Research progress and prospect of comprehensive utilization technology of vanadium extraction tailings from vanadium-titanium magnetite

-

摘要: 钒钛磁铁矿提钒尾渣是转炉钒渣提钒的副产品,因含有多种有价元素而极具回收价值。但因目前缺乏有效的利用工艺而大量填埋或堆积,造成资源浪费和环境污染。根据钒渣提钒工艺和化学成分对钒钛磁铁矿提钒尾渣进行了分类,阐述了采用氧化法(包括氧化焙烧、电场耦合H2O2+CaF2浸出法)、直接浸出法(包括酸浸和亚熔盐法)、还原法(包括熔融还原和直接还原)对提钒尾渣中有价元素提取的原理和优缺点,以及作为功能材料用于制备蓄热材料的研究现状。认为酸浸工艺是当前研究的热点,但熔融还原能够同时回收铁、钒、铬、钛,具有综合回收率高、工艺流程短的特点,应用前景较广。指出了当前综合利用工艺存在的问题,提出了火法冶金+湿法冶金+物理分离的耦合技术以及作为热能蓄热材料使用的研究方向,并应加强终渣、废液排放的监管力度和毒性检测的研究,为钒钛磁铁矿提钒尾渣的高值化、无害化综合利用提供参考。Abstract: Vanadium extraction tailings of vanadium-titanium magnetite, as a by-product of vanadium extraction from converter vanadium slag, have great recovery value because of containing many valuable elements. However, due to the lack of effective utilization technology, they are currently being landfilled or stockpiled in large quantities, leading to resource waste and environmental pollution, resulting in waste of resources and environmental pollution. In this paper vanadium extraction tailings of vanadium-titanium magnetite had been classified based on vanadium extraction technology from vanadium slag and their chemical composition. The principle, advantages and disadvantages of extracting valuable elements from vanadium extraction tailings by oxidation method (including oxidation roasting, electric field coupled leaching of H2O2 + CaF2), direct leaching (including acid leaching and submolten salt process) and reduction method (including melting reduction and direct reduction) were described. The current research status of using them as functional materials for preparing thermal storage materials had been discussed. Acid leaching process is considered to be a hot topic of current research. However, smelting reduction can simultaneously recover iron, vanadium, chromium and titanium, featuring a high comprehensive recovery rate and short process, and therefore has a broader application prospect. Then he problems existing in the current comprehensive utilization process were pointed out. And the coupling technology of pyrometallurgy + hydrometallurgy + physical separation was proposed, as well as research directions for their use as solar thermal storage materials. In addition, the supervision of final residue and waste liquid discharge and the research on toxicity detection should be strengthened. It is hoped these introductions can provide reference for the development direction of high value and harmless comprehensive utilization of vanadium extraction tailings from vanadium titanium magnetite.

-

0. 引言

钒钛磁铁矿是一种以钒、钛、铁为主的多元素共生矿物[1],是钒的主要赋存矿物,目前全世界每年约有88.6%的钒产自于钒钛磁铁矿[2]。钒钛磁铁矿首先在高炉冶炼,得到含钒铁水,然后在转炉中吹氧得到钒渣,转炉钒渣是中国钒生产的主要原料[3−5]。提钒尾渣是转炉钒渣提钒的副产品,即首先对转炉钒渣进行钠化或钙化焙烧,再经过水浸或酸浸提钒后得到的固体废物[6−7],主要含有Fe、Si、Ti、Mn、Al、Ca、Mg、V、Cr、Na等元素[8]。

美国地质调查局的最新数据表明,世界上一半以上的钒(约4.2万t)是由中国供应的[2]。每生产一吨五氧化二钒,会产生10 t提钒尾渣。目前,中国钒企业每年有60万t的提钒尾渣排放[9−10]。大量的提钒尾渣逐年被填埋或堆存,不仅浪费有价金属,严重污染周围环境,而且由于溶出的Cr6+和V5+存在于提钒尾渣中,对人体健康危害极大[11]。因此,对提钒尾渣进行无害化综合利用,对减少环境污染、提高经济效益具有重要意义。

笔者首先对提钒尾渣进行了分类,然后综述了金属钒、铬、钛、铁的回收工艺,以及作为功能材料利用制备蓄热材料的研究进展,指出了目前提钒尾渣综合利用存在的问题,并对今后的发展方向进行了展望。

1. 提钒尾渣的表征

1.1 成分及分类

根据钒渣提钒工艺的不同,钒钛磁铁矿提钒尾渣可分为钠化提钒尾渣(即钠化焙烧+水浸提钒产生的尾渣)和钙化提钒尾渣(即钙化焙烧+酸浸提钒产生的尾渣);根据铬含量不同可分为高铬提钒尾渣和普通提钒尾渣,化学成分如表1所示。可以看出,提钒尾渣主要化学成分为Fe2O3、TiO2和SiO2,这三者含量约51%~88%,含少量Al2O3、MnO、MgO、CaO、Na2O、V2O5、Cr2O3等。其中钠化提钒尾渣的Na2O含量较高,为4.23%~7.68%;钙化提钒尾渣的CaO较高,为1.26%~15.91%。高铬型提钒尾渣Cr2O3含量较高,为4.32%~7.60%,普通型提钒尾渣Cr2O3含量为0.33%~1.53%。

表 1 钒钛磁铁矿提钒尾渣主要化学成分及分类Table 1. Main chemical compositions and classification of vanadium extraction tailings from vanadium titanium-magnetite% 分类1 Fe2O3 TiO2 V2O5 SiO2 Al2O3 CaO Na2O Cr2O3 MgO MnO 分类2 参考文献 钠化

提钒

尾渣54.90 17.40 0.28 2.71 2.86 0.57 4.23 0.33 0.53 普通型 [1] 35.10 10.62 3.60 15.06 1.95 1.96 7.68 6.60 7.86 高铬型 [12] 47.14 11.95 1.75 20.41 2.18 1.94 6.87 4.32 2.63 4.87 高铬型 [13] 钙化

提钒

尾渣33.24 7.08 1.20 10.97 1.54 15.91 4.70 2.33 6.45 高铬型 [13] 45.50 14.89 2.65 14.51 3.36 6.74 1.53 2.57 4.88 普通型 [3] 73.78 12.39 0.47 1.58 3.76 1.26 0.01 0.73 0.25 普通型 [14] 31.08 11.00 0.66 16.95 2.17 5.66 7.60 2.79 4.75 高铬型 [15] 值得注意的是,提钒尾渣虽然是经过数次提钒后的副产品,但是其中的钒含量依然不低,为0.28%~3.60%。提钒尾渣中有价元素含量均已达到天然矿石的品位要求,极具综合利用价值。

1.2 有价元素的物相

提钒尾渣中有价元素的物相类型是尾渣有价金属提取的理论依据。因转炉钒渣提钒工艺不同,提钒尾渣的物相组成会有少许差异。国内转炉钒渣主要采用氧化焙烧工艺提钒[16],焙烧时加入碳酸钠、碳酸钙等添加剂。钙化焙烧提钒尾渣的主要物相为二水硫酸钙(CaSO4·2H2O)、假板钛矿(Fe2TiO5)和赤铁矿(Fe2O3),V、Fe、Ti、Cr、Mg和Al共同构成钙辉石相[17];钠化焙烧提钒尾渣的主要物相为赤铁矿(Fe2O3)和假板钛矿(Fe2TiO5),含硅物相主要为锥辉石(NaFeSi2O6)[18]。

由于转炉钒渣中钒主要以钒铁尖晶石(FeO·V2O3)的形式存在,在氧化焙烧过程中发生4FeO·V2O3+4Na2CO3+5O2=2Fe2O3+8NaVO3+4CO2↑反应,因此提钒尾渣中铁主要以赤铁矿相(Fe2O3)形式存在,少量以假板钛矿(Fe2TiO5)相、尖晶石相存在[19]。

提钒尾渣中钒主要以未反应钒铁尖晶石、硅钒酸盐、钒青铜、被硅酸盐相包裹的高价钒的形式存在[19−20]。其中:①钒钛尖晶石由于被硅和钙包裹,使钒未完全氧化,难以生成可溶性的钒酸盐;②钒渣中的钒与硅酸钙、铝酸钙、钠盐添加剂等反应生成玻璃状的不溶性钒化合物而进入提钒尾渣,钒则以三、四、五价态存在;③低价钒被氧化为高价钒后再被熔融的硅酸盐相包裹而进入提钒尾渣中[19];④焙烧添加剂含量不足时,焙烧后的熟料在冷却过程中易形成钒青铜[5, 16](NaV6O15和Na8V24O53),它既不溶于水也不溶于酸。可见,在提钒尾渣中低价钒和高价钒都有可能存在,且可能与硅酸盐相共存或者被包裹,因此应根据具体情况制定不同的提钒工艺。

提钒尾渣中铬与铁结合形成酸不溶固溶体(Fe0.6Cr0.4)2O3[21],该物质是高铬提钒尾渣中FeCr2O4或Cr2O3与Fe2O3结合的产物[22]。提钒尾渣中主要含钛物相为假板钛矿(Fe2TiO5)[1, 23]。

2. 提钒尾渣中有价金属的提取工艺

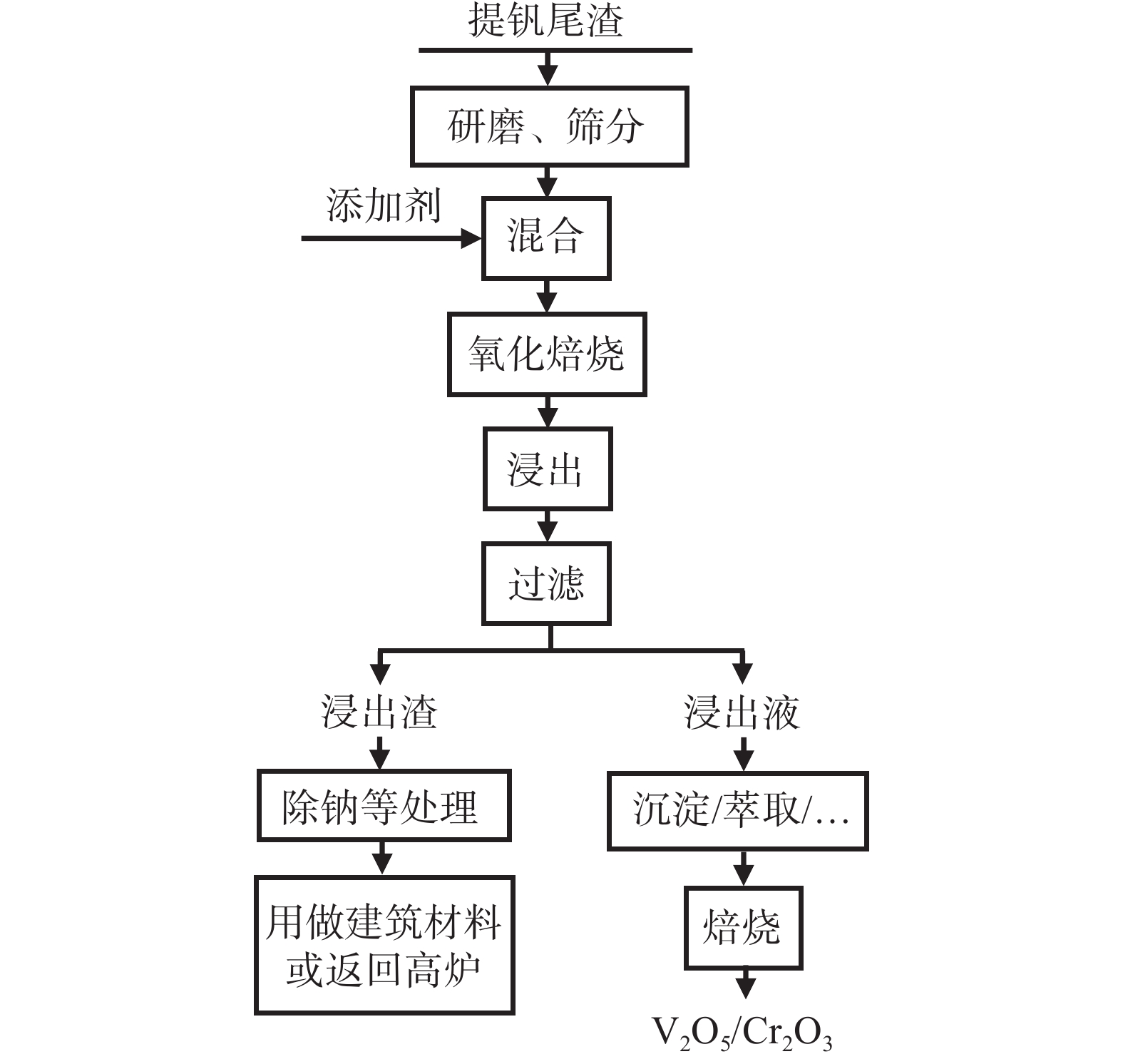

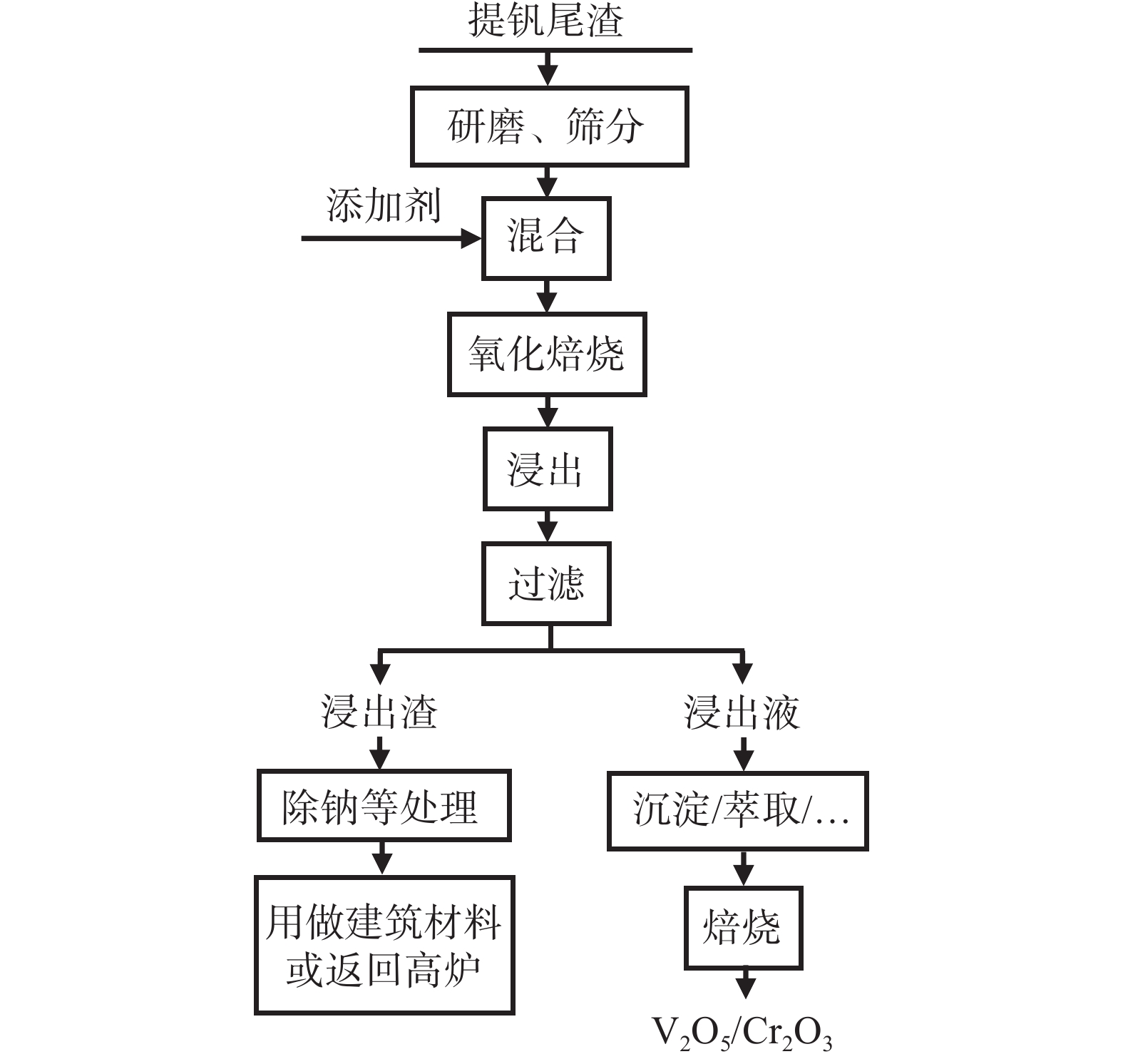

根据提取前后有价金属价态的变化,可分为氧化法、直接浸出法、还原法三大类。其中氧化法和直接浸出法以提取钒和铬为目的,氧化法主要包括氧化焙烧+浸出法和电场耦合H2O2+CaF2浸出法两种;直接浸出法主要有常压酸浸、加压酸浸和亚熔盐法等;还原法能同时回收铁、钛、钒和铬,主要包括熔融还原和直接还原+磁选/熔分。

2.1 氧化法

如前所述,在提钒尾渣中,钒、铬固溶于尖晶石、硅酸盐玻璃相中,所以要高效提取钒、铬,就要破坏尖晶石结构,打破硅酸盐包裹相,使钒、铬从固溶体或包裹相中释放出来,再将低价钒氧化并与添加剂反应生成可溶的钒酸盐或铬酸盐。

2.1.1 氧化焙烧+浸出

氧化焙烧是将提钒尾渣粉碎后制成球团,在氧化气氛下进行高温(800 ~

1100 ℃)[24]焙烧,将低价钒氧化为高价钒。为了提高氧化效果,通常在球团中加入添加剂,如纯碱(NaCO3)、芒硝(Na2SO4)、石灰(CaCO3)等。焙烧过程中添加剂与硅酸盐相反应,生成Na2CaSiO4、Na2Si2O5、Na0.68Fe0.68Si0.32O2等相[25−26];同时钒铁尖晶石(FeO·V2O3)和含铬相((Fe0.6Cr0.4)2O3)与氧和添加剂反应,生成可溶于水或酸/碱的钒酸盐(如NaVO3、Ca(VO3)2等)[13, 27]、铬酸盐(如Na2CrO4)[25],再通过水浸或酸浸/碱浸,获得含钒浸出液和浸出残渣[25]。浸出液中含有硅、铝、方解石、铁和磷等杂质,可采用不同的方法对钒或铬进行提取,如沉淀法、离子交换法和溶剂萃取法。铁、钛等留在浸出残渣中,经过处理后返回高炉或用做建筑材料,工艺流程如图1所示。堵伟桐等[28]将提钒尾渣水洗后,采用钠化焙烧、水浸、铵盐沉钒和煅烧等工艺制备V2O5产品。Na2CO3添加量20%、焙烧时间2 h、焙烧温度850 ℃,此时钒平均浸出率为88.19%。Cheng Jie等[26]以高铬型提钒尾渣为研究对象,在950 ℃下,以n(Na)/n(V + Cr)为6.0的低剂量苏打水焙烧90 min,在60 ℃下,以10.0的液固比进行浸出,浸出时间为40 min,Cr的浸出率可达93.25%;浸出液经Na2S还原、沉淀、煅烧得到Cr2O3产品,总Cr回收率为92.93%。

二次焙烧可以直接利用现有工艺和设备实现提钒尾渣再提钒,但工艺流程长、成本高,冷却过程中无法避免钒青铜的二次生成,钒转化提取效率相对较低,并且铁和钛元素未得到充分利用。

2.1.2 电场耦合H2O2+CaF2浸出

余强[29]提出电场耦合H2O2+CaF2强化提钒技术,以攀钢钙化焙烧提钒尾渣为原料,当浸出温度为80 ℃、浸出时间60 min、水与硫酸的体积比为4∶1、n(V/H2O2)为1∶7、电流密度为

1000 A/m2、CaF2添加量3%时,钒浸出率为71.22%,残钒含量为0.41%。该方法采用电场耦合CaF2来破坏硅酸盐包裹结构,释放出更多的尖晶石到反应溶液中;而电场耦合H2O2能将释放的难溶低价钒氧化到易浸出的高价钒。优点是能耗低,通过使用电场和化学添加剂来优化浸出过程,可以最大限度地降低能耗,从而节省成本。但该方法仍处于实验室阶段,而且工业化存在初始投资高的问题,实施电场和化学添加剂耦合技术可能需要在专用设备和基础设施上进行大量投资,这可能成为小型作业的障碍。

2.2 直接浸出

近年来,对提钒尾渣再次提钒的研究,主要围绕直接浸出工艺开展,例如常压酸浸、加压酸浸、亚熔盐浸出等。这些工艺的特点如表2所示。

表 2 采用直接浸出工艺对提钒尾渣再提钒的研究对比Table 2. Comparison of processes for vanadium re-extraction from vanadium extraction tailings by direct leaching process工艺 钒提取率/% 优点 缺点 常压酸浸 <60 设备简单,处理能力大 钒浸出率较低,酸用量多,腐蚀设备,污染环境 加压酸浸 可达80 工艺流程短,钒浸出率高 对设备要求高,处理能力小 亚熔盐法 可达85 提钒效率高,可以实现钒、铬共同提取 设备投资大,工艺复杂,对环境造成潜在影响 2.2.1 酸浸法

由表2可以看出,常压酸浸法钒提取率相对较低,这可能是由于提钒尾渣中有一部分钒以不固定、可溶的形式存在,在低温条件下容易以VO2+和VO2+的形式浸出,而其余的钒则停留在钙辉石相中,或像钛铁尖晶石一样被硫酸钙相包裹,该包裹相具有刚性结构,即使在高酸度(pH < 0)条件下,仅采用常压酸浸也难以破坏[17]。

加压酸浸是在高压环境中使用酸性溶液,如盐酸(HCl)或硫酸(H2SO4),对含有价金属的矿石进行浸泡,通常用于提取金属或矿石中的有价金属[30]。反应发生在高压环境下有助于提高酸浸效率[31]。

Zhang Ying等[17]以攀枝花某炼钢企业钙化提钒尾渣为研究对象,将其粉碎至粒径小于75 μm,以硫酸为浸出剂进行了常压浸出和加压浸出的对比研究。通过优化浸出工艺,常压浸出法可选择性提取最高为43.5%的可溶性钒;当浸出温度为140 ℃,反应釜内压力达到0.20 ~ 0.25 MPa时,强化加压浸出工艺的钒提取率约为92%。在加压浸出作用下,钙辉石、钛铁尖晶石和二水合硫酸钙的包裹结构被缓慢破坏,大部分V4+和V5+与Fe、Mn、Ti、Cr、Mg一起被酸浸出,微量钒以V2O3的形式残留在残渣中。加压酸浸法能够减少硫酸用量,但对设备要求较高,且处理能力小。

2.2.2 亚熔盐法

亚熔盐是一种特殊类型的熔体,它是由碱金属盐组成的高浓水溶液,可高效分解难溶性矿物质,被广泛应用于天然矿物的活化分解和提取矿物中的高附加值金属元素[32]。近年来,亚熔盐技术被用于钒钛磁铁矿的钒渣和提钒尾渣中钒的提取。李兰杰等[4]对提钒尾渣采用亚熔盐技术提钒,当渣碱比为1:4、反应时间为5 h、碱浓度为80%时,在不通氧气的条件下,渣中的钒含量(以V2O5计)由1.75%降低至0.2%以下,提钒效率为85%;铁含量(以Fe2O3计)富集至60%以上。

在亚熔盐中,OH-浓度较高,因此它富含高化学活性和高离子活度的氧负离子。亚熔盐介质分解了包裹尖晶石的硅酸盐玻璃体,在溶出硅的同时,释放了高价可溶性钒酸盐。反应方程式如下:

$$ \mathrm{Ca}_2 \mathrm{SiO}_4+2 \mathrm{MeOH}+\mathrm{H}_2 \mathrm{O} \rightarrow 2 \mathrm{Ca}(\mathrm{OH})_2+\mathrm{Me}_2 \mathrm{SiO}_3 $$ (1) $$ \mathrm{Ca}_3 \mathrm{SiO}_5+2 \mathrm{MeOH}+2 \mathrm{H}_2 \mathrm{O} \rightarrow 3 \mathrm{Ca}(\mathrm{OH})_2+\mathrm{Me}_2 \mathrm{SiO}_3 $$ (2) $$ \mathrm{Ca}_2 \mathrm{Fe}_2 \mathrm{O}_5 + 4 \mathrm{MeOH} \rightarrow 2 \mathrm{Ca}(\mathrm{OH})_2 + \mathrm{Me}_4 \mathrm{Fe}_2 \mathrm{O}_5 $$ (3) 亚熔盐法主要针对提钒尾渣中四价和五价钒,这类钒都是碱熔性的,所以亚熔盐法提钒过程不需要氧化性气氛即可进行,

亚熔盐法提钒效率高,反应物易于分离纯化,且减少了有害废物的产生和处理,对环境的污染较小。但工业化仍然存在以下困难:①初始投资高,地下盐提取所需的设备和基础设施的安装成本很高,这使得小型作业在经济上不太可行;②工艺复杂,熔融盐萃取钒的工艺涉及多个步骤,需要仔细控制各种参数,与其他提取方法相比更为复杂;③环境影响:虽然熔融盐萃取通常被认为比传统方法更环保,但该过程中使用的化学品仍可能对环境造成潜在影响。

2.3 还原法

还原法的原理是用还原剂在高温下将提钒尾渣中含铁矿物Fe2O3和Fe2TiO5还原为金属铁,同时钒、铬等金属也被还原,钛则进入渣中回收,反应机理如下式(4)~(7)所示[1,3,15, 33]。

$$ \mathrm{Fe}_2 \mathrm{O}_3+3 \mathrm{C}=2 \mathrm{Fe}+3 \mathrm{CO} $$ (4) $$ \mathrm{Fe}_2 \mathrm{TiO}_3+\mathrm{C}=2 \mathrm{Fe}+\mathrm{TiO}_2+\mathrm{CO} $$ (5) $$ \mathrm{FeCr}_2 \mathrm{O}_4+4 \mathrm{C}=\mathrm{Fe}+2 \mathrm{Cr}+4 \mathrm{CO} $$ (6) $$ \mathrm{FeV}_2\mathrm{O}_4+4\mathrm{C}=\mathrm{Fe}+2\mathrm{V}+4\mathrm{CO} $$ (7) 典型的研究结论如表3所示。

表 3 还原法回收提钒尾渣中有价元素的研究对比Table 3. Comparison of processes on recovery of valuable elements in vanadium extraction tailings by reduction method工艺名称 工艺参数 Fe回收率/% 其它有价金属的处置 V、Cr回收率/% 参考文献 熔融还原 ① >90 V、Cr被还原进入铁水 >90 [33] 提钒尾渣与铬铁矿协同还原熔分 ② 93.49 Cr被还原进入铁水 95.18 [15] 高温直接还原+磁选 ③ 99 V、Cr被还原进入铁水 V:90 Cr:95 [3] CaCO3还原焙烧+磁选 ④ 91.05 TiO2含量为41.75%的含钛渣 [14] 注:①采用电弧炉熔融还原,配碳量为12%~14%,碱度为1.0~1.1;②铬铁矿与提钒尾渣配比为5∶1、SiO2添加量为5.08%、配碳量为20.54%、还原熔分时间为35 min;③ 1400 ℃焙烧+磁选;④还原温度1250 ℃、还原时间2 h、还原剂用量为尾渣质量的20%、CaCO3加入量为5% 。熔融还原或直接还原工艺不但能还原回收铁,同时能回收钒和铬,并且回收率均能达到90%以上,但所需还原温度较高。理论上在

1128 ℃以上的铁液中,几乎所有的钒铬都能溶解。但在实际生产中,为了使钒铬作为铁合金回收利用,还原温度应远远高于理论温度,否则钒、铬会集中在炉渣中,不利于此类炉渣的应用或清洁处理[3]。而且相比直接还原+磁选,熔融还原工艺流程短,还原时间短,具有较好的应用前景。但该工艺将钒和铬都还原进入铁水,存在钒、铬分离的问题,这给钒和铬的单独利用造成了困难。

3. 提钒尾渣作为功能材料回收利用

提钒尾渣作为功能材料利用通常用来制造钒钛黑瓷、远红外涂料、建筑材料等[34],但近年来相关研究主要集中在制备蓄热材料,如显热蓄热材料、相变蓄热材料。

热能蓄热技术是重要的储能技术之一,在实现可再生能源的整合、提高能源效率和增强能源系统的弹性方面发挥着至关重要的作用。蓄热方式主要有显热蓄热、潜热蓄热或相变蓄热以及热化学蓄热。显热蓄热是利用蓄热材料本身在温度升高和降低过程中发生的热能变化来储存或释放热量[35];潜热蓄热是利用相变蓄热材料发生相变时吸收或放出热量来实现能量的存储[36]。对蓄热材料性能的要求为:高的蓄热能力、良好的导热性能和良好的抗热震性能等[37]。常用的显热蓄热材料有水泥、混凝土、导热油、氧化物陶瓷、铸铁、铸钢等。提钒尾渣中含有大量的第四周期元素,导致其具有很高的太阳光吸收率和优良的成瓷性能,并且在较高温度范围内都比较稳定。基于上述特点,可考虑提钒尾渣在高温显热蓄热材料或复合相变蓄热材料中的应用。

3.1 制备显热蓄热材料

朴荣勋等[38]利用提钒尾渣制备显热蓄热材料,研究了材料的蓄热能力和导热能力[39]。将提钒尾渣除铁处理后得到的提铁尾渣作为主要原料,以石墨材料为改性剂,采用粉末冶金方法进行了高温显热蓄热材料制备的研究。除铁后提钒尾渣粒度为<74 μm,石墨按0~15%的比例添加。研究结果如表4[38−40]所示。可以看出,提钒尾渣制备的显热蓄热材料的蓄热能力和导热能力与常用显热蓄热材料相当。因此提钒尾渣可用于制备高温(>500 ℃)显热蓄热材料。

表 4 钒钛磁铁矿提钒尾渣制备显热蓄热材料的性能研究Table 4. Study on properties of sensible heat storage materials prepared from vanadium extraction tailings of vanadium titanium-magnetite密度/(g·cm−3) 导热系数/[W·(m·K)−1] 比热容/[J·(kg·K)−1] 蓄热密度/(kJ·kg−1) 蓄热量/(kWh·kg−1) 1000 kWh所需质量/kg提钒尾渣蓄热材料 2.27~2.551 0.848~1.54 133~7 064 207~255 0.058~0.071 14100 ~17300 常用显热蓄热材料① 1.8~3.0 1.1~7.0 850~ 1400 135~298 0.038~0.083 12100 ~20300 注:①指高温混凝土、镁耐火砖、硅耐火砖、固体氯化钠、砂石。 3.2 制备相变蓄热材料

徐众等[41]以攀枝花提钒尾渣(VT)为导热强化剂,普通泡沫碳(CF)或膨胀石墨(EG)为支撑材料,十六酸(PA)、硬脂酸(SA)或石蜡(PW)为相变主材,制备相变蓄热材料,研究了添加提钒尾渣对相变蓄热材料的蓄热性、稳定性、导电性[42]和导热性[43]的影响,研究结果见表5[41−43]。从效果来看,提钒尾渣适合做复合相变材料的导热强化剂使用,对材料的稳定性影响小,能够增强蓄热性、导电性和导热性。

表 5 添加钒钛磁铁矿提钒尾渣对相变蓄热材料性能的影响研究Table 5. Study on the effect of vanadium extraction tailings from vanadium titanium magnetite on the properties of phase-change thermal storage materials原料 制备工艺 性能 参数及效果 VT+CF+PA+SA+PW 恒温浸渍法和浇注法 蓄热性 ① VT+EG+PW 熔融共混法 稳定性 ② 导电性 ③ ④ 导热性 ⑤ 注:①在三种复合材料CF+PW、CF+PA和CF+SA中分别添加2%、1.6%和0.8%的微米级VT后,材料蓄-放热时间缩短,中心处温度和最高温度的差值分别提高2.7~3.8 ℃、6.4~7.8 ℃和5~11.9 ℃;②进行60次热循环,添加VT前后,复合材料EG+PW的质量损失率由小于0.03%升高到0.08%,添加VT对材料热稳定性影响较小;③成型压力为2~8 MPa时,添加粒度小于45 µm的VT后的材料电阻率均比未添加的小,电阻率随VT添加量增加而减小,说明添加VT可以增强材料的导电性能;④成型压力从2 MPa增加到8 MPa时,电阻率下降率在49%以下,添加VT后复合材料电阻率下降率变大,添加VT可以使复合材料电阻率的压敏性提高;⑤添加1%~3%的微米级VT之后,在4 MPa下压制成型,进行60次热循环,复合材料在不同温度下热导率多数变大,添加微米级VT可以增强复合材料的导热性能。 4. 存在问题

1)存在环境污染隐患

对于有价元素的钒、铬的提取,目前主要采用湿法浸出工艺,通过外场强化和多场耦合来破坏包裹物相和氧化浸出低价钒、铬。然而,不论是二次焙烧、加压浸出,或采用高浓度硫酸直接浸出,这些技术普遍存在能耗高、对设备安全性要求高、无法大规模生产等问题。而且处理过程又产生新的废渣、废水,清洁生产问题得不到根本解决。

2)缺乏高效的综合提取技术

由于提钒尾渣的成分、组成复杂,给元素有效地提取和利用带来了挑战。因此,因技术限制、环境考虑和经济因素,实现提钒尾渣中有价元素的充分利用可能是复杂的。这些因素导致目前的提取方法往往只针对某一种或两者元素,这使有价元素利用单一,不能实现有价元素的充分利用。

3)做功能材料利用浪费有价金属

提钒尾渣中有价金属含量可观,综合利用价值极高。直接将提钒尾渣用作建材、涂料、蓄热材料等功能材料利用,而没有经过有价元素的提取,会导致其中的钒、铬等资源的损失,错失创收和节约成本的机会。另外,缺少对此类功能材料毒性的测试和研究,存在环境污染隐患。

5. 结语及展望

钒钛磁铁矿提钒尾渣组织、成分复杂,综合利用工艺种类繁多,应根据不同的成分选择不同的利用工艺。钒含量高时以提钒为主,铬含量高时以提铬为主,钒、铬含量都不高时以回收铁为主,并兼顾其它有价金属的回收,实现有价金属的高效回收利用。加强提钒尾渣综合利用工艺研究,提升该危险废物综合利用能力和处置技术水平,实现资源可持续发展,构建节约型社会,达成危险废物无害化、减量化、资源再利用的目的。

重点关注以下方面:

1)多组元高效提取

提钒尾渣中有价元素的提取是一个复杂的过程,涉及到不同组分的分离,需采用多种技术来分离尾渣的不同组分,如钒、铬、铁和钛。在考虑到经济效益、环境污染等因素的前提下,根据不同的提钒尾渣成分,结合还原焙烧、氧化焙烧、浸出、萃取、磁选等工艺,开展火法冶金+湿法冶金+物理分离的耦合技术研究,实现有价元素的多元、高效提取。

2)整体化增值利用

从整体化利用的角度出发,在有价元素充分提取的前提下,大力开展提钒尾渣作为功能材料利用及循环利用研究,有助于解决大量尾渣堆存及环境污染难题。当前我国能源和环境问题日益突出,提钒尾渣作为太阳能蓄热材料使用,不仅能提高蓄热材料的使用性能,更能降低成本,前景广阔。

3)末端无害化处置

开展提钒尾渣提取有价金属后终渣、钒泥、废液等解毒技术研究,以及终渣、钒泥等返回烧结、炼钢或钒渣焙烧的循环利用研究;加强终渣、废液排放的监管力度,并加强对其毒性的检测。采取有效方法对末端废物进行无害化处置,实现提钒尾渣的清洁利用。

-

表 1 钒钛磁铁矿提钒尾渣主要化学成分及分类

Table 1. Main chemical compositions and classification of vanadium extraction tailings from vanadium titanium-magnetite

% 分类1 Fe2O3 TiO2 V2O5 SiO2 Al2O3 CaO Na2O Cr2O3 MgO MnO 分类2 参考文献 钠化

提钒

尾渣54.90 17.40 0.28 2.71 2.86 0.57 4.23 0.33 0.53 普通型 [1] 35.10 10.62 3.60 15.06 1.95 1.96 7.68 6.60 7.86 高铬型 [12] 47.14 11.95 1.75 20.41 2.18 1.94 6.87 4.32 2.63 4.87 高铬型 [13] 钙化

提钒

尾渣33.24 7.08 1.20 10.97 1.54 15.91 4.70 2.33 6.45 高铬型 [13] 45.50 14.89 2.65 14.51 3.36 6.74 1.53 2.57 4.88 普通型 [3] 73.78 12.39 0.47 1.58 3.76 1.26 0.01 0.73 0.25 普通型 [14] 31.08 11.00 0.66 16.95 2.17 5.66 7.60 2.79 4.75 高铬型 [15] 表 2 采用直接浸出工艺对提钒尾渣再提钒的研究对比

Table 2. Comparison of processes for vanadium re-extraction from vanadium extraction tailings by direct leaching process

工艺 钒提取率/% 优点 缺点 常压酸浸 <60 设备简单,处理能力大 钒浸出率较低,酸用量多,腐蚀设备,污染环境 加压酸浸 可达80 工艺流程短,钒浸出率高 对设备要求高,处理能力小 亚熔盐法 可达85 提钒效率高,可以实现钒、铬共同提取 设备投资大,工艺复杂,对环境造成潜在影响 表 3 还原法回收提钒尾渣中有价元素的研究对比

Table 3. Comparison of processes on recovery of valuable elements in vanadium extraction tailings by reduction method

工艺名称 工艺参数 Fe回收率/% 其它有价金属的处置 V、Cr回收率/% 参考文献 熔融还原 ① >90 V、Cr被还原进入铁水 >90 [33] 提钒尾渣与铬铁矿协同还原熔分 ② 93.49 Cr被还原进入铁水 95.18 [15] 高温直接还原+磁选 ③ 99 V、Cr被还原进入铁水 V:90 Cr:95 [3] CaCO3还原焙烧+磁选 ④ 91.05 TiO2含量为41.75%的含钛渣 [14] 注:①采用电弧炉熔融还原,配碳量为12%~14%,碱度为1.0~1.1;②铬铁矿与提钒尾渣配比为5∶1、SiO2添加量为5.08%、配碳量为20.54%、还原熔分时间为35 min;③ 1400 ℃焙烧+磁选;④还原温度1250 ℃、还原时间2 h、还原剂用量为尾渣质量的20%、CaCO3加入量为5% 。表 4 钒钛磁铁矿提钒尾渣制备显热蓄热材料的性能研究

Table 4. Study on properties of sensible heat storage materials prepared from vanadium extraction tailings of vanadium titanium-magnetite

密度/(g·cm−3) 导热系数/[W·(m·K)−1] 比热容/[J·(kg·K)−1] 蓄热密度/(kJ·kg−1) 蓄热量/(kWh·kg−1) 1000 kWh所需质量/kg提钒尾渣蓄热材料 2.27~2.551 0.848~1.54 133~7 064 207~255 0.058~0.071 14100 ~17300 常用显热蓄热材料① 1.8~3.0 1.1~7.0 850~ 1400 135~298 0.038~0.083 12100 ~20300 注:①指高温混凝土、镁耐火砖、硅耐火砖、固体氯化钠、砂石。 表 5 添加钒钛磁铁矿提钒尾渣对相变蓄热材料性能的影响研究

Table 5. Study on the effect of vanadium extraction tailings from vanadium titanium magnetite on the properties of phase-change thermal storage materials

原料 制备工艺 性能 参数及效果 VT+CF+PA+SA+PW 恒温浸渍法和浇注法 蓄热性 ① VT+EG+PW 熔融共混法 稳定性 ② 导电性 ③ ④ 导热性 ⑤ 注:①在三种复合材料CF+PW、CF+PA和CF+SA中分别添加2%、1.6%和0.8%的微米级VT后,材料蓄-放热时间缩短,中心处温度和最高温度的差值分别提高2.7~3.8 ℃、6.4~7.8 ℃和5~11.9 ℃;②进行60次热循环,添加VT前后,复合材料EG+PW的质量损失率由小于0.03%升高到0.08%,添加VT对材料热稳定性影响较小;③成型压力为2~8 MPa时,添加粒度小于45 µm的VT后的材料电阻率均比未添加的小,电阻率随VT添加量增加而减小,说明添加VT可以增强材料的导电性能;④成型压力从2 MPa增加到8 MPa时,电阻率下降率在49%以下,添加VT后复合材料电阻率下降率变大,添加VT可以使复合材料电阻率的压敏性提高;⑤添加1%~3%的微米级VT之后,在4 MPa下压制成型,进行60次热循环,复合材料在不同温度下热导率多数变大,添加微米级VT可以增强复合材料的导热性能。 -

[1] Sui Yulei, Guo Yufeng, Travyanov A Y, et al. Reduction roasting-magnetic separation of vanadium tailings in presence of sodium sulfate and its mechanisms[J]. Rare Met., 2016,35:954-960. doi: 10.1007/s12598-015-0616-0 [2] Yuan Rui, Li Shaolong, Che Yusi, et al. A critical review on extraction and refining of vanadium metal[J]. Int. J. Refract. H., 2021,101:105696. doi: 10.1016/j.ijrmhm.2021.105696 [3] Xiang Junyi, Huang Qingyun, Lü Wei, et al. Recovery of tailings from the vanadium extraction process by carbothermic reduction method: Thermodynamic, experimental and hazardous potential assessment[J]. J. Hazard. Mater., 2018,357:128-137. doi: 10.1016/j.jhazmat.2018.05.064 [4] Li Lanjie, Zhao Beibei, Gao Minglei, et al. Clean utilization of solid waste of vanadium chemical and metallurgy[J]. The Chinese Journal of Process Engineering, 2019,19(S1):99-108. (李兰杰, 赵备备, 高明磊, 等. 钒化工冶金固废资源化清洁利用[J]. 过程工程学报, 2019,19(增刊1):99-108.Li Lanjie, Zhao Beibei, Gao Minglei, et al. Clean utilization of solid waste of vanadium chemical and metallurgy[J]. The Chinese Journal of Process Engineering, 2019, 19(S1): 99-108. [5] Gilligan R, Nikoloski A N. The extraction of vanadium from titanomagnetites and other sources[J]. Miner. Eng., 2020,146:10610. [6] Wang Xin, Xiang Junyi, Ling Jiawei, et al. Comprehensive utilization of vanadium extraction tailings: A brief review[C]// Energy Technology 2020: Recycling, Carbon Dioxide Management, and Other Technologies. Springer, 2020: 327-334. [7] Huo Zhihao, Wang Mei, Yue Hongrui. Technology of extracting vanadium from vanadium slag by sodium roasting and comprehensive utilization of vanadium tailings[C]//Proceedings of the 2022 Annual Science and Technology Conference of the Chinese Society of Environmental Sciences (II). Nanchang: China Agricultural University Press, 2022: 1075-1078. (霍志豪, 王梅, 岳宏瑞. 钒渣钠化焙烧提钒工艺及提钒尾渣综合利用[C]//中国环境科学学会2022年科学技术年会论文集(II). 南昌: 中国农业大学出版社, 2022: 1075-1078.Huo Zhihao, Wang Mei, Yue Hongrui. Technology of extracting vanadium from vanadium slag by sodium roasting and comprehensive utilization of vanadium tailings[C]//Proceedings of the 2022 Annual Science and Technology Conference of the Chinese Society of Environmental Sciences (II). Nanchang: China Agricultural University Press, 2022: 1075-1078. [8] Xu Chongguang, Wang Hailin, Yang Huan, et al. Comprehensive utilization of extracting vanadium tailings[J]. Ferro Alloys, 2018,49(1):40-43. (许崇光, 王海林, 杨欢, 等. 提钒尾渣的综合利用[J]. 铁合金, 2018,49(1):40-43.Xu Chongguang, Wang Hailin, Yang Huan, et al. Comprehensive utilization of extracting vanadium tailings[J]. Ferro Alloys, 2018, 49(1): 40-43. [9] Li Lanjie, Zhao Beibei, Wang Haixu, et al. The process of high efficiency dealkalization and ore blending in ironmaking of the extracted vanadium residue[J]. Chin. J. Process Eng, 2017,17(1):138-143. (李兰杰, 赵备备, 王海旭, 等. 提钒尾渣高效脱碱及配矿炼铁工艺[J]. 过程工程学报, 2017,17(1):138-143. doi: 10.12034/j.issn.1009-606X.216215Li Lanjie, Zhao Beibei, Wang Haixu, et al. The process of high efficiency dealkalization and ore blending in ironmaking of the extracted vanadium residue[J]. Chin. J. Process Eng, 2017, 17(1): 138-143. doi: 10.12034/j.issn.1009-606X.216215 [10] Guo Rui, Zhou Mi, Xie Huaqing, et al. Experimental research on preparation of ferrochrome by reducing vanadium tailings with peanut shell[J]. Sintering and Pelletizing, 2022,47(6):116-122. (郭锐, 周密, 谢华清, 等. 花生壳还原提钒尾渣制备铬铁合金的试验研究[J]. 烧结球团, 2022,47(6):116-122.Guo Rui, Zhou Mi, Xie Huaqing, et al. Experimental research on preparation of ferrochrome by reducing vanadium tailings with peanut shell[J]. Sintering and Pelletizing, 2022, 47(6): 116-122. [11] Kim E, Spooren J, Broos K, et al. Selective recovery of Cr from stainless steel slag by alkaline roasting followed by water leaching[J]. Hydrometallurgy, 2015,158:139-148. doi: 10.1016/j.hydromet.2015.10.024 [12] Zhao Qifeng, Wang Xiwen, Xia Wei, et al. Research status and prospect of vanadium sodium waste waste[C]//Proceedings of the 11th National Energy and Thermal Industry Annual Conference. Ma, anshan: Chinese Society for Metals, 2021: 515-520. (赵奇丰, 王熙文, 夏伟, 等. 钠化提钒废渣综合利用研究现状及展望[C]//第十一届全国能源与热工学术年会论文集. 马鞍山: 中国金属学会能源与热工分会, 2021: 515-520.Zhao Qifeng, Wang Xiwen, Xia Wei, et al. Research status and prospect of vanadium sodium waste waste[C]//Proceedings of the 11th National Energy and Thermal Industry Annual Conference. Ma, anshan: Chinese Society for Metals, 2021: 515-520. [13] Liu Jinsheng, Ding Xueyong, Xue Xiangxin, et al. Research progress of comprehensive utilization of vanadium extraction tailings[J]. Iron and Steel, 2021,56(7):152-160. (刘金生, 丁学勇, 薛向欣, 等. 提钒尾渣资源化综合利用的研究进展[J]. 钢铁, 2021,56(7):152-160.Liu Jinsheng, Ding Xueyong, Xue Xiangxin, et al. Research progress of comprehensive utilization of vanadium extraction tailings[J]. Iron and Steel, 2021, 56(7): 152-160. [14] Gao Feng, Du Hao, Liu Biao, et al. Study on the technology of enhanced reduction-magnetic separation of titanium and iron from calcium-based vanadium extraction tailings[J]. Iron Steel Vanadium Titanium, 2023,44(1):84-91. (高峰, 杜浩, 刘彪, 等. 钙基提钒尾渣强化还原-磁选分离钛铁技术研究[J]. 钢铁钒钛, 2023,44(1):84-91.Gao Feng, Du Hao, Liu Biao, et al. Study on the technology of enhanced reduction-magnetic separation of titanium and iron from calcium-based vanadium extraction tailings[J]. Iron Steel Vanadium Titanium, 2023, 44(1): 84-91. [15] Wang Guang. Fundamental study on synergistic reduction of vanadium extraction tailings with high content chromium and chromite to smelt high carbon ferrochromium[D]. Chongqing: Chongqing University, 2020. (王广. 高铬型提钒尾渣与铬铁矿协同还原冶炼高碳铬铁的基础研究[D]. 重庆: 重庆大学, 2020.Wang Guang. Fundamental study on synergistic reduction of vanadium extraction tailings with high content chromium and chromite to smelt high carbon ferrochromium[D]. Chongqing: Chongqing University, 2020. [16] Liu Shiyuan, Wang Lijun, Chen Jun, et al. Research progress of vanadium extraction processes from vanadium slag: A review[J]. Sep. Purif. Technol. , 2024: 127035. [17] Zhang Ying, Zhang Ting,an, Dreisinger David, et al. Recovery of vanadium from calcification roasted-acid leaching tailing by enhanced acid leaching[J]. J. Hazard. Mater., 2019,369:632-641. doi: 10.1016/j.jhazmat.2019.02.081 [18] Li Fangfang, Wen Jing, Yu Tangxia, et al. Synergic acid leaching of vanadium from sodium vanadium extraction tailings[J/OL]. Multipurpose Utilization of Mineral Resources [2023-11-13]. https://link.cnki.net/urlid/51.1251.TD.20231110.1042.010. (李芳芳, 温婧, 余唐霞, 等. 钠化提钒尾渣协同酸浸提钒[J/OL]. 矿产综合利用 [2023-11-13]. https://link.cnki.net/urlid/51.1251.TD.20231110.1042.010.Li Fangfang, Wen Jing, Yu Tangxia, et al. Synergic acid leaching of vanadium from sodium vanadium extraction tailings[J/OL]. Multipurpose Utilization of Mineral Resources [2023-11-13]. https://link.cnki.net/urlid/51.1251.TD.20231110.1042.010. [19] Meng Lipeng, Zhao Chu, Wang Shaona, et al. Improvement of vanadium extraction from extracted vanadium residue in China[J]. Iron Steel Vanadium Titanium, 2015,36(3):49-56. (孟利鹏, 赵楚, 王少娜, 等. 国内提钒尾渣再提钒技术研究进展[J]. 钢铁钒钛, 2015,36(3):49-56.Meng Lipeng, Zhao Chu, Wang Shaona, et al. Improvement of vanadium extraction from extracted vanadium residue in China[J]. Iron Steel Vanadium Titanium, 2015, 36(3): 49-56. [20] Liu Bao, Li Jin, Ren Qianqian, et al. Leaching behavior and mineralogical evolution of vanadium released from sodium roasted-acid leaching tailing of vanadium slag[J]. J. of Iron Steel Res. Int., 2022,29(5):772-782. doi: 10.1007/s42243-021-00716-w [21] Zhang Xuefeng, Liu Fengguo, Xue Xiangxin, et al. Effects of microwave and conventional blank roasting on oxidation behavior, microstructure and surface morphology of vanadium slag with high chromium content[J]. J. Alloy. Comp., 2016,686:356-365. doi: 10.1016/j.jallcom.2016.06.038 [22] Li Wei, Fu Guiqin, Chu Mansheng, et al. Oxidation induration process and kinetics of Hongge vanadium titanium-bearing magnetite pellets[J]. Ironmak. Steelmak., 2016,44:294-303. [23] Lü Changxiao, Zhang Ting, an, Zhang Ying, et al. Comprehensive recovery of vanadium from calcification roasting-acid leaching tailings[J]. Chinese Journal of Rare Metals, 2020,44(11):1208-1214. (吕昌晓, 张廷安, 张莹, 等. 从钙化焙烧-酸浸尾渣中综合回收钒的研究[J]. 稀有金属, 2020,44(11):1208-1214.Lü Changxiao, Zhang Ting, an, Zhang Ying, et al. Comprehensive recovery of vanadium from calcification roasting-acid leaching tailings[J]. Chinese Journal of Rare Metals, 2020, 44(11): 1208-1214. [24] Rahman A, Behnam S. Recovery of vanadium from secondary tailing of iron ore by salt roasting-alkaline leaching and solvent extraction processes[J]. Iran. J. Earth Sci., 2019,11(1):30-37. [25] Wen Jin, Jiang Tao, Gao Huiyang, et al. An efficient utilization of chromium-containing vanadium tailings: Extraction of chromium by soda roasting-water leaching and preparation of chromium oxide[J]. J. Environ. Manage., 2019,244:119-126. doi: 10.1016/j.jenvman.2019.05.037 [26] Cheng Jie, Li Hongyi, Chen Xinmian, et al. Eco-friendly chromium recovery from hazardous chromium-containing vanadium extraction tailings via low-dosage roasting[J]. Process Saf. Environ., 2022,164:818-826. doi: 10.1016/j.psep.2022.06.065 [27] Tavakolikhaledi M R. Vanadium: Leaching and solvent extraction[D]. Vancouver: University of British Columbia, 2014. [28] Du Weitong, Jiang Congxiang, Chen Zhuo, et al. Vanadium extraction by roasting from high chlorine-and-iron titanium tetrachloride tailings after vanadium removal[J]. Mining and Metallurgical Engineering, 2022,42(2):106-108. (堵伟桐, 姜丛翔, 陈卓, 等. 高氯高铁型四氯化钛除钒尾渣焙烧提钒工艺研究[J]. 矿冶工程, 2022,42(2):106-108.Du Weitong, Jiang Congxiang, Chen Zhuo, et al. Vanadium extraction by roasting from high chlorine-and-iron titanium tetrachloride tailings after vanadium removal[J]. Mining and Metallurgical Engineering, 2022, 42(2): 106-108. [29] Yu Qiang. Study on deep extraction of vanadium from calcified acid leaching tailings[D]. Chongqing: Chongqing University, 2021. (余强. 钙化酸浸提钒尾渣深度提钒的研究[D]. 重庆: 重庆大学, 2021.Yu Qiang. Study on deep extraction of vanadium from calcified acid leaching tailings[D]. Chongqing: Chongqing University, 2021. [30] Dong Mengqi. Recovery and utilization of iron resources in pressurized acid leaching residue of laterite nickel ore[D]. Kunming: Kunming University of Science and Technology, 2023. (董梦奇. 红土镍矿加压酸浸渣铁资源的回收利用[D]. 昆明: 昆明理工大学, 2023.Dong Mengqi. Recovery and utilization of iron resources in pressurized acid leaching residue of laterite nickel ore[D]. Kunming: Kunming University of Science and Technology, 2023. [31] Kolmachikhina E B, Lugovitskaya T N, Tretiak M A, et al. Surfactants and their mixtures under conditions of autoclave sulfuric acid leaching of zinc concentrate: Surfactant selection and laboratory tests[J]. Trans. Nonferrous Met. Soc. China, 2023,33:3529-3543. doi: 10.1016/S1003-6326(23)66352-6 [32] Liu Cun, Li Yun, Guo Hongfei, et al. Preparation of spherical hydroxycancrinite from potassic rocks activated by sub-molten salt[J]. Journal of Chemical Engineering of Chinese Universities, 2023,37(4):623-632. (刘存, 李雲, 郭宏飞, 等. 亚熔盐活化含钾岩石制备球形羟基钙霞石[J]. 高校化学工程学报, 2023,37(4):623-632.Liu Cun, Li Yun, Guo Hongfei, et al. Preparation of spherical hydroxycancrinite from potassic rocks activated by sub-molten salt[J]. Journal of Chemical Engineering of Chinese Universities, 2023, 37(4): 623-632. [33] Wu Enhui, Zhu Rong, Yang Shaoli, et al. Experimental and thermodynamic study on reduction of carbon-containing pellet of vanadium tailings smelted by electric arc furnace[J]. Iron Steel Vanadium Titanium, 2015,36(5):40-46. (吴恩辉, 朱荣, 杨绍利, 等. 提钒尾渣含碳球团电弧炉熔融还原热力学分析与试验[J]. 钢铁钒钛, 2015,36(5):40-46.Wu Enhui, Zhu Rong, Yang Shaoli, et al. Experimental and thermodynamic study on reduction of carbon-containing pellet of vanadium tailings smelted by electric arc furnace[J]. Iron Steel Vanadium Titanium, 2015, 36(5): 40-46. [34] Hou Jing, Wu Enhui, Li Jun. Current situation and progress of comprehensive utilization of vanadium extraction tailings[J]. Conservation and Utilization of Mineral Resources, 2017(6):103-108. (侯静, 吴恩辉, 李军. 提钒尾渣的综合利用研究现状及进展[J]. 矿产保护与利用, 2017(6):103-108.Hou Jing, Wu Enhui, Li Jun. Current situation and progress of comprehensive utilization of vanadium extraction tailings[J]. Conservation and Utilization of Mineral Resources, 2017(6): 103-108. [35] Leng Guanghui, Cao Hui, Peng Hao, et al. The new research progress of thermal energy storage materials[J]. Energy Storage Science and Technology, 2017,6(5):1058-1075. (冷光辉, 曹惠, 彭浩, 等. 储热材料研究现状及发展趋势[J]. 储能科学与技术, 2017,6(5):1058-1075.Leng Guanghui, Cao Hui, Peng Hao, et al. The new research progress of thermal energy storage materials[J]. Energy Storage Science and Technology, 2017, 6(5): 1058-1075. [36] Kuravi S, Trahan J, Yogi Goswami D, et al. Thermal energy storage technologies and systems for concentrating solar power plants[J]. Prog. Energ. Combust., 2013,39:285-319. doi: 10.1016/j.pecs.2013.02.001 [37] Xu Xiaohong, Lao Xinbin, Wu Jianfeng, et al. Synthesis and characterization of Al2O3/SiC composite ceramics via carbothermal reduction of alumino-silicate precursor for solar sensible thermal storage[J]. J. Alloys Compd., 2016,662:126-137. doi: 10.1016/j.jallcom.2015.12.038 [38] Piao Rongxun, Li Xuan, Li Guowei, et al. Preparation of high temperature sensible heat storage material from vanadium extraction tailings and graphite[J]. Iron Steel Vanadium Titanium, 2020,41(6):52-59. (朴荣勋, 李轩, 李国伟, 等. 利用提钒尾渣和石墨制备高温显热蓄热材料的研究[J]. 钢铁钒钛, 2020,41(6):52-59.Piao Rongxun, Li Xuan, Li Guowei, et al. Preparation of high temperature sensible heat storage material from vanadium extraction tailings and graphite[J]. Iron Steel Vanadium Titanium, 2020, 41(6): 52-59. [39] Piao Rongxun, Li Xuan, Ji Ying. Research and modeling on thermal conductivity of high temperature heat storage material based on vanadium tailings[J]. Iron Steel Vanadium Titanium, 2021,42(1):93-99. (朴荣勋, 李轩, 季颖. 基于提钒尾渣的高温显热蓄热材料导热性能研究及模拟[J]. 钢铁钒钛, 2021,42(1):93-99.Piao Rongxun, Li Xuan, Ji Ying. Research and modeling on thermal conductivity of high temperature heat storage material based on vanadium tailings[J]. Iron Steel Vanadium Titanium, 2021, 42(1): 93-99. [40] Hou Zongchen. Preparation and performance research on a new modified solid high-temperature sensible heat storage materials[D]. Zhejiang: Zhejiang University, 2023. (侯宗臣. 新型改性固体高温显热蓄热材料的制备与性能研究[D]. 浙江: 浙江大学, 2023.Hou Zongchen. Preparation and performance research on a new modified solid high-temperature sensible heat storage materials[D]. Zhejiang: Zhejiang University, 2023. [41] Xu Zhong, Hou Jing, Li Jun, et al. Investigation on heat storage characteristics of vanadium tailings/carbon foam/organic matter composite phase change material[J/OL]. Multipurpose Utilization of Mineral Resources, https://link.cnki.net/urlid/51.1251.TD.20231123.1039.008. (徐众, 侯静, 李军, 等. 提钒尾渣/泡沫碳/有机质复合相变材料蓄热性能[J/OL]. 矿产综合利用, https://link.cnki.net/urlid/51.1251.TD.20231123.1039.008.Xu Zhong, Hou Jing, Li Jun, et al. Investigation on heat storage characteristics of vanadium tailings/carbon foam/organic matter composite phase change material[J/OL]. Multipurpose Utilization of Mineral Resources, https://link.cnki.net/urlid/51.1251.TD.20231123.1039.008. [42] Xu Zhong, Li Jun, Wu Enhui, et al. Influence of vanadium tailings on the thermal stability and electrical conductivity of expanded graphite/paraffin composite phase change materials[J]. Chinese Journal of Applied Chemistry, 2022(3):461-469. (徐众, 李军, 吴恩辉, 等. 添加提钒尾渣对膨胀石墨/石蜡复合相变材料稳定性和导电性的影响[J]. 应用化学, 2022(3):461-469.Xu Zhong, Li Jun, Wu Enhui, et al. Influence of vanadium tailings on the thermal stability and electrical conductivity of expanded graphite/paraffin composite phase change materials[J]. Chinese Journal of Applied Chemistry, 2022(3): 461-469. [43] Xu Zhong, Hou Jing, Li Jun, et al. Influence of vanadium tailing on the thermal conductivity performance of EG/PW phase change composite material[J]. New Chemical Materials, 2021,49(5):115-119. (徐众, 侯静, 李军, 等. 提钒尾渣对膨胀石墨/石蜡复合相变材料导热性能的影响[J]. 化工新型材料, 2021,49(5):115-119.Xu Zhong, Hou Jing, Li Jun, et al. Influence of vanadium tailing on the thermal conductivity performance of EG/PW phase change composite material[J]. New Chemical Materials, 2021, 49(5): 115-119. -

下载:

下载:

下载:

下载: