Study on the effects of oxygen enrichment modes on the tuyere raceway states of blast furnace

-

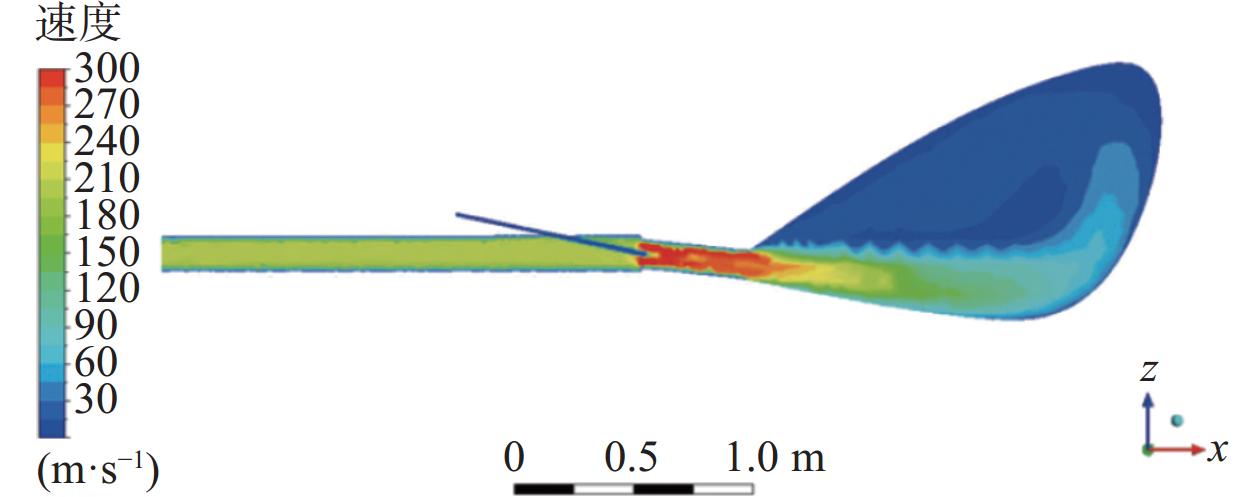

摘要: 依据国内某企业冶炼钒钛磁铁矿高炉的实际尺寸建立了三维物理模型,利用数值模拟的方法对比研究了不同富氧方式下煤粉在风口回旋区内的流动、燃烧行为。结果表明,减风富氧与定风富氧方式工况下,风口气流速度变化随富氧率变化的整体趋势一致,但变化幅度差距显著,即富氧率增加1%,风口截面速度分别增加4.25 m/s(定风)和0.41 m/s(减风)。两种富氧方式下,回旋区内的温度、还原气体含量及煤粉燃尽率与富氧率的变化趋势一样,即富氧率增加,温度增加,高温区域扩大,还原气体含量增加,煤粉的燃尽率上升。其中,减风富氧时由于热风流量减小,带入高炉的N2量减少,煤气中CO和H2的含量变化较大,对高炉减少氮化碳和碳化钛生成、改善铁矿还原效果具有较好的帮助,建议高炉提高富氧率采用减风富氧模式。经计算,富氧率每增加1%,回旋区平均温度增加34.22 K(定风)和32.88 K(减风);减风富氧条件下,富氧率每增加1%,热风带入高炉的N2量减少10 m3/min,煤气中的CO质量浓度上升8.61%。Abstract: In this paper, based on the actual dimension of the vanadium titanomagnetite blast furnace of a domestic enterprise, a three-dimensional physical model is established. The numerical simulation method is used to compare and study the flow and combustion behavior of pulverized coal in the tuyere gyration area under different oxygen enrichment methods. The results show that the overall trend of the tuyere velocity change with the oxygen enrichment rates is consistent with that of the constant air enrichment mode, but the difference in the change amplitude is significant. That is, when the oxygen enrichment rate is increased by 1%, the cross-sectional velocity of the tuyere is increased by 4.25 m/s (fixed air) and 0.41 m/s (reduced air), respectively. Under the two oxygen enrichment modes, the temperature, reducing gas content and burnout rate of the pulverized coal in the gyratory area have the same trend with the oxygen enrichment rates. As temperature increases, the high temperature area expands with the increase in the reducing gas content, and the burnout rate of pulverized coal increases. Among them, the amount of N2 brought into the blast furnace decreases due to the decrease in hot air flow rate, and the content of CO and H2 in the coal gas changes greatly, preventing the formation of carbon nitrides and titanium carbides, and improving the reduction effect of iron ore in the blast furnace. It is calculated that the average temperature of the gyratory zone is increased by 34.22 K (fixed air) and 32.88 K (reduced air) for every 1% increase in the oxygen enrichment rate. Under the condition of reduced air and oxygen enrichment, the N2 content brought into the blast furnace is reduced by 10 m3/min and the CO concentration in the gas is increased by 8.61%.

-

Key words:

- blast furnace /

- oxygen-enriching mode /

- raceway status /

- CFD numerical simulation

-

表 1 高炉的实际操作条件

Table 1. Actual operating conditions of blast furnaces

风口数/个 高炉有效容积/m3 风量/(m3·min−1) 风压/kPa 氧气浓度/% 煤比/(kg·t−1) 热风温度/℃ 载气成分 24 1750 4000 360 24(基准工况) 95 1220 氮气 表 2 定风富氧条件下富氧率变化时的风量

Table 2. The air volumes with changes of the oxygen enrichment rates of the fixed air

序号 定风富氧率/% 总风量(工况条件)/(m3·min−1) 热风流量(工况条件)/(m3·min−1) 直吹管入口速度/(m·s−1) 煤枪入口速度/(m·s−1) 1 3 4157.89 4000 195.77 12.50 2 5 4270.27 4000 201.07 12.50 3 7 4388.89 4000 206.65 12.50 4 9 4514.29 4000 212.56 12.50 5 11 4647.06 4000 218.81 12.50 表 3 减风富氧富氧率变化时的风量条件

Table 3. Air volumes with changes of the oxygen enrichment rate of the reduced air

序号 减风富氧率/% 总风量(工况条件)/(m3·min−1) 热风流量(工况条件)/(m3·min−1) 直吹管入口速度/(m·s−1) 煤枪入口速度/(m·s−1) 1 3 4157.89 4000 195.77 12.50 2 5 4157.89 3895 195.77 12.50 3 7 4157.89 3789 195.77 12.50 4 9 4157.89 3684 195.77 12.50 5 11 4157.89 3579 195.77 12.50 表 4 沿煤粉流股上最高温度和回旋区内平均温度

Table 4. Maximum temperatures along the distance from lance tip and average temperature in the raceway

减风富氧率/% 沿煤粉流股中心线最高温度/K 回旋区平均温度/K 3 2859.87 2676.71 5 2912.92 2767.03 7 2976.11 2838.74 9 3027.91 2895.40 11 3071.75 2939.71 -

[1] Zhang Cuiliu, Wang Guangwei, Ning Xiaojun, et al. Numerical simulation of combustion behaviors of hydrochar derived from low-rank coal in the raceway of blast furnace[J]. Fuel, 2020,278:118267. doi: 10.1016/j.fuel.2020.118267 [2] Babich A, Yaroshevskii S, Formoso A, et al. Co-injection of noncoking coal and natural gas in blast furnace[J]. ISIJ International, 1999,39(3):229-238. doi: 10.2355/isijinternational.39.229 [3] Peter Richard Austin, Hiroshi Nogami, Jun-ichiro Yagi. A mathematical model of four phase motion and heat transfer in the blast furnace[J]. ISIJ International, 1997,37(5):458-467. doi: 10.2355/isijinternational.37.458 [4] Dong X F, Yu A B, Chew S J, et al. Modeling of blast furnace with layered cohesive zone[J]. Metallurgical and Materials Transactions B, 2010,41(2):330-349. doi: 10.1007/s11663-009-9327-y [5] Kuang S B, Li Z Y, Yan D L, et al. Numerical study of hot charge operation in ironmaking blast furnace[J]. Minerals Engineering, 2014, 63: 45-56. [6] Hannu Helle, Mikko Helle, Henrik Saxén. Nonlinear optimization of steel production using traditional and novel blast furnace operation strategies[J]. Chemical Engineering Science, 2011,66(24):6470-6481. doi: 10.1016/j.ces.2011.09.006 [7] Zhang Wei, Zhang Juhua, Xue Zhengliang, et al. Unsteady analyses of the top gas recycling oxygen blast furnace[J]. ISIJ International, 2016,56(8):1358-1367. doi: 10.2355/isijinternational.ISIJINT-2016-090 [8] Kushnir D, Hansen T, Vogl V, et al. Adopting hydrogen direct reduction for the Swedish steel industry: A technological innovation system (TIS) study[J]. J Clean Prod, 2020,242:13. [9] Zhang Fuming, Cao Chaozhen, Meng Xianglong, et al. Technological status and tendency of modern blast furnace[J]. Advanced Materials Research, 2013,813:192-195. doi: 10.4028/www.scientific.net/AMR.813.192 [10] Duan Guojian, Zhao Zhilong. Discussion of blast furnace oxygen enriched coal injection[J]. Hebei Metallurgy, 2017(6):8-12. (段国建, 赵志龙. 高炉富氧喷煤技术探讨[J]. 河北冶金, 2017(6):8-12.Duan Guojian, Zhao Zhilong. Discussion of blast furnace oxygen enriched coal injection[J]. Hebei Metallurgy, 2017(6): 8-12. [11] Zhang Fuming. Technological progress for contemporary ultra large sized blast furnoace[C]// 2012 National Conference on Ironmaking Production Technology and Annual Conference on Ironmaking. Wuxi: Chinese Society for Metals, 2012. (张福明. 当代巨型高炉技术进步[C]//2012年全国炼铁生产技术会议暨炼铁学术年会. 无锡: 中国金属学会, 2012.Zhang Fuming. Technological progress for contemporary ultra large sized blast furnoace[C]// 2012 National Conference on Ironmaking Production Technology and Annual Conference on Ironmaking. Wuxi: Chinese Society for Metals, 2012. [12] Liu Yingshu, Yang Tianjun, Cang Daqiang, et al. The progress of research and development in BF oxygen-coal injection[J]. Ironmaking, 1996(4):9-12. (刘应书, 杨天钧, 苍大强, 等. 高炉富氧喷煤技术研究开发的进展[J]. 炼铁, 1996(4):9-12.Liu Yingshu, Yang Tianjun, Cang Daqiang, et al. The progress of research and development in BF oxygen-coal injection[J]. Ironmaking, 1996(4): 9-12. [13] Cheng Lanbo, Gao Guangchun, Ma Shuhan. Experiment of BF operation with oxygen rich coal injection at Anshan iron and steel[J]. Iron & Steel, 1988(11):1-10. (成兰伯, 高光春, 马树涵. 鞍钢2号高炉富氧大喷吹冶炼试验[J]. 钢铁, 1988(11):1-10.Cheng Lanbo, Gao Guangchun, Ma Shuhan. Experiment of BF operation with oxygen rich coal injection at Anshan iron and steel[J]. Iron & Steel, 1988(11): 1-10. [14] Zeng Weitao, Zhang Qingxi. Operating system adjustment under production limitation mode in WISCO No. 8 BF[J]. Ironmaking, 2022,41(1):6-9. (曾伟涛, 张庆喜. 武钢8号高炉限产模式下操作制度的调整[J]. 炼铁, 2022,41(1):6-9.Zeng Weitao, Zhang Qingxi. Operating system adjustment under production limitation mode in WISCO No. 8 BF[J]. Ironmaking, 2022, 41(1): 6-9. [15] Xiang Mingwu, Zhou Qiang, Zhang Ling, et al. Technical characteristics of Shagang 5800 m3 blast furnace[J]. Ironmaking, 2010,29(2):1-6. (项明武, 周强, 张灵, 等. 沙钢5800 m3高炉工艺技术特点[J]. 炼铁, 2010,29(2):1-6.Xiang Mingwu, Zhou Qiang, Zhang Ling, et al. Technical characteristics of Shagang 5800 m3 blast furnace[J]. Ironmaking, 2010, 29(2): 1-6. [16] Wang Jun, Xu Hui, Zhang Peifeng, et al. Management for maintaining low consumption production in baosteel’s No. 4 BF[J]. Ironmaking, 2020,39(4):1-7. (王俊, 徐辉, 张培峰, 等. 宝钢4号高炉长期低耗生产管理[J]. 炼铁, 2020,39(4):1-7.Wang Jun, Xu Hui, Zhang Peifeng, et al. Management for maintaining low consumption production in baosteel’s No. 4 BF[J]. Ironmaking, 2020, 39(4): 1-7. [17] Liu Yiran, Shen Yansong. Three-dimensional modelling of charcoal combustion in an industrial scale blast furnace[J]. Fuel, 2019,258:116088. doi: 10.1016/j.fuel.2019.116088 [18] Hu Z J, Liu Y R, Xu H, et al. Co-combustion of semicoke and coal in an industry ironmaking blast furnace: Lab experiments, model study and plant tests[J]. Fuel Processing Technology, 2019, 196: 106165. [19] Shen Y S, Maldonado D, Guo B Y, et al. Computational fluid dynamics study of pulverized coal combustion in blast furnace raceway[J]. Industrial and Engineering Chemistry Research, 2009,48(23):10314-10323. doi: 10.1021/ie900853d [20] Zhou Zhenfeng, Wang Ruihao, Yi Qiujie, et al. Combustion enhancement of pulverized coal with targeted oxygen-enrichment in an ironmaking blast furnace[J]. Processes, 2021,9(3):440. [21] Rastko Jovanovic, Aleksandra Milewska, Bartosz Swiatkowski, et al. Numerical investigation of influence of homogeneous/heterogeneous ignition/combustion mechanisms on ignition point position during pulverized coal combustion in oxygen enriched and recycled flue gases atmosphere[J]. International Journal of Heat and Mass Transfer, 2011,54(4):921-931. doi: 10.1016/j.ijheatmasstransfer.2010.10.011 [22] Nie Haiqi, Li Zhaoyang, Kuang Shibo, et al. Numerical investigation of oxygen-enriched operations in blast furnace ironmaking[J]. Fuel, 2021,296:120662. doi: 10.1016/j.fuel.2021.120662 [23] Liu Yiran, Shen Yansong. CFD study of charcoal combustion in a simulated ironmaking blast furnace[J]. Fuel Processing Technology, 2019,191:152-167. doi: 10.1016/j.fuproc.2019.04.004 [24] Shen Y S, Yu A B. Modelling of injecting a ternary coal blend into a model ironmaking blast furnace[J]. Minerals Engineering, 2016,90:89-95. doi: 10.1016/j.mineng.2015.12.009 [25] Liu Yiran, Curtis Jennifer, Shen Yansong. Computational fluid dynamics study of re-blowin operation in an ironmaking blast furnace[J]. Powder Technology, 2020,361:145-159. doi: 10.1016/j.powtec.2019.09.061 [26] Shivadev K Ubhayakar, David B Stickler, Charles W Von Rosenberg, et al. Rapid devolatilization of pulverized coal in hot combustion gases[J]. Symposium (International) on Combustion, 1977,16(1):427-436. doi: 10.1016/S0082-0784(77)80342-1 [27] Du Shanwen, Yeh Chengpeng, Chen Weihsin, et al. Burning characteristics of pulverized coal within blast furnace raceway at various injection operations and ways of oxygen enrichment[J]. Fuel, 2015,143:98-106. doi: 10.1016/j.fuel.2014.11.038 [28] Liao Junhai, Yu Aibing, Shen Yansong. Modelling the injection of upgraded brown coals in an ironmaking blast furnace[J]. Powder Technology, 2016,314:550-556. [29] Kou Mingyin, Zhou Heng, Hong Zhibin, et al. Numerical analysis of effects of different blast parameters on the gas and burden distribution characteristics inside blast furnace[J]. ISIJ International, 2020,60(5):856-864. doi: 10.2355/isijinternational.ISIJINT-2019-389 [30] Xue Qingguo, Dong Zeshang, Wang Jingsong, et al. The introduction and process optimization research of oxygen blast furnace ironmaking technology [M]//Liu Xingbo, Liu Zhengdong, Brinkman Kyle, et al. Energy Materials 2017. Cham: Springer International Publishing, 2017: 31-39. [31] Zhou Zhenfeng, Xue Qingguo, Li Changle, et al. Coal flow and combustion characteristics under oxygen enrichment way of oxygen-coal double lance[J]. Applied Thermal Engineering, 2017,123:1096-1105. doi: 10.1016/j.applthermaleng.2017.05.177 -

下载:

下载: