Microstructure and properties of inertia friction welding joint of TA18 titanium alloy tube

-

摘要: 对TA18钛合金管材开展惯性旋转摩擦焊接(IRFW)研究,采用光学显微镜与扫描电镜观察了TA18钛合金管摩擦焊接头各个区域的组织形态,结合焊接过程分析了组织的特征与演化机制,根据拉伸试验、室温冲击试验、显微硬度试验等测试结果分析了焊接接头的力学性能。结果表明,由于短时间内焊接接头处发生了强烈的塑性变形,IRFW接头焊缝处的组织为针状α′相;热影响区的组织为等轴α相、部分针状α′相和残余β相。TA18钛合金管材IRFW接头的抗拉强度与母材相当,且断裂位置均位于远离焊缝中心的位置。IRFW接头显微硬度较均匀,各区域硬度匹配性好,接头具有良好的冲击韧性,达到母材的96.85%。Abstract: Inertial rotary friction welding (IRFW) research was conducted on TA18 titanium alloy tube. The microstructure of the IRFW joint of TA18 titanium alloy tube was observed using optical microscopy and scanning electron microscopy, and the characteristics and evolution mechanism of the microstructure were analyzed in combination with the welding process. The mechanical properties of welded joints were analyzed using methods including tensile testing, impact testing, and microhardness testing. The results indicate that due to strong plastic deformation occurring at the welded joint in a short period of time, the microstructure of the welded zone of IRFW joint welded is mainly composed of needle-like α′ phase. The microstructure of the thermal mechanical affected zone of IRFW joint welded is mainly composed of equiaxed α phase, needle-like α′ phase and residual β phase. The tensile strength of the IRFW joint of TA18 titanium alloy tube is equivalent to that of the base material, and the fracture positions are all located far from the center of the weld zone. The microhardness of the IRFW joint is relatively uniform, and the hardness of each region can be matched. The impact toughness of the weld zone of the IRFW joint reached 96.85% of the base material.

-

0. 引言

钛及其合金具有高的比强度和良好的耐腐蚀性,在航空航天、石油化工等领域的承压管道、轴类构件上具有广泛的应用[1-2]。其中,TA18(Ti-3Al-2.5V)为中强近α型钛合金,由于其良好的加工性能和服役性能,广泛应用于对耐蚀性、轻量化、抗氧化性等性能具有一定要求的航空发动机及航天器的管材、环件等构件中[3-7]。

在生产与研究中,钛合金主要采用钨极氩弧焊(TIG焊)、电子束焊、激光焊等熔化焊接的方式进行连接。李军兆等人[8]研究了直流TIG焊、脉冲TIG焊和激光焊接TA18板的组织与性能,发现激光焊接组织最为细小,且具有更高的延伸率。郭纪龙等人[9]研究了TA18钛合金TIG焊接头的耐蚀性与应力腐蚀性能,发现焊接接头中耐蚀性从好到差依次为母材、焊缝、热影响区。陈伟等人[10]进行了TA18钛合金薄板激光焊接工艺研究,发现激光焊接制备的TA18钛合金薄板接头质量良好,未观察到焊接缺陷,接头抗拉强度达到母材的92.46%。Long等人[11]使用电子束焊接制备了80 mm厚TB18钛合金接头,结果表明,热处理后接头的抗拉强度与母材相当,达到

1341 MPa。由此可见,熔化焊接仍是钛合金焊接的主要方法。惯性旋转摩擦焊接(Inertial Rotary Friction Welding,IRFW,简称惯性摩擦焊接)是一种固相焊接方法,广泛应用于石油钻杆、航空发动机转子组件制备中[12-13]。与熔化焊相比,惯性摩擦焊接加工速度快、焊接过程中焊缝温度较低、焊缝金属不易被氧化,在钛合金管、棒、环等轴类构件的焊接上具有显著的优势[14-15]。TA18钛合金以管、轴状的形式获得了广泛应用,而目前使用惯性摩擦焊的方式焊接TA18钛合金鲜有报道。笔者采用惯性摩擦焊接的方式制备了TA18合金管焊接接头,研究了接头的组织和力学性能,为惯性摩擦焊接TA18钛合金构件提供技术支撑。

1. 试验材料与方法

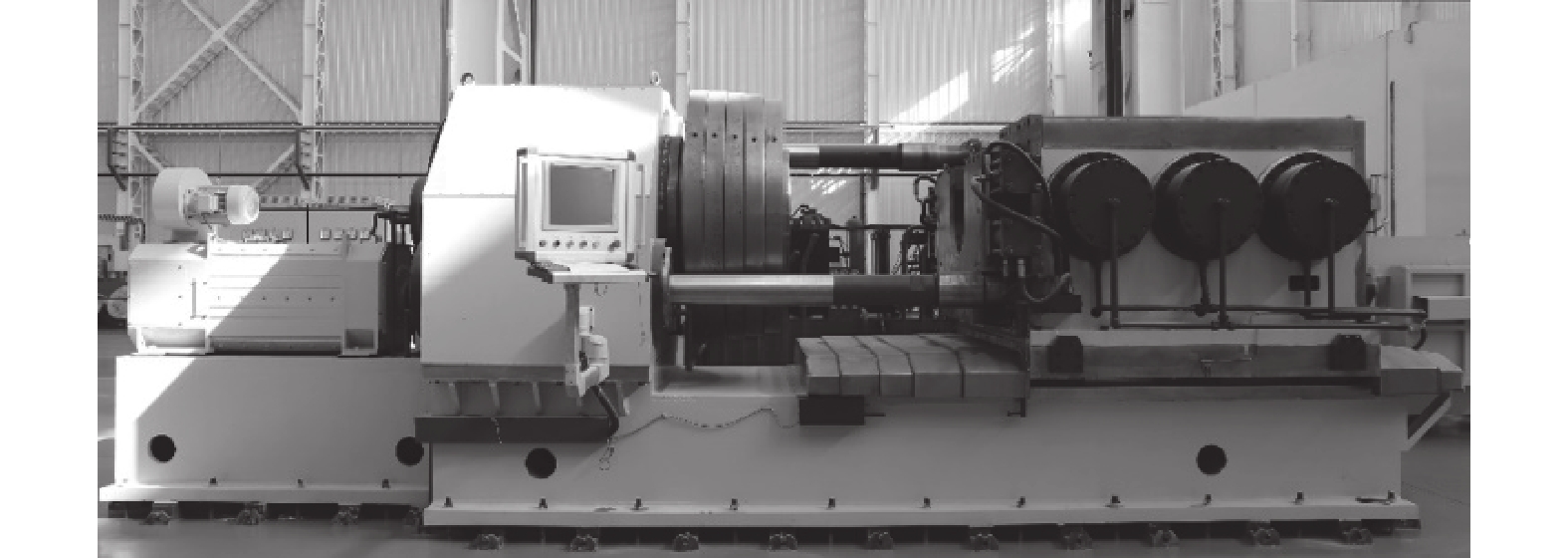

试验材料为TA18钛合金锻棒,通过机加方式制备Ø208 mm×12.5 mm TA18钛合金无缝管,化学成分如表1所示。将TA18钛合金无缝试验管焊接面车光后装配在HWI-IFW-400K型惯性摩擦焊机(如图1所示)上进行焊接。HWI-IFW-400K型惯性摩擦焊机的最大顶锻力为400 t,主轴最大转速为560 r/min,主轴惯性盘的最大惯性量为

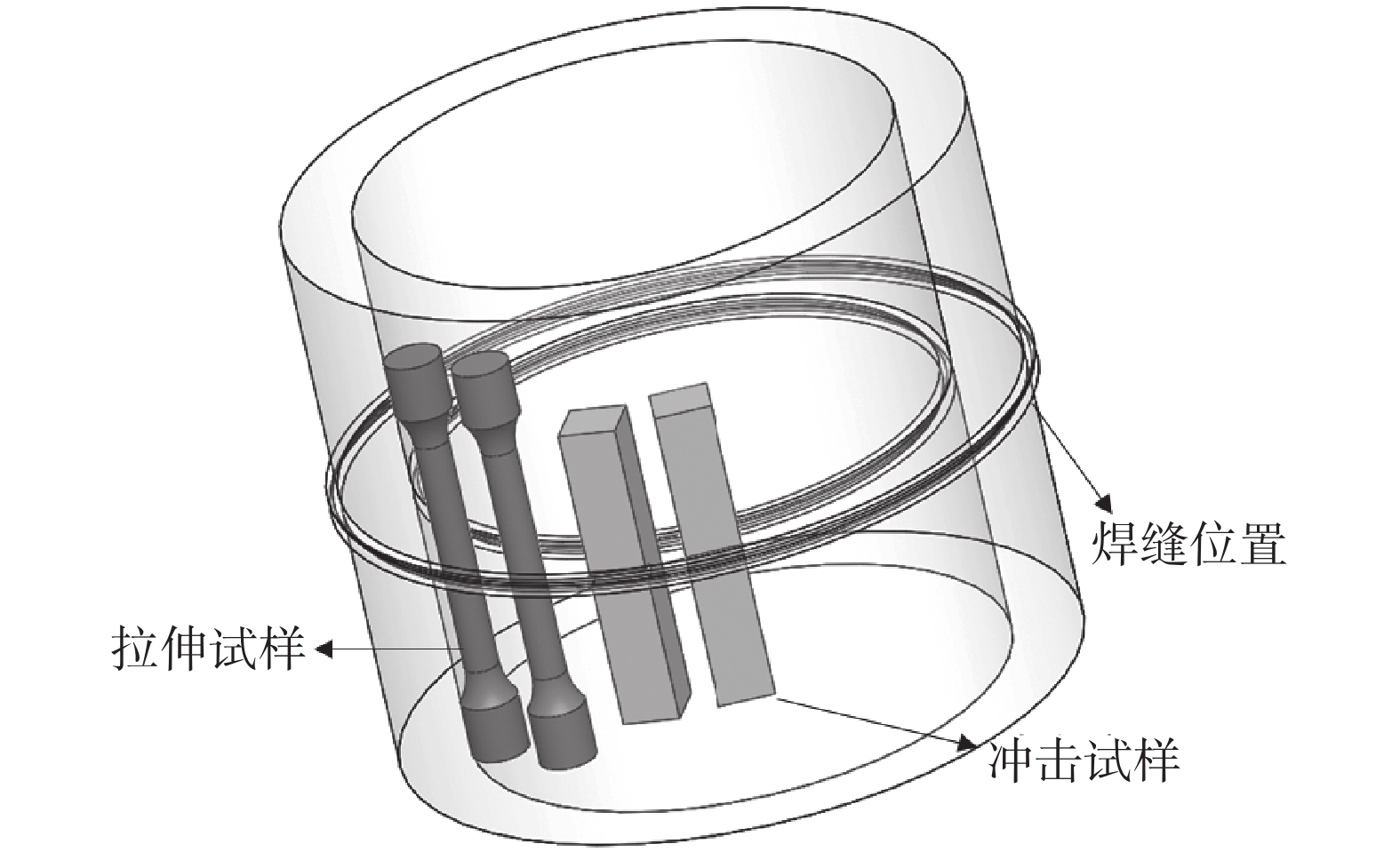

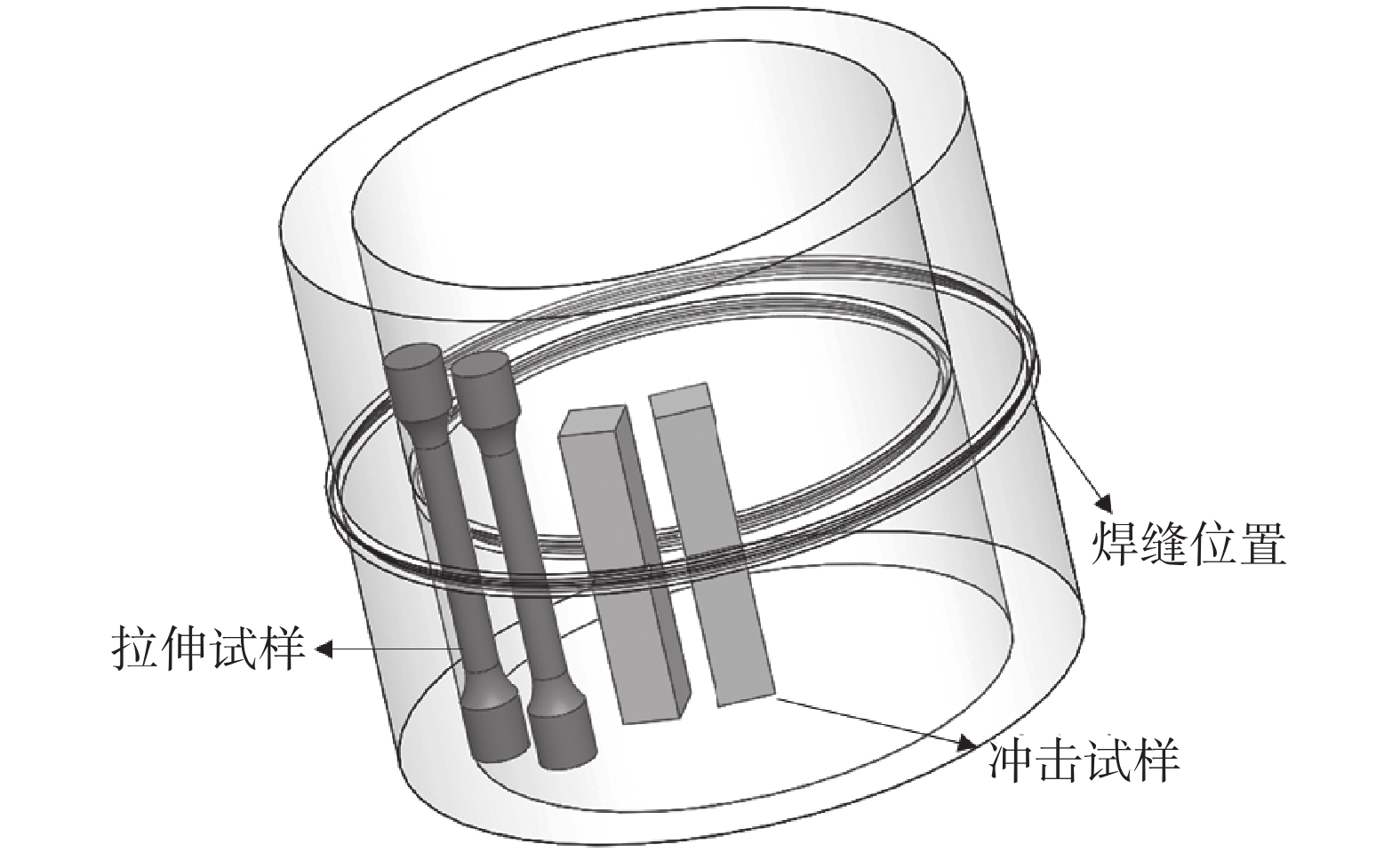

3500 kg·m2。根据焊接工件的面积和焊接材料的种类制定焊接工艺参数,如表2所示。焊接前,使用酒精冲洗焊接面并吹干,防止杂质进入焊缝中对焊缝造成污染。在摩擦焊接过程中,焊接面上的金属在扭矩和顶锻力的作用下产生剧烈摩擦并挤出,在焊缝外侧形成飞边,从而保护焊缝金属不被氧化。因此,摩擦焊接时不需要使用保护气氛进行保护。表 1 TA18钛合金管化学成分Table 1. Chemical composition of TA18 titanium alloy tube% Al V Fe C O N H Ti 3.0 2.5 0.2 0.05 0.08 0.03 0.01 Balance 表 2 TA18管惯性摩擦焊接工艺参数Table 2. Processing parameters for IRFW of TA18 tube顶锻压力/MPa 转动惯量/(kg·m2) 主轴转速/(r·min-1) 保压时间/s 7 990 300 15 焊接完成后的接头使用线切割机在TA18钛合、金管焊接接头处分别切取拉伸、冲击金相试样,接头区域的取样位置如图2所示。母材位置取样方向与接头处相同,均为轴向。根据GB/T 228.1-2021标准分别进行了焊接接头与母材的拉伸性能测试,拉伸开始时,拉伸速度为0.5 mm/min,到达屈服点后,将拉伸速度提高到5 mm/min以提高测试效率。冲击试样按照GB/T 228.1-2021进行取样测试,缺口形状为U型。冲击与拉伸试验均在室温下完成。金相试样磨抛后使用Kroll试剂(HF∶HNO3∶H2O=3∶7∶90)腐蚀15 s后进行焊缝宏观形貌与显微组织观察。最后,采用显微硬度测试仪进行显微维氏硬度测试,载荷为1.96 N,保载时间为15 s。

2. 试验结果及讨论

2.1 焊接过程与接头宏观形貌

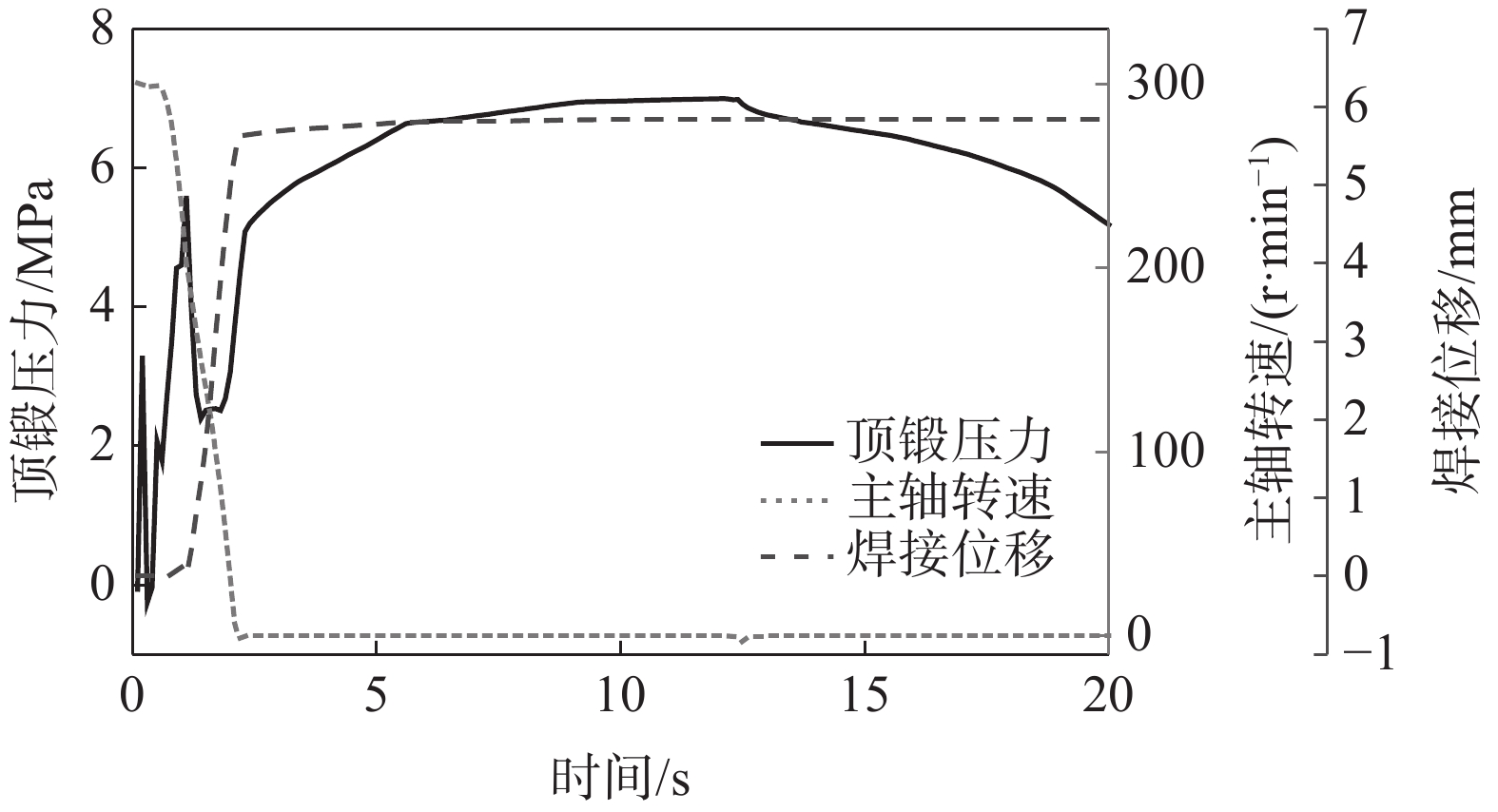

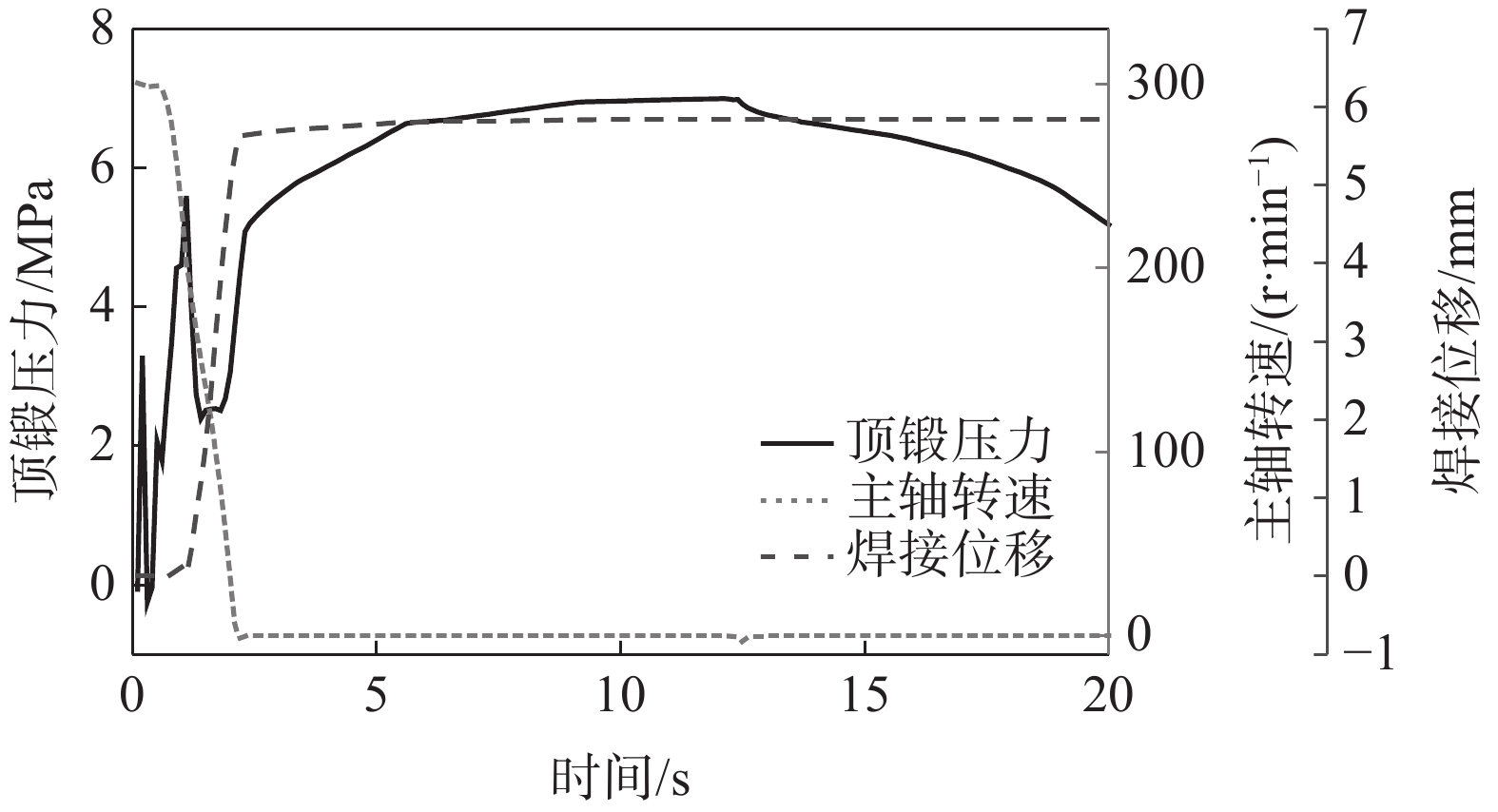

图3为焊接过程中主轴转速、顶锻压力和位移的变化情况。焊接开始后,主轴开始提速,达到目标转速(300 r/min)的110%后,主轴电机与主轴惯性盘之间解耦,主轴速度开始下降。当主轴的转速降低至焊接速度时,尾座端开始向主轴侧推进并与主轴侧接触,此时记录系统开始记录焊接过程的特征参数。两侧工件接触后,尾座的轴向顶锻压力持续增加并达到设定的顶锻压力。在顶锻压力的作用下,焊接工件两端产生剧烈摩擦,部分金属被挤出形成飞边,焊接位移开始增加,试管总长度降低;摩擦过程中主轴惯性盘的能量迅速消耗,导致主轴转速降低归零。主轴停止运动后,焊机继续进行保压,防止材料在高温状态下产生变形。保压结束后,等待焊缝冷却到低于150 ℃时,即可将试管从焊机上拆卸。

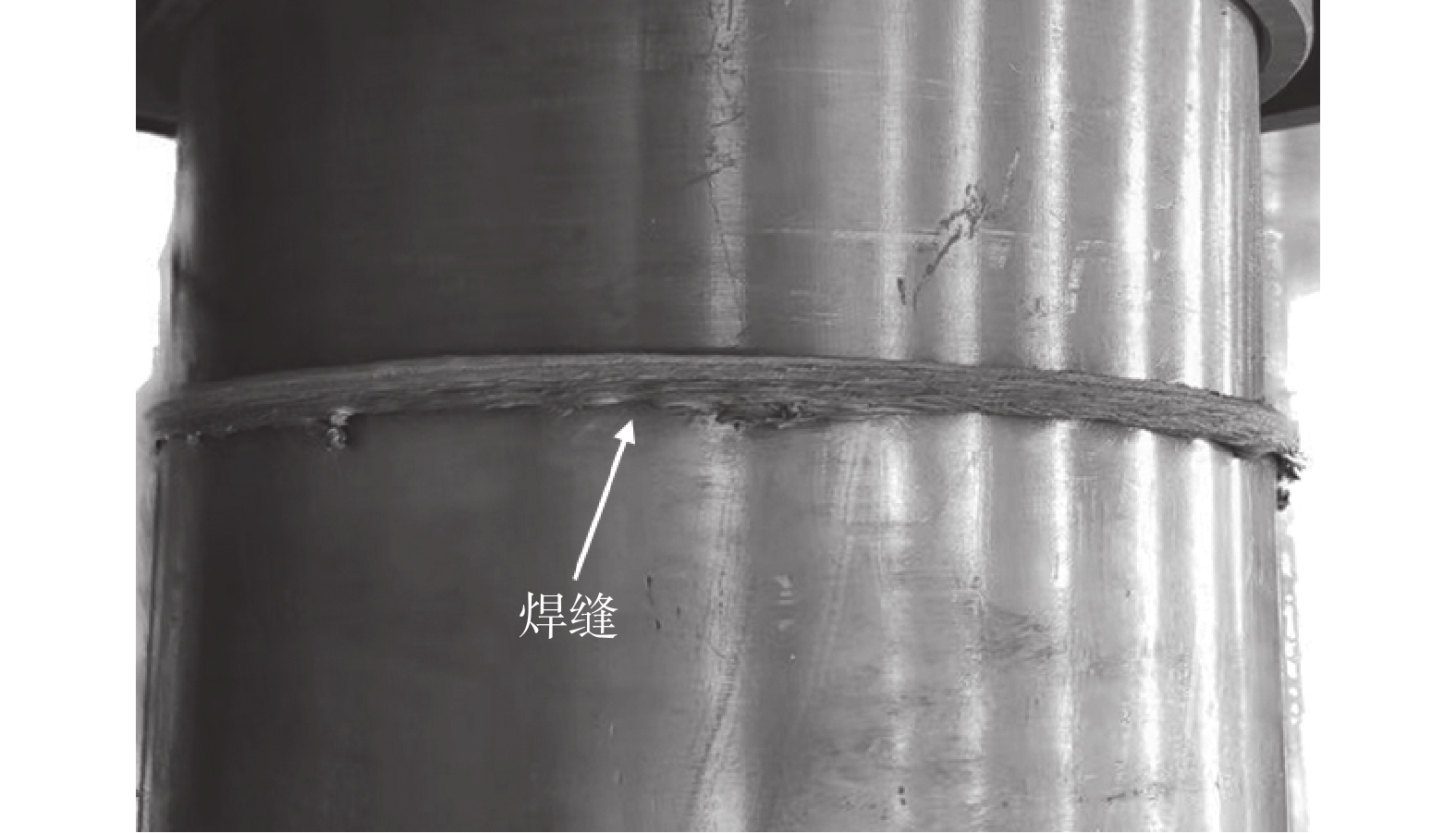

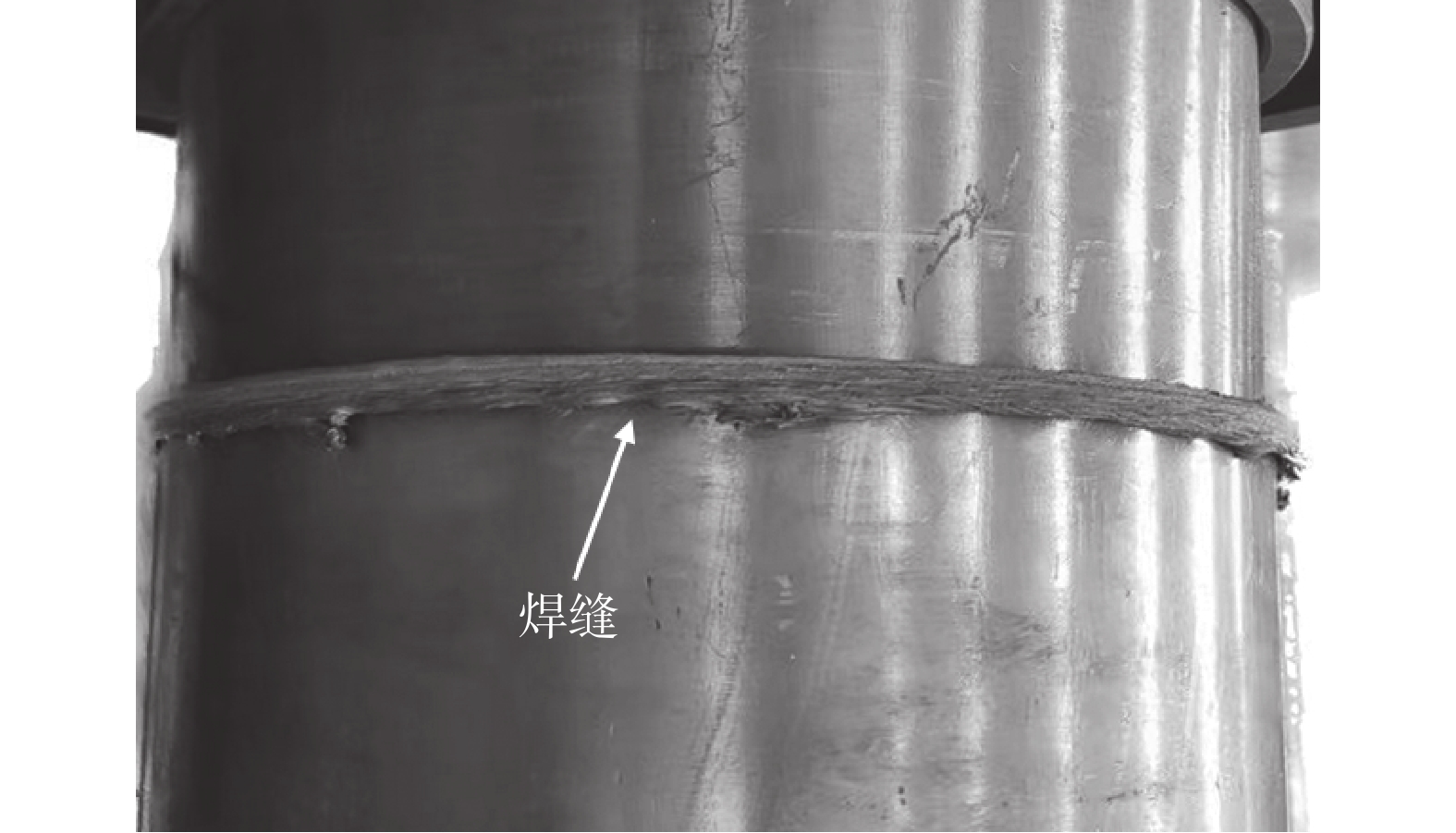

图4为TA18管摩擦焊接接头的宏观形貌。焊接前后对管的总长度进行测量,测得管的焊接缩短量为5.1 mm。焊接过程中缩短的部分主要以飞边的形式挤出,从而保护焊缝金属不被氧化,并防止界面处杂质污染焊缝。从接头的宏观形貌可以看出,接头两侧飞边均匀、连续,呈现灰黄色。焊缝周围未观察到裂纹或未结合的缺陷。

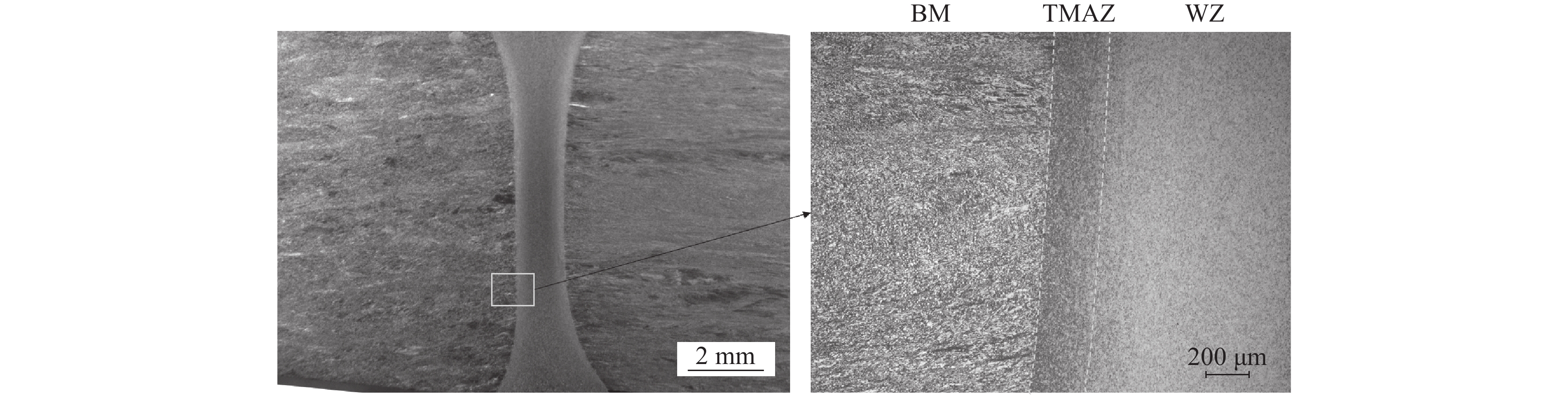

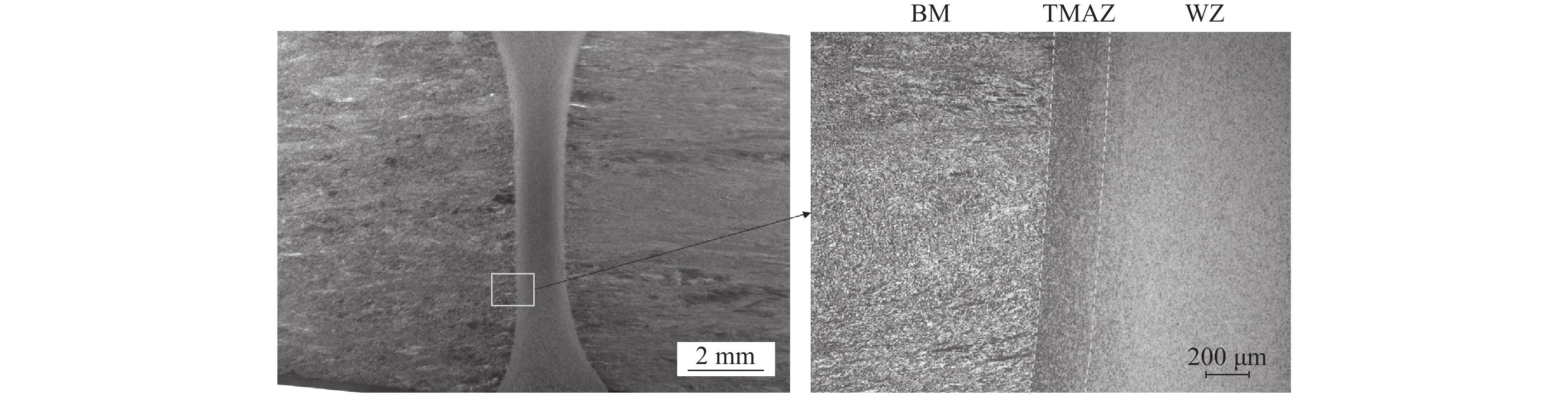

图5为TA18管摩擦焊接头的横截面形貌,按照不同特征可以分为焊缝区(Weld zone,WZ)、热影响区(Thermal-mechanically affected zone,TMAZ)和母材区(Base metal,BM)。其中,焊缝区没有明显的熔合界面,未观察到气孔、未熔合、裂纹等宏观缺陷。焊缝区平均宽度为1.63 mm,小于熔化焊接钛合金接头[8-9]。TA18合金为近α合金,焊接过程中容易被挤出并消耗大量的焊接能量[14],这导致了接头处热影响区的宽度较窄,约为0.2 mm。

2.2 焊接接头显微组织

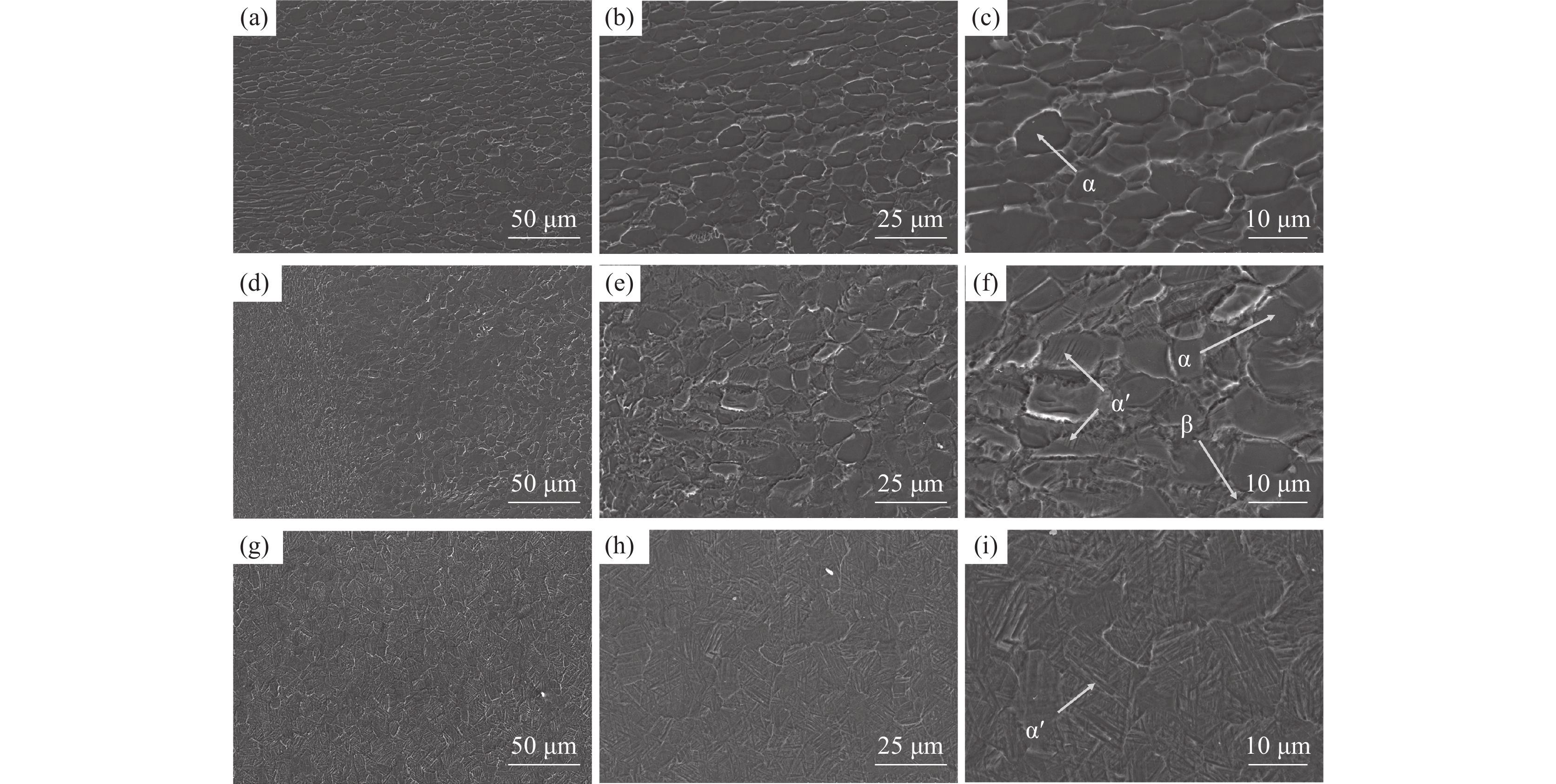

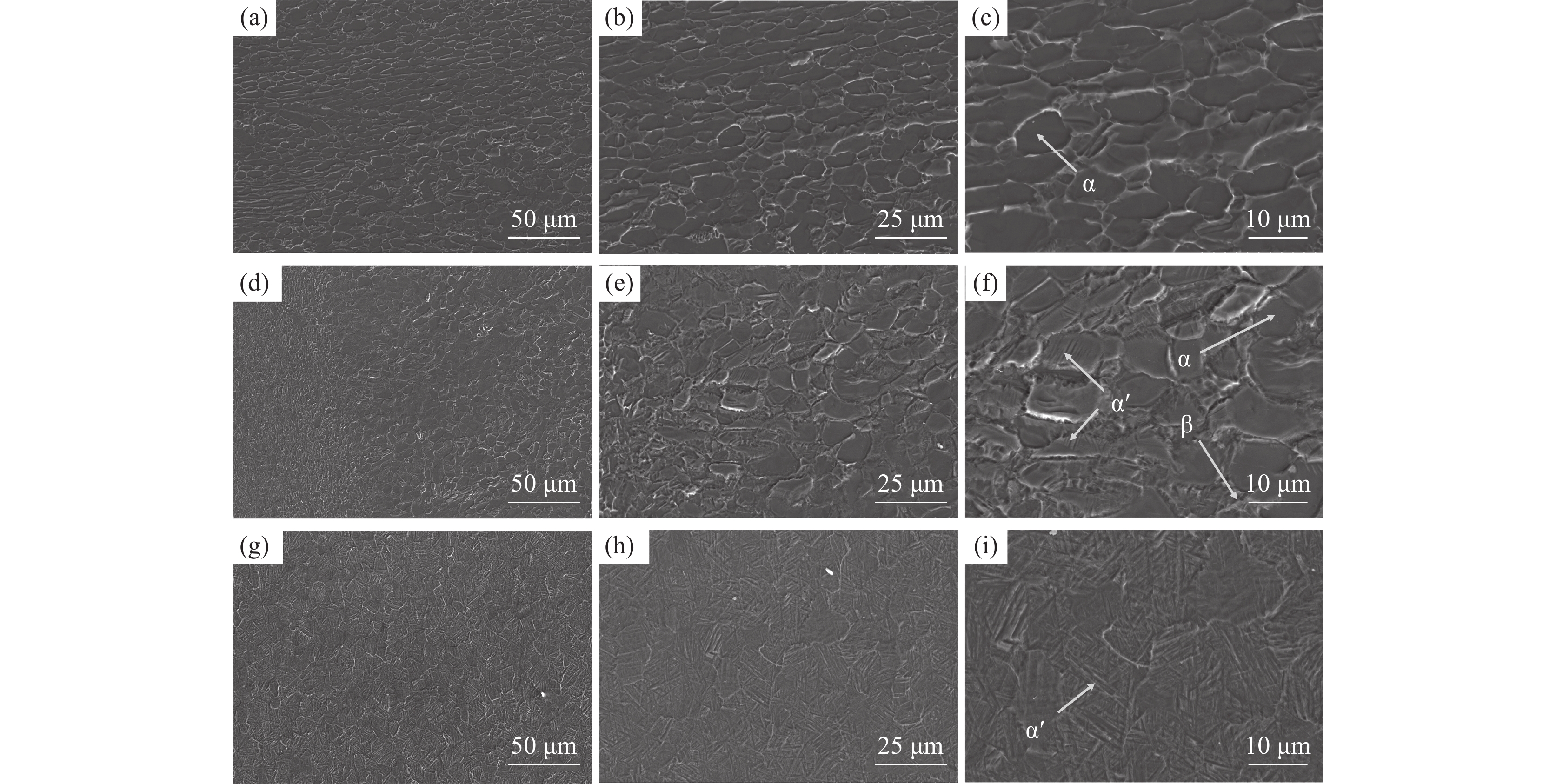

图6为TA18管摩擦焊接头横截面不同区域的显微组织。图6 (a)~ (c)为接头母材区的组织形貌,可以看出TA18管母材处组织为等轴α相和少量分布在α相界面处的β相,等轴α相的尺寸为10~20 μm;图6 (d)~ (f)为接头热机影响区的组织形貌,该区域中存在原始的等轴α相,同时也存在部分针状α′相和残余β相;图6 (g)~ (i)为接头焊缝区的组织形貌,接头焊缝区域的组织主要为针状α′相。

惯性摩擦焊接过程中,焊缝区的组织会在惯性盘的旋转摩擦作用下与尾座提供的顶锻力作用下产生剧烈的塑性变形,焊缝区温度快速增加。近α钛合金旋转摩擦焊接时,焊缝的温度通常会达到

1100 ℃左右,远高于TA18合金的β相转变温度(~910 ℃)。因此,在焊接过程中,焊缝处组织几乎全部转变为高温β相。这部分组织在焊接完成后发生快速冷却,从β晶界处向晶内以非扩散型相变的形式析出了取向不同、相互交错的针状α′相。在焊接过程中,热机影响区所经历的最高温度要显著低于焊缝区的温度。该区域原始组织中的部分等轴α相得以保留,而原始组织中晶界处的β相有所长大,在冷却的过程中形成了图6(f)中的针状α′相和残余β相。2.3 焊接接头力学性能

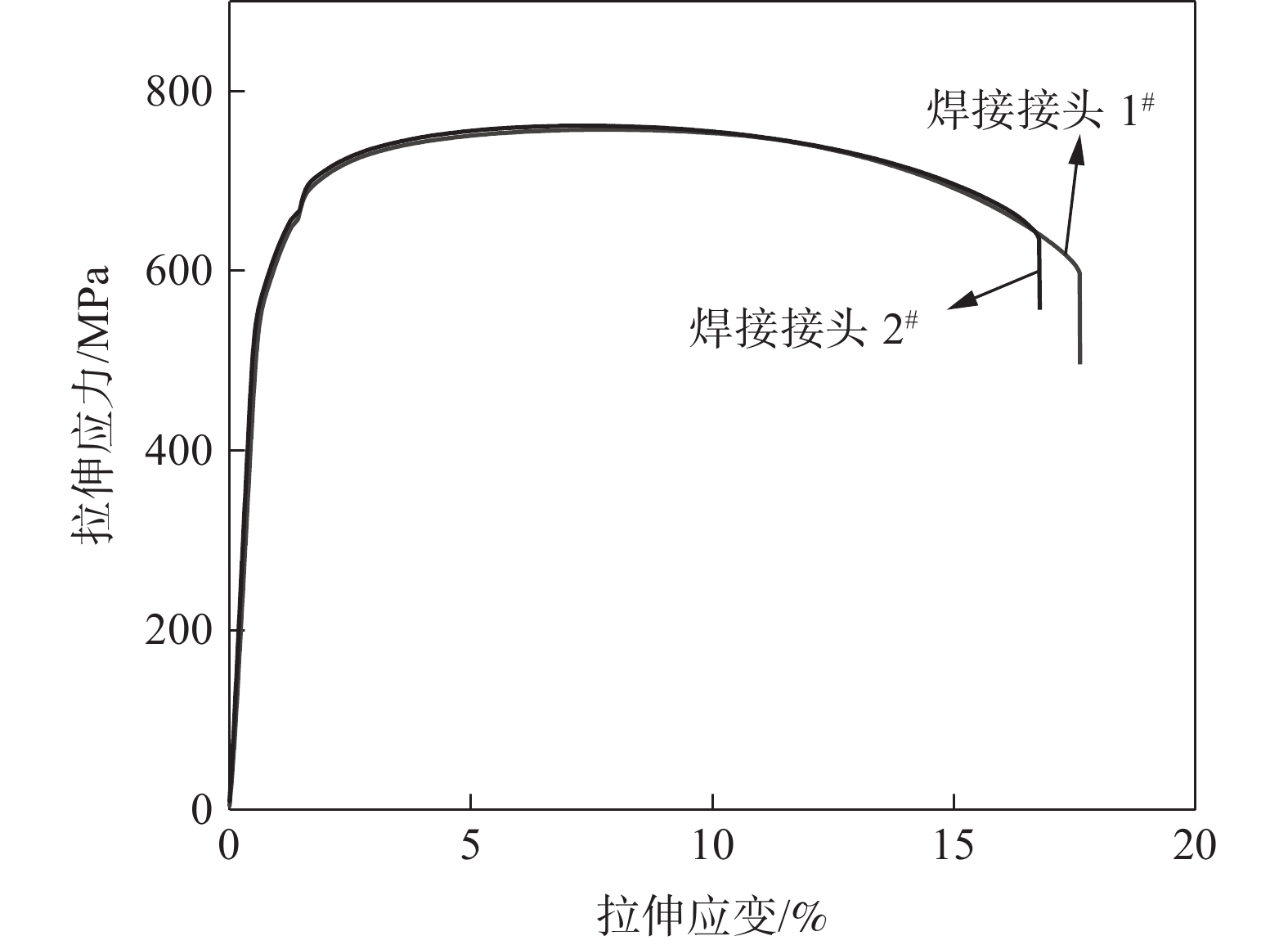

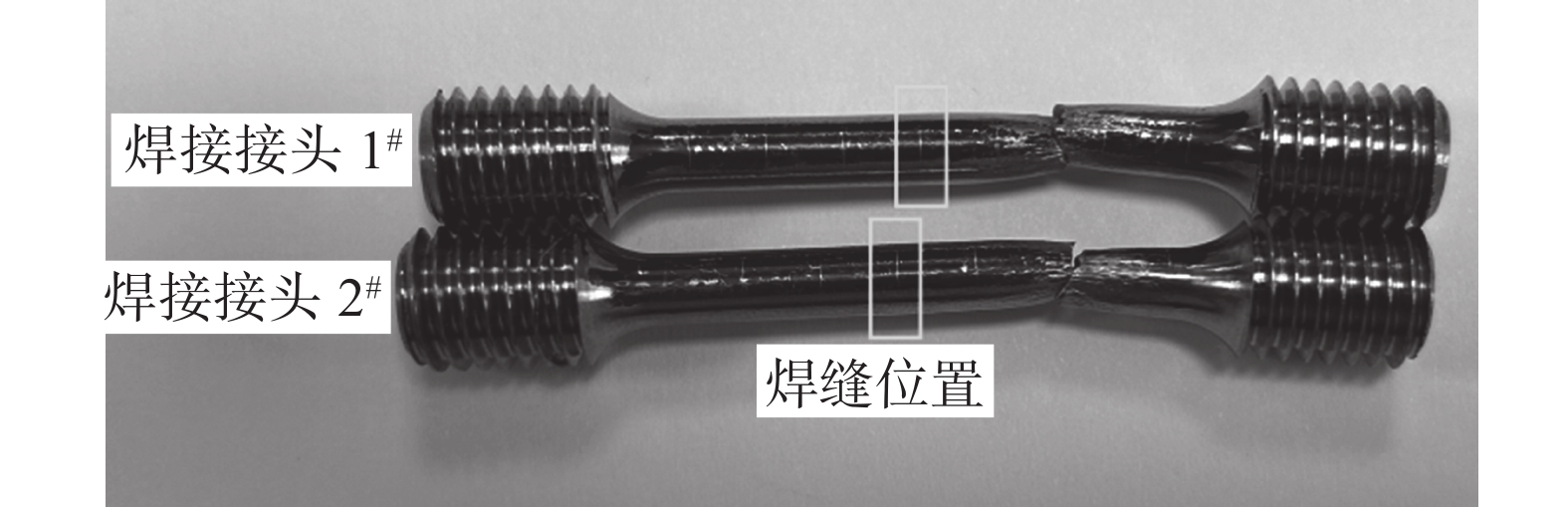

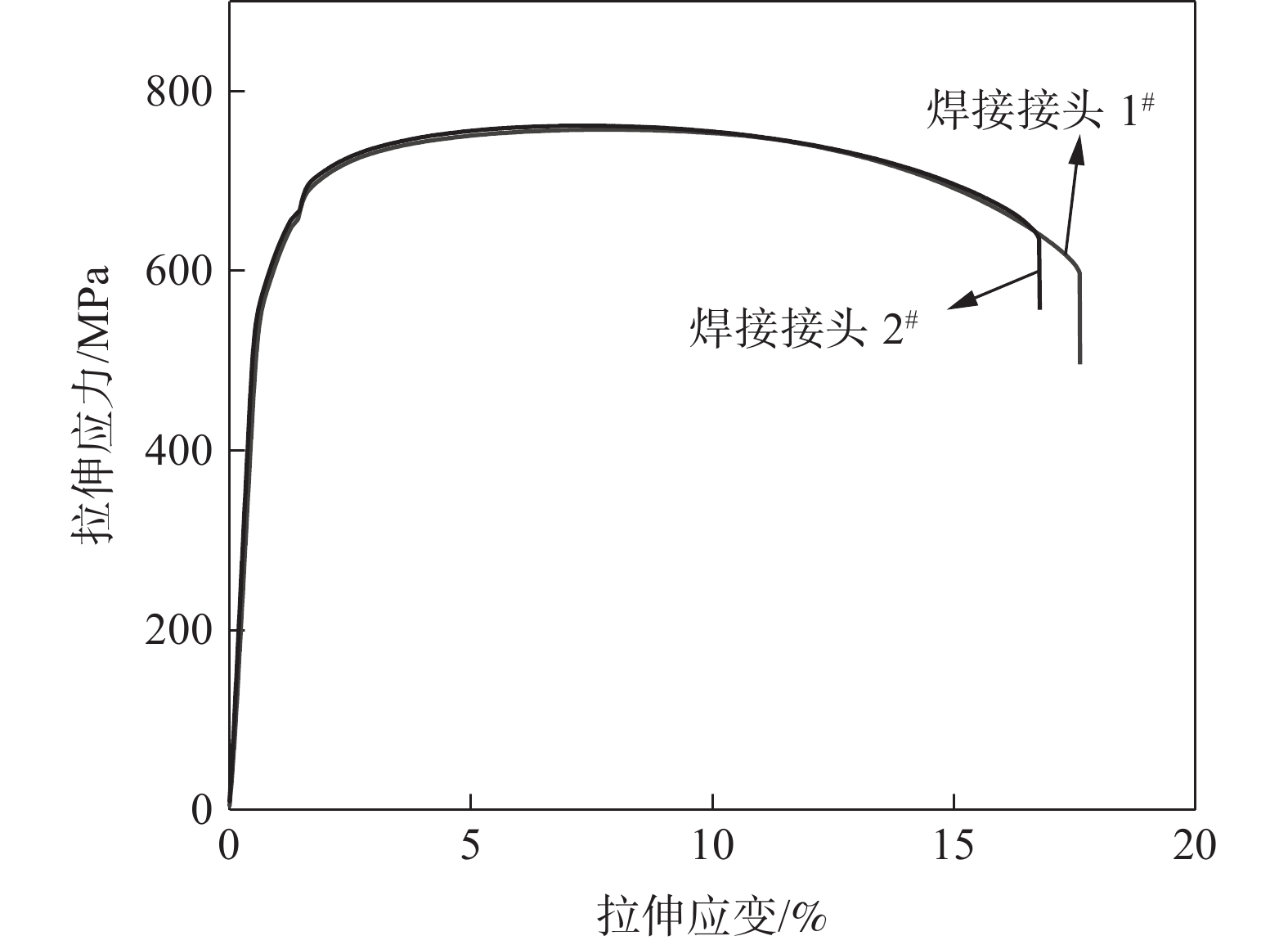

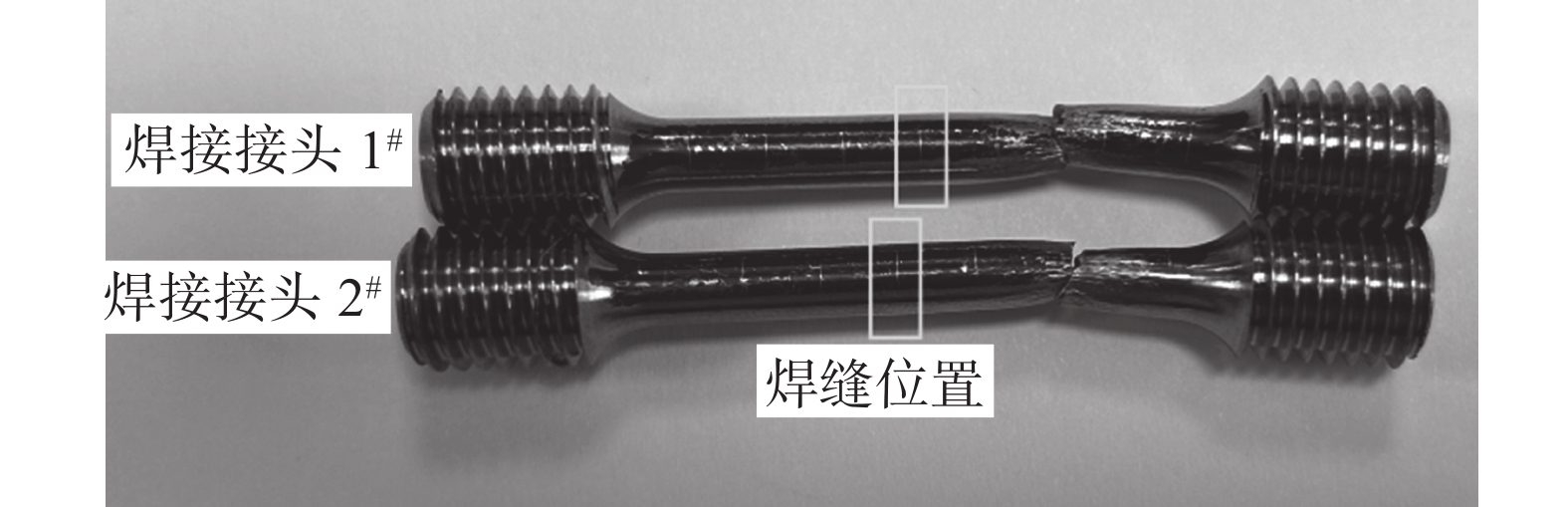

TA18管焊接接头与母材的拉伸性能如表3所示。可以看出TA18管母材的平均抗拉强度为752.5 MPa,平均屈服强度为643 MPa,平均断后伸长率为14.75%;TA18管焊接接头的平均抗拉强度为759.5 MPa,平均屈服强度为585.5 MPa,平均断后伸长率为15%。TA18管惯性摩擦焊接头的抗拉强度和断后伸长率均与母材相当,而惯性摩擦焊接头的屈服强度相比母材较低,为母材的91.05%。TA18管焊接接头的拉伸曲线如图7所示,由结果可知TA18管焊接接头试样在屈服后仍然表现出了良好的塑性。图8为TA18管惯性摩擦焊接头拉伸试样照片。从断后试样的照片中也可以看出,TA18管焊接接头试样均在母材处发生断裂。

表 3 TA18管摩擦焊接头与母材的拉伸性能Table 3. Tensile test result of BM and IRFW joint of TA18 tube试样 抗拉强度/MPa 屈服强度/MPa 断后伸长率/% 断面收缩率/% 焊接接头1# 757 585 15.5 44 焊接接头2# 762 586 14.5 38 母材1# 747 635 13.5 41 母材2# 758 651 16.0 44 TA18管焊接接头与母材的冲击性能如表4所示。可以看出,TA18管惯性摩擦焊接头冲击韧性的平均值为76.8 J/cm2,TA18管母材的冲击韧性平均值为79.3 J/cm2,焊缝的冲击韧性达到母材冲击韧性的96.85%。熔化焊接钛合金接头的冲击韧性通常会显著低于母材,而TA18管摩擦焊接头的冲击韧性却达到了母材的96.85%,主要有以下两个原因:首先,与熔化焊接头相比,摩擦焊接后TA18管接头焊缝处的组织更加精细;而熔化焊接时焊缝处为铸态组织,较为粗大,细小的组织有助于提高焊缝处的冲击韧性[16]。其次,摩擦焊接时,焊缝外侧挤出的飞边能够保证焊缝处金属不会被氧化,在顶锻压力的作用下也不易产生孔隙等焊接缺陷;而熔化焊接焊缝重熔的过程中容易氧化,若工艺不当还会产生气孔、夹杂等缺陷。因此,摩擦焊接的工艺特点使得摩擦焊接头具有更好的冲击韧性[14-15,17-18]。

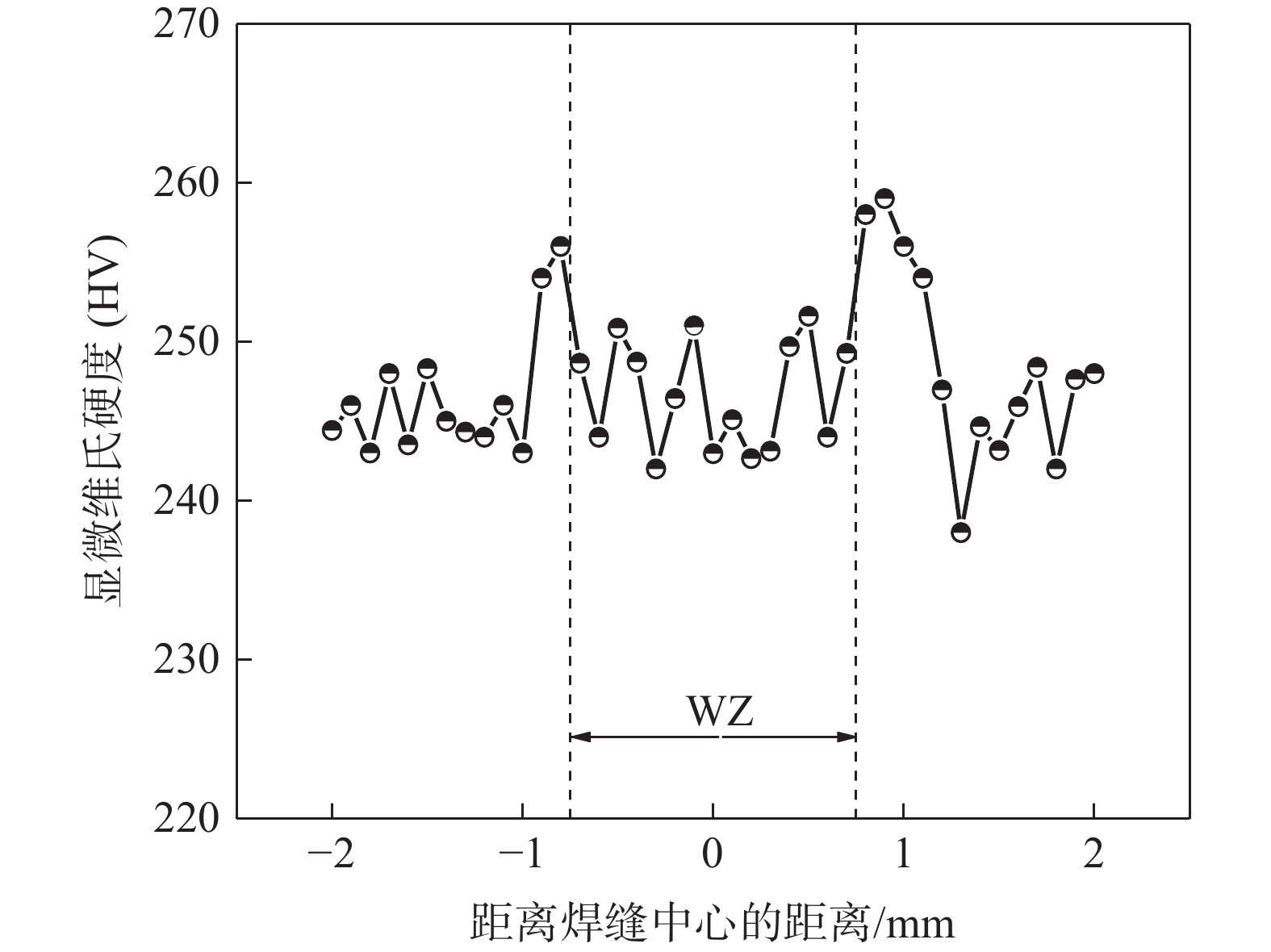

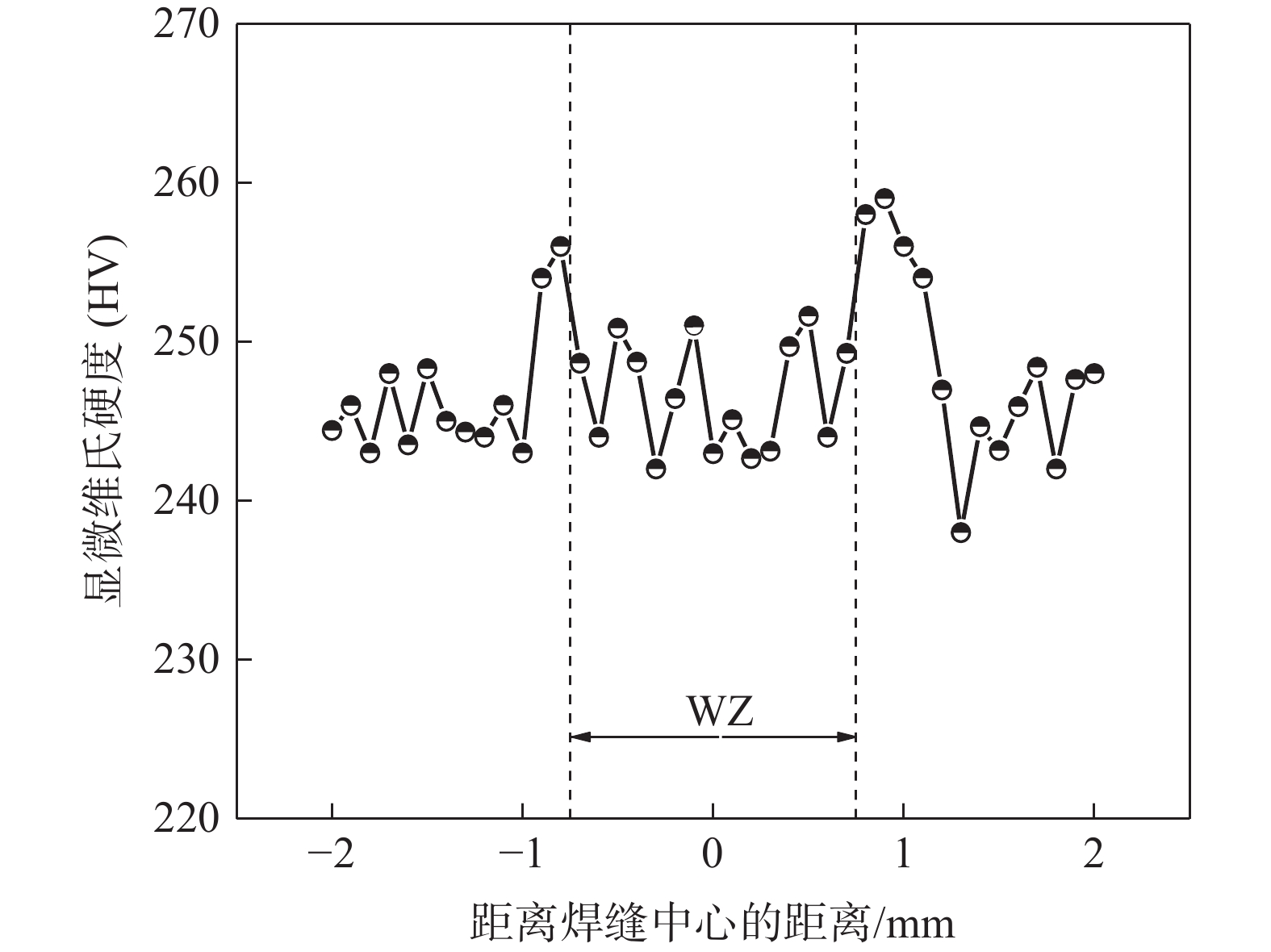

表 4 TA18管摩擦焊接头与母材的冲击韧性Table 4. Impact toughness of BM and IRFW joint of TA18 tube试样 冲击功/J 冲击韧性/(J·cm−2) 焊接接头1# 47.3 78.5 焊接接头2# 45.2 75 母材1# 45.8 76 母材2# 49.8 82.6 TA18管摩擦焊接头处的显微硬度如图9所示。可以看出,焊缝区的显微硬度与母材区的显微硬度(HV)较为接近,约为245,而热机影响区的显微硬度(HV)有所增加,约为255。整体来看,TA18管接头中焊缝区、热机影响区及母材区硬度差异不大,呈现出良好的硬度匹配性。

3. 结论

1)TA18管具有良好的摩擦焊接性能,焊接接头的平均抗拉强度为759.5 MPa,平均断后伸长率为15%,与母材相当;平均屈服强度达到了母材的91.05%,略低于母材;焊接接头的断裂位置远离焊缝中心区域,表明焊接接头的最薄弱位置为母材区。

2)TA18管摩擦焊接头焊缝区温度超过了β相转变温度,高温β相在快冷的情况下在焊缝区形成了针状α′相;热影响区形成了等轴α相、部分针状α′相和残余β相的混合组织。

3)TA18管摩擦焊接头的冲击韧性为79.3 J/cm2,达到母材的96.85%;TA18管摩擦焊接头焊缝区、母材区的平均硬度(HV)为245 ,热影响区的平均硬度(HV)为255 ;良好的冲击韧性和硬度匹配性表明惯性摩擦焊是一种高质量的焊接TA18轴类部件的方法。

-

表 1 TA18钛合金管化学成分

Table 1. Chemical composition of TA18 titanium alloy tube

% Al V Fe C O N H Ti 3.0 2.5 0.2 0.05 0.08 0.03 0.01 Balance 表 2 TA18管惯性摩擦焊接工艺参数

Table 2. Processing parameters for IRFW of TA18 tube

顶锻压力/MPa 转动惯量/(kg·m2) 主轴转速/(r·min-1) 保压时间/s 7 990 300 15 表 3 TA18管摩擦焊接头与母材的拉伸性能

Table 3. Tensile test result of BM and IRFW joint of TA18 tube

试样 抗拉强度/MPa 屈服强度/MPa 断后伸长率/% 断面收缩率/% 焊接接头1# 757 585 15.5 44 焊接接头2# 762 586 14.5 38 母材1# 747 635 13.5 41 母材2# 758 651 16.0 44 表 4 TA18管摩擦焊接头与母材的冲击韧性

Table 4. Impact toughness of BM and IRFW joint of TA18 tube

试样 冲击功/J 冲击韧性/(J·cm−2) 焊接接头1# 47.3 78.5 焊接接头2# 45.2 75 母材1# 45.8 76 母材2# 49.8 82.6 -

[1] Zhao Yongqing, Ge Peng, Xin Shewei. Progresses of R&D on Ti-alloy materials in recent 5 years[J]. Materials China, 2020,39(Z1):527-534, 557-558. (赵永庆, 葛鹏, 辛社伟. 近五年钛合金材料研发进展[J]. 中国材料进展, 2020,39(Z1):527-534, 557-558.Zhao Yongqing, Ge Peng, Xin Shewei. Progresses of R&D on Ti-alloy materials in recent 5 years[J]. Materials China, 2020, 39(Z1): 527-534, 557-558. [2] Zhao Heng, Li Lanyun, Xin Chao, et al. Application and research status of titanium alloy in oil and gas exploitation[J]. Hot Working Technology, 2023(4):1-4, 15. (赵恒, 李兰云, 辛超, 等. 钛合金在油气开采中的应用及研究现状[J]. 热加工工艺, 2023(4):1-4, 15.Zhao Heng, Li Lanyun, Xin Chao, et al. Application and research status of titanium alloy in oil and gas exploitation[J]. Hot Working Technology, 2023(4): 1-4, 15. [3] Zhang Xuesong, Chen Yongjun, Hu Junling. Recent advances in the development of aerospace materials[J]. Progress in Aerospace Sciences, 2018,97:22-34. doi: 10.1016/j.paerosci.2018.01.001 [4] Zheng Pengfei, Wang Wenbo, Zhang Xiaolong, et al. The effect of heat treatment system on the structure and properties of TA18 bar[J]. Forging & Metalforming, 2022(21):53-55. (郑鹏飞, 王文波, 张晓龙, 等. 热处理制度对TA18棒材组织与性能的影响[J]. 锻造与冲压, 2022(21):53-55.Zheng Pengfei, Wang Wenbo, Zhang Xiaolong, et al. The effect of heat treatment system on the structure and properties of TA18 bar[J]. Forging & Metalforming, 2022(21): 53-55. [5] Yang Jianchao, Xi Jinhui, Yang Yashe, et al. Research and application of TA18 titanium alloy tube in aerospace industry[J]. Titanium Industry Progress, 2014,31(4):6-10. (杨建朝, 席锦会, 杨亚社, 等. 航空航天用TA18钛合金管材的研发及应用[J]. 钛工业进展, 2014,31(4):6-10.Yang Jianchao, Xi Jinhui, Yang Yashe, et al. Research and application of TA18 titanium alloy tube in aerospace industry[J]. Titanium Industry Progress, 2014, 31(4): 6-10. [6] Huang Tao, Yang Fangfang, Zhan Mei, et al. Section flattening in numerical control bending process of TA18 high strength tube[J]. Rare Metal Materials and Engineering, 2018,47(8):2347-2352. doi: 10.1016/S1875-5372(18)30190-5 [7] Luo Dengchao, Nan Li, Yang Yashe, et al. Effect of annealing temperature on mechanical properties and microstructure of TA18 tubes[J]. Hot Working Technology, 2012,41(20):206-208. (罗登超, 南莉, 杨亚社, 等. 退火温度对TA18管材性能和组织的影响[J]. 热加工工艺, 2012,41(20):206-208.Luo Dengchao, Nan Li, Yang Yashe, et al. Effect of annealing temperature on mechanical properties and microstructure of TA18 tubes[J]. Hot Working Technology, 2012, 41(20): 206-208. [8] Li Junzhao, Yu Hang, Fan Cheng, et al. Comparative study on welding process of TA18 titanium alloy sheet[J]. Titanium Industry Progress, 2023,40(2):30-34. (李军兆, 于航, 樊程, 等. TA18钛合金板材焊接工艺对比研究[J]. 钛工业进展, 2023,40(2):30-34.Li Junzhao, Yu Hang, Fan Cheng, et al. Comparative study on welding process of TA18 titanium alloy sheet[J]. Titanium Industry Progress, 2023, 40(2): 30-34. [9] Guo Jilong, Fu Juan, Zhao Yong, et al. Study on microstructure and corrosion resistance of TA18 titanium alloy TIG welding joint[J]. Hot Working Technology, 2024(7):11-15. (郭纪龙, 付娟, 赵勇, 等. TA18钛合金TIG焊接头组织及耐腐蚀性能研究[J]. 热加工工艺, 2024(7):11-15.Guo Jilong, Fu Juan, Zhao Yong, et al. Study on microstructure and corrosion resistance of TA18 titanium alloy TIG welding joint[J]. Hot Working Technology, 2024(7): 11-15. [10] Chen Wei, Zhang Yupeng, Dong Yong, et al. Effect of laser welding parameters on microstructure and mechanical properties of titanium alloy sheet[J]. Journal of Netshape Forming Engineering, 2022,14(5):100-108. (陈伟, 张宇鹏, 董勇, 等. 激光焊接参数对钛合金薄板组织及力学性能影响[J]. 精密成形工程, 2022,14(5):100-108.Chen Wei, Zhang Yupeng, Dong Yong, et al. Effect of laser welding parameters on microstructure and mechanical properties of titanium alloy sheet[J]. Journal of Netshape Forming Engineering, 2022, 14(5): 100-108. [11] Long Jian, Zhang Linjie, Zhang Long, et al. Effect of post-welding heat treatment on microstructure and properties of electron beam welding joint of new high-strength TB18 titanium alloy[J]. Welding in the World, 2024,68(1):155-162. doi: 10.1007/s40194-023-01644-x [12] Zhang Chunbo, Wu Yanquan, Piao Dongguang, et al. Inertia friction welding procedure of TA19 titanium alloy[J]. Transactions of the China Welding Institution, 2018,39(12):44-48, 131. (张春波, 乌彦全, 朴东光, 等. TA19钛合金惯性摩擦焊接工艺[J]. 焊接学报, 2018,39(12):44-48, 131.Zhang Chunbo, Wu Yanquan, Piao Dongguang, et al. Inertia friction welding procedure of TA19 titanium alloy[J]. Transactions of the China Welding Institution, 2018, 39(12): 44-48, 131. [13] Zhao Zhanglong, Song Xuyang, Cao Lanchuan, et al. Effect of isothermal deforming on the microstructure and property of inertial friction welding IMI834/Ti6246 dual titanium alloy[J]. Rare Metal Materials and Engineering, 2020,49(7):2388-2392. (赵张龙, 宋旭阳, 曹澜川, 等. 等温变形对惯性摩擦焊IMI834/Ti6246双钛合金组织与性能的影响[J]. 稀有金属材料与工程, 2020,49(7):2388-2392.Zhao Zhanglong, Song Xuyang, Cao Lanchuan, et al. Effect of isothermal deforming on the microstructure and property of inertial friction welding IMI834/Ti6246 dual titanium alloy[J]. Rare Metal Materials and Engineering, 2020, 49(7): 2388-2392. [14] Liu Yingying, Tian Wantao, Yang Qihao, et al. Inertia radial friction welding of Ti60(near-α)/TC18(near-β) bimetallic components: Interfacial bonding mechanism, heterogenous microstructure and mechanical properties[J]. Materials Characterization, 2024,208:113598. doi: 10.1016/j.matchar.2023.113598 [15] Ho Thi My Nu, Truyen The Le, Luu Phuong Minh, et al. A study on rotary friction welding of titanium alloy (Ti6Al4V)[J]. Advances in Materials Science and Engineering, 2019,2019(1):1-9. [16] Zhou Feng, Cao Yuxin, Wan Xiangliang. Effect of rare earth lanthanum addition on toughness of coarse-grained heat-affect zone of high strength low alloy steel[J]. Transactions of Materials and Heat Treatment, 2021, 42(12):84-92. (周峰, 曹羽鑫, 万响亮. 稀土镧的添加对低合金高强钢粗晶热影响区韧性的影响[J]. 材料热处理学报, 2021, 42(12):84-92.Zhou Feng, Cao Yuxin, Wan Xiangliang. Effect of rare earth lanthanum addition on toughness of coarse-grained heat-affect zone of high strength low alloy steel[J]. Transactions of Materials and Heat Treatment, 2021, 42(12): 84-92. [17] Wang Shiqing, Ma Tiejun, Li Wenya, et al. Microstructure and fatigue properties of linear friction welded TC4 titanium alloy joints[J]. Science and Technology of Welding and Joining, 2017,22(3):177-181. doi: 10.1080/13621718.2016.1212971 [18] Gavalec M, Barenyi I, Krbata M, et al. The effect of rotary friction welding conditions on the microstructure and mechanical properties of Ti6Al4V titanium alloy welds[J]. Materials, 2023,16(19):6492. doi: 10.3390/ma16196492 -

下载:

下载:

下载:

下载: