Preparation of electrically conductive carbon fiber-cement mortars with carbonized titanium-bearing blast furnace slag as an aggregate

-

摘要: 以含钛高炉渣的碳化产物(含钛碳化渣)为集料,以碳纤维为导电相,制备了导电水泥砂浆。测试了含钛碳化渣-碳纤维水泥砂浆在不同碳纤维含量下的抗折、抗压强度和电阻率,并与标准砂-碳纤维水泥砂浆进行了性能比较。结果显示,以含钛碳化渣替代标准砂作为集料,不仅能显著提升碳纤维水泥砂浆的抗压和抗折强度,使其满足建筑水泥砂浆的要求,还将导电水泥砂浆的渗流阈值从0.5 %降低至0.2 %。当碳纤维含量为2.0 %时,以含钛碳化渣作为集料的水泥砂浆表现出优异的性能:28 d抗压和抗折强度分别为39.9 MPa和10.2 MPa,湿润条件下电阻率为10.7 Ω·m,干燥条件下电阻率为10.9 Ω·m。该研究既为含钛高炉渣的再利用提供了一种新思路,也为导电水泥基复合材料的制备提供了新选择。Abstract: Electrically conductive cement mortars were prepared by using carbon fiber as a conductive phase and carbonized titanium-bearing blast furnace slag (CTBFS) as an aggregate. The content of carbon fiber on the rupture strength, compressive strength, and electrical resistivity of the as-prepared cement mortar was investigated and compared with those with standard sand as an aggregate. The results show that the replacement of standard sand with CTBFS as the aggregate not only significantly improved the rupture and compressive strength of carbon fiber cement mortar, making it meet the requirements of building cement mortar, but also reduced the threshold of conductive cement mortar from 0.5% to 0.2%. With a carbon fiber content of 2.0%, the as-prepared cement mortar with CTBFS as the aggregate showed excellent performance with 28 d compression and rupture strength of 39.9 MPa and 10.2 MPa, respectively, as well as electrical resistance of 10.7 Ω·m in wet state and 10.9 Ω·m in dry state, respectively. The investigation provides a new way for the reuse of titanium-bearing blast furnace slag and the preparation of conductive cement-based composites.

-

0. 引言

含钛高炉渣是我国四川攀枝花-西昌地区的钒钛磁铁矿经过高炉冶炼处理后所得的一种固体废弃物,其TiO2含量约为20%~25% [1-2]。我国含钛高炉渣的堆存量已达8000多万t,并且还在以每年300万t的速度增长[3-4],其堆放占用了大量的土地,造成环境污染。由于国家对环境保护的不断重视,以及高品质钛矿资源的不断稀缺,含钛高炉渣作为一种钛资源逐渐受到了研究人员和工业界的青睐。当前,对含钛高炉渣的利用主要围绕着提取TiO2和制备含钛化合物两个方面展开,提取TiO2的主要途径为采用酸解法制备TiO2,制备含钛化合物主要包括制备TiCl4、Ti(C,N)和钛合金等制品[5-13]。尽管现有的工艺可以从含钛高炉渣中提取或者应用其中的Ti元素,但均存在过程复杂或成本较高等问题。更为重要的是,在这些工艺中,只有Ti元素被考虑作为资源,而其它元素只能作为固体废弃物,产生二次污染。因此,急需探索含钛高炉渣全组分、大宗量、高附加值的利用方法[14]。

水泥基复合材料,包括涂料、砂浆和混凝土,因其优良的物理性能和低廉的成本而广泛应用于土木工程。常规的水泥基复合材料导电性能较差,在干燥状态下电阻率一般在103~106 Ω·m,但制备过程中加入一定比例的导电相可以显著降低其电阻率,得到可应用于建筑加热采暖、电磁干扰屏蔽、静电释放、建筑自检测及桥梁路面融雪化冰等领域的水泥基导电复合材料[15-19]。目前制备水泥基导电复合材料常用的导电相为钢纤维、石墨、碳纤维和钢渣等[18]。钢纤维具有高强度和良好的导电性,并且易于机械加工,是作为水泥基导电复合材料中导电相的首选[20],试验表明,钢纤维的掺入大大提高了水泥基复合材料的拉伸、弯曲、剪切强度和导电性;但由于混凝土基体内部为碱性环境,钢纤维表面会发生氧化被钝化膜覆盖,从而导致水泥基复合材料的电阻率急剧增加[20-21]。石墨具有较强的抗氧化和抗碱腐蚀性能,适合作为导电相制备电阻率稳定的水泥基复合材料[22],但是当石墨含量达到使水泥基复合材料转变为导电材料的阈值时,材料的强度大幅降低,无法满足实际应用的需要。也就是说,采用石墨作为导电相很难实现电学性能与力学性能的同时兼顾[22-24]。碳纤维具有优异的导电性、热稳定性和抗腐蚀性能,并且自身特殊的结构更容易形成导电网络,改善导电混凝土的力学性能,但碳纤维和水泥的混合搅拌会在水泥基复合材料中引入大量气泡,造成强度的下降[24-25]。研究表明,水泥基复合材料的抗压强度往往取决于材料内部集料之间的相互接触程度,但集料通常不具有导电性,如果集料占比过高,则会阻断碳纤维的导电通路,会影响材料的导电性能。因此,引入导电集料是使水泥基复合材料兼顾电学性能与力学性能的一种新思路[26]。研究表明,使用导电集料可降低导电水泥基复合材料的导电渗流阈值,这对改善水泥基复合材料的力学性能和降低导电相成本都非常有利[27]。导电水泥基复合材料作为一种潜在的土木工程材料,消耗量巨大,其成本决定了其应用前景。人工合成的导电集料由于工艺复杂,成本高,不适合实际应用。因此,使用固体废弃物作为导电填料或集料引起了众多科研工作者们的关注[28-30]。例如,使用电弧炉渣作为导电集料可实现水泥砂浆的强度和电磁屏蔽效果的兼顾[31]。

含钛碳化渣是攀钢“高温碳化-低温氯化”提钛工艺的中间产物[7],在高温碳化过程中,含钛高炉渣中的TiO2被碳热还原成TiC,而TiC是一种具有较强抗氧化性和耐酸碱腐蚀性的导电陶瓷相,虽然非碳化高炉渣中的TiO2也可以作为导电集料,但是碳化渣中的TiC具有更好的导电性能。因此含钛碳化渣有望作为导电集料用于制备水泥基导电复合材料。笔者以含钛碳化渣为集料,碳纤维为导电相,制备了导电水泥砂浆,系统研究了以含钛碳化渣替代传统标准砂为集料对导电水泥砂浆力学和电学性能的影响。

1. 试验

1.1 材料与试剂

含钛碳化渣取自攀钢研究院有限公司;水泥为马鞍山海螺水泥有限责任公司生产的PII 42.5型硅酸盐水泥;短切碳纤维来自深圳中森领航科技有限公司,其性质如表1所示;标准砂来自厦门艾思欧标准砂有限公司。

表 1 短切碳纤维性质Table 1. Properties of chopped carbon fibers长度/

mm碳含量/

%抗拉强度/

GPa密度/

(g·cm−3)体积电阻率/

(Ω·cm)6 ≥ 95 3.8 1.76 1.5×10−3 我们前期的工作表明,含钛碳化渣的主要晶相为TiC,呈小颗粒弥散在硅酸盐相表面,含量约为20%,适合作为导电水泥基复合材料的导电集料[31]。含钛碳化渣颗粒粒径范围为0.015~0.45 mm,其微观形貌不规则、棱角分明,有利于在基体内与水泥形成互锁结构,提升结合强度[31]。

1.2 碳纤维水泥砂浆的制备

表2为碳纤维水泥砂浆的配料比,样品编号1~6添加了不同含量的碳纤维,以探究碳纤维含量对制备出的样品性能的影响,样品编号7~12是1~6的对照组,目的是比较以碳化渣和标准砂分别作为导电集料制备出的样品之间的性能差异。首先将水加热到60 ℃,然后加入水泥质量分数0.4%的甲基纤维素,用玻璃棒搅拌均匀后加入短切碳纤维,再次搅拌至杯中碳纤维无明显团聚;将水泥和水在水泥砂浆搅拌机中低速搅拌30 s;随后,加入分散均匀的碳纤维,并以慢速混合30 s,然后加入含钛碳化渣,高速混合90 s后将胶砂装入40 mm×40 mm×160 mm的不锈钢模套中;经水泥胶砂振实台振实后,插入4个电极,电极由30 mm×50 mm不锈钢网组成,金属丝直径为0.23 mm,孔边长度为1.1 mm;将试样置入标准养护箱养护24 h后脱模;最后将试样用水浸泡在标准养护箱中养护至相应龄期。标准养护箱的温度为20~21℃,相对湿度~95%。为了获得干燥的样品,将养护28 d后的样品放入烘箱中,在90 ℃下干燥24 h[31]。

表 2 碳纤维水泥砂浆的配合比Table 2. Mix proportion of carbon fiber cement mortar编号 碳纤维含量/% 材料配比/g 水泥 碳化渣 标准砂 水 短切碳纤维 1 0.2 450 1350 0 225 0.90 2 0.5 450 1350 0 225 2.25 3 0.8 450 1350 0 225 3.60 4 1.1 450 1350 0 225 4.95 5 1.5 450 1350 0 225 6.75 6 2.0 450 1350 0 225 9.00 7 0.2 450 0 1350 225 0.90 8 0.5 450 0 1350 225 2.25 9 0.8 450 0 1350 225 3.60 10 1.1 450 0 1350 225 4.95 11 1.5 450 0 1350 225 6.75 12 2.0 450 0 1350 225 9.00 1.3 分析和测试

试块养护至规定龄期后取出,采用直流电源,利用四电极伏安法测量试样电阻,并计算材料的体积电阻率[31]。采用天津鑫高伟业科技有限公司生产的YAW-300C 型全自动水泥抗折抗压试验机测试试样的抗折强度及抗压强度[31]。采用场发射扫描电子显微镜(FSEM,MIRA3,捷克TESCAN)观察材料的微观形貌。所有的数据经过Origin软件绘制成柱状图,SEM图像由Photoshop软件进行处理。

2. 结果与讨论

2.1 碳纤维含量对水泥砂浆强度的影响

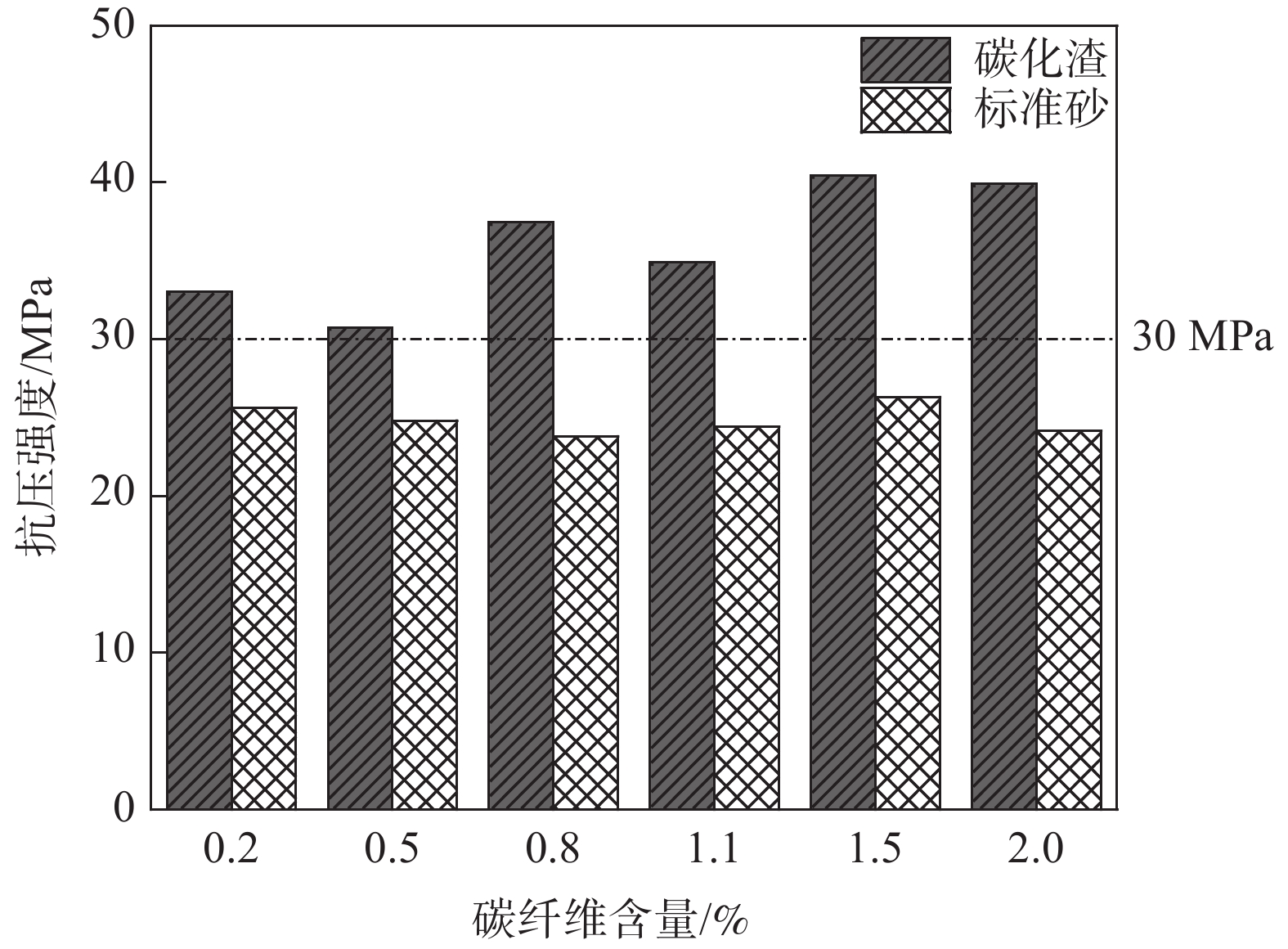

图1为碳纤维含量对两种集料碳纤维水泥砂浆28 d抗压强度的影响。在碳纤维含量为0.2%~2.0%时,含钛碳化渣-碳纤维水泥砂浆始终具有比标准砂-碳纤维水泥砂浆更高的抗压强度。我们前期的工作表明,未添加碳纤维时,以标准砂为集料的水泥砂浆的抗压强度为59.4 MPa,当使用含钛碳化渣取代标准砂后,所得水泥砂浆的抗压强度为72.8 MPa[31]。当碳纤维的含量为0.2%时,含钛碳化渣-碳纤维水泥砂浆的抗压强度为33.0 MPa,下降了54.7%;而标准砂-碳纤维水泥砂浆的强度为25.6 MPa,较未添加碳纤维的试件下降了56.9%。添加碳纤维后两种水泥砂浆的抗压强度均产生了明显的下降,这是因为在碳纤维分散以及搅拌混合的过程中引入了大量气泡,造成水泥砂浆基体内孔隙率升高,整体粘结性变差。随着碳纤维含量的进一步增加,含钛碳化渣-碳纤维水泥砂浆的抗压强度缓慢上升,最终稳定在40.0 MPa左右;而标准砂-碳纤维水泥砂浆的抗压强度始终稳定在25.0 MPa左右。当碳纤维含量为2.0 %时,含钛碳化渣-碳纤维水泥砂浆的抗压强度为39.9 MPa,而标准砂-碳纤维水泥砂浆的抗压强度为24.2 MPa。在碳纤维含量为0.2%~2.0%范围内,含钛碳化渣-碳纤维水泥砂浆的抗压强度始终满足建筑强度要求(30 MPa),而标准砂-碳纤维水泥砂浆在该范围内均不满足建筑强度要求。

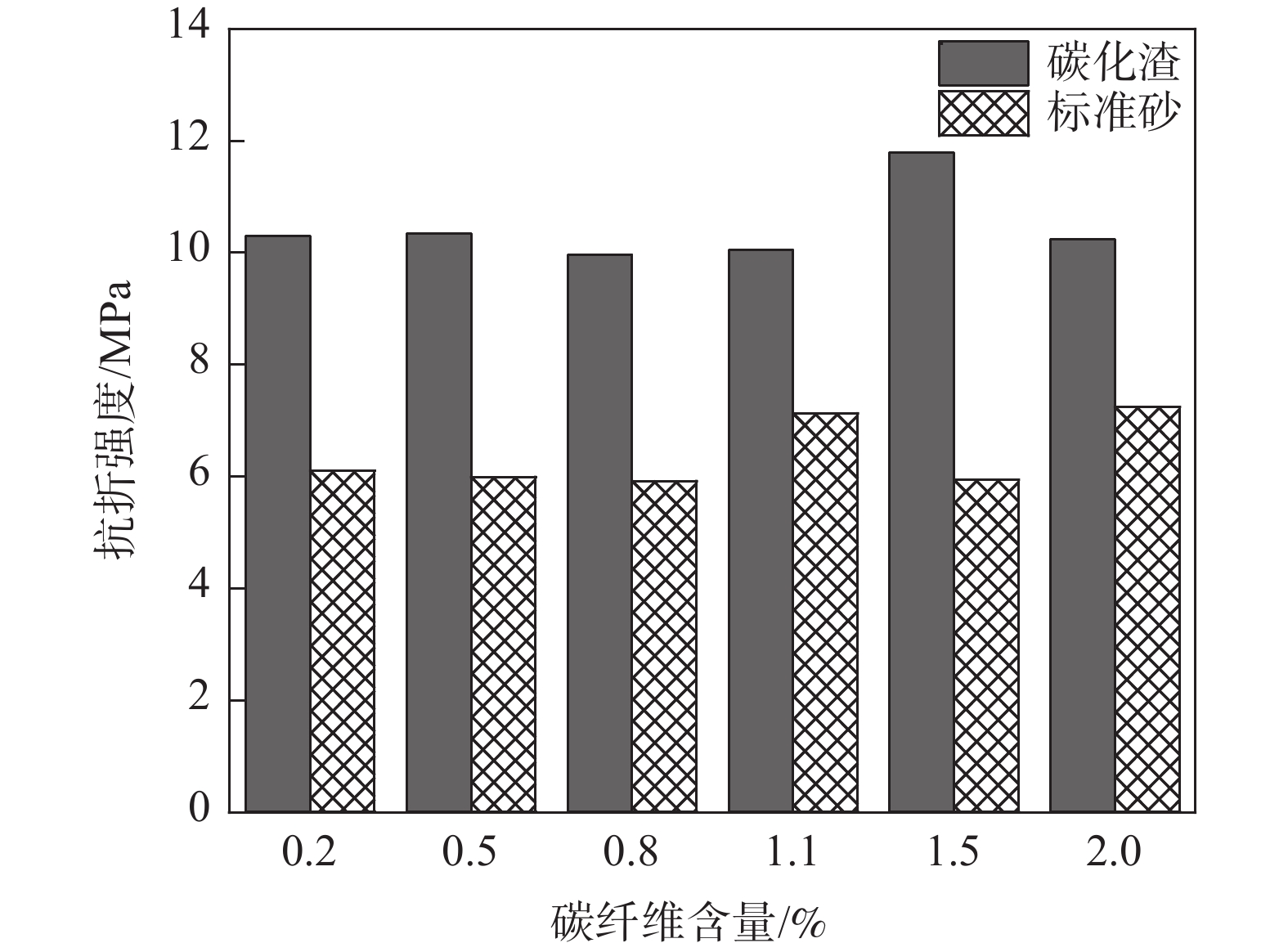

图2为碳纤维含量对两种集料碳纤维水泥砂浆28 d抗折强度的影响。根据图2,含钛碳化渣-碳纤维水泥砂浆始终比标准砂-碳纤维水泥砂浆具有更高的抗折强度。在碳纤维含量为0.2%~2.0%范围内,标准砂-碳纤维水泥砂浆的抗折强度维持在6.0 MPa左右,并在碳纤维含量为2.0%时达到最大值7.2 MPa,而含钛碳化渣-碳纤维水泥砂浆的抗折强度稳定在10.0 MPa左右,并在碳纤维含量为1.5% 时达到最大值11.8 MPa,较相同碳纤维含量的标准砂-碳纤维水泥砂浆的强度提高了98.6%。

含钛碳化渣对碳纤维水泥砂浆强度的增强作用与以下因素有关:①含钛碳化渣经过高温处理,比标准砂具有更高的本征抗压强度。②含钛碳化渣具有一定活性,可以参与水化反应。含钛碳化渣经高温处理和水淬后,渣中大部分Si、Ca、Al等元素以氧化物的形式形成玻璃态,但还有部分会以结晶2CaO·SiO2、3CaO·SiO2、3CaO·Al2O3 和 4CaO·Al2O3·Fe2O3的形式存在,均具有水化活性。③含钛碳化渣外观形貌不规则,颗粒棱角分明,有利于与水泥、碳纤维形成互锁结构,这也有利于其保持较高的抗压强度。

2.2 碳纤维含量对水泥砂浆电阻率的影响

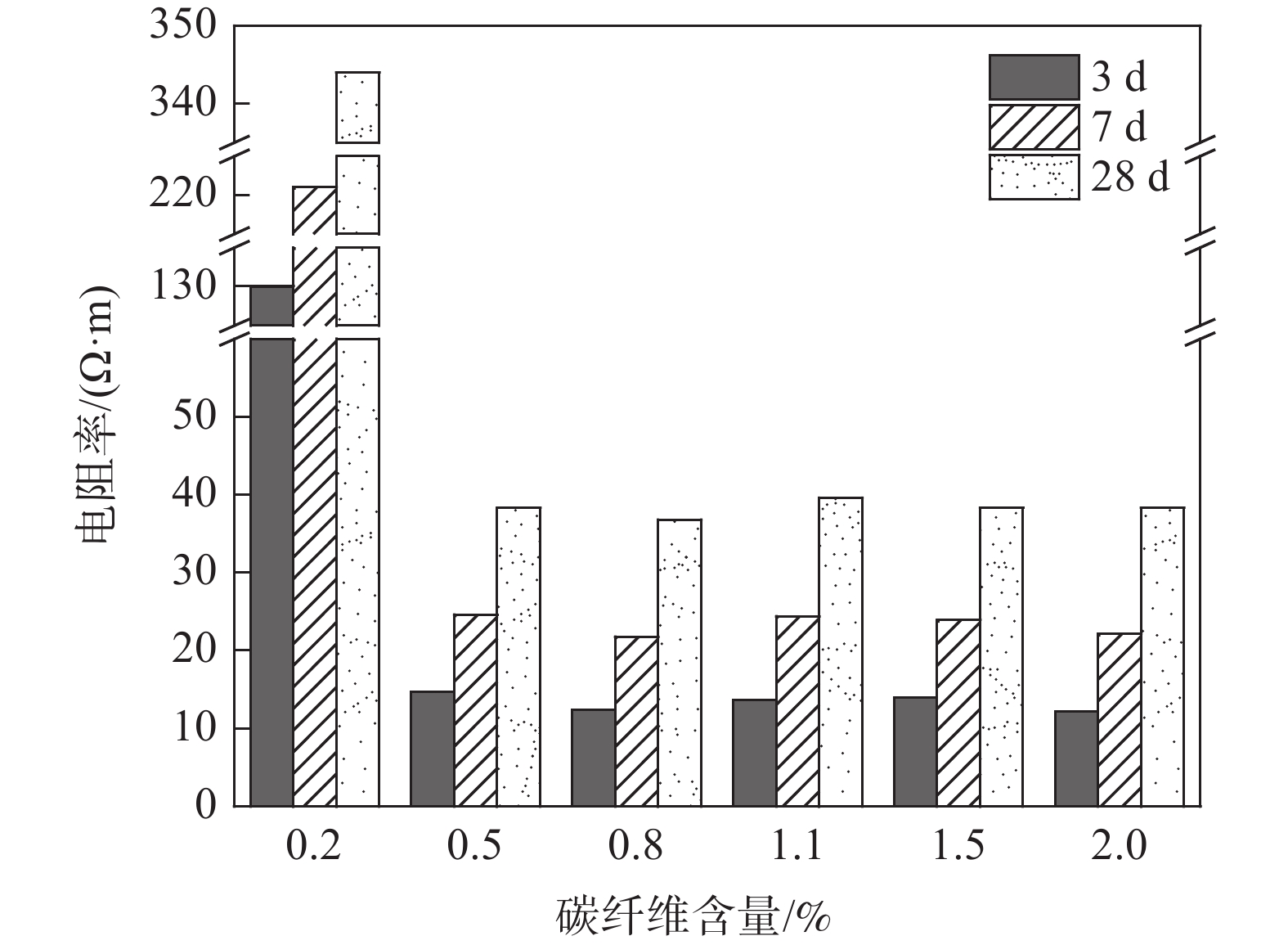

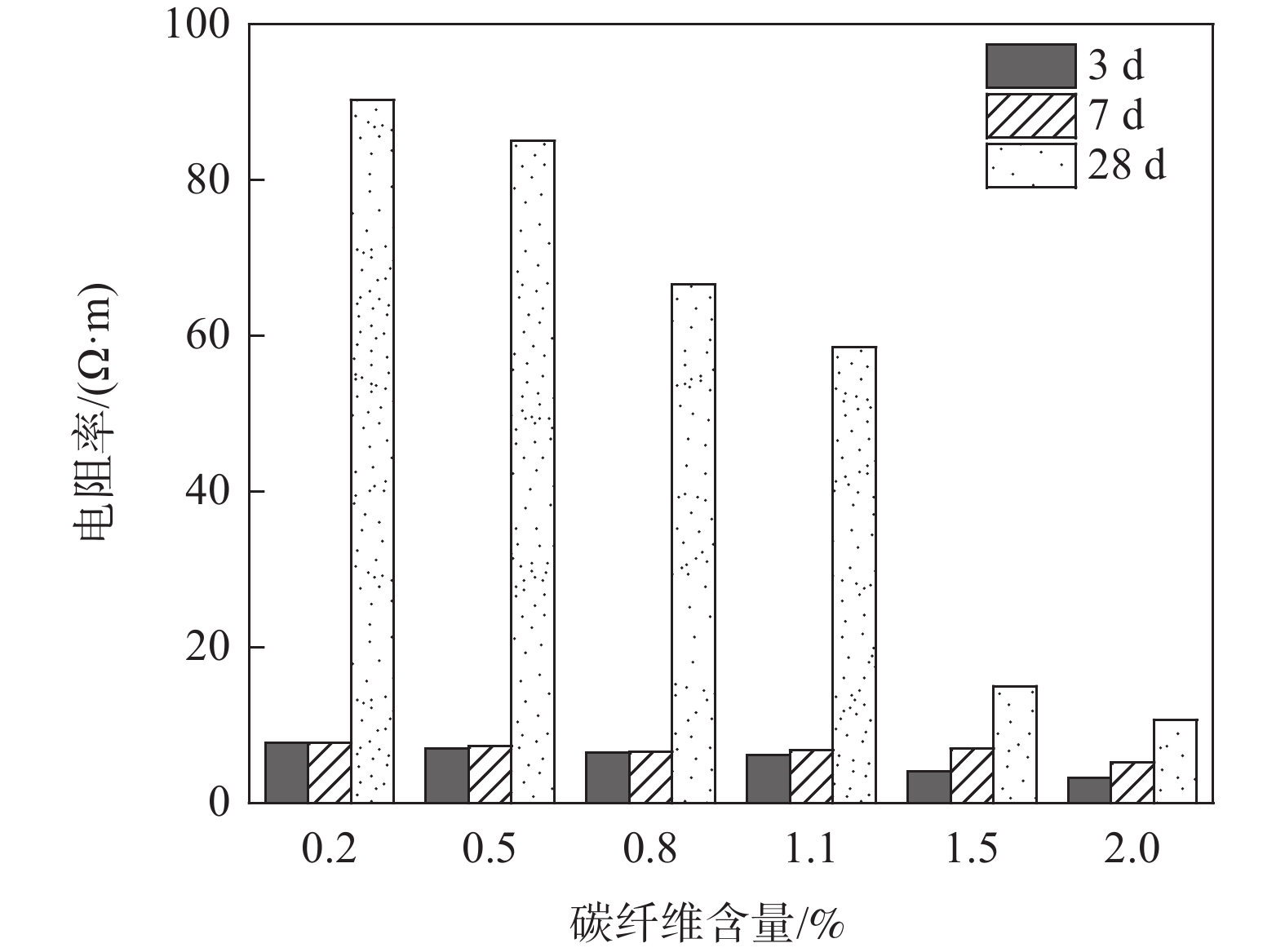

以碳纤维为导电相制备碳纤维水泥砂浆,比较了含钛碳化渣和标准砂两种集料对不同碳纤维含量下碳纤维水泥砂浆电阻率的影响,其结果如图3和图4所示。

从图3、4可以看出,尽管碳纤维含量和集料类型不同,水泥砂浆的电阻率均随着养护龄期的延长而增加,这与水泥砂浆的孔隙结构和含水量有关。在制备碳纤维水泥砂浆时,碳纤维分散和材料混合搅拌会引入大量气泡,造成基体内部孔隙率上升;材料制备过程中实际加水量远高于水泥水化反应所需的水量,同时水化反应需要一定的时间,在水泥砂浆中还存在Ca2+、K+、Na+等离子,这使得材料中自由水具有良好的离子电导性能。在低养护龄期,基体孔洞中充满着离子液体,因此电阻率较低[31-32];随着养护龄期的延长,水化反应不断吸收基体内的自由水,水分减少留下的孔洞破坏了原有的三维离子导电网络,导致水泥砂浆的电阻率上升。

当不添加导电相时,3、7 d和28 d 龄期的标准砂水泥砂浆的电阻率分别为2420 、 2792 Ω·m和3387 Ω·m,而对应的含钛碳化渣水泥砂浆的电阻率为623、1180 Ω·m 和5282 Ω·m[31]。当0.2%碳纤维作为导电相加入水泥砂浆后,两种集料水泥砂浆各龄期的体积电阻率均发生了1到2个数量级的骤减,3、7 d和28 d龄期的标准砂-碳纤维水泥砂浆的电阻率值分别降低至130、221 Ω·m和344 Ω·m,而含钛碳化渣-碳纤维水泥砂浆的电阻率分别降低至7.7、7.8 Ω·m和90.3 Ω·m。这说明碳纤维的加入可以有效改善水泥砂浆的三维导电网络,此时除了离子溶液引起的离子电导外,添加碳纤维可以增加接触电导。值得注意的是,此时含钛碳化渣-碳纤维水泥砂浆的电阻率远低于标准砂-碳纤维水泥砂浆,这说明含钛碳化渣作为集料更有利于导电路径的搭接。随着碳纤维的含量的增加,标准砂-碳纤维水泥砂浆各龄期的电阻率在碳纤维含量达到0.5%时均发生了一个数量级的骤降,继而各龄期电阻率均趋于平稳,表明此时碳纤维在标准砂-碳纤维水泥砂浆内部形成了导电通路,碳纤维的含量达到了渗流阈值浓度。在这一范围内,随着碳纤维含量的逐渐增加,低龄期含钛碳化渣-碳纤维水泥砂浆的电阻率缓慢降低,并且始终低于标准砂-碳纤维水泥砂浆,28 d龄期的电阻率是先降低后趋于平稳,在碳纤维含量为0.5%~1.1%时,电阻率高于标准砂-碳纤维水泥砂浆,当含量达到1.5%后,低于标准砂-碳纤维水泥砂浆。

以上现象和导电相与集料的匹配有关。在碳纤维含量为0.5%~1.1%范围内,虽然水泥砂浆中形成了部分导电通路,但由于碳纤维添加量较低,离子导电仍然发挥着主要作用,此时水泥砂浆的电阻率仍然由孔隙大小和分布决定。标准砂具有较碳化渣更合理的颗粒集配,在与碳纤维搅拌时引入的气泡较少,因此制备的水泥砂浆孔隙较少,分布均匀。由于含钛碳化渣的粒径低于标准砂,导致集料中大颗粒减少,在与碳纤维搅拌时引入的气泡较多,孔隙增多,潮湿状态下离子导电能力较强,所以3 d和7 d龄期内含钛碳化渣-碳纤维水泥砂浆的电阻率低于标准砂-碳纤维水泥砂浆。随着龄期的增加,水化反应不断进行,基体内游离水逐渐减少,留下的孔隙成为了导电通路的阻碍,所以在这一范围内,28 d龄期含钛碳化渣水泥砂浆的电阻率高于标准砂-碳纤维水泥砂浆。当碳纤维含量超过1.5%时,碳纤维与含钛碳化渣在基体内部形成了密集的三维导电网络,电子导电的作用取代离子导电占主要地位,因此这一含量范围内的28 d龄期的含钛碳化渣水泥砂浆电阻率低于标准砂-碳纤维水泥砂浆。

标准砂-碳纤维水泥砂浆28 d龄期的电阻率在碳纤维含量达到0.5%时急剧下降后趋于稳定,最终降低到38.3 Ω·m;而含钛碳化渣水泥砂浆28 d龄期的电阻率在碳纤维含量达到0.2%时已经达到相同的数量级,并最终降低到10.7 Ω·m。以上现象说明标准砂-碳纤维水泥砂浆的渗流阈值浓度为0.5%,而含钛碳化渣水泥砂浆的渗流阈值浓度为0.2%。因此,含钛碳化渣作为集料可以降低导电水泥砂浆的渗流阈值。

实际上,水泥砂浆在养护28 d后仍含有一定量未蒸发完全的水分,这意味着离子电导对碳纤维水泥砂浆的电阻率仍有影响,并且这种影响在碳纤维含量较低的情况下更为显著。也就是说,由于游离水的存在,仅仅比较28 d龄期水泥砂浆的电阻率,无法真正评价含钛碳化渣替代标准砂为集料对碳纤维水泥砂浆电阻率的影响。此外,对于用作建筑加热材料的水泥砂浆,由于水在材料的使用过程中会被蒸发,在材料设计过程中应排除水溶液产生的离子电导。为此,通过干燥去除碳纤维水泥砂浆中的水分,排除离子电导的干扰后,比较了碳纤维含量对干燥后含钛碳化渣-碳纤维水泥砂浆和标准砂-碳纤维水泥砂浆电阻率的影响,结果如图5所示。干燥状态下,两种水泥砂浆的电阻率都随着碳纤维含量的增加而降低。相比标准砂-碳纤维水泥砂浆,含钛碳化渣-碳纤维水泥砂浆的电阻率得到了显著的下降,说明含钛碳化渣替代标准砂可以显著提高水泥砂浆的电子电导。标准砂-碳纤维水泥砂浆在碳纤维含量为0.5%时发生了两个数量级的骤降,随后稳步降低,说明0.5%的碳纤维含量为标准砂-碳纤维水泥砂浆的渗流阈值,而含钛碳化渣水泥砂浆在碳纤维含量为0.2%时,电阻率已经降低至相同数量级。当碳纤维含量为0.2%~0.5 %时,含钛碳化渣水泥砂浆电阻率降低最快,0.5%~1.1 %趋于缓和,超过1.5%后又急剧下降,继续增加碳纤维含量至2.0%,电阻率降低到10.9 Ω·m,并几乎不再改变。当碳纤维含量为0.8%时,含钛碳化渣-碳纤维水泥砂浆的电阻率已降至建筑加热采暖用材料所需的电阻率范围内,而标准砂-碳纤维水泥砂浆的电阻率降低至相应范围至少需要2%的碳纤维添加量。根据以上分析,可以得出以下结论:含钛碳化渣替代标准砂可以显著提高碳纤维水泥砂浆的电子电导;含钛碳化渣替代标准砂作为集料可有效降低导电碳纤维水泥砂浆的渗流阈值。

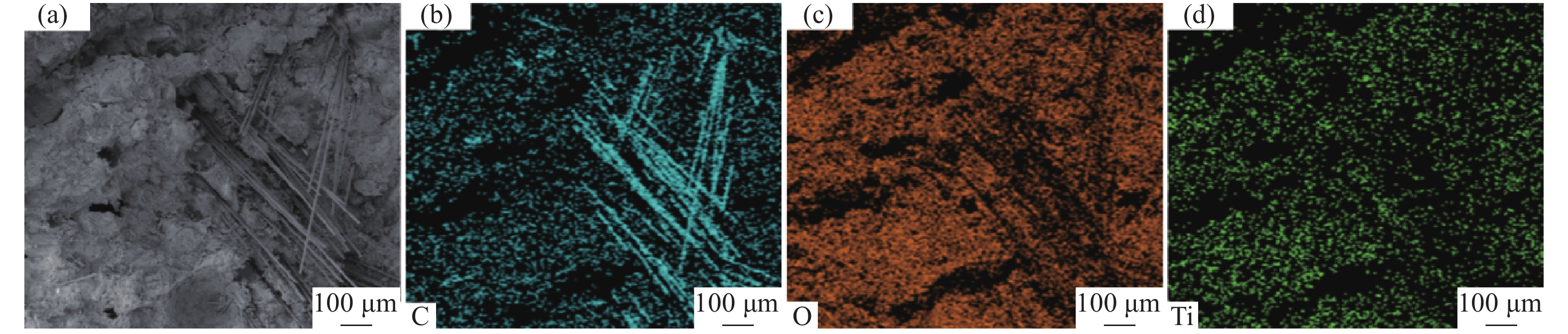

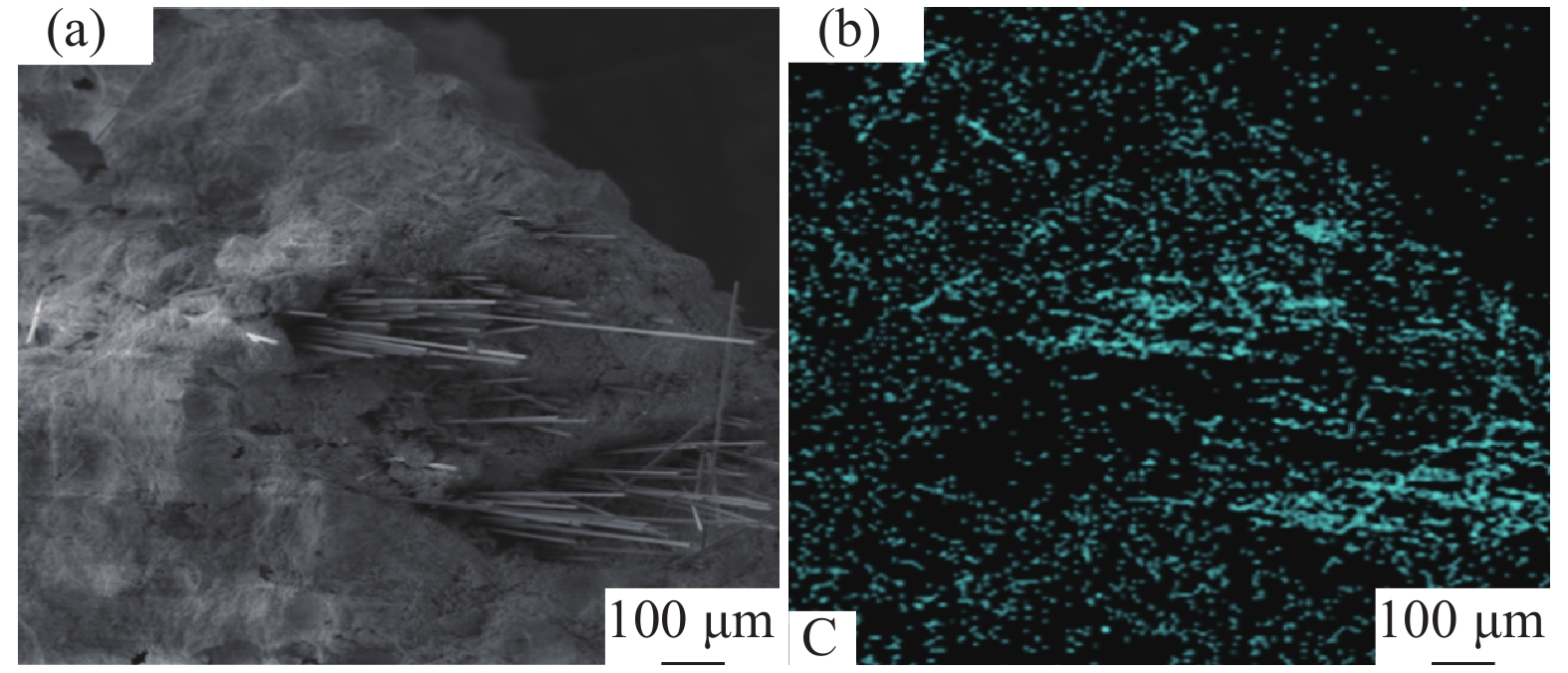

为进一步解释含钛碳化渣替代标准砂降低碳纤维水泥砂浆电阻率的机制,对碳纤维含量为2.0%的两种碳纤维水泥砂浆进行了SEM显微结构和元素面扫描EDX分析,分别如图6、7所示。图6显示,含钛碳化渣-碳纤维水泥砂浆断口处有纤维状物质拔出,结合元素分布图中纤维状区域富C且贫O和Ti的特征,可以推断该物质为碳纤维;根据前述分析,含钛碳化渣是一种由导电TiC颗粒分散在硅酸盐玻璃基体中形成的导电复合颗粒,因此,在图6中,C、O、Ti均有分布的区域为含钛碳化渣。因此图6中含有碳元素的物质包括碳纤维、TiC,这些均为良好的导体。图7中碳元素聚集的纤维状区域为碳纤维,其他区域为水泥和标准砂。显然,图6中碳纤维周围分布有更多具有导电性物质,更有利于基体内导电路径的搭接,形成导电网络。由于含钛碳化渣的加入,碳纤维水泥砂浆中含有更多的导电集料,这些导电集料起到了减小碳纤维间阻碍的作用,含钛碳化渣-碳纤维水泥砂浆中的导电网络比标准砂-碳纤维水泥砂浆更加完善。此外,由于含钛碳化渣的颗粒远小于标准砂,这有利于提高碳纤维的分散与搭接,增强基体的导电性。

3. 结论

1) 含钛碳化渣取代标准砂可显著提高水泥砂浆的抗压强度和抗折强度,在碳纤维含量0~2.0 %范围内始终满足建筑水泥砂浆的要求。

2) 由于含钛碳化渣具有比标准砂更低的电阻率,用含钛碳化渣替代标准砂作为集料可显著降低干燥条件下碳纤维水泥砂浆的电阻率,并将渗流阈值浓度由0.5 %降低至0.2%。

3) 当碳纤维含量为2.0%时,含钛碳化渣-碳纤维水泥砂浆表现出优异的综合性能,28 d抗压强度为39.9 MPa,湿润条件下电阻率为10.7 Ω·m,干燥条件下电阻率为10.9 Ω·m。以上数据表明:含钛碳化渣-碳纤维水泥砂浆是一种具有应用潜力的结构功能一体化复合材料。

4) 采用含钛碳化渣作为制备导电水泥砂浆的集料,既探索了含钛高炉渣大规模、全组分、高附加值的利用方法,又提升了导电水泥砂浆的力电性能,减少了导电相的用量,降低了成本,在环保和经济上均具有重要的意义。

-

表 1 短切碳纤维性质

Table 1. Properties of chopped carbon fibers

长度/

mm碳含量/

%抗拉强度/

GPa密度/

(g·cm−3)体积电阻率/

(Ω·cm)6 ≥ 95 3.8 1.76 1.5×10−3 表 2 碳纤维水泥砂浆的配合比

Table 2. Mix proportion of carbon fiber cement mortar

编号 碳纤维含量/% 材料配比/g 水泥 碳化渣 标准砂 水 短切碳纤维 1 0.2 450 1350 0 225 0.90 2 0.5 450 1350 0 225 2.25 3 0.8 450 1350 0 225 3.60 4 1.1 450 1350 0 225 4.95 5 1.5 450 1350 0 225 6.75 6 2.0 450 1350 0 225 9.00 7 0.2 450 0 1350 225 0.90 8 0.5 450 0 1350 225 2.25 9 0.8 450 0 1350 225 3.60 10 1.1 450 0 1350 225 4.95 11 1.5 450 0 1350 225 6.75 12 2.0 450 0 1350 225 9.00 -

[1] Zhu Fuxing, Jiao Yu, Li Liang, et al. The status and trends of material processing technology for vanadic titanomagnetite in Panxi area[J]. Mining and Metallurgy, 2021,30(4):26−32. (朱福兴, 焦钰, 李亮, 等. 攀西钒钛磁铁矿的选矿技术现状及发展趋势[J]. 矿冶, 2021,30(4):26−32. doi: 10.3969/j.issn.1005-7854.2021.04.005 [2] Ou Yang, Sun Yongsheng, Yu Jianwen, et al. Research status and development prospect of utilization of vanadium-titanium magnetitie[J]. Journal of Iron and Steel Research, 2021,33(4):267−278. (欧杨, 孙永升, 余建文, 等. 钒钛磁铁矿加工利用研究现状及发展趋势[J]. 钢铁研究学报, 2021,33(4):267−278. [3] Xu Ying, Li Dandan, Yang Shanshan, et al. Research progress of comprehensive utilization of Ti-bearing blast furnace slag[J]. Multipurpose Utilization of Mineral Resources, 2021,(1):23−31. (许莹, 李单单, 杨姗姗, 等. 含钛高炉渣综合利用研究进展[J]. 矿产综合利用, 2021,(1):23−31. doi: 10.3969/j.issn.1000-6532.2021.01.004 [4] Hao Baichuan, Li Ziyue, Jia Dongfang, et al. Comprehensive utilization of blast furnace slag containing titanium[J]. Multipurpose Utilization of Mineral Resources, 2020,(6):1−6. (郝百川, 李子越, 贾东方, 等. 含钛高炉渣的综合利用[J]. 矿产综合利用, 2020,(6):1−6. doi: 10.3969/j.issn.1000-6532.2020.06.001 [5] Fan G, Wang M, Dang J, et al. A novel recycling approach for efficient extraction of titanium from high-titanium-bearing blast furnace slag[J]. Waste Manage, 2021,120:626−634. doi: 10.1016/j.wasman.2020.10.024 [6] Han Jiqing, Zhang Jing, Zhang Jiahao, et al. Recovery of Fe, V, and Ti in modified Ti-bearing blast furnace slag[J]. Transactions of Nonferrous Metals Society of China, 2022,32(1):333−344. (韩吉庆, 张晶, 张加豪, 等. 改性含钛高炉渣中铁、钒和钛的回收[J]. 中国有色金属学报: 英文版, 2022,32(1):333−344. [7] Zhang Yue, Wang Sijia, Xue Xiangxing. Recovery of titanium dioxide from titanium-bearing solution by using ammonium as precipitant[J]. CIESC Journal, 2012,63(10):3345−3349. (张悦, 王思佳, 薛向欣. 氨水沉淀法由含钛滤液提取二氧化钛[J]. 化工学报, 2012,63(10):3345−3349. doi: 10.3969/j.issn.0438-1157.2012.10.048 [8] Zheng F, Guo Y, Qiu G, et al. A novel process for preparation of titanium dioxide from Ti-bearing electric furnace slag: NH4HF2-HF leaching and hydrolyzing process[J]. J. Hazard. Mater., 2018,344:490−498. doi: 10.1016/j.jhazmat.2017.10.042 [9] Xue T, Wang L, Qi T, et al. Decomposition kinetics of titanium slag in sodium hydroxide system[J]. Hydrometallurgy, 2009, 95(1–2): 22-27. [10] Zhang Suxin, Yang Yangjun, Lu Ping, et al. Study on preparation of TiCl4 using titanium-containing carbonized blast furnace slag as raw material[J]. Iron Steel Vanadium Titanium, 2016,37(6):24−28. (张苏新, 杨仰军, 陆平, 等. 含钛碳化高炉渣为原料制备TiCl4试验研究[J]. 钢铁钒钛, 2016,37(6):24−28. doi: 10.7513/j.issn.1004-7638.2016.06.005 [11] Gao Qirui, Song Bo, Yang Zhanbing, et al. Carbonization of blast furnace slag bearing titanium and separation of TiC phase by super gravity[J]. Nonferrous Metals Science and Engineering, 2017,8(2):1−7. (高启瑞, 宋波, 杨占兵, 等. 含钛高炉渣碳化及超重力分离碳化钛的研究[J]. 有色金属科学与工程, 2017,8(2):1−7. [12] Li Z, Lei Y, Ma W, et al. Preparation of high-purity TiSi2 and eutectic Si–Ti alloy by separation of Si–Ti alloy for clean utilization of Ti-bearing blast furnace slag[J]. Sep. Purif. Technol., 2021,265:118473. doi: 10.1016/j.seppur.2021.118473 [13] Zhang Z, Lv H, Li X, et al. Conversion of CaTi1–xMnxO3–δ-based photocatalyst for photocatalytic reduction of NO via structure-reforming of Ti-bearing blast furnace slag[J]. ACS Sustain. Chem. Eng., 2019,7:10299−10309. doi: 10.1021/acssuschemeng.9b00097 [14] Qiu Shengtao, Zhang Mingbo, Li Jianxin, et al. Recent progress and prospective of comprehensive utilization of Ti-bearing blast furnace slag[J]. Iron & Steel, 2016,51(7):1−8. (仇圣桃, 张明博, 李建新, 等. 含钛高炉渣资源化综合利用研究现状与展望[J]. 钢铁, 2016,51(7):1−8. [15] Frac M, Pichor W, Szoldra P, et al. Cement composites with expanded graphite/paraffin as storage heater[J]. Constr Build Mater., 2021,275:122126. doi: 10.1016/j.conbuildmat.2020.122126 [16] Yuan T F, Choi J S, Hong S H, et al. Enhancing the electromagnetic shielding and impact resistance of a reinforced concrete wall for protective structures[J]. Cem Concr Compos., 2021,122:104148. doi: 10.1016/j.cemconcomp.2021.104148 [17] Monteiro A O, Costa P M F J D, Oeser M, et al. Dynamic sensing properties of a multifunctional cement composite with carbon black for traffic monitoring[J]. Smart Mater Struct., 2020,29:025023. doi: 10.1088/1361-665X/ab62e2 [18] Wang H, Shi F, Shen J, et al. Research on the self-sensing and mechanical properties of aligned stainless steel fiber-reinforced reactive powder concrete[J]. Cem Concr Compos., 2021,119:104001. doi: 10.1016/j.cemconcomp.2021.104001 [19] Ma Shining, Liu Xiaojun, Zhang Yuanlong, et al. Application study on snow-ice melting for airport carbon fiber conductive concrete pavement[J]. Subgrade Engineering, 2011,(3):182−184. (马世宁, 刘晓军, 张元龙. 碳纤维导电混凝土道面机场除冰雪的应用研究[J]. 路基工程, 2011,(3):182−184. doi: 10.3969/j.issn.1003-8825.2011.03.053 [20] Zhang Yiming, Yu Lehua. Smart properties of steel fiber and carbon nano tube reinforced conductive concrete during flexural process[J]. Concrete, 2017,(9):49−52. (张苡铭, 俞乐华. 钢纤维-碳纳米管导电混凝土的受弯机敏性试验研究[J]. 混凝土, 2017,(9):49−52. [21] 丁益林. 钢纤维锈蚀对砂浆力学及物质传输性能影响的试验研究[D]. 大连: 大连理工大学, 2021.Ding Yilin. Experiment study on the influence of steel fiber corrosion on mechanical and mass transport properties of mortar [D]. Dalian: Dalian University of Technology, 2021. [22] Guo Chuanhui, Tang Wuan, Liu Shuhua. Properties and microstructure of conductive concrete containing graphite powder[J]. Bulletin of the Chinese Ceramic Society, 2017,36(9):3174−3179. (郭传慧, 汤婉, 刘数华. 石墨粉导电混凝土的性能与微结构[J]. 硅酸盐通报, 2017,36(9):3174−3179. doi: 10.16552/j.cnki.issn1001-1625.2017.09.052 [23] 崔素萍, 刘永肖, 兰明章, 等. 石墨-水泥基复合材料的制备与性能[J]. 硅酸盐学报, 2007, 35: 91-95.Cui Suping, Liu Yongxiao, Lan Mingzhang, et al. Preparation and properties of graphite-cement based composites[J]. Journal of the Chinese Ceramic Society, 2007, 35: 91-95. [24] Fang Zhenggang, Huang Peng, Xue Feng, et al. Effects of the mixing amount of graphite and carbon fiber on macro properties of concrete[J]. Building Structure, 2017,47(21):59−62. (房正刚, 黄彭, 薛峰, 等. 石墨和碳纤维掺量对混凝土宏观性能的影响[J]. 建筑结构, 2017,47(21):59−62. doi: 10.19701/j.jzjg.2017.21.011 [25] Ge Yuchuan, Liu Shuhua. Research progress on characteristics of carbon fiber conductive concrete[J]. Bulletin of the Chinese Ceramic Society, 2019,38(8):2442−2447. (葛宇川, 刘数华. 碳纤维导电混凝土特性研究进展[J]. 硅酸盐通报, 2019,38(8):2442−2447. [26] 邓宵. 掺铁导电集料及其水泥基导电复合材料的制备与性能研究[D]. 武汉: 武汉理工大学, 2011.Deng Xiao. Preparation and performance investigation of iron containing aggregate and its cement-based conductive composites [D]. Wuhan: Wuhan University of Technology, 2011. [27] Lamastra F R, Chougan M, Marotta E, et al. Toward a better understanding of multifunctional cement-based materials: The impact of graphite nanoplatelets (GNPs)[J]. Ceram Int, 2021,47(14):20019−20031. doi: 10.1016/j.ceramint.2021.04.012 [28] Dong W, Guo Y, Sun Z, et al. Development of piezoresistive cement-based sensor using recycled waste glass cullets coated with carbon nanotubes[J]. J Clean Prod, 2021,314:127968. doi: 10.1016/j.jclepro.2021.127968 [29] Dong Q, Wang G, Chen X, et al. Recycling of steel slag aggregate in Portland cement concrete: An overview[J]. J Clean Prod, 2021,282:124447. doi: 10.1016/j.jclepro.2020.124447 [30] Ozturk M, Akgol O, Sevim U K, et al. Experimental work on mechanical, electromagnetic and microwave shielding effectiveness properties of mortar containing electric arc furnace slag[J]. Constr Build Mater, 2018,165:58−63. doi: 10.1016/j.conbuildmat.2018.01.031 [31] Tang Chenjun, Xuan Ming, Ding Xiang, et al. Effects of carbonized titanium-bearing blast furnace slag on the compressive strength and electrical resistivity of cement mortar[J]. The Chinese Journal of Process Engineering, 2022,(4):499−505. (唐晨钧, 宣明, 丁祥, 等. 含钛高炉渣的碳化产物对水泥砂浆强度及电阻率的影响[J]. 过程工程学报, 2022,(4):499−505. doi: 10.12034/j.issn.11009-12606X.221095 [32] Doo-Yeol Y, You I, Seung-Jung L. Electrical properties of cement-based composites with carbon nanotubes, graphene, and graphite nanofibers[J]. Sensors, 2017,17(5):1064−1076. doi: 10.3390/s17051064 -

下载:

下载:

下载:

下载: