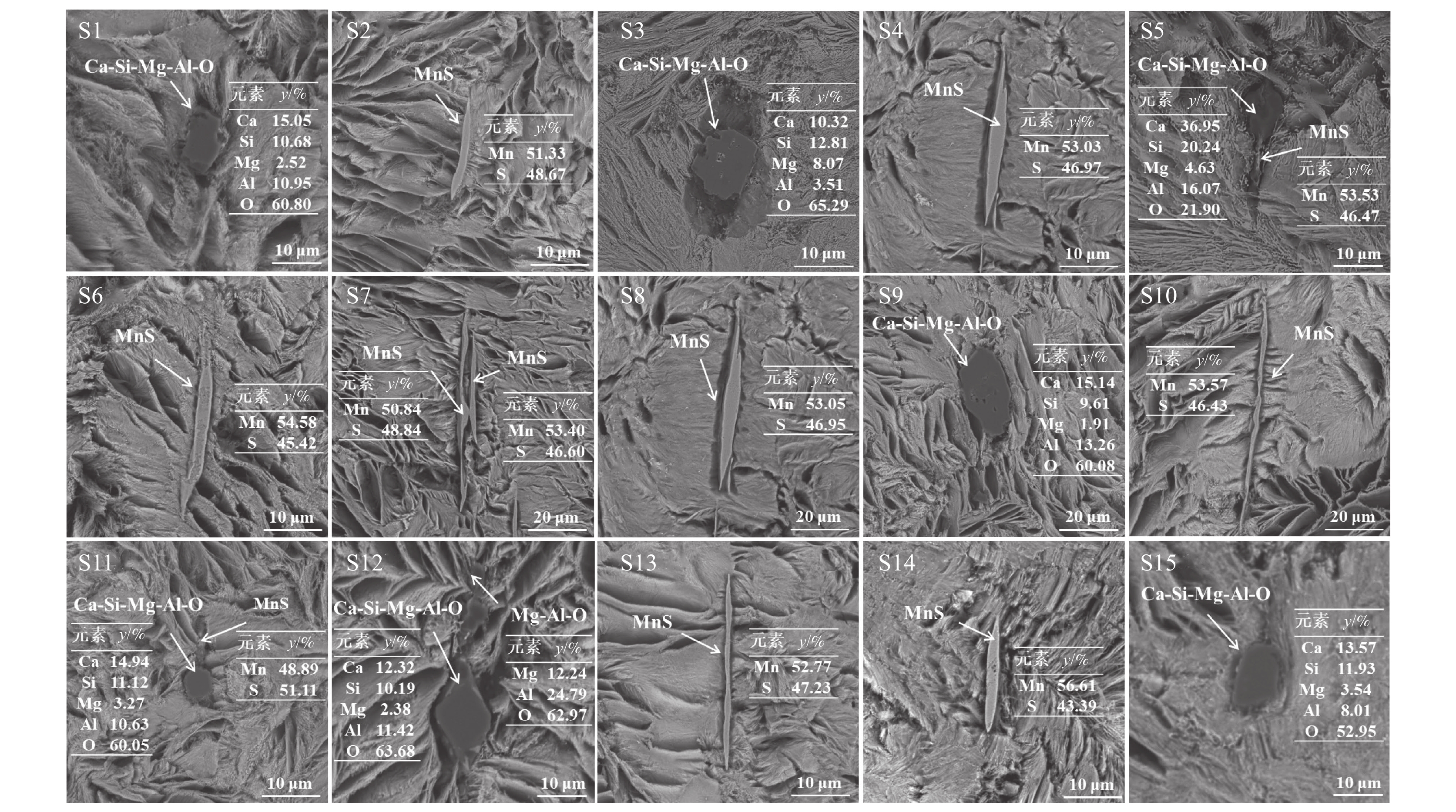

图9为U71Mn重轨钢典型夹杂物的形貌和成分。可以看出,U71Mn的夹杂物沿轧制方向普遍呈现长条状、片状和近球形,轨腰的夹杂物尺寸较大,轨头、轨底次之。由于冶炼过程中采用硅钙钡脱氧而不是铝脱氧,因此夹杂物类型以A类、C类为主。A类夹杂物主要是MnS,在扫描电镜背散射模式下呈灰白色,MnS是面心立方结构,具有较强的塑性与延展性,其在压缩的过程中晶体结构会向六个滑移面变形[16−19],故MnS夹杂物在钢轨内沿轧制方向普遍呈长条状。C类夹杂物主要为CaO·Al2O3·SiO2·MgO类,在扫描电镜背散射模式下呈灰黑色,其中Al、Mg等元素可能来源于钢包内衬以及钢液中的炉渣,此类夹杂物多呈近球形和不规则形,尺寸较大、塑性较差。此外,还存在有CaO·Al2O3·SiO2·MgO与MnS、MgO·Al2O3的复合夹杂物。

根据众多学者研究[20−22],结合热力学计算,MnS夹杂物在

1360 ℃时析出(图7)。在凝固初期,Mn和S的含量不足以使钢中析出MnS;随着凝固的进行,Mn和S元素显著富集,当枝晶间液相中的Mn和S的浓度积超过热力学平衡浓度积时,MnS便开始析出。CaO·Al2O3·SiO2·MgO类复合夹杂物可能与钢液卷渣有关。当钢液在LF精炼时,体系中存在夹杂物-钢液-炉渣,三者的成分变化趋于平衡,生成Ca-Al-Si-O类夹杂物,而在冶炼过程中,耐材或者精炼渣会向钢液中传递Mg,使Ca-Al-Si-O类复合夹杂物表面部分转化为MgO,最终形成CaO·Al2O3·SiO2·MgO类复合夹杂物。图10为三维电解腐刻后的U71Mn重轨钢典型夹杂物的三维分布。可以看出,MnS夹杂物在钢轨内沿轧制方向普遍呈长条状和片状,轨头和轨底处变形量小,尺寸在10~50 μm居多;轨腰处变形量最大,MnS夹杂物尺寸较大,在20~80 μm居多,且存在多条大尺寸的MnS被轧制在同一条水平线上。这是因为U71Mn重轨钢铸坯经过轧制后外形会发生较大的变化,铸坯中的MnS夹杂物在轧制过程中沿着轧制方向被拉长,轨腰的压缩变形量最大、轨头和轨底变形量相对较小,故轨腰处的夹杂物尺寸较大,轨头、轨底次之。这与前文Image Pro Plus软件统计结果一致。CaO·Al2O3·SiO2·MgO类复合夹杂物沿轧制方向普遍呈近球形和不规则形,不同位置处差别较小,这与CaO·Al2O3·SiO2·MgO类复合夹杂物塑性较差、不易变形有关。钢轨中的这些大尺寸夹杂物的存在会降低钢材的力学性能,易引起探伤不合格,严重危害钢轨性能,并可能导致焊接缺陷和组织不均匀等问题。

总体而言,U71Mn重轨钢中的夹杂物类型以单独存在的MnS、CaO·Al2O3·SiO2·MgO复合夹杂物为主,存在少量的CaO·Al2O3·SiO2·MgO与MnS、MgO·Al2O3的复合夹杂物,当钢中存在较多大尺寸的MnS、CaO·Al2O3·SiO2·MgO夹杂物时,将严重降低重轨的力学性能、抗疲劳性能和抗腐蚀性能等[23-24]。MnS夹杂物的析出与钢液中的非金属元素含量有很大的关系,工厂应根据实际生产情况,通过降低钢中的S含量、增大凝固的冷却速度、选择合适的保温温度和时间,可以有效减少钢中的MnS夹杂,而对于CaO·Al2O3·SiO2·MgO夹杂物,应尽量通过调控钢水成分、精炼渣碱度和减少合金中钙的加入量来避免形成大尺寸夹杂。

3. 结论

1) U71Mn重轨钢中的夹杂物特征受到各部分轧制变形量的显著影响。轨腰处变形量最大,平均等效直径和长宽比最大,数量密度最小。轨头、轨腰、轨底的夹杂物密度分别为18、12、14 个/mm2,平均等效直径分别为2.5、2.7 、2.4 μm,平均长宽比分别为7.4、13.3、6.4。

2) U71Mn重轨钢中的夹杂物以单独存在的MnS、CaO·Al2O3·SiO2·MgO复合夹杂物为主。MnS夹杂物沿轧制方向普遍呈长条状和片状,轨头、轨腰、轨底MnS夹杂物的尺寸相对较大;CaO·Al2O3·SiO2·MgO类复合夹杂物沿轧制方向普遍呈近球形和不规则形,不同位置处差别较小。

-

表 1 U71Mn重轨钢化学成分

Table 1. U71Mn heavy rail steel composition

% C Si Mn P S Al Ca V O Fe 0.73 0.35 0.95 0.012 0.002 0.003 0.0012 0.004 0.0009 余量 -

[1] Bai Guojun, Yang Jichun, Liang Wenjing. Evaluation and analysis of the influence of rare-earth ce on inclusions in heavy rail steel[J]. Metals, 2023,13(3):614. doi: 10.3390/met13030614 [2] Fei Junjie, Zhou Guifeng, Zhou Jianhua, et al. Research on the effect of pearlite lamellar spacing on rolling contact wear behavior of U75V rail steel[J]. Metals, 2023,13(2):237. doi: 10.3390/met13020237 [3] Wang Yi, Li Changrong, Wang Linzhu, et al. Modification of alumina inclusions in SWRS82B steel by adding rare earth cerium[J]. Metals, 2020,10(12):1696. doi: 10.3390/met10121696 [4] Yang Guang, Yang Wen, Zhang Lifeng, Modification of inclusion calcium in aluminum-killed steel and its influencing factors[J]. Iron & Steel, 2022, 57(12): 66-78. (杨光, 杨文, 张立峰. 铝镇静钢中夹杂物钙处理改性及其影响因素[J]. 钢铁, 2022, 57(12): 66-78.Yang Guang, Yang Wen, Zhang Lifeng, Modification of inclusion calcium in aluminum-killed steel and its influencing factors[J]. Iron & Steel, 2022, 57(12): 66-78. [5] Song Guangjie, Zhu Haoran, Ji Dengping, et al. Analysis of inclusions and carbides in 102Cr17Mo bearing steel billet[J]. Iron & Steel, 2023,58(8): 157-168. (宋光洁, 朱浩然, 季灯平, 等. 102Cr17Mo轴承钢铸坯夹杂物及碳化物解析[J]. 钢铁, 2023,58(8): 157-168.Song Guangjie, Zhu Haoran, Ji Dengping, et al. Analysis of inclusions and carbides in 102Cr17Mo bearing steel billet[J]. Iron & Steel, 2023,58(8): 157-168. [6] Guo Shuai, Zhu Hangyu, Han Yun, et al. Research on influence of inclusions on plasticity and toughness of steel[J]. Iron and Steel Research Journal. 2022(8): 713-726. (郭帅, 朱航宇, 韩赟, 等. 夹杂物对钢塑性和韧性的影响研究进展[J]. 钢铁研究学报, 2022(8): 713-726.Guo Shuai, Zhu Hangyu, Han Yun, et al. Research on influence of inclusions on plasticity and toughness of steel[J]. Iron and Steel Research Journal. 2022(8): 713-726. [7] Song Y, Zhang H, Ren L. A review of research on MnS inclusions in high-quality steel[J]. Engineering Reports, 2024,6(5):12892. doi: 10.1002/eng2.12892 [8] Yang Jian, Cai Wenjing. Effect of magnesium treatment on inclusions and HAZ structure and properties in steel[J]. Iron & Steel, 2021,56(7):13-24. (杨健, 蔡文菁. 镁处理对钢中夹杂物以及HAZ组织和性能的影响[J]. 钢铁, 2021,56(7):13-24.Yang Jian, Cai Wenjing. Effect of magnesium treatment on inclusions and HAZ structure and properties in steel[J]. Iron & Steel, 2021, 56(7): 13-24. [9] Xu Jianfei, Wang Kunpeng, Wang Ying, et al. Evolution law of inclusions in GCr15 bearing steel under different secondary oxidation degree[J]. Iron and Steel Research Journal, 2023, 35(12): 1496-1504. (徐建飞, 王昆鹏, 王郢, 等. GCr15轴承钢不同二次氧化程度下的夹杂物演变规律 [J]. 钢铁研究学报, 2023,35(12): 1496-1504.Xu Jianfei, Wang Kunpeng, Wang Ying, et al. Evolution law of inclusions in GCr15 bearing steel under different secondary oxidation degree[J]. Iron and Steel Research Journal, 2023, 35(12): 1496-1504. [10] Zhang Xuewei. Study on morphology analysis and control of MnS inclusions in heavy rail steel [D]. Beijing: University of Science and Technology Beijing, 2017. (张学伟. 重轨钢中MnS夹杂物形貌分析与控制研究 [D]. 北京: 北京科技大学, 2017.Zhang Xuewei. Study on morphology analysis and control of MnS inclusions in heavy rail steel [D]. Beijing: University of Science and Technology Beijing, 2017. [11] Liu Hongbo, Xie Rongyuan, Li Min, et al. Analysis of the evolution law of oxide inclusions in U75V heavy rail steel during the LF–RH refining process[J]. High Temperature Materials and Processes, 2023, 42(1). [12] Zhang Yuexin, Zhang Lifeng, Chu Yanping, et al. Transformation of inclusions in a complicated‐deoxidized heavy rail steels during heating[J]. Steel Research Rnternational, 2020, 91(9): 202000120. [13] Zhuo Chao. Study on removal and modification mechanism of inclusions in high speed heavy rail steel[D]. Beijing: University of Science and Technology Beijing, 2023. (卓超. 高速重轨钢中夹杂物去除及改性机理研究[D]. 北京: 北京科技大学, 2023.Zhuo Chao. Study on removal and modification mechanism of inclusions in high speed heavy rail steel[D]. Beijing: University of Science and Technology Beijing, 2023. [14] Chu Yanping, Chen Zhiyong, Liu Nan, et al. Formation and control of spinel inclusion in high speed heavy rail steel[J]. Iron & Steel, 2020,55(1):38-46, 55. (储焰平, 谌智勇, 刘南, 等. 高速重轨钢中尖晶石夹杂物的形成及控制[J]. 钢铁, 2020,55(1):38-46, 55.Chu Yanping, Chen Zhiyong, Liu Nan, et al. Formation and control of spinel inclusion in high speed heavy rail steel[J]. Iron & Steel, 2020, 55(1): 38-46, 55. [15] Fan Zhiming, Yang Jichun, Zhang Ying, et al. Effect of holding time on inclusions in U75V heavy rail steel[J]. Metal Heat Treatment, 2022,47(6):33-8. (樊志明, 杨吉春, 张滢, 等. 保温时间对U75V重轨钢中夹杂物的影响[J]. 金属热处理, 2022,47(6):33-38.Fan Zhiming, Yang Jichun, Zhang Ying, et al. Effect of holding time on inclusions in U75V heavy rail steel[J]. Metal Heat Treatment, 2022, 47(6): 33-8. [16] Liu Yue. Study on evolution mechanism of CASM inclusions in aluminum-free deoxidized heavy rail steel[D]. Shenyang: Northeastern University, 2018. (刘越. 无铝脱氧重轨钢中CASM类夹杂物演变机制研究[D]. 沈阳: 东北大学, 2018.Liu Yue. Study on evolution mechanism of CASM inclusions in aluminum-free deoxidized heavy rail steel[D]. Shenyang: Northeastern University, 2018. [17] Tian Qianren, Liu Nianfu, Shen Wei, et al. Morphological differences of MnS inclusions in medium-carbon steel with different manganese and sulfur contents[J]. Steel Research International, 2023,94(9):2300074. doi: 10.1002/srin.202300074 [18] Xie Xiaoyu, Gu Chao, Wang Min, et al. Control technology of manganese sulfide inclusion in medium and high sulfur steel[J]. Iron & Steel, 2021,56(12):52-61. (谢啸宇, 顾超, 王敏, 等. 中高硫钢中硫化锰夹杂物控制技术[J]. 钢铁, 2021,56(12):52-61.Xie Xiaoyu, Gu Chao, Wang Min, et al. Control technology of manganese sulfide inclusion in medium and high sulfur steel[J]. Iron & Steel, 2021, 56(12): 52-61. [19] Fang Mengting, Yuan Huazhi, Xie Xin, et al. Precipitation and growth of MnS inclusions in cast billet of heavy rail steel[J]. Iron & Steel, 2023,58(5):59-69. (房孟婷, 袁华志, 谢鑫, 等. 重轨钢铸坯中MnS夹杂物的析出与长大[J]. 钢铁, 2023,58(5):59-69.Fang Mengting, Yuan Huazhi, Xie Xin, et al. Precipitation and growth of MnS inclusions in cast billet of heavy rail steel[J]. Iron & Steel, 2023, 58(5): 59-69. [20] Shen Ping, Zhou Lei, Yang Qiankun, et al. Modification of MnS inclusion by tellurium in 38MnVS6 micro-alloyed steel[J]. Metall Res Technol, 2020,117(6):615. doi: 10.1051/metal/2020066 [21] Lin Tengchang, Zhu Rong, Zeng Jiaqing, et al. Multi-scale structure of influencing factors for CaO-SiO2-Al2O3-MgO inclusion control[J]. Iron & Steel, 2015,50(6):21-25. (林腾昌, 朱荣, 曾加庆, 等. CaO-SiO2-Al2O3-MgO夹杂物控制影响因素的多尺度结构[J]. 钢铁, 2015,50(6):21-25.Lin Tengchang, Zhu Rong, Zeng Jiaqing, et al. Multi-scale structure of influencing factors for CaO-SiO2-Al2O3-MgO inclusion control[J]. Iron & Steel, 2015, 50(6): 21-25. [22] Chen Zhiyong, Wang Wenyi, Chu Yanping, et al. Analysis of inclusion evolution in U75V heavy rail steel of baotou steel[J]. Continuous Casting, 2020(5):57-61. (谌智勇, 王文义, 储焰平, 等. 包钢U75V重轨钢夹杂物演变规律分析[J]. 连铸, 2020(5):57-61.Chen Zhiyong, Wang Wenyi, Chu Yanping, et al. Analysis of inclusion evolution in U75V heavy rail steel of baotou steel[J]. Continuous Casting, 2020(5): 57-61. [23] Hou Zewang. Research on refining control of MnS inclusions in heavy rail steel[D]. Beijing: University of Science and Technology Beijing, 2022. (侯泽旺. 重轨钢MnS夹杂物细化控制研究[D]. 北京: 北京科技大学, 2022.Hou Zewang. Research on refining control of MnS inclusions in heavy rail steel[D]. Beijing: University of Science and Technology Beijing, 2022. [24] Li Xiangchuan. Analysis of inclusions evolution in CRRE steel [D]. Baotou: Inner Mongolia University of Science and Technology, 2022. -

下载:

下载:

下载:

下载: