| [1] |

Gan Yong, Peng Suping, Mao Jingwen, et al. High-quality development strategy for the supply chain of critical minerals and its material industry in China[J]. Strategic Study of CAE, 2022,24(3):1-9. (干勇, 彭苏萍, 毛景文, 等. 我国关键矿产及其材料产业供应链高质量发展战略研究[J]. 中国工程科学, 2022,24(3):1-9. doi: 10.15302/J-SSCAE-2022.03.001Gan Yong, Peng Suping, Mao Jingwen, et al. High-quality development strategy for the supply chain of critical minerals and its material industry in China[J]. Strategic Study of CAE, 2022, 24(3): 1-9. doi: 10.15302/J-SSCAE-2022.03.001

|

| [2] |

Zhu Miaoyong. A study of transport phenomena and key technologies for high-speed continuous casting of steel[J]. Iron & Steel, 2021,56(7):1-12. (朱苗勇. 高拉速连铸过程传输行为特征及关键技术探析[J]. 钢铁, 2021,56(7):1-12.Zhu Miaoyong. A study of transport phenomena and key technologies for high-speed continuous casting of steel[J]. Iron & Steel, 2021, 56(7): 1-12.

|

| [3] |

Deng X, Ji C, Cui Y, et al. Flow pattern control in continuous slab casting moulds: physical modelling and plant trials[J]. Ironmaking & Steelmaking, 2017,44(6):461-471.

|

| [4] |

Dauby P H. Continuous casting: make better steel and more of it[J]. Revue De Métallurgie, 2012,109(2):113-136.

|

| [5] |

Pütz O, Rödl S. Investigations of unsteady and asymmetric flow phenomena in continuous casting moulds by advanced simulation techniques[J]. Steel Research International, 2003,74(2):104-113. doi: 10.1002/srin.200300168

|

| [6] |

Wang Y, Zhang L. Transient fluid flow phenomena during continuous casting: Part II—Cast speed change, temperature fluctuation, and steel grade mixing[J]. ISIJ international, 2010,50(12):1783-1791. doi: 10.2355/isijinternational.50.1783

|

| [7] |

Yuan Peng, Wang Xinhua, Jiang Min, et al. Inclusions in low carbon aluminum killed steel slabs at high casting speed[J]. Chinese Journal of Engineering, 2016,38(3):342-350. (苑鹏, 王新华, 姜敏, 等. 高拉速连铸低碳铝镇静钢铸坯中夹杂物[J]. 工程科学学报, 2016,38(3):342-350.Yuan Peng, Wang Xinhua, Jiang Min, et al. Inclusions in low carbon aluminum killed steel slabs at high casting speed[J]. Chinese Journal of Engineering, 2016, 38(3): 342-350.

|

| [8] |

Chen Wei, Zhang Lifeng, Ren Qiang, et al. Large eddy simulation on four-phase flow and slag entrainment in the slab continuous casting mold[J]. Metallurgical and Materials Transactions B, 2022,53(3): 1446-1461.

|

| [9] |

Zhang Lifeng, Yang Subo, Cai Kaike, et al. Investigation of fluid flow and steel cleanliness in the continuous casting strand[J]. Metallurgical and Materials Transactions B, 2007,38(1):63-83. doi: 10.1007/s11663-006-9007-0

|

| [10] |

Liu Z Q, Qi F S, Li B K, et al. Modeling of bubble behaviors and size distribution in a slab continuous casting mold[J]. International Journal of Multiphase Flow, 2016,79:190-201. doi: 10.1016/j.ijmultiphaseflow.2015.07.009

|

| [11] |

Ishiguro K, Iguchi M. Model experiment on the behavior of argon gas in immersion nozzle[J]. ISIJ International, 2003,43(5):663-670. doi: 10.2355/isijinternational.43.663

|

| [12] |

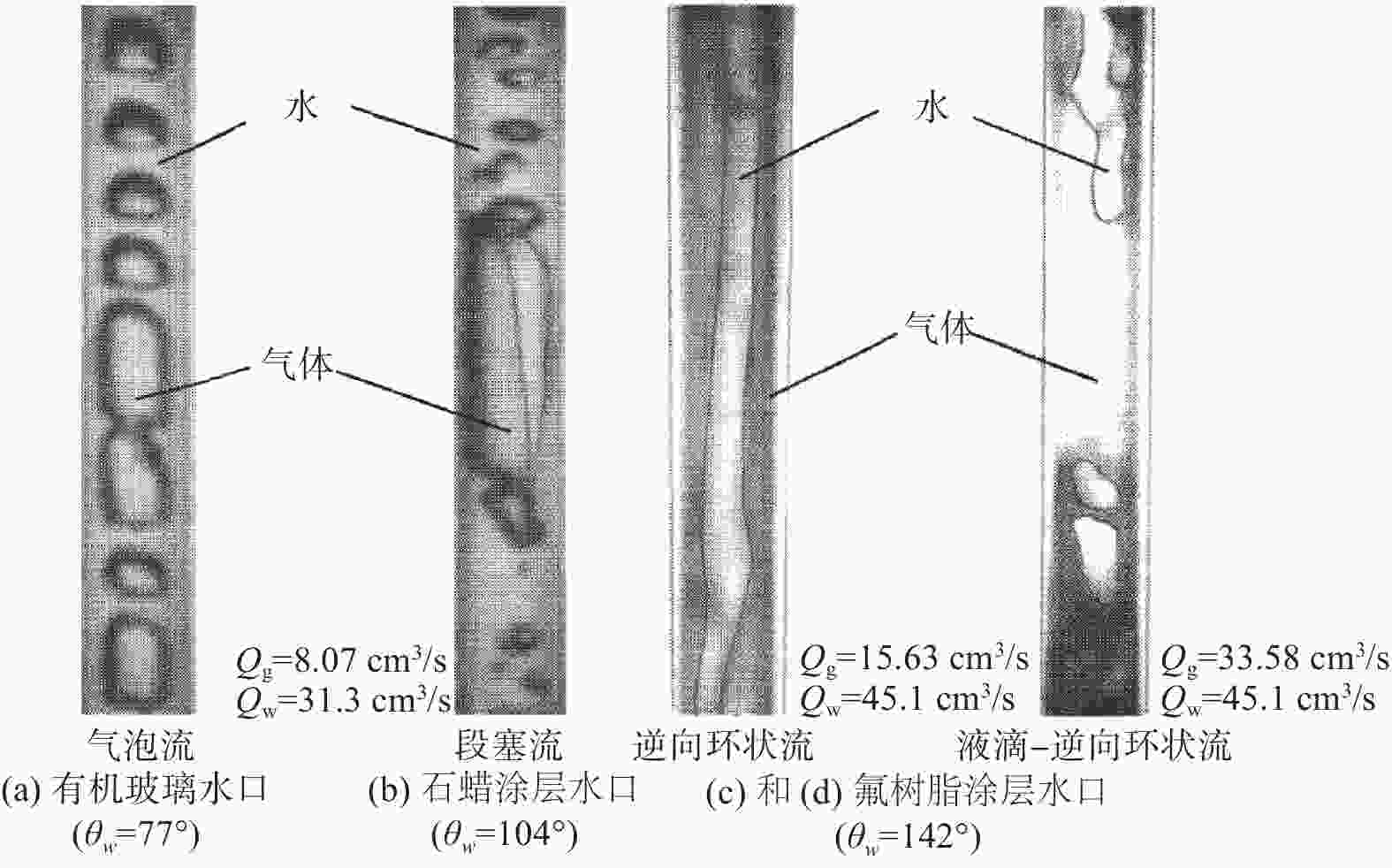

Terauchi Y, Iguchi M, Kosaka H, et al. Wettability effect on the flow pattern of air-water two-phase flows in a vertical circular pipe[J]. Tetsu-to-Hagane, 1999,85(9):645-651. doi: 10.2355/tetsutohagane1955.85.9_645

|

| [13] |

Burty M, Larrecq M, Pusse C, et al. Experimental and theoretical analysis of gas and metal flows in submerged entry nozzles in continuous casting[J]. Revue de Metallurgie-CIT, 1996,93(10):1249-1255. doi: 10.1051/metal/199693101249

|

| [14] |

Ren Lei, Zhang Lifeng, Wang Qiangqiang, et al. Study on fluid flow in a continuous casting slab mold using particle image velocimetry[J]. Chinese Journal of Engineering, 2016,38(10):1393-1403. (任磊, 张立峰, 王强强, 等. 基于 PIV 技术的板坯连铸结晶器内钢水流动行为研究[J]. 工程科学学报, 2016,38(10):1393-1403.Ren Lei, Zhang Lifeng, Wang Qiangqiang, et al. Study on fluid flow in a continuous casting slab mold using particle image velocimetry[J]. Chinese Journal of Engineering, 2016, 38(10): 1393-1403.

|

| [15] |

Liu Rui, Thomas B G, Sengupta J, et al. Measurements of molten steel surface velocity and effect of stopper-rod movement on transient multiphase fluid flow in continuous casting[J]. ISIJ International, 2014,54(10):2314-2323. doi: 10.2355/isijinternational.54.2314

|

| [16] |

Zhu Xiaowei, Li Dewei, Wu Chunlei, et al. Influence of large-scale vortex movement in lower recirculation zone on instable flow field in the mold[J]. ISIJ International, 2018,58(9):1687-1694. doi: 10.2355/isijinternational.ISIJINT-2018-160

|

| [17] |

Chen Wei, Ren Ying, Zhang Lifeng, et al. Numerical simulation of steel and argon gas two-phase flow in continuous casting using LES+ VOF+ DPM model[J]. JOM, 2019,71(3):1158-1168. doi: 10.1007/s11837-018-3255-8

|

| [18] |

Liu Zhongqiu, Li Baokuan, Jiang Maofa, et al. Modeling of transient two-phase flow in a continuous casting mold using Euler-Euler large eddy simulation scheme[J]. ISIJ International, 2013,53(3):484-492. doi: 10.2355/isijinternational.53.484

|

| [19] |

Dauby P H, Assar M B, Lawson G D. PIV and MFC measurements in a continuous caster mould. New tools to penetratethe caster black box[J]. Revue de Métallurgie, 2001,98(4):353-366.

|

| [20] |

Salazar-Campoy M M, Morales R D, Najera-Bastida A, et al. A physical model to study the effects of nozzle design on dense two-phase flows in a slab mold casting ultra-low carbon steels[J]. Metallurgical and Materials Transactions B, 2017,48(2):1376-1389. doi: 10.1007/s11663-017-0918-8

|

| [21] |

Andrzejewski P, Köhler K U, Pluschkell W. Model investigations on the fluid flow in continuous casting moulds of wide dimensions[J]. Steel Research, 1992,63(6):242-246. doi: 10.1002/srin.199200508

|

| [22] |

Deng Xiaoxuan, Ji Chenxi, Cui Yang, et al. Flow pattern in continuous casting slab mold with argon blowing[J]. Iron & Steel, 2016,51(10):23-30. (邓小旋, 季晨曦, 崔阳, 等. 吹氩板坯连铸结晶器内钢水流态[J]. 钢铁, 2016,51(10):23-30.Deng Xiaoxuan, Ji Chenxi, Cui Yang, et al. Flow pattern in continuous casting slab mold with argon blowing[J]. Iron & Steel, 2016, 51(10): 23-30.

|

| [23] |

Asad A, Kratzsch C, Schwarze R. Numerical investigation of the free surface in a model mold[J]. Steel Research International, 2016,87(2):181-190. doi: 10.1002/srin.201400600

|

| [24] |

Huang Caide, Zhou Haichen, Zhang Lifeng, et al et al. Effect of casting parameters on the flow pattern in a steel continuous casting slab mold: numerical simulation and industrial trials[J]. Steel Research International, 2022,93(2):2100350. doi: 10.1002/srin.202100350

|

| [25] |

Kohler K U, Andrzejewski P, Julius E, et al. Steel flow velocity measurement and flow pattern monitoring in the mould[C]//78th Steelmaking Conference Proceedings. Warrendale: Iron and Steel Society, 1995: 445-449.

|

| [26] |

Liu Zhongqiu, Qi Fengsheng, Li Baokuan, et al. Vortex flow pattern in a slab continuous casting mold with argon gas injection[J]. Journal of Iron and Steel Research, International, 2014,21(12):1081-1089. doi: 10.1016/S1006-706X(14)60187-4

|

| [27] |

Salazar-Campoy M M, Morales R D, Nájera-Bastida A, et al. A physical model to study the effects of nozzle design on dispersed two-phase flows in a slab mold casting ultra-low-carbon steels[J]. Metallurgical and Materials Transactions B, 2018,49(2):812-830. doi: 10.1007/s11663-018-1181-3

|

| [28] |

Zhang Tao, Yang Jian, Jiang Peng. Measurement of molten steel velocity near the surface and modeling for transient fluid flow in the continuous casting mold[J]. Metals, 2019,9(1):36. doi: 10.3390/met9010036

|

| [29] |

Liu Fenggang, Zhou Haichen, Zhang Lifeng, et al. Dependency of flow pattern in the mold on the distribution of inclusions along the thickness of continuous casting slabs[J]. Metallurgical and Materials Transactions B, 2021,52(4):2536-2550. doi: 10.1007/s11663-021-02201-x

|

| [30] |

Assar M B, Dauby P H, Lawson G D. Opening the black box: PIV and MFC measurements in a continuous caster mold[C]//83rd Steelmaking Conference Proceedings. Warrendale: Iron and Steel Society, 2000: 397-411.

|

| [31] |

Andrzejewski P, Gotthelf D, Julius E, et al. Mould flow monitoring at no. 3 slab caster, Krupp Hoesch Stahl AG[C]//80th Steelmaking Conference proceedings. Warrendale: Iron and Steel Society, 1997: 153-157.

|

| [32] |

Hibbeler L C, Thomas B G. Mold slag entrainment mechanisms in continuous casting molds[J]. Iron and Steel Technology, 2013,10(10):121-136.

|

| [33] |

Li Xianglong, Li Baokuan, Liu Zhongqiu, et al. Evaluation of slag entrapment in continuous casting mold based on the LES-VOF-DPM coupled model[J]. Metallurgical and Materials Transactions B, 2021,52(5):3246-3264. doi: 10.1007/s11663-021-02253-z

|

| [34] |

Kunstreich S, Dauby P H. Effect of liquid steel flow pattern on slab quality and the need for dynamic electromagnetic control in the mould[J]. Ironmaking & Steelmaking, 2005,32(1):80-86.

|

| [35] |

Burty M, De Santis M, Gesell M. Behaviour of argon gas bubbles in the continuous casting machine[J]. Metallurgical Research & Technology, 2002,99(1):49-53.

|

| [36] |

Liu Yibo, Yang Jian, Huang Fuxiang, et al. Comparison of the flow field in a slab continuous casting mold between the thicknesses of 180 mm and 250 mm by high temperature quantitative measurement and numerical simulation[J]. Metals, 2021,11(12):1886. doi: 10.3390/met11121886

|

| [37] |

Zhou Haichen, Luo Yanzhao, Li Haibo, et al. Online prediction of surface velocity, vortex position and fluid flow pattern in mold[J]. Continuous Casting, 2023(5):80-86. (周海忱, 罗衍昭, 李海波, 等. 结晶器表面流速、涡心位置和流场流态在线预测[J]. 连铸, 2023(5):80-86.Zhou Haichen, Luo Yanzhao, Li Haibo, et al. Online prediction of surface velocity, vortex position and fluid flow pattern in mold[J]. Continuous Casting, 2023(5): 80-86.

|

| [38] |

Chen Wei, Zhou Haichen, Wang Shengdong, et al. Nail board industrial experiment on effect of argon flow rate on mold flow field[J]. Iron & Steel, 2019,54(8):102-106. (陈威, 周海忱, 王胜东, 等. 吹氩流量对结晶器流场影响的插钉工业试验[J]. 钢铁, 2019,54(8):102-106.Chen Wei, Zhou Haichen, Wang Shengdong, et al. Nail board industrial experiment on effect of argon flow rate on mold flow field[J]. Iron & Steel, 2019, 54(8): 102-106.

|

| [39] |

Zhou Haichen, Zhang Lifeng, Chen Wei, et al. Determination of transient flow pattern in steel continuous casting molds using nail board measurement and onsite top flux observation[J]. Metallurgical and Materials Transactions B, 2021,52(2):1106-1117. doi: 10.1007/s11663-021-02083-z

|

| [40] |

Thomas B G, Huang X, Sussman R C. Simulation of argon gas flow effects in a continuous slab caster[J]. Metallurgical and Materials Transactions B, 1994,25(4):527-547. doi: 10.1007/BF02650074

|

| [41] |

Liu Zhongqiu, Li Baokuan, Jiang Maofa. Transient asymmetric flow and bubble transport inside a slab continuous-casting mold[J]. Metallurgical and Materials Transactions B, 2014,45(2):675-697. doi: 10.1007/s11663-013-9972-z

|

| [42] |

Robertson T, Moore P, Hawkins R J. Computational flow model as aid to solution of fluid flow problems in the steel industry[J]. Ironmaking & Steelmaking, 1986,13(4):195-203.

|

| [43] |

Tripathi A, Ajmani S K, Chandra S. Numerical investigation of bias flow in a slab caster mould[J]. Canadian Metallurgical Quarterly, 2021,60(3):203-214. doi: 10.1080/00084433.2021.1997278

|

| [44] |

Liu Zhongqiu, Li Baokuan, Zhang Li, et al. Analysis of transient transport and entrapment of particle in continuous casting mold[J]. ISIJ International, 2014,54(10):2324-2333. doi: 10.2355/isijinternational.54.2324

|

| [45] |

Honeyands T, Herbertson J. Flow dynamics in thin slab caster moulds[J]. Steel Research International, 1995,66(7):287-293. doi: 10.1002/srin.199501126

|

| [46] |

Yasunaka H, Taniguchi K, Kokita M, et al. Surface quality of stainless steel type 304 cast by twin-roll type strip caster[J]. ISIJ International, 1995,35(6):784-789. doi: 10.2355/isijinternational.35.784

|

| [47] |

Li B K, Tsukihashi F. Vortexing flow patterns in a water model of slab continuous casting mold[J]. ISIJ International, 2005,45(1):30-36. doi: 10.2355/isijinternational.45.30

|

| [48] |

Li Baokuan, Liu Zhongqiu, Qi Fengsheng, et al. Large eddy simulation for unsteady turbulent flow in thin slab continuous casting mold[J]. Acta Metallurgica Sinica, 2012,48(1):23-32. (李宝宽, 刘中秋, 齐凤升, 等. 薄板坯连铸结晶器非稳态湍流大涡模拟研究[J]. 金属学报, 2012,48(1):23-32. doi: 10.3724/SP.J.1037.2011.00464Li Baokuan, Liu Zhongqiu, Qi Fengsheng, et al. Large eddy simulation for unsteady turbulent flow in thin slab continuous casting mold[J]. Acta Metallurgica Sinica, 2012, 48(1): 23-32. doi: 10.3724/SP.J.1037.2011.00464

|

| [49] |

Ren Lei, Ren Ying, Zhang Lifeng, et al. Investigation on fluid flow inside a continuous slab casting mold using particle image velocimetry[J]. Steel Research International, 2019,90(11):1900209. doi: 10.1002/srin.201900209

|

| [50] |

Birat, J P, Larrecq M, Lamant J Y, et al. The continuous casting mold: a basic tool for surface quality and strand productivity[C]//74th Steelmaking Conference Proceedings. Warrendale: Iron and Steel Society, 1991: 39-50.

|

| [51] |

Lee J, Kim Y, Yi K. Analysis of the origin of periodic oscillatory flow in the continuous casting mold[J]. Metals and Materials International, 2015,21(2):295-302. doi: 10.1007/s12540-015-4223-2

|

| [52] |

Yuan Q, Thomas B G, Vanka S P. Study of transient flow and particle transport in continuous steel caster molds: Part I. Fluid flow[J]. Metallurgical and Materials Transactions B, 2004,35(4):685-702. doi: 10.1007/s11663-004-0009-5

|

| [53] |

Torres-Alonso E, Morales R D, Palafox-Ramos J, et al. Oscillating jet flows in a thin slab mold and their influence on meniscus stability[J]. Steel Research International, 2008,79(7):553-563. doi: 10.1002/srin.200806166

|

| [54] |

Gupta D, Lahiri A K. A water model study of the flow asymmetry inside a continuous slab casting mold[J]. Metallurgical & Materials Transactions B, 1996,27(5):757-764.

|

| [55] |

Gupta D, Chakraborty S. Asymmetry and oscillation of the fluid flow pattern in a continuous casting mould: a water model study[J]. ISIJ International, 1997,37(7):654-658. doi: 10.2355/isijinternational.37.654

|

| [56] |

Gupta D, Subramaniam S, Lahiri A K. Study of fluid flow and residence-time distribution in a continuous slab casting mould[J]. Steel Research, 1991,62(11):496-500. doi: 10.1002/srin.199100438

|

| [57] |

Torres-Alonso E, Morales R D, Demedices LG, et al. Flow dynamics in thin slab molds driven by sustainable oscillating jets from the feeding SEN[J]. ISIJ International, 2007,47(5):679-688. doi: 10.2355/isijinternational.47.679

|

| [58] |

Torres-Alonso E, Morales R D, García-Hernández S, et al. Cyclic turbulent instabilities in a thin slab mold. Part I: physical model[J]. Metallurgical and Materials Transactions B, 2010,41(3):583-597. doi: 10.1007/s11663-010-9361-9

|

| [59] |

Bai H, Thomas B G. Effects of clogging, argon injection, and continuous casting conditions on flow and air aspiration in submerged entry nozzles[J]. Metallurgical & Materials Transactions B, 2001,32(4):707-722.

|

| [60] |

Lee G G, Shin H J, Thomas B G, et al. Asymmetric multi-phase fluid flow and particle entrapment in a continuous casting mold[C]//Proceedings of AISTech 2008 Steelmaking Conference. Pittsburgh: The Association for Iron and Steel Technology, 2008: 63-73.

|

| [61] |

Zhang Lifeng, Wang Yufeng, Zuo Xiangjun. Flow transport and inclusion motion in steel continuous-casting mold under submerged entry nozzle clogging condition[J]. Metallurgical and Materials Transactions B, 2008,39(4):534-550. doi: 10.1007/s11663-008-9154-6

|

| [62] |

Bai H, Thomas B G. Turbulent flow of liquid steel and argon bubbles in slide-gate tundish nozzles: Part II. Effect of operation conditions and nozzle design[J]. Metallurgical and Materials Transactions B, 2001,32(2):269-284. doi: 10.1007/s11663-001-0050-6

|

| [63] |

Honeyands T, Lucas J, Chambers J, et al. Preliminary modelling of steel delivery to thin slab caster moulds[C]//75th Steelmaking Conference Proceedings. Warrendale: Iron and Steel Society, 1992: 451-459.

|

| [64] |

Najjar F M, Thomas B G, Hershey D E. Numerical study of steady turbulent flow through bifurcated nozzles in continuous casting[J]. Metallurgical & Materials Transactions B, 1995,26(4):749-765.

|

| [65] |

Scoones D J, Nijman S. Measurement of steel velocities in the mould[J]. Revue de Métallurgie, 2003,100(6):633-635.

|

| [66] |

Li B, Okane T, Umeda T. Modeling of biased flow phenomena associated with the effects of static magnetic-field application and argon gas injection in slab continuous casting of steel[J]. Metallurgical and Materials Transactions B, 2001,32(6):1053-1066. doi: 10.1007/s11663-001-0094-7

|

| [67] |

Wang Y H. A study of the effect of casting conditions on fluid flow in the mold using water modelling[C]//73rd Steelmaking Conference Proceedings. Warrendale: Iron and Steel Society, 1990: 473-480.

|

| [68] |

He Qinglin. Observations of vortex formation in the mould of a continuous slab caster[J]. ISIJ International, 1993,33(2):343-345. doi: 10.2355/isijinternational.33.343

|

| [69] |

Herbertson J, He Q L, Flint P J, et al. Modeling of metal delivery to continuous casting moulds[C]//74th Steelmaking Conference Proceedings. Warrendale: Iron and Steel Society, 1991: 171-185.

|

| [70] |

Lawson G D, Sander S C, Emling W H, et al. Prevention of shell thinning breakouts associated with widening width changes[C]//77th Steelmaking Conference Proceedings. Warrendale: Iron and Steel Society, 1994: 329-336.

|

| [71] |

Han S W, Cho H J, Jin S Y, et al. Effects of simultaneous static and traveling magnetic fields on the molten steel flow in a continuous casting mold[J]. Metallurgical and Materials Transactions B, 2018,49:2757-2769. doi: 10.1007/s11663-018-1356-y

|

| [72] |

Schurmann D, Glavinić I, Willers B, et al. Impact of the electromagnetic brake position on the flow structure in a slab continuous casting mold: An experimental parameter study[J]. Metallurgical and Materials Transactions B, 2020,51(1):61-78. doi: 10.1007/s11663-019-01721-x

|

下载:

下载: