Crystal plasticity finite element study of tensile behavior of two-phase titanium alloy Ti-6Al-4V

-

摘要: 通过晶体塑性有限元方法探究了α/β相含量和晶粒尺寸对Ti-6Al-4V双相钛合金拉伸力学性能的影响,通过滑移相对分数定量化评估不同滑移系对塑性变形的贡献。结果表明:Ti-6Al-4V钛合金拉伸变形过程中应力应变分布不均匀,应力集中在β相变体晶粒及晶界处,应变集中在α相晶粒附近。随β相含量升高,应力集中区域更多,三叉晶界处越易产生应变集中,β相$ \left\{110\right\} $滑移系对塑性变形的贡献大幅提高。随着α相、β相或两相晶粒尺寸同时扩大,塑性段应力应变曲线下降,且初始变形都主要由柱面滑移系主导,锥面$ \left\langle\mathrm{c}+\mathrm{a}\right\rangle $滑移系贡献次之。增大α相晶粒尺寸,锥面$ \left\langle\mathrm{c}+\mathrm{a}\right\rangle $滑移系活性下降,导致塑性阶段应力值降低。增大β相晶粒尺寸,塑性阶段应力的降低与β相中$ \left\{110\right\} $滑移系活性下降有关。同时增大α及β相晶粒尺寸时,会同时影响柱面滑移系和$ \left\{110\right\} $滑移系的相对分数,应力值的下降与界面数量的显著下降有关。Abstract: The influence of α/β volume fraction and grain size on the tensile mechanical properties of Ti-6Al-4V dual-phase titanium alloy was investigated in this study using the crystal plasticity finite element method. The contribution of different slip systems to plastic deformation was evaluated quantitatively by slip relative fraction. The results demonstrate that the stress-strain distribution during the tensile deformation of Ti-6Al-4V titanium alloy is non-uniform. The stress is primarily concentrated on the β phase grain and grain boundary, while the strain is concentrated on the α phase grain. Increasing the volume fraction of β phase leads to a larger stress concentration area, easier generation of strain concentration at the triple-junction of grain boundaries, and a significant increase in contribution from the β phase{110} slip system to the plasticity deformation. Increasing α, β or two-phase grain size results in decreased stress-strain curve in the plastic region, where initial deformation is predominantly governed by prismatic slip system while pyramidal <c+a> slip system contribute slightly less. An increase in α-phase grain size leads to a decrease in the activity of pyramidal <c+a> slip system, resulting in reduced stress values in the plastic region. Increasing the β-phase grain size results in a reduction of stress during the plastic stage, which is attributed to the decreased activity of {110} slip system within the β-phase. Simultaneously increasing the grain size of both the α and β phases will affect the activation fraction of prismatic and {110} slip systems. The reduction in stress is associated with the significant decrease in the number of interfaces.

-

Key words:

- Ti-6Al-4V /

- tensile behaviors /

- crystal plasticity /

- stress-strain /

- slip system /

- finite element method

-

0. 引言

钛合金中最常见的两种结构相为α相和β相,大多数α+β型钛合金在室温下通常含有4%~20%的β相,α+β型钛合金的组织形态大致可分为等轴组织、网篮组织、魏氏体组织、双态组织四类[1−2]。钛合金的机械性能主要由其组织形貌、晶粒尺寸及取向所决定[3]。初生α相和β相变体作为两相钛合金中重要组成成分,随着α/β相界面的变化,晶粒及相界面与位错的交互阻碍作用致使材料强度会有所变化。

在研究微观组织特征对单轴宏观力学变形行为影响过程中,已有诸多研究关注α/β相含量和晶粒尺寸因素的影响。李进元等[4]通过高温水冷处理使合金组织中的初生α含量减少,由于晶间β组织对位错移动起到阻碍作用,致使强度明显提高。高宇昊等人[5−6]研究发现初生α相含量增加,β转变相含量减少,导致强度降低,塑性增加。针对TC10、TC11、TC4等钛合金力学性能的研究表明初生α相的含量和尺寸对钛合金的力学性能有显著影响,晶粒粗化会造成钛合金强度降低[7−13]。此外,α相形貌对钛合金的力学性能也有显著影响。调节β变体组织中片层α相的长宽比尺寸,会使位错滑移难以穿过界面,钛合金强度及综合性能提升[14−16]。

上述研究多利用试验方法,初步研究了α及β相含量和晶粒尺寸对双相钛合金宏观力学性能的影响,缺乏微观变形机理的定量化评估研究。位错滑移是双相钛合金的主要变形机制,研究微观组织对位错滑移行为的影响有助于深入理解钛合金的微观变形机理[17]。笔者基于晶体塑性有限元计算框架PRISMS-Plasticity[18],以应用广泛的 Ti-6Al-4V钛合金为例,创建不同几何结构特征的代表性体积单元(representative volume element, RVE)模型,定量化研究不同α、β相体积分数及晶粒尺寸大小对塑性变形行为和力学性能的影响,关注空间应力应变分布特点,揭示不同组织特征影响下的拉伸变形微观机制。

1. 晶体塑性方法

1.1 率相关晶体塑性模型

塑性变形速度梯度$ {L}_{P} $[19]可表示为:

$$ {L}_{P}={\sum }_{\alpha =1}^{{n}_{s}}{\dot{{\gamma }_{\alpha }}}{S}_{0}^{\alpha } $$ (1) 其中,$ {n}_{s} $为滑移系启动总数量;$ \dot{\gamma_{\mathrm{\alpha}}} $为α滑移系的剪切速率;$ {S}_{0}^{\alpha } $为α滑移系滑移方向与滑移面法向的矩阵张量积。

在唯象粘塑性定律(Phenomenological Viscoplastic Power Law)[20]本构关系中,剪切速率可表示为:

$$ \dot{{\gamma }^{\alpha }}={\dot{{\gamma }_{0}}\left(\frac{\left|{\tau }^{\alpha }-{\omega }^{\alpha }\right|}{{S}^{\alpha }}\right)}^{m}\mathrm{s}\mathrm{i}\mathrm{g}\mathrm{n}\left({\tau }^{\alpha }-{\omega }^{\alpha }\right) $$ (2) 其中,$ \dot{{\gamma }_{0}} $为初始剪切速率;$ {\tau }^{\alpha } $为滑移分切应力;$ {\omega }^{\alpha } $为背应力;$ {s}^{\alpha } $为滑移阻力,也称临界分切应力(critical resolved shear stress, CRSS);m为应变率敏感系数。

CRSS值大小可由临界分切应力变化率$ \dot{{S}^{\alpha }} $表示:

$$ \dot{{S}^{\alpha }=}\sum _{\beta }{H}_{\alpha \beta }\left|\dot{{\gamma }^{\beta }}\right|=\sum _{\beta }{q}_{\alpha \beta }{h}_{0}{\left(1-\frac{{S}^{\beta }}{{S}_{s}^{\beta }}\right)}^{a}\left|\dot{{\gamma }^{\beta }}\right| $$ (3) 其中,$ {H}_{\alpha \beta } $为硬化模量,$ {q}_{\alpha \beta } $为不同滑移系之间的硬化系数,常取1;$ {h}_{0} $为初始硬化模量;$ {S}_{s}^{\beta } $为滑移系饱和分切应力;$ {S}^{\beta } $为滑移系启动阻力;$ {\gamma }^{\beta }\mathrm{为}{\beta }$滑移系的剪切速率;$a $为硬化指数。

1.2 晶体塑性模拟参数的确定和验证

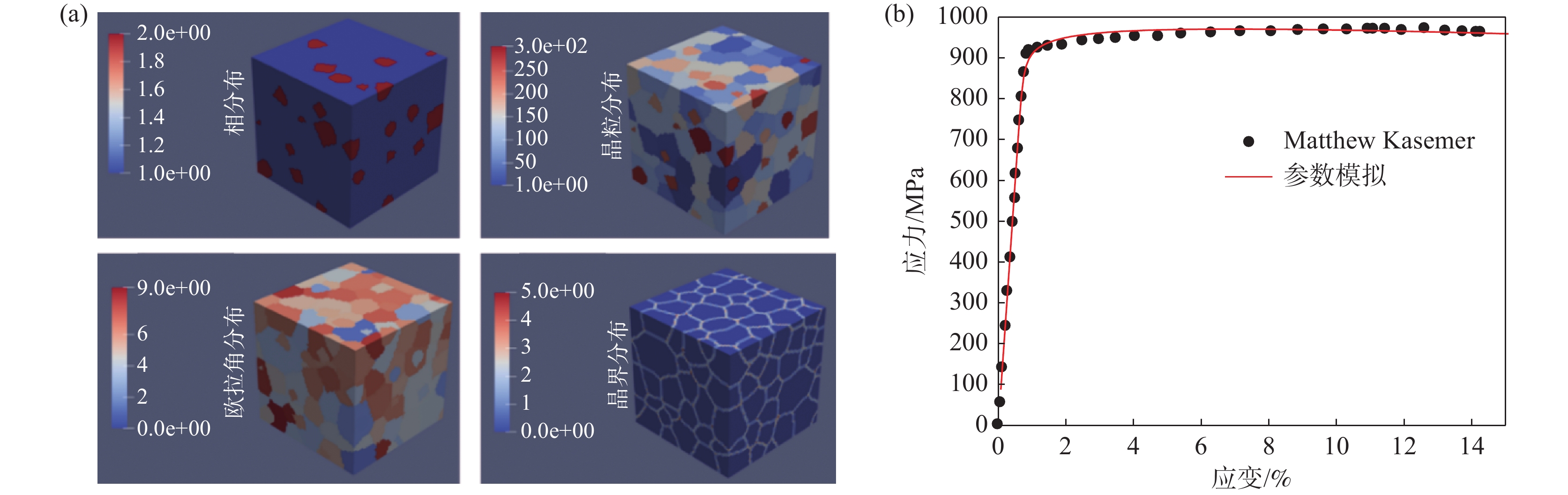

针对轧制退火和β退火的Ti-6Al-4V钛合金,Kasemer等[21]根据单轴拉伸试验,确定了不同组织形态钛合金的宏观屈服强度及延展性。进一步根据试验数据建立了β退火态片层组织晶体塑性有限元模型,探究β退火Ti-6Al-4V钛合金微观组织形态对屈服强度和延展性影响。然而,关于α、β相体积分数和晶粒尺寸对轧制退火Ti-6Al-4V钛合金性能的影响并未研究。因此,笔者根据Kasemer等[21]提供的轧制退火Ti-6Al-4V合金拉伸应力应变曲线及相关材料信息,采用相同的晶体塑性有限元本构参数进行模拟,进一步探究α、β相体积分数和晶粒尺寸对轧制退火Ti-6Al-4V钛合金性能和变形机理的影响。

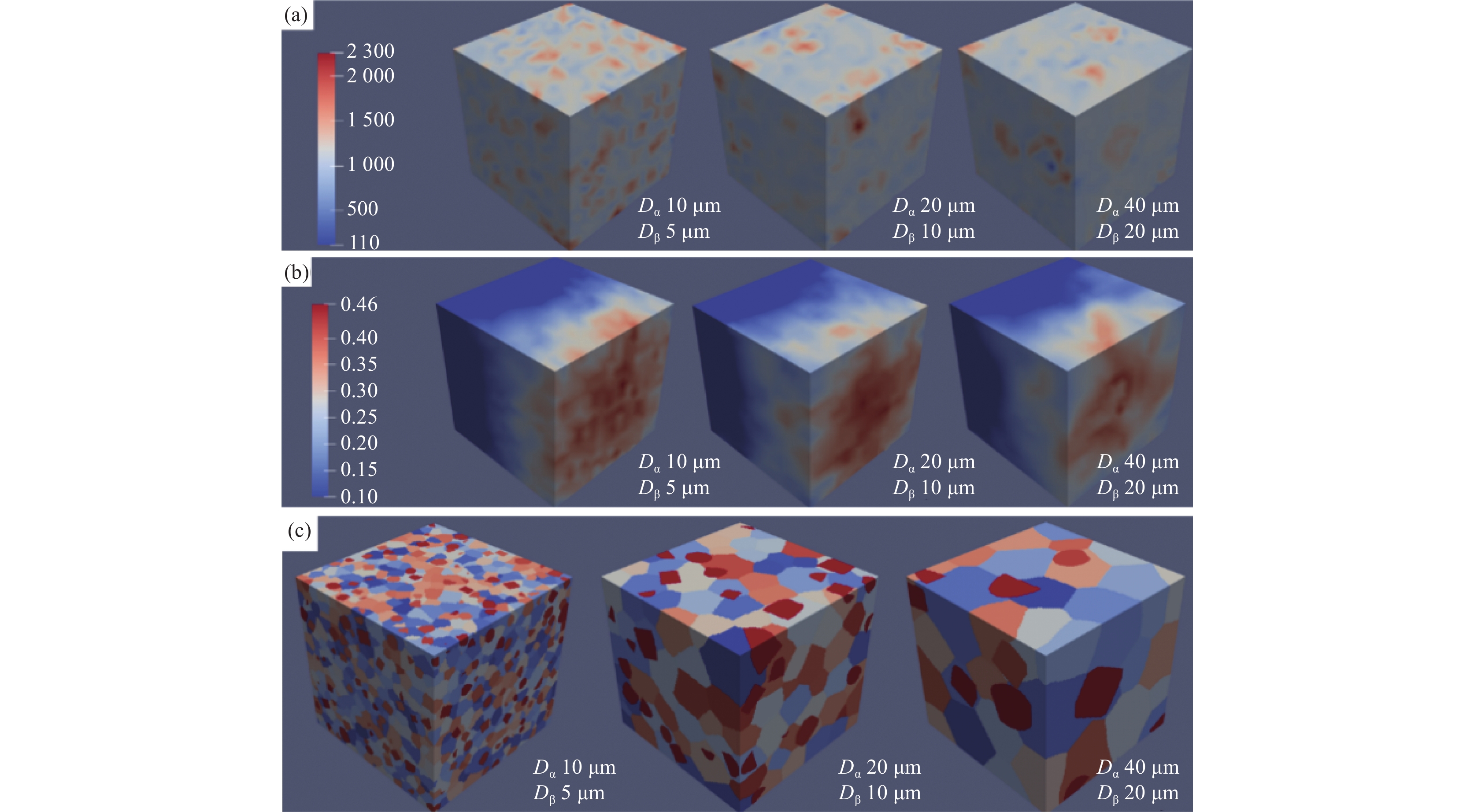

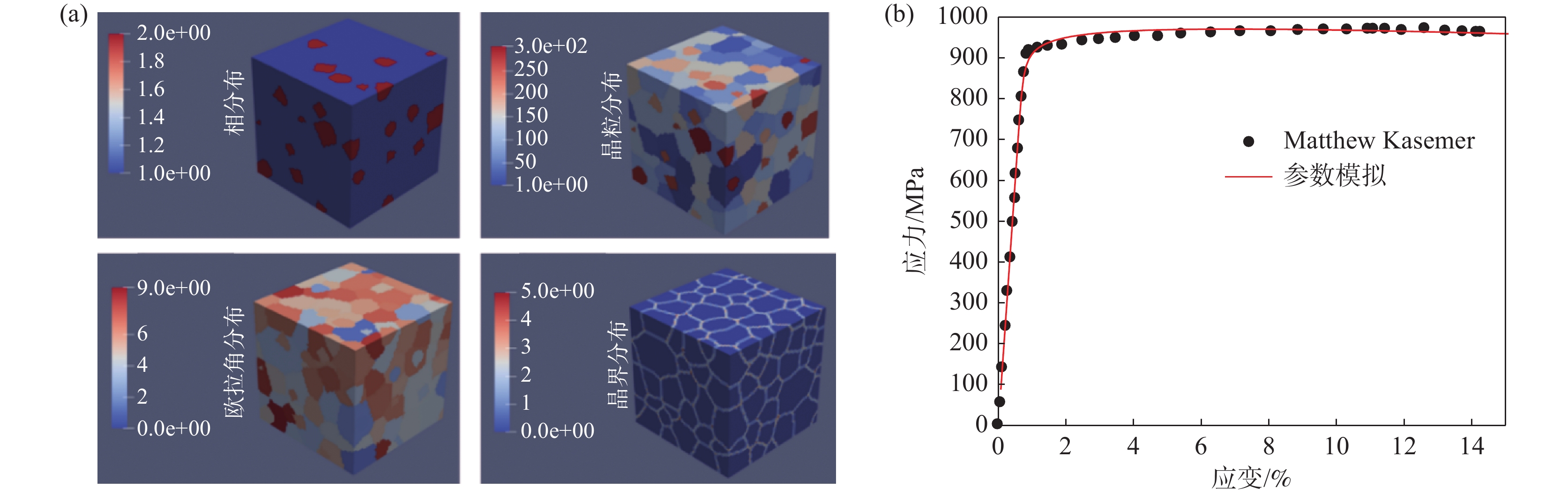

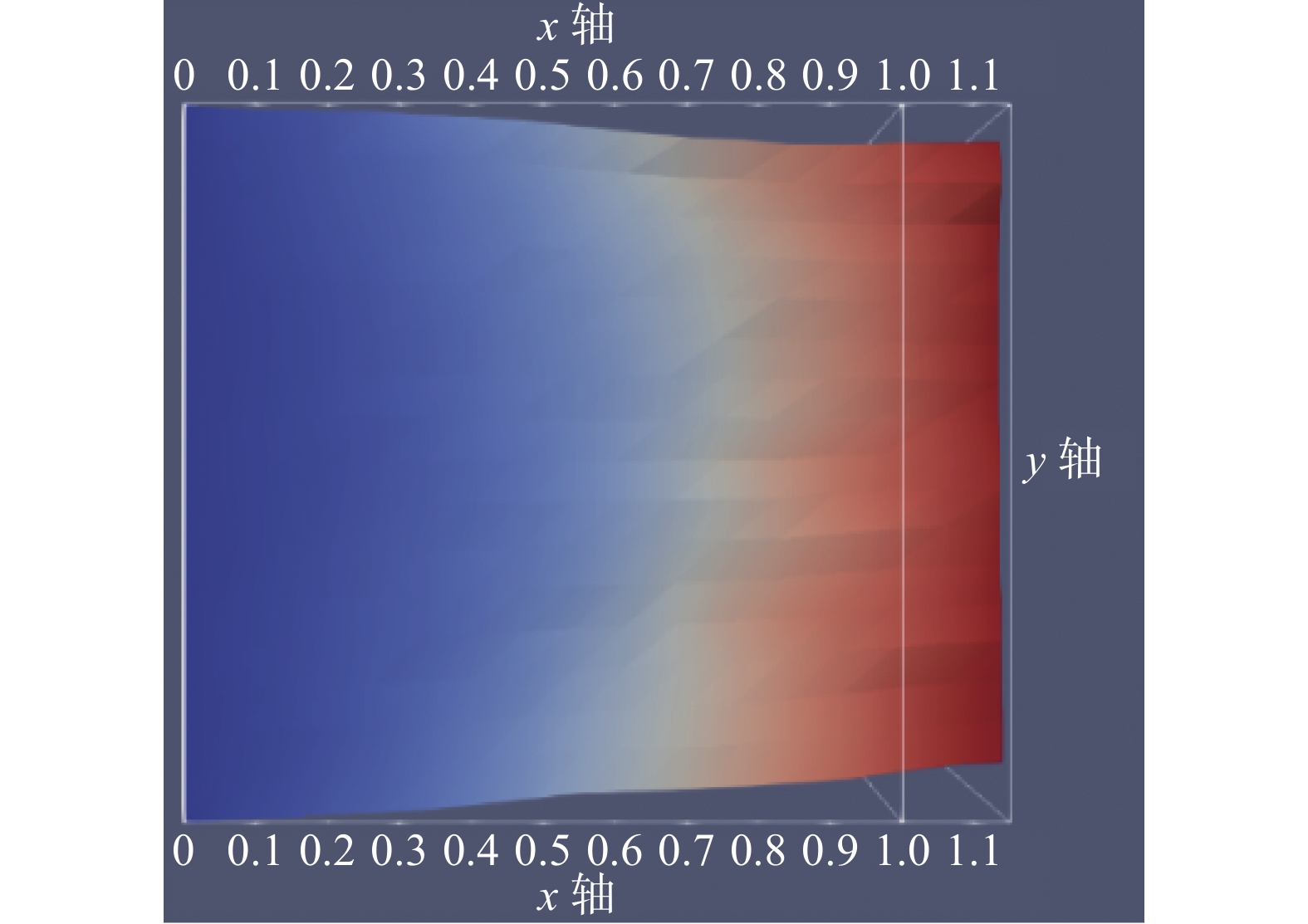

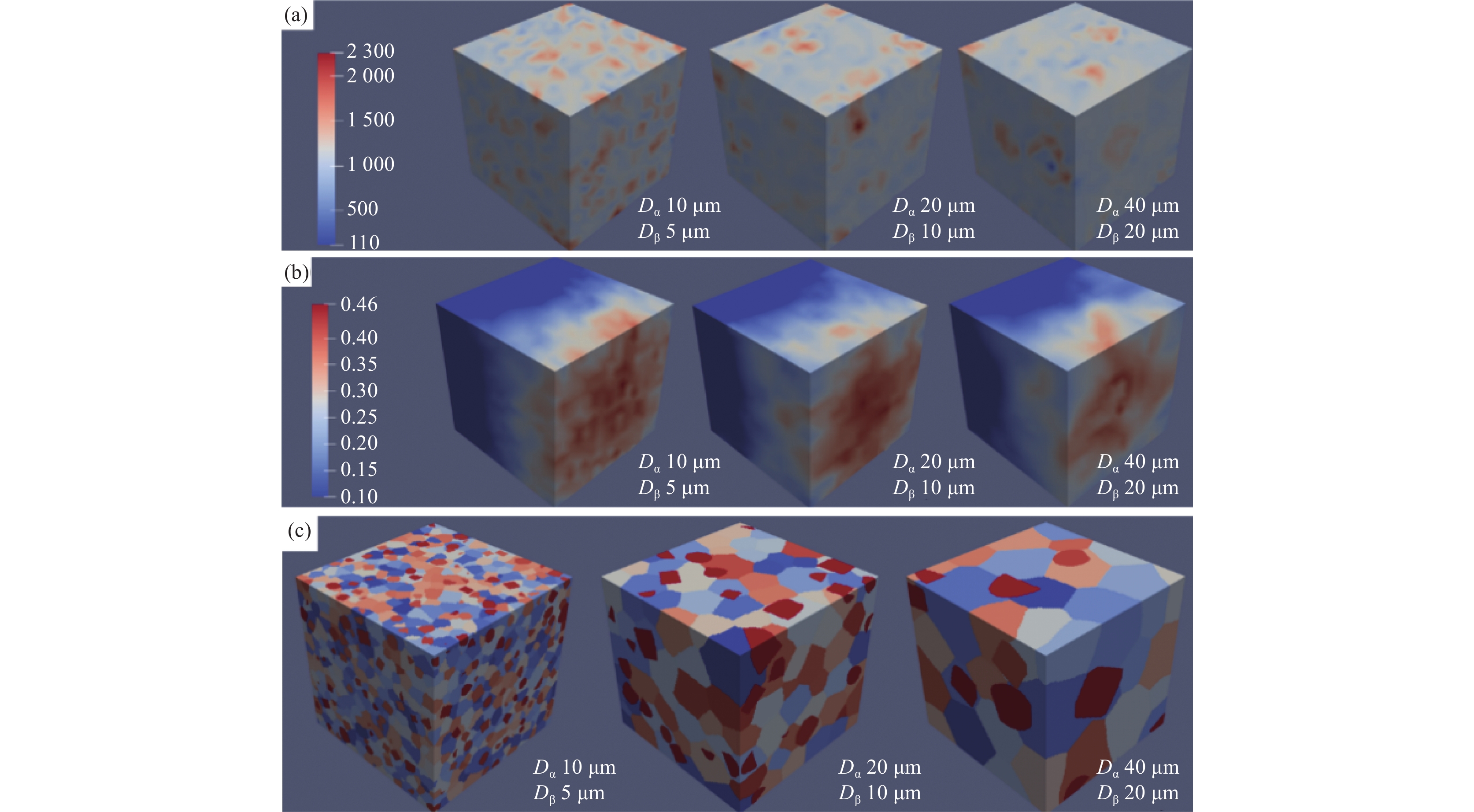

图1(a)为基于初始材料信息建立的双相多晶体模型,RVE模型采用Dream3D[22]开源软件生成,其中蓝色代表α相,晶粒尺寸约为10 μm,体积分数为92%,红色代表β相,晶粒尺寸约为5 μm,体积分数为8%,晶粒取向随机生成,整体模型大小采用64×64×64单元,大约含180个晶粒。晶体塑性模拟所用参数[21]见表1,其中α相HCP晶体考虑了基面$ \left\langle\mathrm{a}\right\rangle $型滑移系、柱面$ \left\langle\mathrm{a}\right\rangle $型滑移系和锥面$ \left\langle\mathrm{c}+\mathrm{a}\right\rangle $型滑移系,β相BCC晶体考虑了$ \left\{110\right\}\left\langle{111}\right\rangle $滑移系。设置α及β相弹性常数[21]见表2。图1(b)同时给出了单轴拉伸模拟结果与试验结果曲线。显然在原有晶体塑性参数下,红色模拟曲线与文献中轧制退火态Ti-6Al-4V钛合金拉伸试验数据重合度高,验证了基于本计算框架模拟的可行性和Dream3D创建RVE模型的可靠性,为后续模拟工作奠定基础。

滑移系 $ {\tau }_{0}/\mathrm{M}\mathrm{P}\mathrm{a} $ m $ {\dot{\gamma }}_{0}/{\mathrm{s}}^{-1} $ $ {h}_{0}/\mathrm{M}\mathrm{P}\mathrm{a} $ $ a $ 基面$ \left\langle\mathrm{a}\right\rangle $ 390 0.01 1.0 190 50 柱面$ \left\langle\mathrm{a}\right\rangle $ 390 0.01 1.0 190 50 锥面$ \left\langle\mathrm{c}+\mathrm{a}\right\rangle $ 663 0.01 1.0 190 50 β$ \left\{110\right\}\left\langle{111}\right\rangle $ 390 0.01 1.0 190 50 2. 计算结果比较与讨论

2.1 β相体积分数的影响

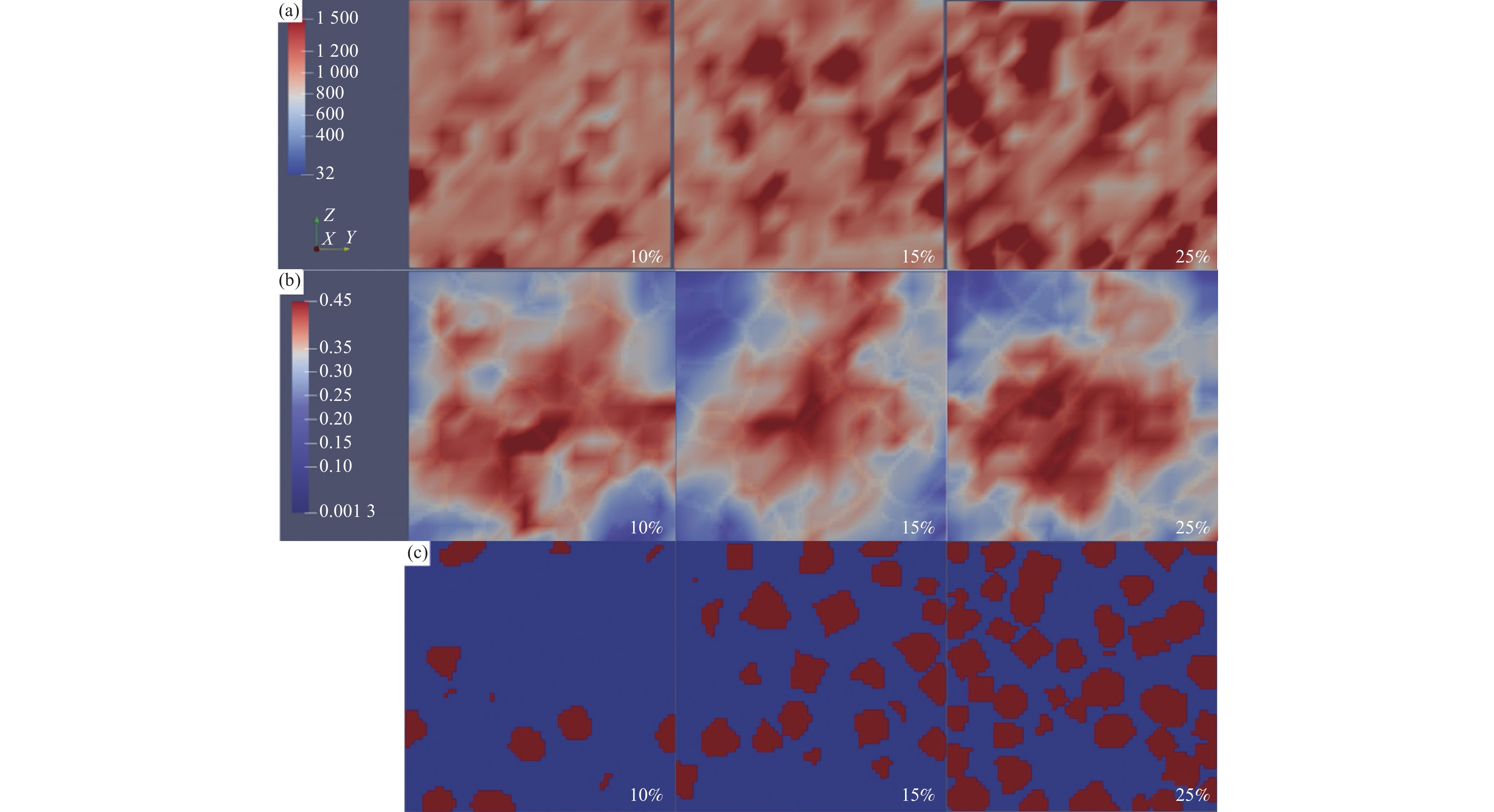

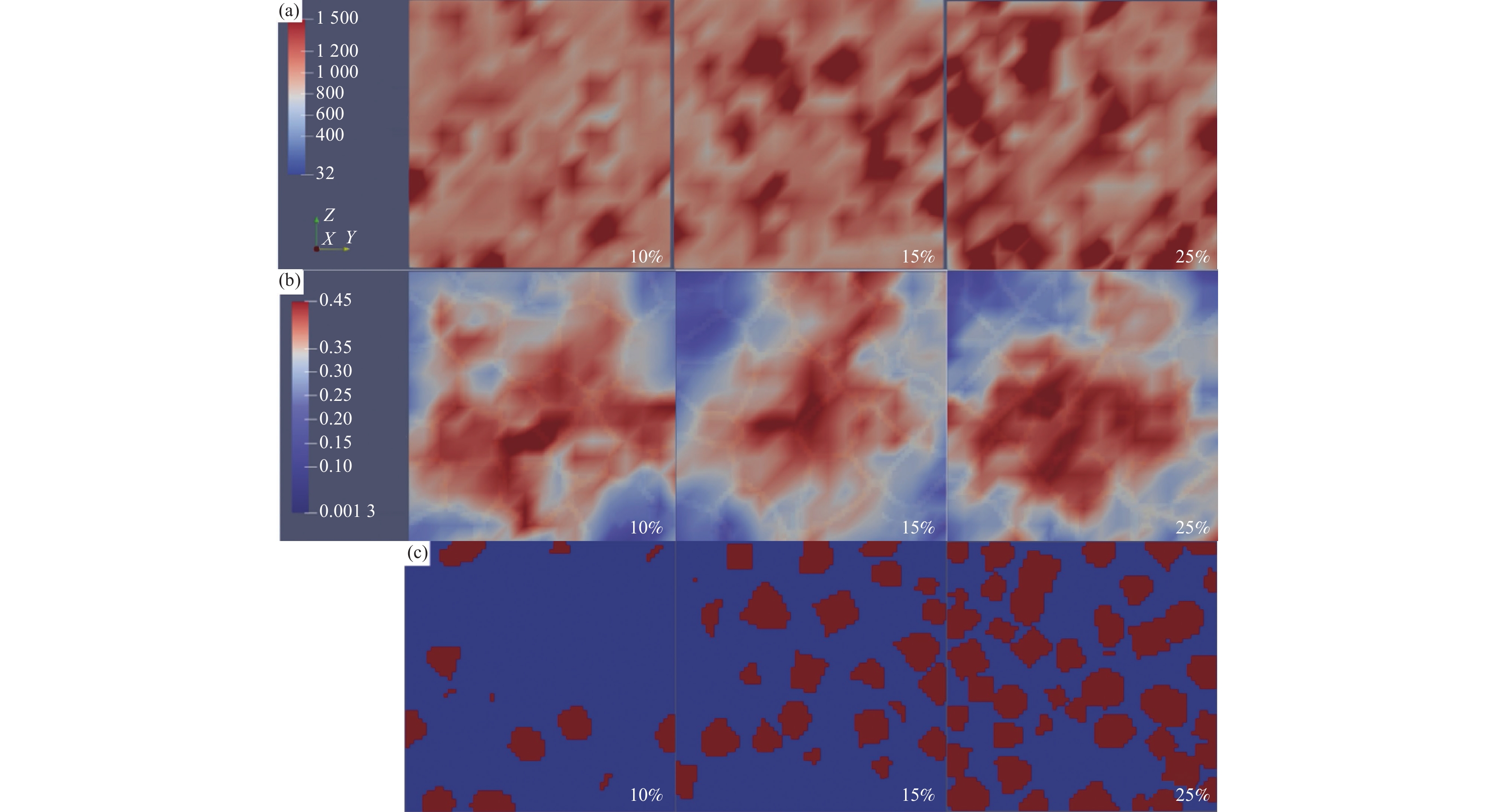

研究表明,通过固溶和固溶时效处理可改变Ti-6Al-4V合金中等轴α组织和β相基体转变组织的数量,从而影响钛合金材料的抗拉强度、屈服强度、断裂韧性及抵抗裂纹扩展能力等[23]。本节构建4种不同β相体积分数的两相RVE模型,分析两相体积分数变化对其性能的影响。图2从左至右分别表示10%、15%和25% β相体积分数下拉伸15%后的应力应变云图,晶界分布和相分布。

从图2(a)中可看出整体应力分布呈现出明显不均匀现象,应力多集中在β相变体晶粒上及晶界处,且随β相含量升高,应力集中区域变得更多,分布更扩散。从图2(b)中可看出应变主要集中分布在α相晶粒附近,且随β相含量升高,在三叉晶界处越容易产生应变集中。因为在相同变形条件下β相晶粒屈服点比α相高,而α相内滑移系优先激活,导致α晶粒区域应变集中现象产生,且室温下晶界强晶粒弱,晶粒内部易发生滑移,而晶界会阻碍晶粒内部滑移,产生位错累积,阻碍应力应变的传递分配,致使α及β相晶粒之间应力应变分布不一致[24−25]。

25% β相含量下拉伸15%应变后的颈缩变形情况如图3所示。不同β相体积分数下拉伸变形大致相同,仅颈缩收缩程度有细微差别,都在颈缩区域几何表面呈现出“橘皮状”不均匀变形,且从拉伸方向看,近表面区域形状变形扭曲程度比内部要大。“橘皮状”表面的形成是拉伸过程中晶粒在空间中发生转动,较有利取向的晶粒受周围晶粒约束较小,各晶粒产生变形差异,且不易传递到相邻晶粒,同时晶粒中心区滑移量大于边缘区(晶界附近区域),致使两者滑移台阶高低不同,造成宏观上不均匀现象,且晶粒越粗大橘皮组织越严重[26]。

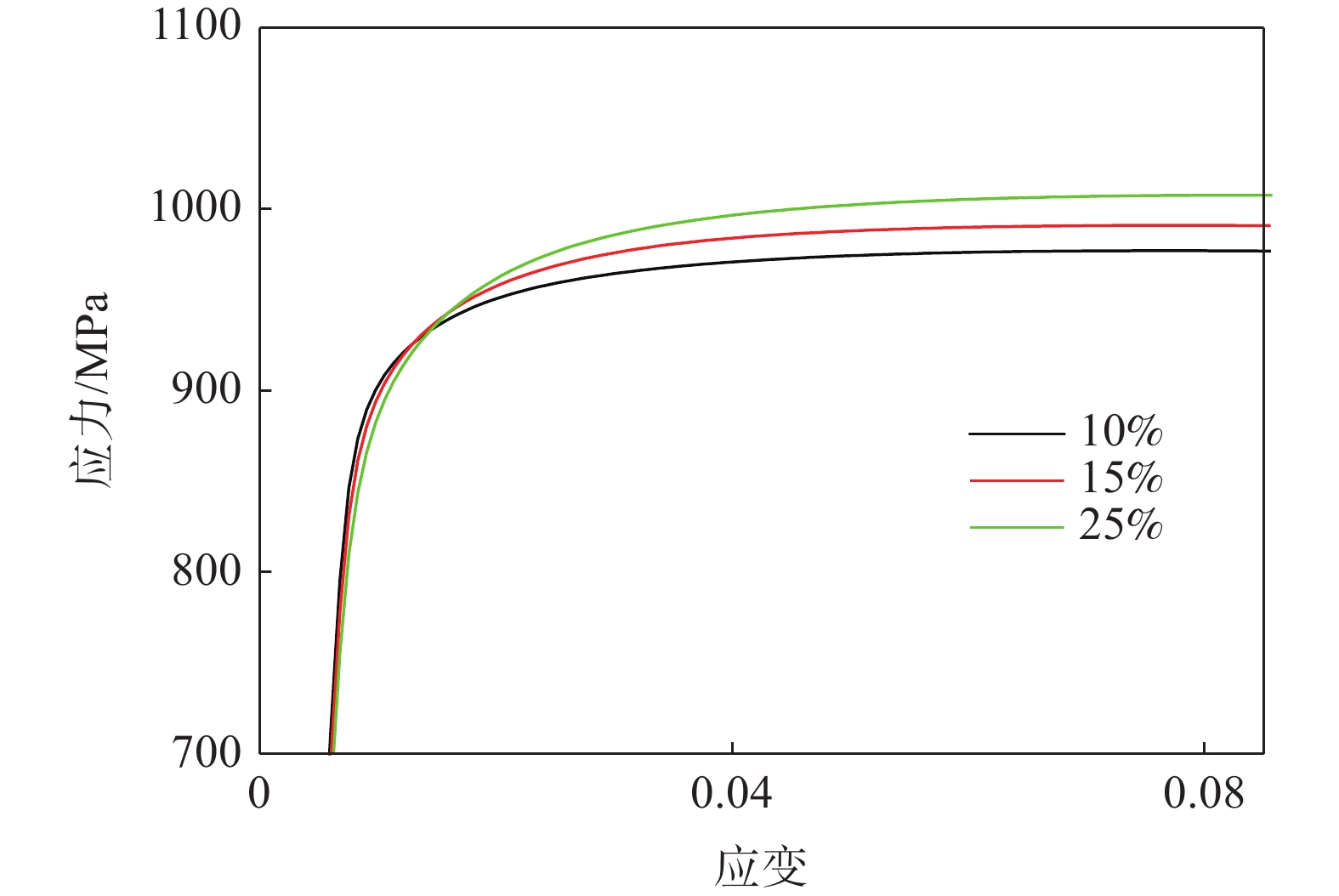

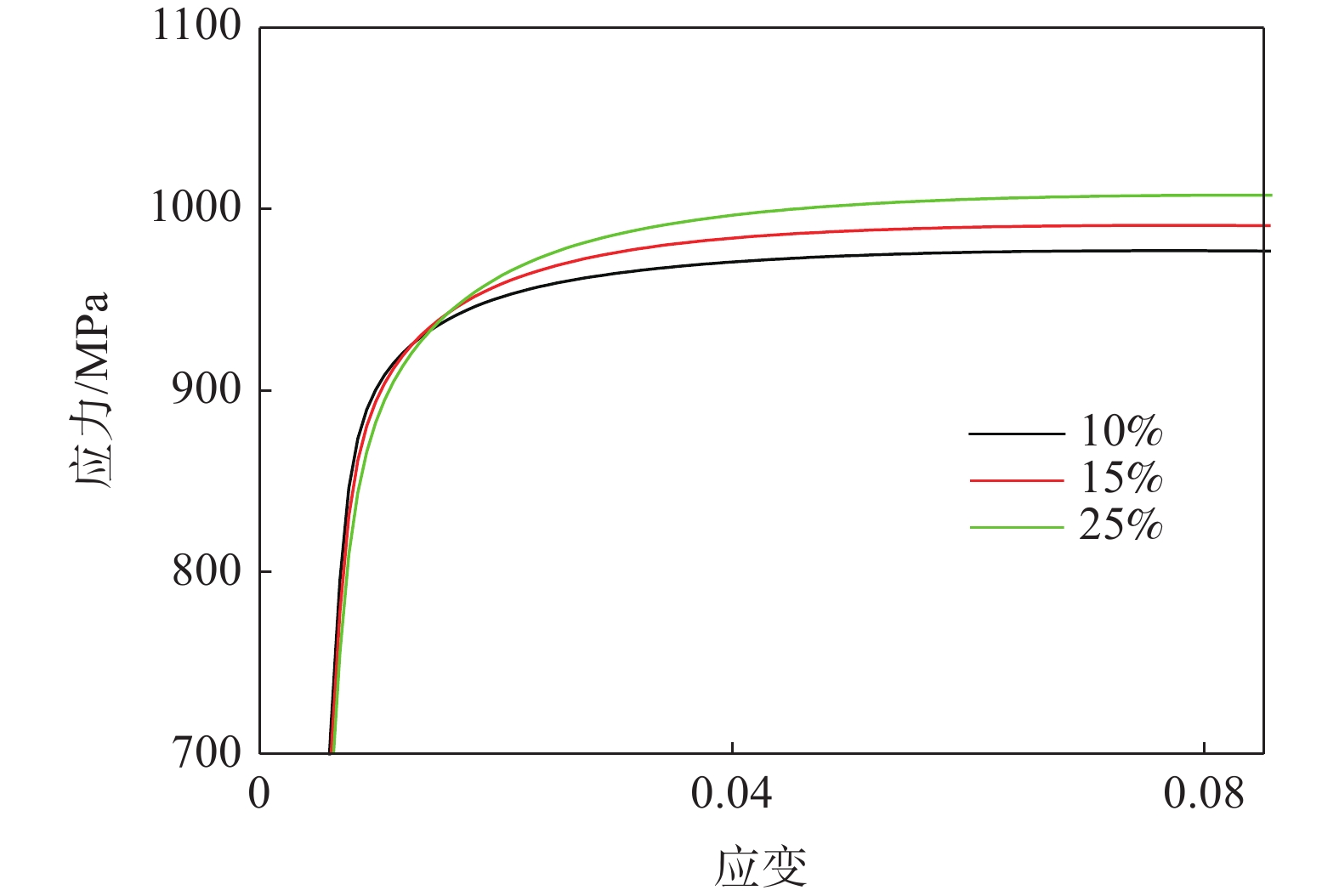

不同β相体积分数下模拟所得拉伸应力应变曲线如图4所示。在不同β相含量下,尽管两相模量设置不同,但曲线在弹性阶段几乎没有差别,塑性阶段应力会随着β相含量的增加而增加,塑性阶段加工硬化率低,变化不明显。李学雄等[25]和唐斌等[27]对α+β双相钛合金的拉伸行为进行晶体塑性模拟研究,结果同样表明微观组织的变化对弹性段几乎没影响。据前述分析知,在β相晶粒区域会发生应力集中,而β相含量增加意味着β相晶粒及界面增多,局部应力集中现象更显著,造成塑性变形阶段应力值随着β相体积分数升高而不断增加。

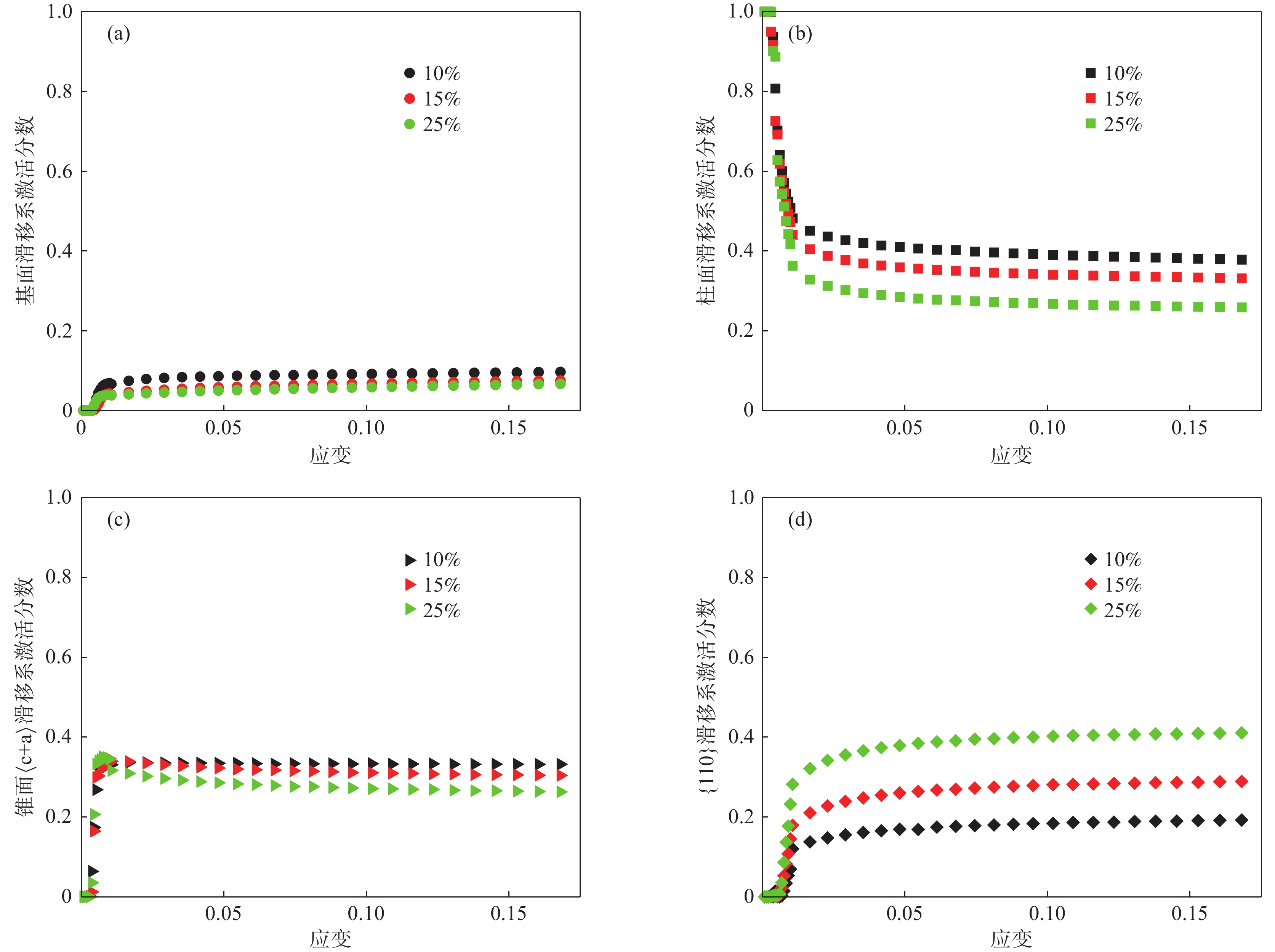

为深入探究变形过程中β相含量对不同滑移系激活比例的影响,图5作出了各滑移系激活相对分数。β相中$ \left\{110\right\} $滑移系的CRSS值与α相中柱面及基面滑移系CRSS值相同。

对比不同滑移系相对分数可以看出,α相中柱面滑移系最先激活,随后β相中$ \left\{110\right\} $滑移系激活,并随着应变的增加,柱面滑移占据主导地位,柱面滑移系的相对分数先迅速下降而后缓慢下降,β相中$ \left\{110\right\} $滑移系的相对分数先迅速增加而后缓慢增加。尽管β相含量远低于α相,但是β相含量的变化会对α相中不同滑移系的相对分数产生显著影响。随着β相含量的增加,α相内的基面、柱面、锥面$ \left\langle\mathrm{c}+\mathrm{a}\right\rangle $滑移系激活量下降,β相中$ \left\{110\right\} $滑移系的相对贡献增加。25% β相体积分数下,$ \left\{110\right\} $滑移系的相对分数接近0.4,超过柱面和锥面$ \left\langle\mathrm{c}+\mathrm{a}\right\rangle $滑移系的相对分数。因此,β相基体一定程度上会产生滑移阻力效用阻碍α相内晶粒产生滑移,进而在α/β相区域形成应力应变集中现象。

2.2 α相晶粒尺寸的影响

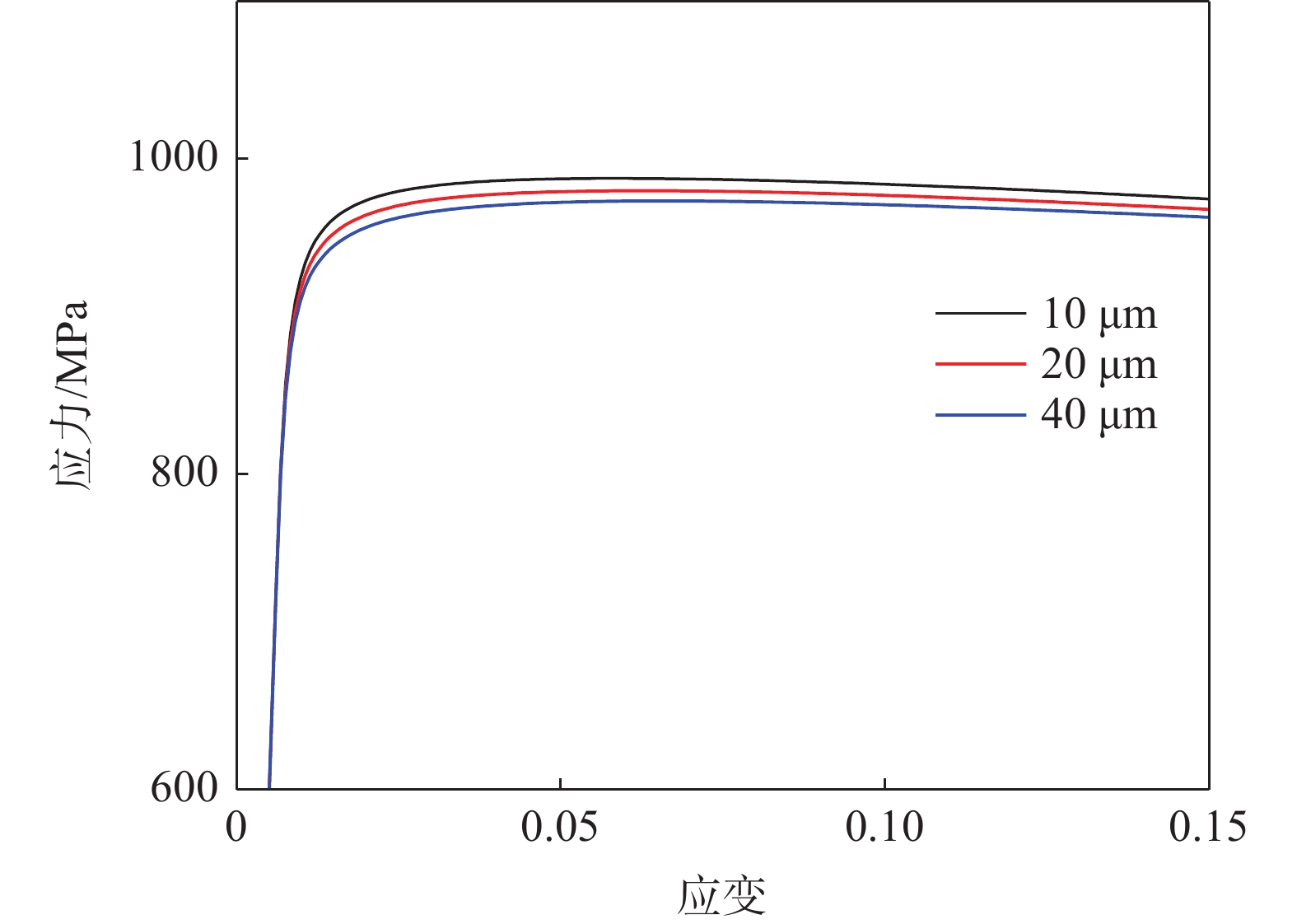

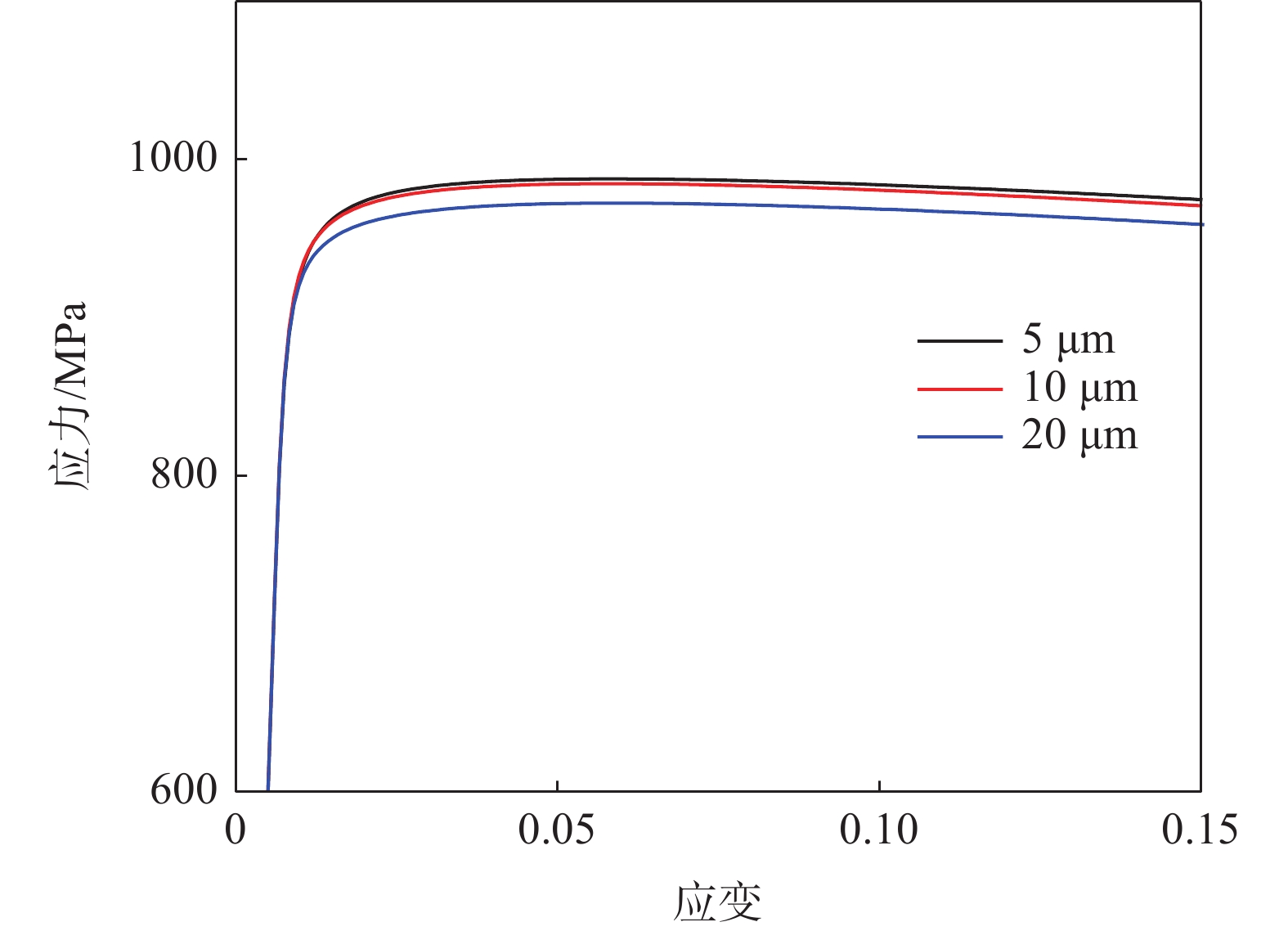

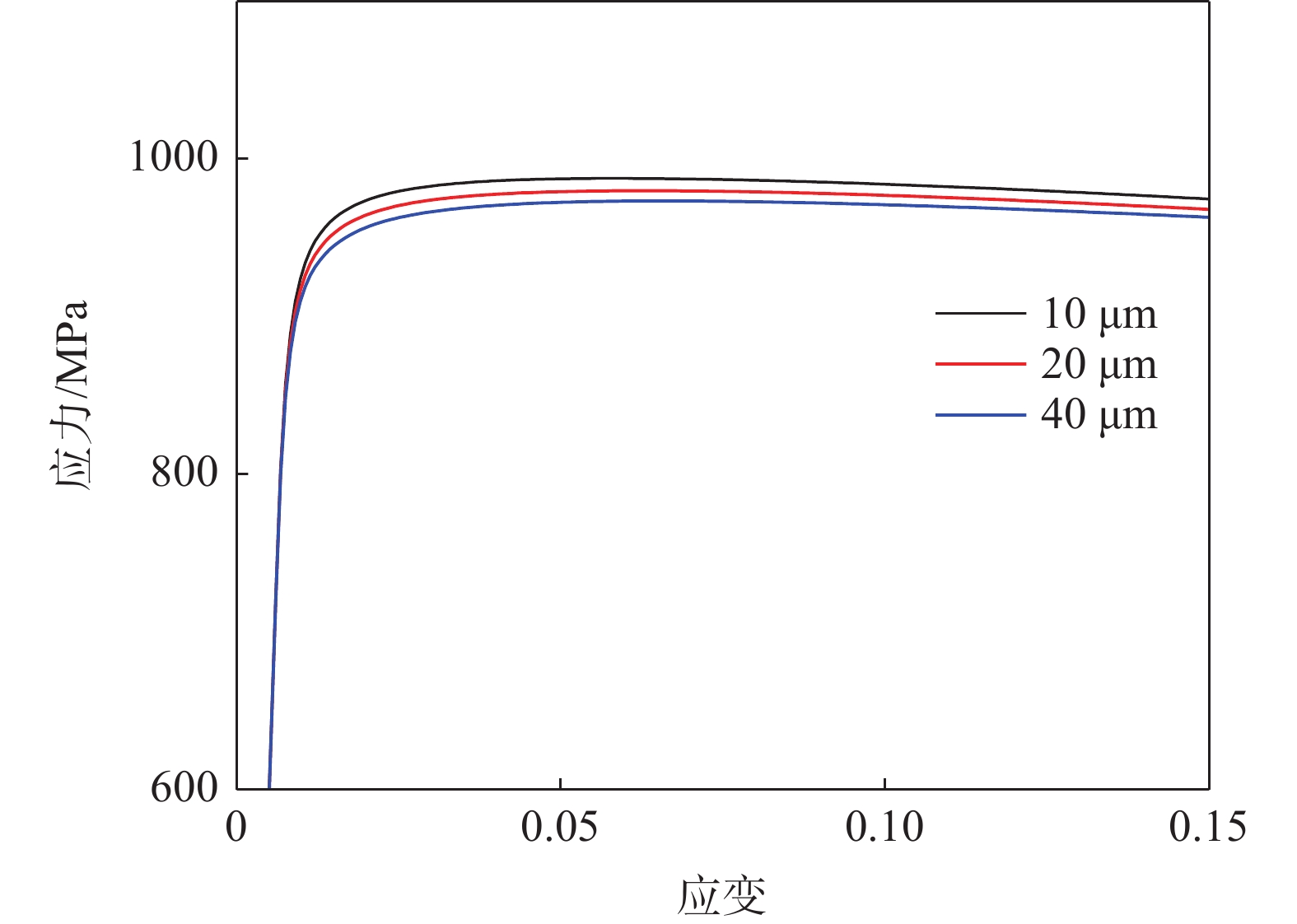

图6给出了α相晶粒尺寸为10、20、40 μm时的拉伸应力应变曲线。从图6可以看出,随着α相晶粒尺寸变大,应力应变曲线下降,塑性阶段硬化率几乎不变。

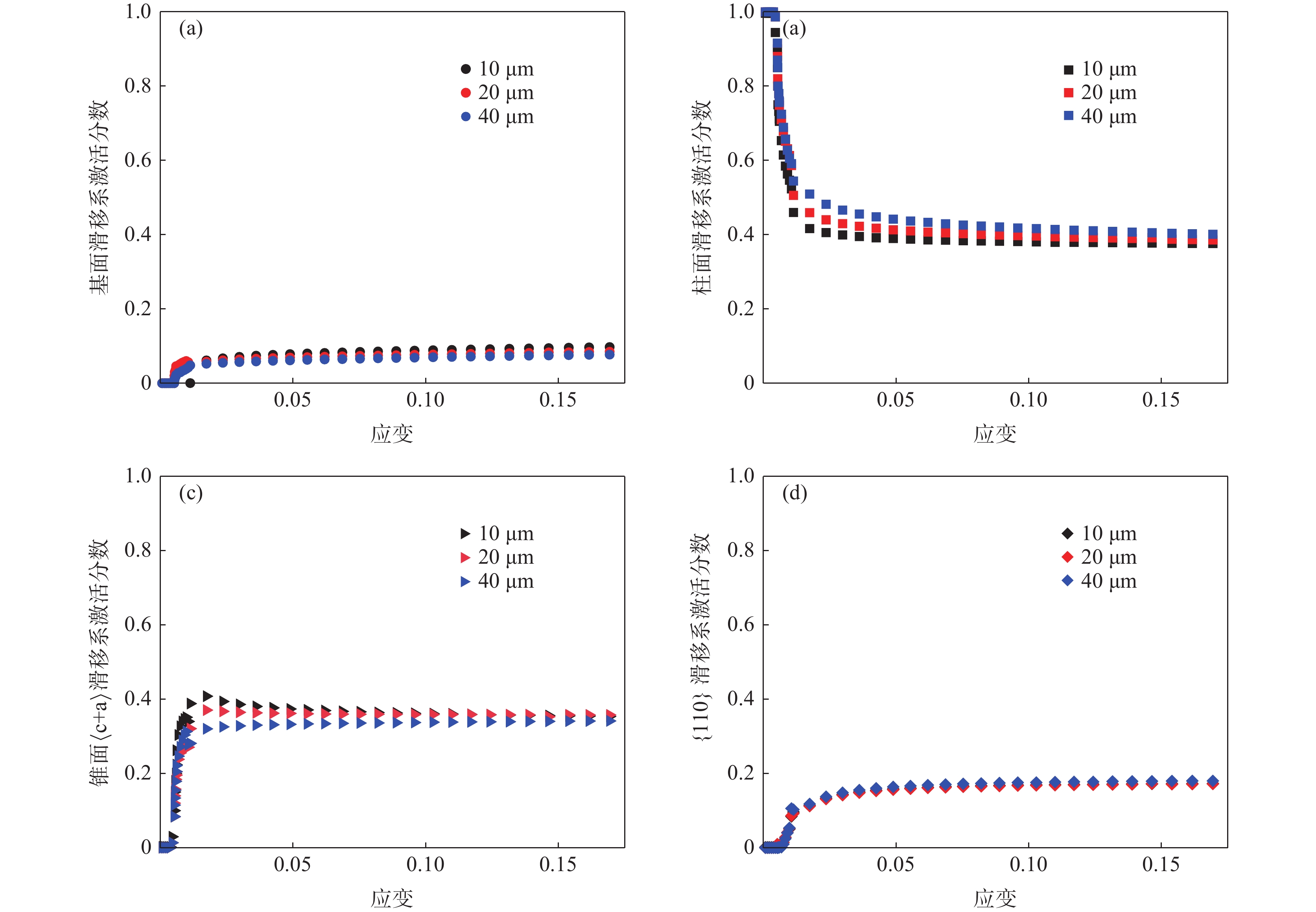

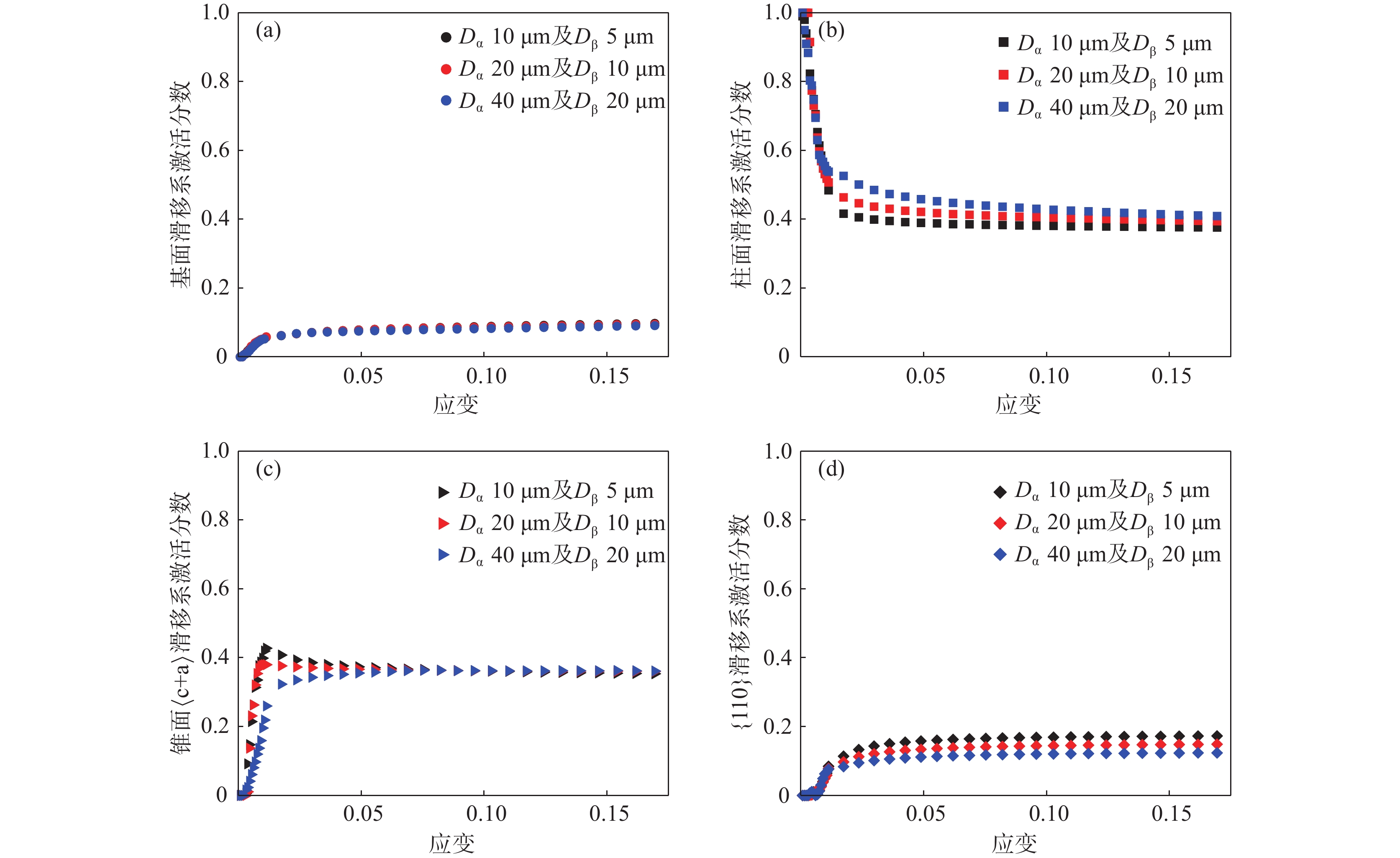

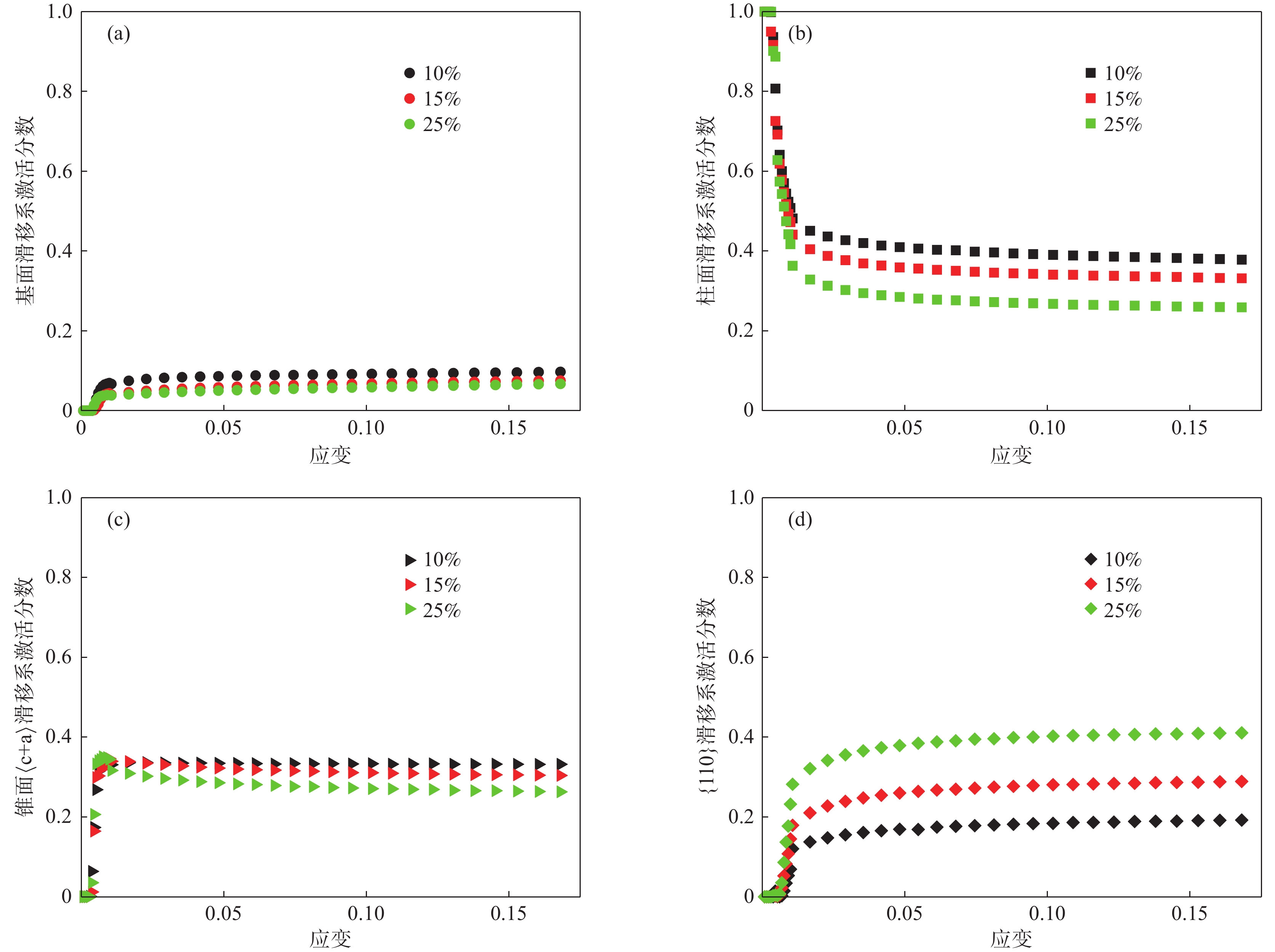

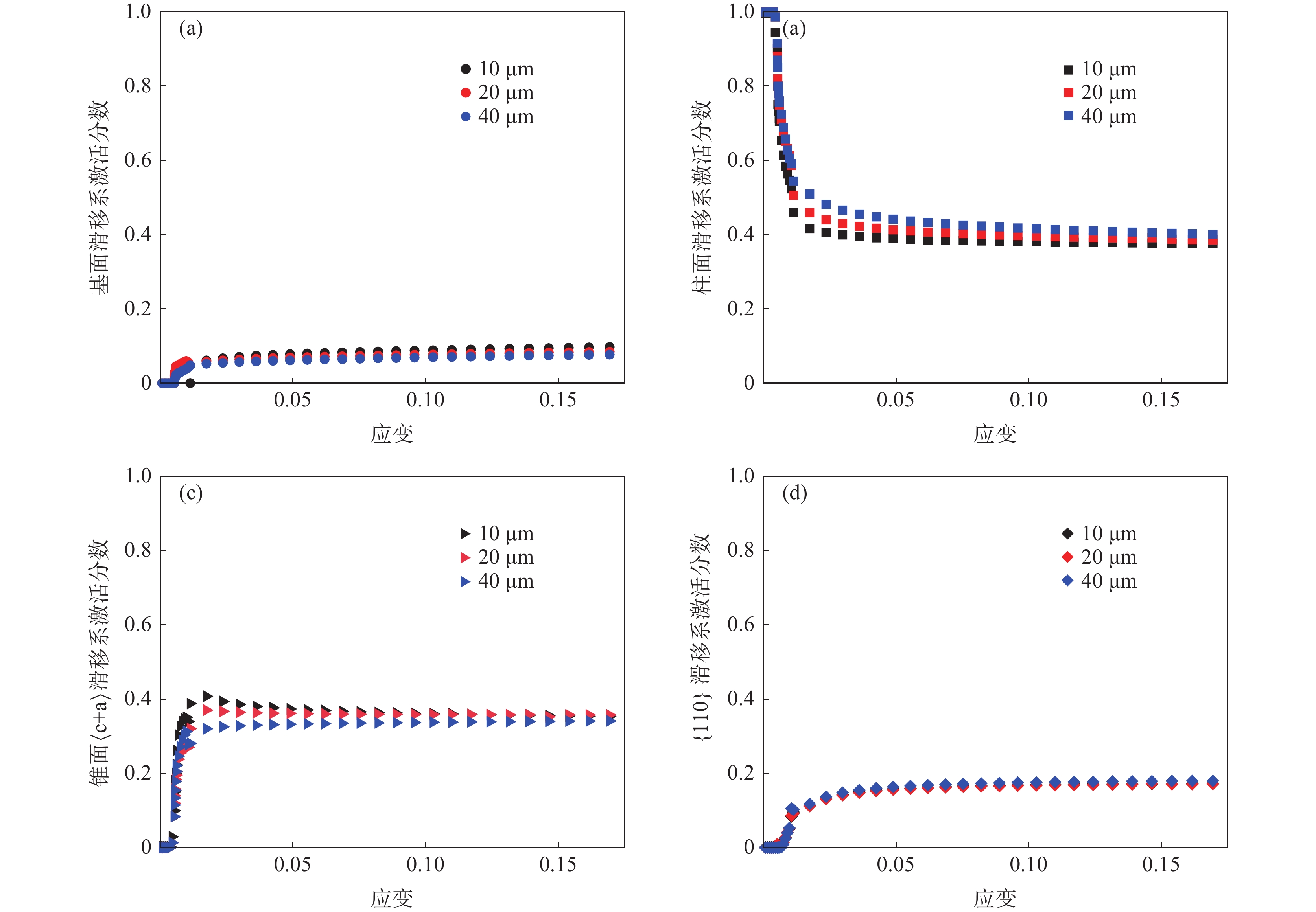

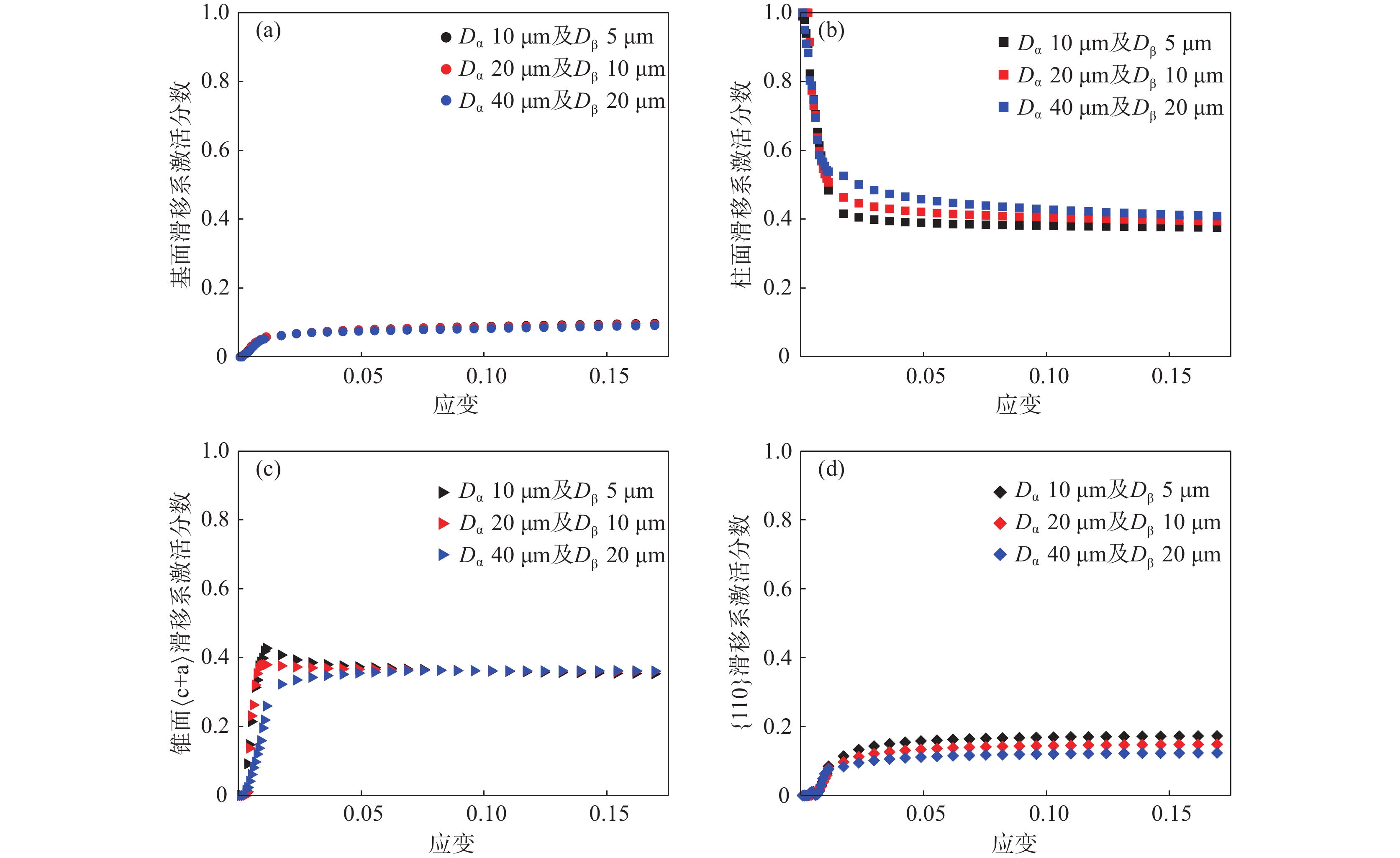

图7给出了α相晶粒尺寸为10、20、40 μm时拉伸变形过程中不同滑移系的相对分数变化。从图7可以看出,初始变形由柱面滑移主导,2%应变后锥面$ \left\langle\mathrm{c}+\mathrm{a}\right\rangle $对滑移贡献接近柱面滑移,而基面滑移和$ \left\{110\right\} $滑移激活相对分数较低。随着α相晶粒尺寸增加,图7(b)中柱面滑移激活相对分数增加,图7(a)及(c)中基面和锥面$ \left\langle\mathrm{c}+\mathrm{a}\right\rangle $滑移激活相对分数降低,而图7(d)中$ \left\{110\right\} $滑移系激活量几乎无变化。随着α相晶粒尺寸增加,尽管柱面滑移系激活比例增加,由于锥面$ \left\langle\mathrm{c}+\mathrm{a}\right\rangle $滑移系临界分切应力明显高于柱面滑移系,锥面$ \left\langle\mathrm{c}+\mathrm{a}\right\rangle $滑移系相对分数下降会导致塑性阶段应力值降低。

2.3 β相晶粒尺寸的影响

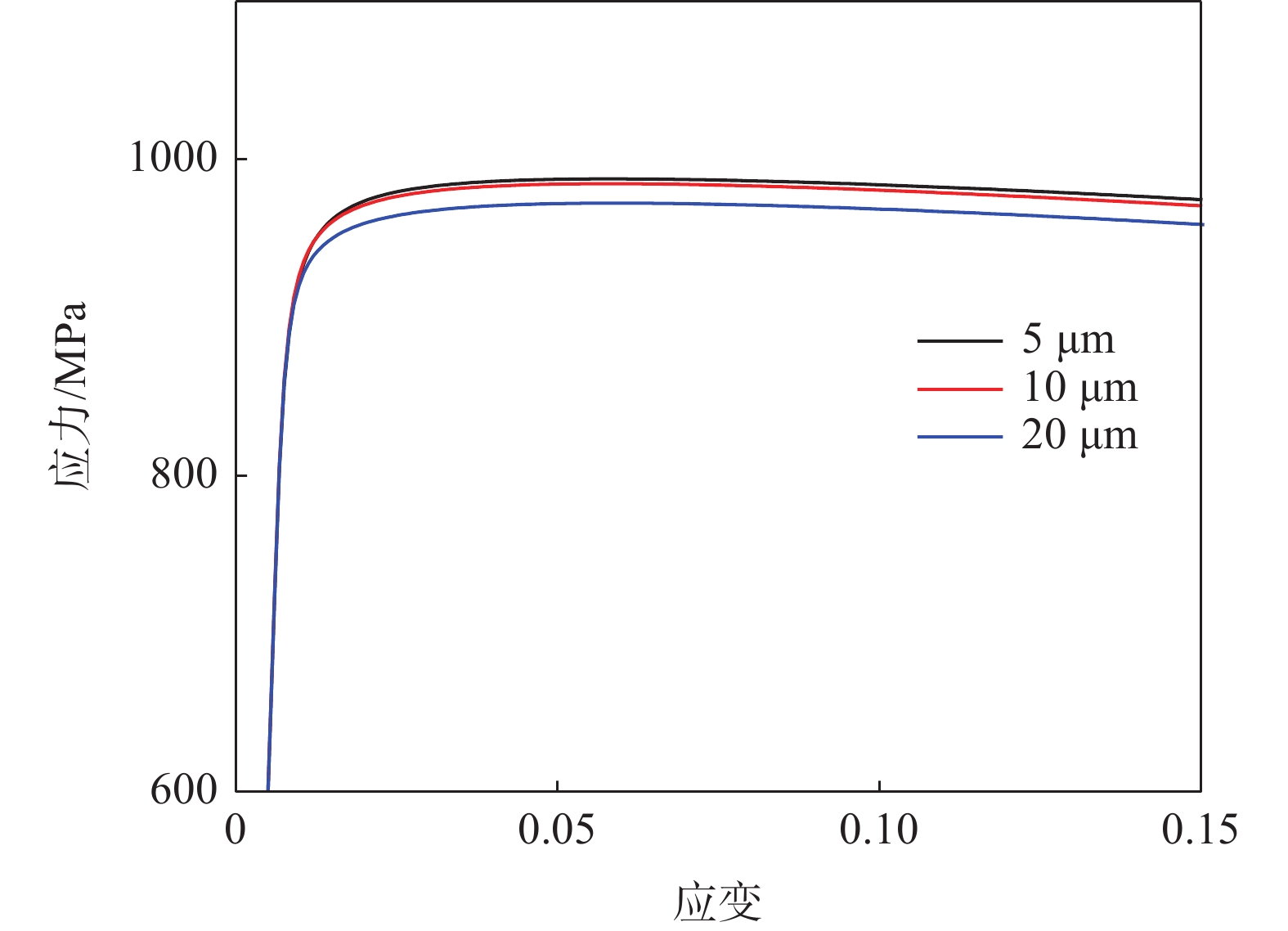

图8给出了β相晶粒尺寸为5、10 、20 μm时的拉伸应力应变曲线。从图8可以看出,随着β相晶粒尺寸增加,应力应变曲线下降。

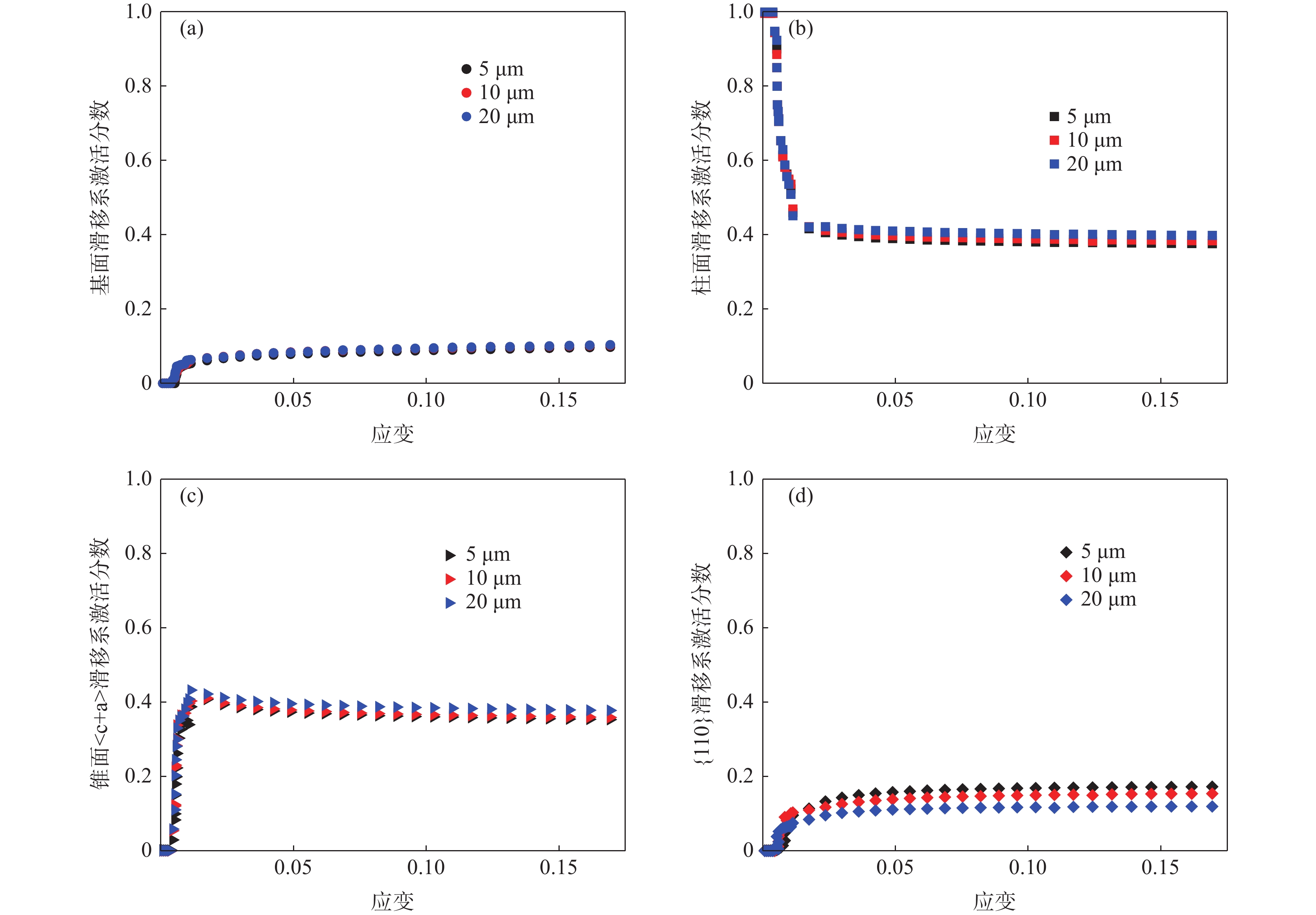

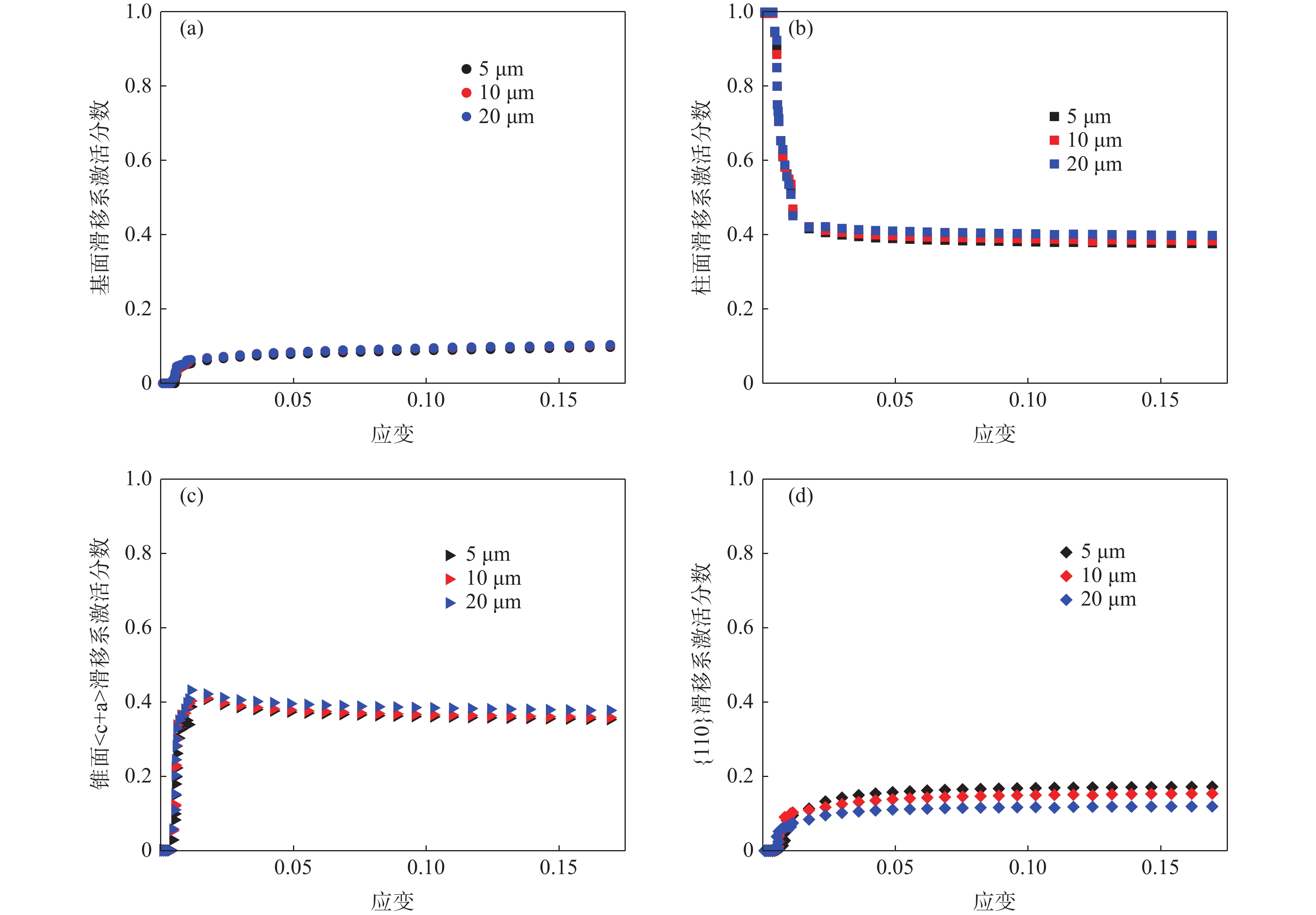

图9给出了β相变体晶粒尺寸为5、10、20 μm时拉伸变形中基面、柱面、锥面$ \left\langle\mathrm{c}+\mathrm{a}\right\rangle $和$ \left\{110\right\} $滑移系的激活贡献比例。初始变形主要由柱面滑移主导,2%应变后锥面$ \left\langle\mathrm{c}+\mathrm{a}\right\rangle $滑移系相对分数接近0.4,基面滑移系对变形整体贡献比例最低。随着β相晶粒尺寸的增大,基面、柱面和锥面$ \left\langle\mathrm{c}+\mathrm{a}\right\rangle $滑移系的相对分数变化不大,而$ \left\{110\right\} $滑移系相对贡献呈明显下降趋势。因此,随β相晶粒尺寸的增加,塑性阶段应力的降低与β相中$ \left\{110\right\} $滑移系激活相对分数下降有关。

2.4 α及β相晶粒尺寸的影响

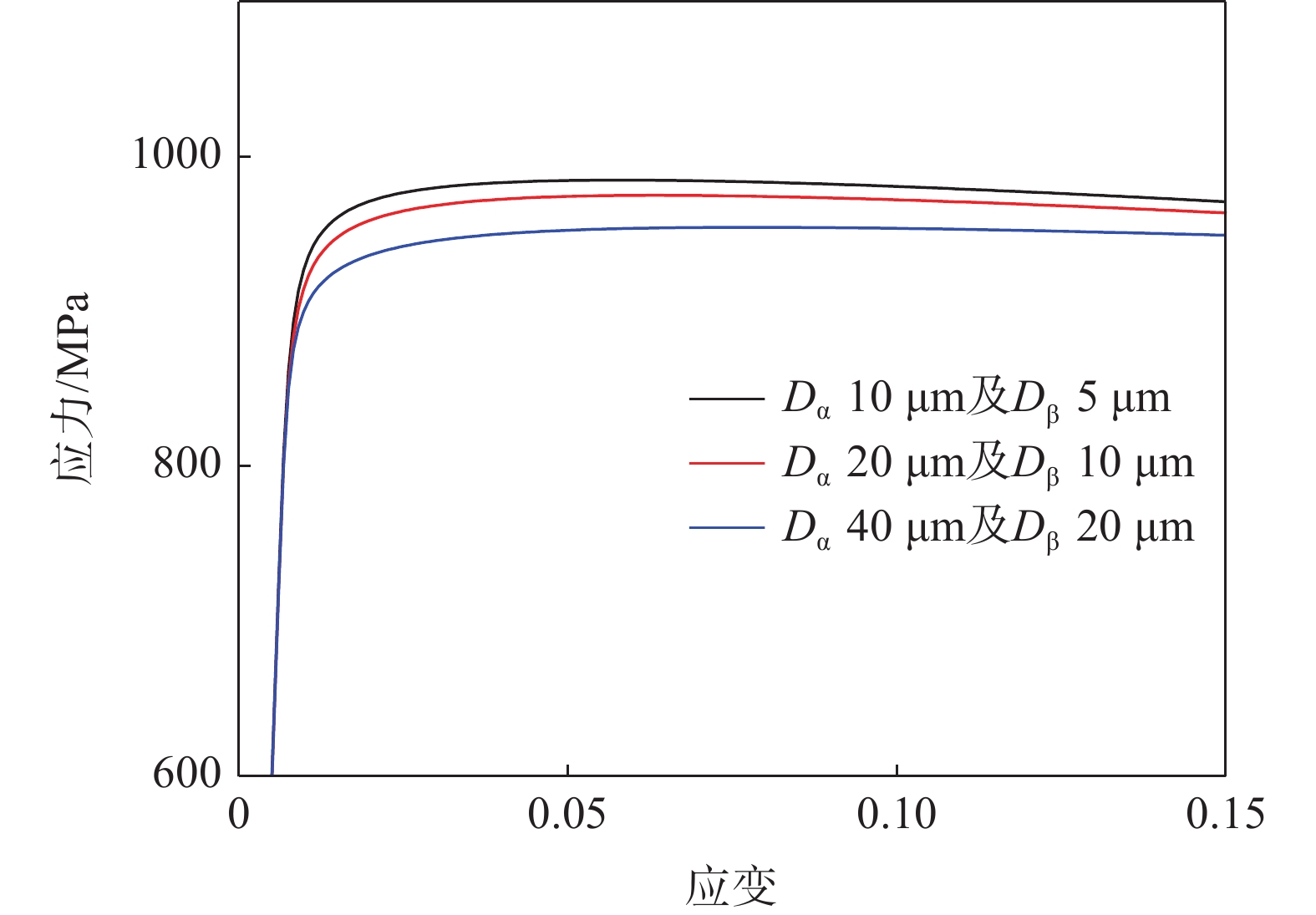

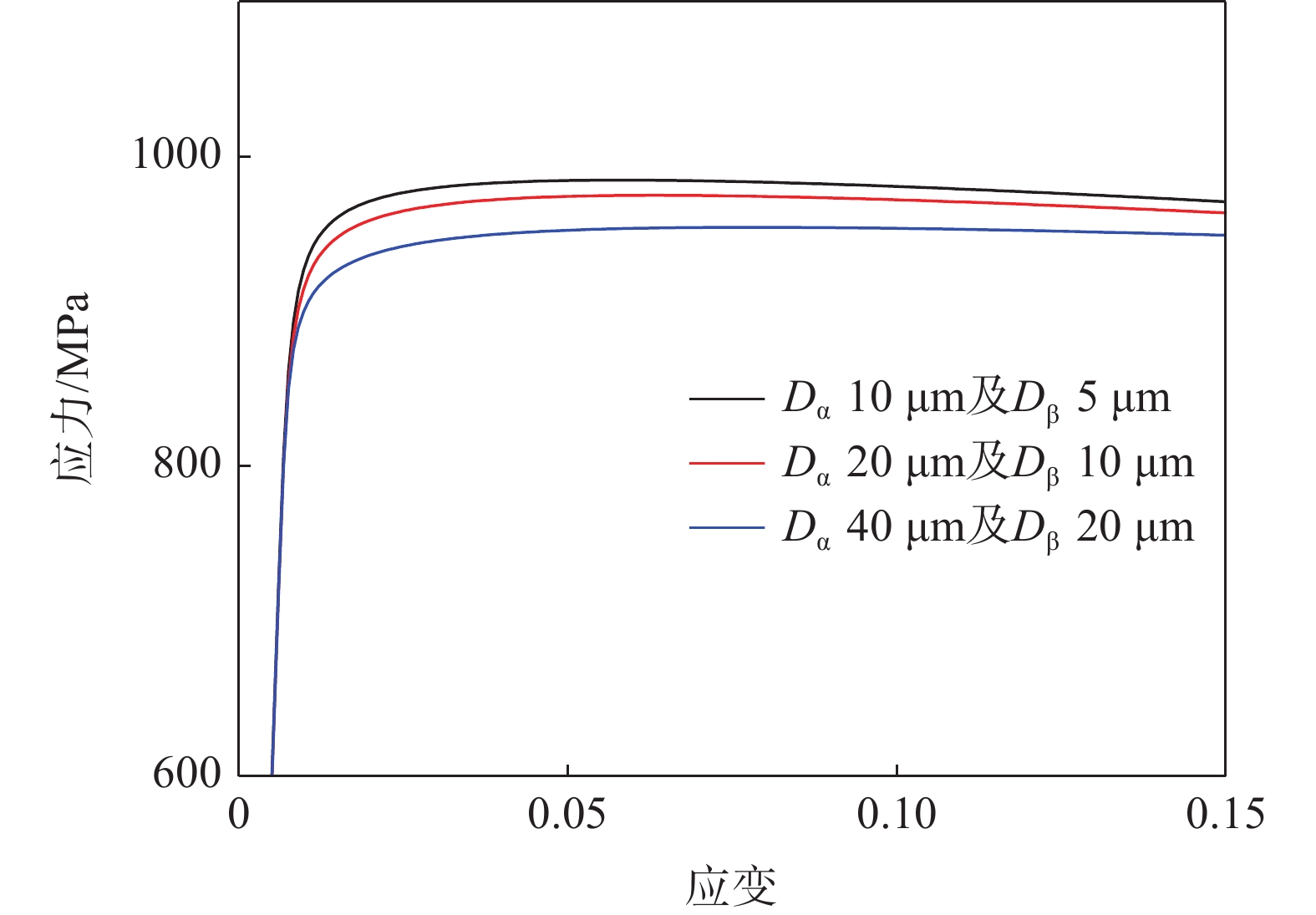

图10给出了α相晶粒尺寸为10 μm及β晶粒尺寸为5 μm、α相晶粒尺寸为20 μm及β晶粒尺寸为10 μm、α相晶粒尺寸为40 μm及β晶粒尺寸为20 μm时的应力应变曲线,为方便表达,使用$ {D}_{\alpha } $和$ {D}_{\beta } $表示两相晶粒尺寸。从中可以看出,同时增大α及β相晶粒尺寸后,应力应变曲线显著下降。与图6和图8相对比,同时增大α和β相晶粒尺寸导致的应力下降值略高于仅增大单相晶粒尺寸。

图11给出了$ D{_{\alpha}} $为10 μm及$ D{_{\beta}} $为5 μm、$ {D}_{\alpha } $为20 μm及$ {D}_{\beta } $为10 μm、$ {D}_{\alpha } $为40 μm及$ {D}_{\beta } $为20 μm时拉伸变形过程中各滑移系激活相对分数。初始变形依然由柱面滑移系主导,2%应变后锥面$ \left\langle\mathrm{c}+\mathrm{a\mathrm{ }}\right\rangle $滑移系对变形的贡献比例增加,逐渐接近于柱面滑移系。同时增大α及β相晶粒尺寸时,主要影响柱面滑移系和$ \left\{110\right\} $滑移系的激活贡献。图12为不同α及β晶粒尺寸下拉伸模拟得到的应力应变云图、晶粒分布结果。从中可以看出,同时增加α相和β相晶粒尺寸,会使得相同模型尺寸下,α/β相晶粒和α/β相界面数量急剧下降,界面对位错滑移的阻碍作用下降,应力应变集中现象变得不明显,从而导致模型整体的应力应变曲线下降更显著。

3. 结论

研究了不同α/β相体积分数及晶粒尺寸大小对塑性变形行为和力学性能的影响,揭示了不同组织特征影响下Ti-6Al-4V钛合金拉伸变形机制,通过滑移相对分数定量化评估不同滑移系对变形的贡献,主要结论如下:

1) Ti-6Al-4V钛合金拉伸变形过程中应力应变分布不均匀,应力集中在β相变体晶粒及晶界处,应变集中在α相晶粒附近。随着β相含量升高,应力集中区域更多,三叉晶界处越易发生应变集中,β相$ \left\{110\right\} $滑移系对变形贡献大幅提高,而α相内滑移系激活比例下降。

2) 随着α相、β相或两相晶粒尺寸同时增大,会造成塑性变形阶段的应力应变曲线有不同程度下降,且初始变形都主要由柱面滑移系主导,2%应变后锥面$ \left\langle\mathrm{c}+\mathrm{a}\right\rangle $滑移系激活相对分数接近柱面滑移系。

3) 随着α相晶粒尺寸增大,锥面$ \left\langle{\mathrm{c}+\mathrm{a}}\right\rangle $滑移系活性下降会导致塑性阶段应力值降低。随着β相晶粒尺寸增大,塑性阶段应力的降低与β相中$ \left\{110\right\} $滑移系活性下降有关。同时增大α及β相晶粒尺寸时,主要会影响柱面滑移系和$ \left\{110\right\} $滑移系的相对分数,α和β相界面数量的显著下降导致应力下降更明显。

-

滑移系 $ {\tau }_{0}/\mathrm{M}\mathrm{P}\mathrm{a} $ m $ {\dot{\gamma }}_{0}/{\mathrm{s}}^{-1} $ $ {h}_{0}/\mathrm{M}\mathrm{P}\mathrm{a} $ $ a $ 基面$ \left\langle\mathrm{a}\right\rangle $ 390 0.01 1.0 190 50 柱面$ \left\langle\mathrm{a}\right\rangle $ 390 0.01 1.0 190 50 锥面$ \left\langle\mathrm{c}+\mathrm{a}\right\rangle $ 663 0.01 1.0 190 50 β$ \left\{110\right\}\left\langle{111}\right\rangle $ 390 0.01 1.0 190 50 -

[1] Chen Wei, Liu Yunxi, Li Zhiqiang. Research status and development trends of high strength β-titanium alloy[J]. Journal of Aeronautical Materials, 2020,40(3):63-76. (陈玮, 刘运玺, 李志强. 高强β钛合金的研究现状与发展趋势[J]. 航空材料学报, 2020,40(3):63-76. doi: 10.11868/j.issn.1005-5053.2020.000071Chen Wei, Liu Yunxi, Li Zhiqiang. Research status and development trends of high strength β-titanium alloy[J]. Journal of Aeronautical Materials, 2020, 40(3): 63-76. doi: 10.11868/j.issn.1005-5053.2020.000071 [2] Liu Yuzhou, Duan Xiaohui, Yang Yaming, et al. Effect of different microstructure types on mechanical properties of TC11 Ti-alloy[J]. Forging and Metalforming, 2023(15):59-61. (刘宇舟, 段晓辉, 杨亚明, 等. 不同显微组织类型对TC11钛合金饼材力学性能的影响[J]. 锻造与冲压, 2023(15):59-61.Liu Yuzhou, Duan Xiaohui, Yang Yaming, et al. Effect of different microstructure types on mechanical properties of TC11 Ti-alloy[J]. Forging and Metalforming, 2023(15): 59-61. [3] Moore J A, Barton N R, Florando J, et al. Crystal plasticity modeling of β phase deformation in Ti-6Al-4V[J]. Modelling and Simulation in Materials Science Engineering, 2017,25(7):075007. doi: 10.1088/1361-651X/aa841c [4] Li Jinyuan, Zhang Zhi, Hou Peng, et al. Effect of heat treatment process on the structure and properties of large TC4 titanium alloy bar[J]. Special Steel Technology, 2018,24(1):22-24, 29 (李进元, 张智, 侯鹏, 等. 热处理工艺对TC4钛合金大规格棒材组织及性能的影响[J]. 特钢技术, 2018,24(1):22-24, 29.Li Jinyuan, Zhang Zhi, Hou Peng, et al. Effect of heat treatment process on the structure and properties of large TC4 titanium alloy bar[J]. Special Steel Technology, 2018, 24(1): 22-24, 29 [5] Gao Yuhao, Zhang Xianfeng, Liu Xilin, et al. The fatigue contrast test on TC4ELI titanium alloy secondary annealed[J]. Development and Application of Material, 2018,33(5):20-27. (高宇昊, 张先锋, 刘希林, 等. TC4ELI钛合金二次退火后的疲劳对比试验[J]. 材料开发与应用, 2018,33(5):20-27.Gao Yuhao, Zhang Xianfeng, Liu Xilin, et al. The fatigue contrast test on TC4ELI titanium alloy secondary annealed[J]. Development and Application of Material, 2018, 33(5): 20-27. [6] Lei Wenguang, Mao Xiaonan, Lu Yafeng. Effects of heat treatment process on microstructure and mechanical properties of TC4-DT titanium alloy plate[J]. Heat Treatment of Metals, 2012,37(9):102-105. (雷文光, 毛小南, 卢亚锋. 热处理工艺对TC4-DT钛合金厚板组织和性能的影响[J]. 金属热处理, 2012,37(9):102-105.Lei Wenguang, Mao Xiaonan, Lu Yafeng. Effects of heat treatment process on microstructure and mechanical properties of TC4-DT titanium alloy plate[J]. Heat Treatment of Metals, 2012, 37(9): 102-105. [7] Zhang Mingyu, Yun Xinbing, Fu Hongwang. Effect of different heat treatment processes on microstructure and properties of TC10 titanium alloy[J]. Journal of Plasticity Engineering, 2021,28(12):237-245. (张明玉, 运新兵, 伏洪旺. 不同热处理工艺对TC10钛合金组织及性能的影响[J]. 塑性工程学报, 2021,28(12):237-245. doi: 10.3969/j.issn.1007-2012.2021.12.030Zhang Mingyu, Yun Xinbing, Fu Hongwang. Effect of different heat treatment processes on microstructure and properties of TC10 titanium alloy[J]. Journal of Plasticity Engineering, 2021, 28(12): 237-245. doi: 10.3969/j.issn.1007-2012.2021.12.030 [8] Qi Yunlian, Du Yu, Liu Wei, et al. Study on microstructure and properties of high aluminum dual phase steel 980DH with high formability[J]. Titanium Industry Progress, 2011,28(5):31-33. (戚运莲, 杜宇, 刘伟, 等. 热处理温度对TC10钛合金棒材组织与性能的影响[J]. 钛工业进展, 2011,28(5):31-33. doi: 10.3969/j.issn.1009-9964.2011.05.008Qi Yunlian, Du Yu, Liu Wei, et al. Study on microstructure and properties of high aluminum dual phase steel 980DH with high formability[J]. Titanium Industry Progress, 2011, 28(5): 31-33. doi: 10.3969/j.issn.1009-9964.2011.05.008 [9] Yun Pengfei, Yang Pei, Liu Dazhe, et al. Effects of heat treatment process on microstructure and mechanical properties of TC11 titanium alloy forging[J]. Hot Working Technology, 2018,47(12):210-212. (贠鹏飞, 杨佩, 刘大喆, 等. 热处理工艺对TC11锻件显微组织和力学性能的影响[J]. 热加工工艺, 2018,47(12):210-212.Yun Pengfei, Yang Pei, Liu Dazhe, et al. Effects of heat treatment process on microstructure and mechanical properties of TC11 titanium alloy forging[J]. Hot Working Technology, 2018, 47(12): 210-212. [10] Zhai Dajun, Shui Yue, Yuan Man, et al. Effects of content and morphology of α phase on microstructure and mechanical properties of TC4 allo[J]. Heat Treatment of Metals, 2019,44(10):129-134. (翟大军, 税玥, 袁满, 等. α相含量及形态对TC4钛合金组织和力学性能的影响[J]. 金属热处理, 2019,44(10):129-134.Zhai Dajun, Shui Yue, Yuan Man, et al. Effects of content and morphology of α phase on microstructure and mechanical properties of TC4 allo[J]. Heat Treatment of Metals, 2019, 44(10): 129-134. [11] Mao Jianghong, Yang Xiaokang, Luo Binli, et al. Effect of heat treatment temperature on microstructure and mechanical properties of TC4ELI alloy[J]. Heat Treatment of Metals, 2020,45(2):166-174. (毛江虹, 杨晓康, 罗斌莉, 等. 热处理温度对TC4ELI合金组织与性能的影响[J]. 金属热处理, 2020,45(2):166-174.Mao Jianghong, Yang Xiaokang, Luo Binli, et al. Effect of heat treatment temperature on microstructure and mechanical properties of TC4ELI alloy[J]. Heat Treatment of Metals, 2020, 45(2): 166-174. [12] Nayan N, Singh G, Prabhu T A, et al. Cryogenic mechanical properties of warm multi-pass caliber-rolled fine-grained titanium alloys: Ti-6Al-4V (normal and ELI grades) and VT14[J]. Metallurgical and Materials Transactions A, 2018,49(1):128-146. doi: 10.1007/s11661-017-4417-y [13] Tong Xiaole, Zhang Mingyu, Yu Chengquan, et al. Microstructure and properties of TC4 titanium alloy sheets with different rolling thicknesses[J]. Forging and Stamping Technology, 2022,47(6):153-159. (同晓乐, 张明玉, 于成泉, 等. 不同轧制厚度TC4钛合金板材的组织与性能[J]. 锻压技术, 2022,47(6):153-159.Tong Xiaole, Zhang Mingyu, Yu Chengquan, et al. Microstructure and properties of TC4 titanium alloy sheets with different rolling thicknesses[J]. Forging and Stamping Technology, 2022, 47(6): 153-159. [14] Dong Xiaofeng, Zhang Mingyu, Zhou Jiangshan, et al. Effects of heat treatment on microstructure and mechanical properties of TC4 ELI titanium alloy[J]. Hot Working Technology, 2022,51(24):142-146. (董晓锋, 张明玉, 周江山, 等. 热处理对TC4 ELI钛合金显微组织与力学性能的影响[J]. 热加工工艺, 2022,51(24):142-146.Dong Xiaofeng, Zhang Mingyu, Zhou Jiangshan, et al. Effects of heat treatment on microstructure and mechanical properties of TC4 ELI titanium alloy[J]. Hot Working Technology, 2022, 51(24): 142-146. [15] Guo Ping, Zhao Yongqing, Zeng Weidong, et al. The effect of microstructure on the mechanical properties of TC4-DT titanium alloys[J]. Materials Science and Engineering A, 2013,563:106-111. doi: 10.1016/j.msea.2012.11.033 [16] Wang Wenjie. Effect of quasi-beta heat treatment on microstructure and mechanical properties of TC4-DT titanium alloy[J]. Titanium Industry Progress, 2016,33(1):23-27. (王文杰. 准β热处理工艺对TC4-DT钛合金组织和性能的影响[J]. 钛工业进展, 2016,33(1):23-27.Wang Wenjie. Effect of quasi-beta heat treatment on microstructure and mechanical properties of TC4-DT titanium alloy[J]. Titanium Industry Progress, 2016, 33(1): 23-27. [17] Li Xuexiong, Xu Dongsheng, Yang Rui, et al. CPFEM study of high temperature tensile behavior of duplex titanium alloy[J]. Chinese Journal of Materials Research, 2019,33(4):241-253. (李学雄, 徐东生, 杨锐, 等. 钛合金双态组织高温拉伸行为的晶体塑性有限元研究[J]. 材料研究学报, 2019,33(4):241-253. doi: 10.11901/1005.3093.2018.514Li Xuexiong, Xu Dongsheng, Yang Rui, et al. CPFEM study of high temperature tensile behavior of duplex titanium alloy[J]. Chinese Journal of Materials Research, 2019, 33(4): 241-253. doi: 10.11901/1005.3093.2018.514 [18] Yaghoobi M, Ganesan S, Sundar S, et al. PRISMS-plasticity: An open-source crystal plasticity finite element software[J]. Computational Materials Science, 2019,169:109078. doi: 10.1016/j.commatsci.2019.109078 [19] Asaro R J, Rice J R. Strain localization in ductile single crystals[J]. Journal of the Mechanics and Physics of Solids, 1977,25(5):309-338. doi: 10.1016/0022-5096(77)90001-1 [20] Kalidindi S R. Incorporation of deformation twinning in crystal plasticity models[J]. Journal of the Mechanics and Physics of Solids, 1998,46(2):267-290. doi: 10.1016/S0022-5096(97)00051-3 [21] Kasemer M, Quey R, Dawson P. The influence of mechanical constraints introduced by β annealed microstructures on the yield strength and ductility of Ti-6Al-4V[J]. Journal of the Mechanics and Physics of Solids, 2017, 103: 179-198. [22] Groeber M A, Jackson M A. DREAM 3D: A digital representation environment for the analysis of microstructure in 3D[J]. Integrating Materials and Manufacturing Innovation, 2014,3(1):56-72. doi: 10.1186/2193-9772-3-5 [23] Wan Mingpan, Wu Yujiao, Sun Jie, et al. Effect of solution temperature on microstructure and mechanical properties of TC4ELI titanium alloy[J]. Material and Heat Treatment, 2012,41(20):145-147. (万明攀, 伍玉娇, 孙捷, 等. 固溶温度对TC4ELI钛合金组织和性能的影响[J]. 热处理技术, 2012,41(20):145-147.Wan Mingpan, Wu Yujiao, Sun Jie, et al. Effect of solution temperature on microstructure and mechanical properties of TC4ELI titanium alloy[J]. Material and Heat Treatment, 2012, 41(20): 145-147. [24] Mayeur J R, McDowell D L. A three-dimensional crystal plasticity model for duplex Ti-6Al-4V[J]. International Journal of Plasticity, 2007,23:1457-1485. doi: 10.1016/j.ijplas.2006.11.006 [25] Li Xuexiong, Xu Dongsheng, Yang Rui. Crystal plasticity finite element method investigation of the high temperature deformation consistency in dual-phase titanium alloy[J]. Acta Metallurgica Sinica, 2019,55(7):928-938. (李学雄, 徐东生, 杨锐. 双相钛合金高温变形协调性的CPFEM研究[J]. 金属学报, 2019,55(7):928-938. doi: 10.11900/0412.1961.2018.00380Li Xuexiong, Xu Dongsheng, Yang Rui. Crystal plasticity finite element method investigation of the high temperature deformation consistency in dual-phase titanium alloy[J]. Acta Metallurgica Sinica, 2019, 55(7): 928-938. doi: 10.11900/0412.1961.2018.00380 [26] Ma Mingtu, Yang Hongya, Wu Emei, et al. Research progress of the cause for orange peel of aluminum alloy sheet during tensile deformation[J]. Strategic Study of CAE, 2014,16(1):4-13. (马鸣图, 杨红亚, 吴娥梅, 等. 铝合金板材拉伸变形时橘皮成因的研究进展[J]. 中国工程科学, 2014,16(1):4-13. doi: 10.3969/j.issn.1009-1742.2014.01.001Ma Mingtu, Yang Hongya, Wu Emei, et al. Research progress of the cause for orange peel of aluminum alloy sheet during tensile deformation[J]. Strategic Study of CAE, 2014, 16(1): 4-13. doi: 10.3969/j.issn.1009-1742.2014.01.001 [27] Tang Bin, Xie Shao, Liu Yi, et al. Crystal plasticity finite element study of incompatible deformation behavior in two phase microstructure in near β titanium alloy[J]. Rare Metal Materials and Engineering, 2015,44(3):532-537. (唐斌, 谢韶, 刘毅, 等. 近β钛合金中两相组织不协调变形行为的晶体塑性有限元研究[J]. 稀有金属材料与工程, 2015,44(3):532-537. doi: 10.1016/S1875-5372(15)30033-3Tang Bin, Xie Shao, Liu Yi, et al. Crystal plasticity finite element study of incompatible deformation behavior in two phase microstructure in near β titanium alloy[J]. Rare Metal Materials and Engineering, 2015, 44(3): 532-537. doi: 10.1016/S1875-5372(15)30033-3 -

下载:

下载:

下载:

下载: